- DL manuals

- Karcher

- Vacuum Cleaner

- BRC 40/22 C

- Operating Instructions Manual

Karcher BRC 40/22 C Operating Instructions Manual

Summary of BRC 40/22 C

Page 1

Original instructions 86417210 - b 01/13/17 brc 40/22 c - 230v carpet extractor operating instructions (eng) models: brc 40/22 c 1.008-062.0

Page 2

2 86417210 operator’s manual - armada brc 40/22 c machine data label overview this carpet extractor is an electrical powered, portable carpet extractor intended for commercial use. The appliance sprays a cleaning solution onto the carpet, agitates the wet carpet, and then extracts the soiled solutio...

Page 3

3 table of contents machine data label . . . . . . . . . . . . . . . . . . . . . . . . . . 2 overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 how to use this manual . . . . . . . . . . . . . . . ....

Page 4

4 how to use this manual this manual contains the following sections: • how to use this manual • safety • operations • maintenance the how to use this manual section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized dealers. When ...

Page 5

5 notes 86417210 operator’s manual - armada brc 40/22 c.

Page 6

6 safety important safety instructions when using this machine, basic precaution must always be followed, including the following: read all instructions before using this machine. To reduce the risk of fire, electric shock, or injury: connect to a properly grounded outlet. See grounding instructions...

Page 7

7 safety the following symbols are used throughout this guide as indicated in their descriptions: hazard intensity level there are three levels of hazard intensity identified by signal words -warning and caution and for safety. The level of hazard intensity is determined by the following definitions...

Page 8

8 safety grounding instructions this product is for commercial use only. Electrical: this machine operates on 220-240v, 50/60 hz. The amp, hertz, and voltage are listed on the data label found on each machine. Using voltages above or below those indicated on the data label will cause serious damage ...

Page 9

9 operations how this machine works this carpet extractor is an electrical powered, self contained portable carpet extractor intended for commercial use. The appliance sprays a cleaning solution onto the carpet, agitates the wet carpet and then extracts the soiled solution back into the unit's recov...

Page 10

10 operations technical specification this appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person ...

Page 11

11 operations technical specifications item dimension/capacity technical specifications power nominal voltage 220-240v (50/60hz) type of protection ipx4 average power consumption 1800 w suction engine output 350 w brush engine output 400 w cleaning brushes working width 400mm brush diameter 95mm bru...

Page 12

12 operations controls display the led lights in the center are (from left to right): 1. Power 2. Vacuum 3. Brush 4. Solution 5. Not used the switch on the left controls the solution flow. The switch on the right allows the operator to reverse the brush motor, effectively moving the machine in an op...

Page 13

13 operations display 1. Power light • green indicates that the machine has power. • off indicates the machine does not have power or rotary switch is set to the off position. • see trouble shooting section if green light is not on when it should be. 2. Vacuum light • green indicates the vacuum moto...

Page 14

14 operations transporting the machine over stairs the machine should be carried up or down stairs by two people. One person to grab the front of the solution tank using the two grip points / pockets on the front lower section. With the steering wheel fully extended, the second person can grab the s...

Page 15

15 operations pre run setup 1. To unfold handle, loosen knob, rotate upper steering column and steering wheel back to stop. Tighten knob. 2. Install the vacuum shoe and brush. Fill solution tank with water and chemical. (see filling the solution tank instructions). 3. To adjust handle to comfortable...

Page 16

16 operations filling the solution tank do not put defoamer or solvent chemicals in the solution tank. Do not allow water to spill into vacuum motor inlet. Dry spills from top of solution tank. Do not tip machine on back when full as water may spill from machine. Use only the suitable chemicals list...

Page 17

17 operations operating the machine expected run time the expected run time for this machine depends upon which mode the machine is in. This duty cycle includes an amount of time that the machine will be running along with a period of time that the machine should be off to empty the recovery tank, f...

Page 18

18 operations operating the machine 3. Turn on solution switch. • press the bottom of the switch to turn solution on. • press the top of the switch to turn solution off. 4. Squeeze the large yellow trigger switch to make the machine move, run the brush and dispense solution. Use the steering wheel t...

Page 19

19 operations 6. During operation, observe the following: this machine is equipped with clear dome to facili- tate operator viewing of dirty solution and vacuum air flow. During operation, observe the vacuum intake: any amount of water or foam entering the vacuum system can damage the vacuum motor. ...

Page 20

20 operations to clean under desks or dead end hallways by activating the momentary reverse switch, the brush will spin in the opposite direction. Along with the reverse switch, the trigger switch around the steering wheel must also be engaged. If the deck is pointing forward, jets in front, the mac...

Page 21

21 operations accessory tool connection and use note: use only manufacturer supplied accessory tools. See optional accessories section. 1. Spin the deck 180 ° so that the vacuum shoe is at the front of the machine. 2. To connect solution hose pull back collar and insert over machine mounted fitting,...

Page 22

22 notes 86417210 operator’s manual - armada brc 40/22 c.

Page 23

23 maintenance service schedule maintenance daily weekly quarterly check machine for cord damage * check recovery dome and gasket for damage and cleanliness * check brushes - should be clean with no lint or strings attached * clean debris tray behind brush * clean the underside of the brush deck are...

Page 24

24 maintenance periodic maintenance note: before making any adjustments or repairs to the machine, disconnect the power cord from electrical source twice a month, flush a white vinegar solution (one quart vinegar to two gallons of water) or anti-browning solution (mixed as directed) through the extr...

Page 25

25 maintenance 6. Remove lint and dirt build-up from brush and housing. 7. Check float and shut-off screen and clean as necessary. 8. Remove and clean debris tray. Vacuum shoe and hose note: vacuum shoe and hose flush should be done daily after use. Place machine over drainage area before beginning....

Page 26

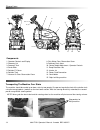

26 maintenance scrub deck 1. Scrub brush motor 2. Scrub brush 3. Brush height adjustment 4. Vacuum motor 5. Solution pump only qualified maintenance personnel are to perform the following repairs. 86417210 operator’s manual - armada brc 40/22 c.

Page 27

27 maintenance scrub head maintenance the cylindrical scrub head is designed to scrub chemicals into the carpet and propel the machine. The scrub brush should be replaced when the brush is no longer able to keep the front of the deck from touching the ground. Scrub brush removal the scrub brush is r...

Page 28

28 maintenance circuit protection circuit breakers interrupt the flow of power in the event of an electrical overload. When a circuit breaker is tripped, reset it by pressing the button. If a circuit breaker continues to trip, contact your service representative. Circuit breaker 86417210 operator’s ...

Page 29

29 maintenance troubleshooting problem cause solution cord is not plugged in. Plug in cord. No power, nothing runs, no circuit breaker tripped on machine. Reset breaker. Green light on power icon with circuit breaker tripped in building. Reset breaker. Switch on faulty switch. Call for service. Faul...

Page 30

30 maintenance troubleshooting problem cause solution machine stops working and brush light blinks red 5 times brush motor is overheating allow brush motor to cool and reduce brush motor load by adjusting deck height to lower number setting with deck height knob. Brush motor temperature sensor is di...

Page 31

31 suggested spare parts 86003630 float shut-off 86409460 strainer 86412780 jet mini promax (2) 86413340 pump 86012550 jet promax 86004570 jet body (3) 86411180 roller brush 86402850 gasket, lid 86402570 recovery drain hose 86403040 solution hose 86413350 vacuum motor 86417210 operator’s manual - ar...