- DL manuals

- Karcher

- Pressure Washer

- HD 6/16-4 M / MX

- Service Manual

Karcher HD 6/16-4 M / MX Service Manual

Summary of HD 6/16-4 M / MX

Page 1

English 5.906-246.0 rev. 01 (09/14) 1 hd 6/16-4 m / mx hd 7/18-4 m / mx hd 9/19 m / mx hd 9/20-4 m / mx service manual.

Page 2

2 english 5.906-246.0 rev. 01 (09/14) 1 contents 2 preface 3 3 safety instructions 3 3.1 hazard levels 3 4 technical features 4 4.1 drive 4 4.2 pump 4 4.3 detergent system 4 4.4 electrical system 4 4.5 other features 5 4.6 field of application 5 4.7 type plate 5 5 parts of the system 6 5.1 front vie...

Page 3

English 5.906-246.0 rev. 01 (09/14) 3 good service work requires extensive and practice-orient- ed training as well as well-structured training materials. Hence we offer regular basic and advanced training pro- grammes covering the entire product range for all service engineers. In addition to this,...

Page 4

4 english 5.906-246.0 rev. 01 (09/14) these devices are the new top models among the mobile high-pressure cleaners of the mid-range. Their compact and vertical design allows easy handling and space-saving storage. Note hd 7/18-4 m/mx pressure switch control with 2-phase switching. – 3 piston axial p...

Page 5

English 5.906-246.0 rev. 01 (09/14) 5 – softgrip-easypress gun with improved ergonomics – highest operating comfort thanks to improved, continu- ous pressure and water volume regulation – servopress rotary regulator with ceramic insert – improved mobility on stairs thanks to large full rubber wheels...

Page 6

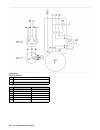

6 english 5.906-246.0 rev. 01 (09/14) 1 lock trigger gun 2 lever for trigger gun 3 trigger gun 4 power press regulator pressure/ quantity regulation 5 high pressure hose 6 spray lance 7 mains cable with mains plug 3-phase appliances 8 mains cable with mains plug 1-phase appliances 9 nozzle 10 high p...

Page 7

English 5.906-246.0 rev. 01 (09/14) 7 1 hose drum 2 crank, hose drum 3 high pressure hose 4 detergent 5 storage mains connection, compartment for replace- ment nozzle 6 connection 2 detergent 7 bottle holder for detergent 8 connection 1 detergent 9 dosage valve for detergent switch-over from deterge...

Page 8

8 english 5.906-246.0 rev. 01 (09/14) note the pressure switch is not adjustable. Note the pressure switch is not adjustable. 5.3 bottom view 5.3.1 pump head hd 6/16, hd 9/20 1 high pressure connection 2 overflow valve 3 pump head 4 control piston, pressure switch 5 pressure switch q2/b1 6 water con...

Page 9

English 5.906-246.0 rev. 01 (09/14) 9 1 electronics system 2 detergent hose 3 pump motor 4 manometer 5 detergent hose with check valve 6 detergent injector 7 high pressure connection 8 high pressure line 9 safety clip, high pressure line. 10 overflow valve 11 pump head 12 connection for water supply...

Page 10

10 english 5.906-246.0 rev. 01 (09/14) hd 6/16-4 version 2 hd 7/18-4 hd 9/19 hd 9/20-4 1 power switch q1 2 capacitors 5.5.2 3-phase device 1 power switch q1 2 pressure switch connection 1 power switch q1 2 contactor k1.

Page 11

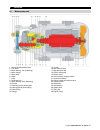

English 5.906-246.0 rev. 01 (09/14) 11 1 screw fan wheel attachment 2 fan wheel 3 motor bearing, rear (b bearing) 4 motor casing 5 motor shaft 6 stator 7 rotor 8 shaft seal ring 9 motor bearing, front (a bearing) 10 oil bath 11 fastening screw, swash plate 12 holding plate of piston spring 13 piston...

Page 12

12 english 5.906-246.0 rev. 01 (09/14) 1 overflow valve 2 detergent injector 3 control pressure injector 4 pressure holding valve 5 pressure valves 6 suction valves 7 pump head a pump head old b pump head new 1 pressure holding valve 6.2 pump head 6.2.1 versions.

Page 13

English 5.906-246.0 rev. 01 (09/14) 13 note pay attention to installation position of the seals. 1 bushing 2 o ring 3 disc 4 high pressure seal 5 low pressure seal 6 disc 1 high pressure seal 2 disc 3 o ring 4 bushing 5 disc 6 washer ring 7 low pressure seal 8 spreader ring 6.2.2 high pressure seal ...

Page 14

14 english 5.906-246.0 rev. 01 (09/14) trigger gun and servopress rotary regulator opened: when the power press regulator is opened all the way, the water flows from the pressure room through the pressure holding valve via the control pressure injector to the high pressure outlet. The ball of the ov...

Page 15

English 5.906-246.0 rev. 01 (09/14) 15 with the power press regulator partially closed, the pres- sure in the pressure room will not rise any further. Howev- er, due to less water volume, the effect of the control pressure injector decreases, so that the pressure in the connecting boring rises. Thus...

Page 16

16 english 5.906-246.0 rev. 01 (09/14) trigger gun closed: upon closing the trigger gun, the pressure in the pressure room rises abruptly. This pressure peak will affect the pis- ton rod and the pressure switch via the connecting boring. The ball is pressed out of its seat by the piston road and the...

Page 17

English 5.906-246.0 rev. 01 (09/14) 17 trigger gun and servopress rotary regulator opened: when the power press regulator is opened all the way, the water flows from the pressure room through the pressure holding valve via the control pressure injector to the high pressure outlet. The ball of the ov...

Page 18

18 english 5.906-246.0 rev. 01 (09/14) servopress rotary regulator partially closed: with the power press regulator partially closed, the pres- sure in the pressure room will not rise any further. Howev- er, due to less water volume, the effect of the control pressure injector decreases, so that the...

Page 19

English 5.906-246.0 rev. 01 (09/14) 19 upon closing the trigger gun, the pressure in the pressure room rises abruptly. This pressure peak will affect the pis- ton rod and the pressure switch via the connecting boring. The ball is pressed out of its seat by the piston road and the entire flow volume ...

Page 20

20 english 5.906-246.0 rev. 01 (09/14) 1 lock trigger gun 2 casing shell 3 hand lever 4 high pressure hose 5 hose guide 6 safety clip 7 needle bearing 8 coupling high-pressure hose/trigger gun 9 o ring 10 node piece function when the manual lever is actuated, the valve in the node piece opens and th...

Page 21

English 5.906-246.0 rev. 01 (09/14) 21 1 connection trigger gun 2 connecting pin 3 ceramic disc on gun side 4 ceramic disc on spray pipe side 5 casing of rotating regulator 6 handle of rotary regulator 7 spray lance connection the pressure and volume regulation is designed as a rota- ry regulator be...

Page 22

22 english 5.906-246.0 rev. 01 (09/14) a high-pressure round jet b flat low pressure spray (chem) for operating using de- tergents or cleaning at low pressure. C high pressure flat spray (25°) for large dirt areas the triple nozzle can be adjusted to three different set- tings. By rotating the nozzl...

Page 23

English 5.906-246.0 rev. 01 (09/14) 23 1 spring 2 setting nut, self-locking 3 overflow valve spindle with hexagon connect the test manometer with high-pressure hose and the trigger gun with servopress rotary regulator to the high pressure outlet. Turn the servopress rotary regulator to the smallest ...

Page 24

24 english 5.906-246.0 rev. 01 (09/14) 9 troubleshooting findings possible cause correction appliance is not running power supply interrupted check connection cable for damages. Check the supply voltage. Engine is overheated turn device switch on "0" and let engine cool off for min. 5 minutes. Power...

Page 25

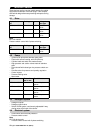

English 5.906-246.0 rev. 01 (09/14) 25 10 technical documentation appliance type piston diame- ter in mm appliance no. Circuit diagram operating instructions spare parts list hd 6/16-4 m 16 1.524.120.0 0.089-003.0 5.964-870.0 5.971-970.0 hd 6/16-4 mx 16 1.524.125.0 0.089-003.0 5.964-870.0 5.972-055....

Page 26

26 english 5.906-246.0 rev. 01 (09/14) sound pressure level l pa db(a) 69 75 76 75 uncertainty k pa db(a) 1 2 1 sound power level l wa + uncertainty k wa db(a) 84 90 91 88 fuel amount of oil l 0,5 0,75 oil grade sae 15w40 sae 90 hypoid dimensions and weights length mm 554 width mm 509 height mm 1000...

Page 27

English 5.906-246.0 rev. 01 (09/14) 27 11 special tools electric measuring appliance 6.803-022.0 shut-off valve with thermometer 4.580-034.0 removal pliers, pressure/suction valves and water sieves 4.901-062.0 installation mandrel oil seal, high-pressure seal piston diameter 16 mm hd 6/16-4 hd 9/19 ...

Page 28

28 english 5.906-246.0 rev. 01 (09/14) adapter system 2000, m22x1.5 with ex- tended union nut 4.401-072.0 for hose drum appliances: adapter m22 (in- side) onto 11 mm male coupling 4.424-004.0 test manometer for working pressure 4.742-025.0 installation and removal tools, overflow valve seat 4.901-05...

Page 29

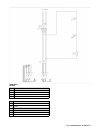

English 5.906-246.0 rev. 01 (09/14) 29 when working on the device, please always use the cur- rent circuit diagram in disis. 0.089-003.0 hd 6/16 12 circuit diagram c1 capacitor c2 capacitor m1 motor q1 power switch q2 pressure switch.

Page 30

30 english 5.906-246.0 rev. 01 (09/14) 0.087-804.0 hd 7/18, hd 9/19 m1 motor q1 power switch q2 pressure switch atb ls u1 red black v1 yellow red w1 black white u2 white yellow v2 blue blue w2 grey brown.

Page 31

English 5.906-246.0 rev. 01 (09/14) 31 0.088-885.0 hd 9/20 b1 pressure switch k1 contactor m motor q1 power switch wsk winding protection in the motor atb u1 red v1 yellow w1 black u2 white v2 blue w2 grey.

Page 32

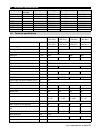

32 english 5.906-246.0 rev. 01 (09/14) 13 torques name nm cylinder head screws 40 - 45 piston casing 5 - 7 trigger gun, pressure regulator 40 screw connection pressure valves 40 - 45 screw connection pressure switch 15 - 17 screw connection suction valves 35 - 40 overflow valve seat 8 - 10 swash pla...