Summary of HD 7/250 DE TR1

Page 1

Hd 7/250 de tr1 59633200 08/10

Page 2

2.

Page 3

- 1 please read and comply with these original instructions prior to the initial operation of your appliance and store them for later use or subsequent own- ers. Danger immediate danger that can cause severe injury or even death. 몇 warning possible hazardous situation that could lead to severe injur...

Page 4

- 2 if the working pressure exceeds the max. Permissible overpressure by approx. 10%, the burst disc will be destroyed and the wa- ter will circulate inside the appliance with- out pressure. High pressure operation no longer possible. The pressure switch switches off the appli- ance if the minimum p...

Page 5

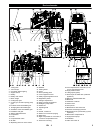

- 3 1 towing hitch 2 tear-off rope 3 connector vehicle lighting 4 support wheel 5 battery 6 battery main switch 7 block wedge 8 oil dip pump gear 9 covering lid, oil drain opening pump gear 10 oil drain screw intermediate gear 11 oil sight glass intermediate gear 12 ventilation screw intermediate ge...

Page 6

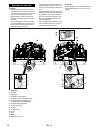

- 4 1 display actual pressure 2 bar graph fuel level 3 bar graph water level in tank 4 display cooling water temperature 5 display oil pressure 6 f6 key, menu preselection 7 key f5, increase nominal value 8 key f4, decrease nominal value 9 key f3, motor off 10 key f2, motor on 11 key f1, reset key (...

Page 7

- 5 please observe chapter "safety instruc- tions" and the enclosed safety instructions for high pressure cleaners (5.063-314.0) note the driver, who operates the towing vehicle with trailer on public roads must ensure that he has the appropriate license for this. Danger when transporting the traile...

Page 8

- 6 caution do not completely deplete the fuel in the fuel tank, otherwise, the fuel system will have to be ventilated. Possibly suctioned dirt from the bottom of the tank can lead to malfunctions. Î check the fill level of the diesel fuel at the bar segment display for the fuel lev- el. If required...

Page 9

- 7 Î connect the water supply hose to the respective water inlet (arrow). Î open the lock on the appliance cover and swivel the appliance cover up- wards. Î swivel the latch of the appliance hood upwards to keep it from shutting inad- vertently. Î check the water filter for contamination, clean/rep...

Page 10

- 8 Î step 3: press the f3 key to switch be- tween brightness and contrast. Î you can change the brightness and contrast levels with the f4 and f5 keys. F4 (-) = set value decreases. F5 (+) = set value increases. Î by pressing the f6 key twice, you will return to the operating display. Î step 1: pre...

Page 11

- 9 Î refill the antifreeze container with anti- freeze. Select the mixing ratio of the water/antifreeze as per the instructions of the antifreeze manufacturer. Î align the actuation lever of the ball tap for antifreeze/water tank vertically. Î unscrew the high pressure hose from the high pressure o...

Page 12

- 10 danger – maintenance procedures may only be carried out by persons who have been in- structed in the safe operation and mainte- nance on the high-pressure systems. – before carrying out any tasks on the machine, switch the key switch off and remove it. Prevent inadvertent startups of the appli-...

Page 13

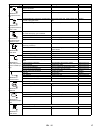

- 11 1 compressor 2 oil cooler module 3 air cooler module 4 cyclone separator 5 2/2 way solenoid valve, 2-stroke 6 condensation drain, return to water tank 7 pressure relief valve 8 silencer 9 backflow valve 10 pressure regulation valve 11 ball tap 12 safety valve 13 pressure container 14 compressed...

Page 14

- 12 note only trained personnel is permitted to add motor, gear and pump oil. Note align the appliance horizontally prior to check the oil level in order not to get a false result. Check the oil prior to starting the appliance or at least 5 minutes after switching off the engine. Caution increased ...

Page 15

- 13 pump and gear Î the oil level is correct if it is within the markings on the oil dip. Î after the check, insert the oil dip and close the lid of the filler neck. Note prior to every operation, the fill level of the coolant in the equalisation container must be checked. Caution observe the brand...

Page 16

- 14 danger this can lead to severe injuries and possi- bly death. An improper startup and repair of the appliance and the spray unit is danger- ous. Faults detected by the control are shown on the display. 1 display 2 fault indication 3 reset key to confirm the fault Î read the fault message on the...

Page 17

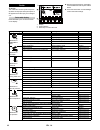

- 15 >malfunction high pressure sen- sor cable plug of high pressure sensor loose or short in connection check for correct fit operator cable breakage replace the cable customer service high pressure sensor defective check / replace the sensor customer service >malfunction high pressurehoch- druck >...

Page 18

- 16 1 main fuse faults without display on the console fault cause remedy by whom appliance stops, dis- play switches off main fuse is blown replace the main fuse operator no display after switching the appli- ance on battery main switch switched off switch on the battery main switch operator batter...

Page 19

- 17 – only use accessories and spare parts which have been approved by the man- ufacturer. The exclusive use of original accessories and original spare parts ensures that the appliance can be oper- ated safely and troublefree. – at the end of the operating instructions you will find a selected list...

Page 20

02/10 ae karcher fze, p.O. Box 17416, jebel ali free zone (south), dubai, united arab emirates, +971 4 886-1177, www.Kaercher.Com ar kärcher s.A., uruguay 2887 (1646) san fernando, pcia. De buenos aires +54-11 4506 3343, www.Karcher.Com.Ar at alfred kärcher ges.M.B.H., lichtblaustraße 7, 1220 wien, ...