- DL manuals

- Karcher

- Pressure Washer

- HDS 10/20 M

- Service Manual

Karcher HDS 10/20 M Service Manual

Summary of HDS 10/20 M

Page 1

English 5.906-432.0 rev. 00 (06/15) 1 hds 7/12 m, hds 8/18 m, hds 9/18 m, hds 10/20 m, hds 12/18 s, hds 13/20 s service manual.

Page 2

2 english 5.906-432.0 rev. 00 (06/15) 1 contents 2 preface 5 3 safety instructions 5 3.1 hazard levels 5 4 technical features 5 4.1 general 5 4.2 connection performance of appliance 5 4.3 pump 5 4.4 electronics system 5 4.5 detergent 5 4.6 accessories 6 4.7 field of application 6 4.8 type plate 6 5 ...

Page 3

English 5.906-432.0 rev. 00 (06/15) 3 6.19.2 safety block (water shortage safeguard new) 44 6.19.3 function water shortage safeguard and dry-run protection 45 6.19.4 function of safety valve 45 6.20 burner blower with fuel pump 46 6.21 booster heater (with ignition transformer) 48 6.22 booster heate...

Page 4

4 english 5.906-432.0 rev. 00 (06/15) 7.28 brightness value of the flame sensor 101 7.29 testing the temperature sensor 101 7.30 testing the water temperature setting and the programme switch 102 7.31 test service switch 102 7.32 testing the sensors 103 7.33 error memory 104 7.34 operating hours 106...

Page 5

English 5.906-432.0 rev. 00 (06/15) 5 good service work requires extensive and practice-orient- ed training as well as well-structured training materials. Hence we offer regular basic and advanced training pro- grammes covering the entire product range for all service engineers. In addition to this,...

Page 6

6 english 5.906-432.0 rev. 00 (06/15) – rotary regulator for pressure and quantity regulation – soft grip - easy press gun – stainless steel spray lance, rotating – power nozzle (stainless steel) – steam nozzle (brass) – hds 7/12-4 m/mx – hds 8/18-4 m/mx – hds 9/18-4 m/mx – hds 10/20-4 m/mx – hds 12...

Page 7

English 5.906-432.0 rev. 00 (06/15) 7 1 push handle 2 cover, upper storage compartment 3 safety catch, soft grip - easy press gun 4 rotating regulator 5 hand lever 6 soft grip - easy press gun 7 lock for fuel tank 8 high pressure hose 9 rotating spray lance 10 high pressure nozzle 11 transport wheel...

Page 8

8 english 5.906-432.0 rev. 00 (06/15) 1 indicator lamps 2 programme selector switch (q1) 3 storage spray pipe 4 setting, water temperature 5 closure, liquid softener tank 6 storage, power cord 7 storage compartment 8 supply cord 9 closure detergent tank 2 10 high pressure outlet 11 chassis 12 water ...

Page 9

English 5.906-432.0 rev. 00 (06/15) 9 1 indicator lamps 2 programme selector switch (q1) 3 storage spray pipe 4 setting, water temperature 5 closure, liquid softener tank 6 storage, power cord 7 hose reel, high-pressure hose 8 supply cord 9 closure detergent tank 2 10 crank, hose drum 11 recess hose...

Page 10

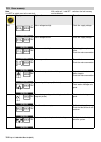

10 english 5.906-432.0 rev. 00 (06/15) 1 control led 0, pump (red) note symbol depending on unit model. 2 control led 1, rotation direction (red) 3 control led 2, operation (green) 4 control led 3, fuel (yellow) 5 control led 4, detergent tank 1 (yellow) 6 control led 5, motor (red) 7 control led 6,...

Page 11

English 5.906-432.0 rev. 00 (06/15) 11 led no. Symbol activity meaning / measure 0 1 x blinking lack of oil. Check/fill oil level of the high pressure pump; repair leaks. 2 x blinking leakage. 10 short startups. Check the high-pressure system for leaks. 3 x blinking dry running (2 minutes). Check / ...

Page 12

12 english 5.906-432.0 rev. 00 (06/15) note tag is an electronic component on the new square soften- er bottle. The tag is located behind the bottle label. The tag can be read and written on electronically (also see 6.10.3 "functionality rfid"). 6 1 x blinking exhaust thermostat open. Check/replace ...

Page 13

English 5.906-432.0 rev. 00 (06/15) 13 for the better distinguishability of numeric value displays in the service functions the template below can be placed on the led displays of the control panel. 5.4.2 template numerical value display.

Page 14

14 english 5.906-432.0 rev. 00 (06/15).

Page 15

English 5.906-432.0 rev. 00 (06/15) 15 5.4.3 control panel, view from the inside 1 service switch and dosing liquid sof- tener 2 control transformer t1 3 transducer 4 fuse 2.0 at for control transformer at: (6.644-052) 5 terminal strip 6 ground point 7 supply cord 8 setting, water temperature 9 prog...

Page 16

16 english 5.906-432.0 rev. 00 (06/15) 1 connection, level sensor detergent tank 1 2 connection, level sensor detergent tank 2 3 connection of level sensor for fuel tank 4 connection of level sensor for liquid softener 5 transducer connection 6 connection flame sensor 7 temperature sensor connection...

Page 17

English 5.906-432.0 rev. 00 (06/15) 17 1 encoding pin 2 recess for encoding pin plug coding the plugs for the pcb connections are designed with en- coding pins and their matching recesses in the pcb base so that only the matching plug can be attached to the re- spective connection. 1 display 2 progr...

Page 18

18 english 5.906-432.0 rev. 00 (06/15) note operating and maintenance displays are shown one after the other like in a slide show. Each picture for 3 seconds. The fault displays remain until the device is switched off. 6 function 6.1 operating displays display explanation remark upper bar: level fue...

Page 19

English 5.906-432.0 rev. 00 (06/15) 19 6.3 setting liquid softener display explanation remark set liquid softener dosing in accordance with the water hard- ness. This display appears for 3s if the liquid softener setting is changed. Attention service mode position. After the restart, the device will...

Page 20

20 english 5.906-432.0 rev. 00 (06/15) 1 cover, upper storage compartment 2 storage operating instructions 3 fastening screws upper storage compartment (4x) 4 storage compartment top 5 nameplate 6 fastening screw control panel 7 operator console 8 storage replacement nozzles 9 storage dirt grinder 1...

Page 21

English 5.906-432.0 rev. 00 (06/15) 21 note open cover and dismantle if necessary 1 screwdriver 2 storage compartment top 3 lock of appliance hood 4 cover push in the locking mechanism of the cover and turn it by 90°. Open the appliance hood. 1 locating lug arrestor cable 2 arrestor cable cover unho...

Page 22

22 english 5.906-432.0 rev. 00 (06/15) 1 fuel line to the booster heater 2 electric box, motor 3 burner blower 4 oil refill container pump 5 motor 6 handle, pressure and volume regulation 7 pump head 8 oil drain screw 9 chassis 10 plug detergent tank 2 11 water hose to the pump 12 casing water fine ...

Page 23

English 5.906-432.0 rev. 00 (06/15) 23 1 fuel line to the booster heater 2 electric box, motor 3 burner blower 4 oil refill container pump 5 motor 6 handle, pressure and volume regulation 7 pump head 8 plug detergent tank 2 9 filter 10 sds hose to the safety block 11 splashboard, safety valve 12 saf...

Page 24

24 english 5.906-432.0 rev. 00 (06/15) 1 position marking 2 service switch setting the water hardness the setting of the liquid softener dosing is done in accord- ance with the local water hardness (ask your local water supply company or determine by means of a hardness tester). Note when using rm 1...

Page 25

English 5.906-432.0 rev. 00 (06/15) 25 1 closure fuel tank 2 seal fuel tank closure 3 filler neck 1 fuel filter 2 level sensor for fuel tank 3 fuel tank 1 level sensor for fuel tank 6.9 fuel tank.

Page 26

26 english 5.906-432.0 rev. 00 (06/15) the feed of the liquid softener takes place in accordance with the setting on the service switch. The setting is de- scribed under 6.8 "service switch". The feed only takes place in the programme switch position "eco" and "warm water" at a set water temperature...

Page 27

English 5.906-432.0 rev. 00 (06/15) 27 1 liquid softener reservoir 2 level sensor 3 dosing valve the feed of the liquid softener takes place in accordance with the setting on the service switch. The setting is de- scribed under 6.8 "service switch". The feed only takes place in the programme switch ...

Page 28

28 english 5.906-432.0 rev. 00 (06/15) 1 liquid softener bottle 2 screws 3 rfid - attachment 1 rfid - attachment 2 bottle opener - insertion 1 liquid softener bottle 2 sealing note the sealing is pierced upon inserting the bottle..

Page 29

English 5.906-432.0 rev. 00 (06/15) 29 rfid (radio frequency identification) stands for the iden- tification by means of high frequency. There is a transponder under the label on the softener bot- tle (microchip with antenna, also called tag). The write-read electronics installed in the rfid attachm...

Page 30

30 english 5.906-432.0 rev. 00 (06/15) 1 label 2 rfid tag, behind the label note tag is an electronic component on the new square soften- er bottle. The tag is located behind the bottle label. The tag can be read and written on electronically. Float tank the float container is integrated in the chas...

Page 31

English 5.906-432.0 rev. 00 (06/15) 31 detergent tank 1 (volume 10l) the detergent tank 1 is located in the rear part of the chas- sis. Suction hose the plug with the connection of the suction hose is located between the booster heater and the lower storage com- partment or the hose reel. Level sens...

Page 32

32 english 5.906-432.0 rev. 00 (06/15) 1 level sensor (option) detergent tank 2 (volume 20l) the detergent tank 2 is located in the right part of the chas- sis. Suction hose the plug with the connection of the suction hose is located above the right transport wheel. A detergent filter is at- tached ...

Page 33

English 5.906-432.0 rev. 00 (06/15) 33 1 stopper 2 cleaning agent filter 3 detergent tank 2 1 level sensor (option) 2 stopper 3 detergent tank 2 4 float detergent dosing valve with automatic clear rinsing in zero position 1 water 2 detergent tank 1 3 detergent tank 2 4 pump 6.13 detergent dosing val...

Page 34

34 english 5.906-432.0 rev. 00 (06/15) 1 electronics system 2 burner blower 3 fuel pump 4 solenoid valve 5 blower, motor cooling 6 engine mount, left 7 engine mount, right 8 pump head 9 oil level sensor 10 oil fill container 11 handle, pressure and volume regulation 12 cover 1 cover 2 oil level sens...

Page 35

English 5.906-432.0 rev. 00 (06/15) 35 1 connecting cable, motor 2 fan wheel 3 stator 4 motor bearing, rear (b bearing) 5 motor shaft 6 rotor 7 casing 8 shaft seal ring 9 motor bearing, front (a bearing) 10 swash plate with axial ball bearing 11 screw 12 oil drain screw 13 detergent suck in 14 sucti...

Page 36

36 english 5.906-432.0 rev. 00 (06/15) 6.15 electrical box, air-cooled motor 1 ground point 2 terminal strip 3 connection to earth, motor 4 engine contactor k1 5 anti-interference filter 6 board, motor distributor 7 connection pressure switch on 8 connection pressure switch off 9 oil level sensor co...

Page 37

English 5.906-432.0 rev. 00 (06/15) 37 1 electronics system 2 burner blower 3 cooling coil 4 fuel pump 5 solenoid valve 6 engine mount, left 7 engine mount, right 8 pump head 9 oil level sensor 10 oil fill container 11 handle, pressure and volume regulation 12 cover oil drain screw the oil drain scr...

Page 38

38 english 5.906-432.0 rev. 00 (06/15) 1 connecting cable, motor 2 cooling coil 3 stator 4 motor bearing, rear (b bearing) 5 motor shaft 6 rotor 7 casing 8 shaft seal ring 9 motor bearing, front (a bearing) 10 screw 11 swash plate 12 slide shoe 13 oil drain screw 14 detergent suck in 15 suction side...

Page 39

English 5.906-432.0 rev. 00 (06/15) 39 1 ground point 2 connection to earth, motor 3 engine contactor 4 anti-interference filter 5 board motor distributor 6 connection pressure switch on 7 connection pressure switch off 8 oil level sensor connection 9 connection printed circuit board, operating pane...

Page 40

40 english 5.906-432.0 rev. 00 (06/15) 1 handle, pressure and volume regulation 2 screwed sealing plug 3 screws pump head 4 pump head 5 suction jumper 6 screwed sealing plug 7 water pipes 8 safety bracket, pressure switch off 9 pressure switch off 10 sds hose to the safety block 11 pressure switch o...

Page 41

English 5.906-432.0 rev. 00 (06/15) 41 1 handle, pressure and volume regulation 2 screwed sealing plug 3 screws pump head 4 pump head 5 suction jumper 6 screwed sealing plug 7 filter 8 safety bracket, pressure switch off 9 pressure switch off 10 sds hose to the safety block 11 pressure switch on 12 ...

Page 42

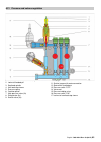

42 english 5.906-432.0 rev. 00 (06/15) 1 connecting cable, reed switch 2 screwed sealing plug 3 clamping bracket 4 reed switch 5 high pressure pipe to the on-demand heater 6 connection hose pressure gauge 7 safety block 8 sds hose 9 adjustment screw, safety valve 10 valve ball 1 connection hose pres...

Page 43

English 5.906-432.0 rev. 00 (06/15) 43 1 connecting cable, reed switch 2 screwed sealing plug 3 spring 4 clamping bracket 5 reed switch 6 magnetic piston 7 holes 8 water inlet, from the high pressure pump 9 high pressure pipe to the on-demand heater 10 mould part 11 water outlet 12 adjusting screw 1...

Page 44

44 english 5.906-432.0 rev. 00 (06/15) note the cartridge replaces the previous design with piston and spring. Note recommended installation direction: the lower drilled hole of the cartridge points towards the high-pressure pipe to the booster heater. 6.19.1 water shortage safeguard as cartridge 6....

Page 45

English 5.906-432.0 rev. 00 (06/15) 45 the lack of water fuse prevents the burner from switching on in case of missing or insufficient water volume and thus protects the on-demand heater from overheating. With an opened gun and a sufficient water flow the sole- noid is lifted against the force of gr...

Page 46

46 english 5.906-432.0 rev. 00 (06/15) 1 return 2 pressure line 3 screw 4 blower lid 5 fuel line 6 setting fuel pressure 7 fuel pump 8 continuous heater 9 connecting cable solenoid valve 10 suction opening, burner blower 11 solenoid valve for fuel 12 fastening screw fuel pump 13 blower lid 6.20 burn...

Page 47

English 5.906-432.0 rev. 00 (06/15) 47 1 rubber collar 2 lock 3 air door, air volume adjustment 4 stop screw 5 burner blower 1 solenoid valve 2 coupling unit 3 connection pressure line 4 setting fuel pressure 5 fuel pump 6 fastening screw uninstall fuel pump – detach pressure line. – unscrew locking...

Page 48

48 english 5.906-432.0 rev. 00 (06/15) 1 capillary exhaust temperature monitor 2 protective conductor 3 cover 4 screws burner 5 locking screw for appliance hood 6 sight glass, ignition monitoring (option) 7 burner 8 ignition cable 9 connection cable ignition transformer 10 ignition transformer 11 sc...

Page 49

English 5.906-432.0 rev. 00 (06/15) 49 1 electronic ignition transformer 2 fastening screw of ignition transformer 3 screws for burner cover (3 x) 4 sight glass, ignition monitoring (option) 5 burner cover 6 fuel line 7 exhaust nozzle, on-demand heater 8 type plate of heating coil 9 exhaust temperat...

Page 50

50 english 5.906-432.0 rev. 00 (06/15) various ignition transformers are installed in the devices. Electronic ignition transformer the integrated electronic ignition transformer (see picture above) is meanwhile used for all devices, except the devic- es for special voltages. The electronic ignition ...

Page 51

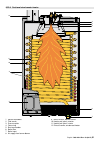

English 5.906-432.0 rev. 00 (06/15) 51 1 ignition electrodes 2 fuel nozzle 3 pressure plate 4 flame ring 5 burning chamber 6 boiler floor 7 boiler input 8 air supply from burner blower 9 boiler exterior, double-walled 10 heating coil spiral, exterior 11 heating coil spiral, interior 12 exhaust nozzl...

Page 52

52 english 5.906-432.0 rev. 00 (06/15) mode of operation the water from the high pressure pump enters the interior heating coil spiral, is heated while flowing through and ex- its to the bottom from the heating coil spiral. The fuel is vaporised by the fuel nozzle and ignited by the spark of the ign...

Page 53

English 5.906-432.0 rev. 00 (06/15) 53 1 looking glass 2 connection pressure line 3 connection ignition electrode 4 connection for air pressure measurement 5 burner cover 1 ignition electrode 2 fuel nozzle 3 pressure plate 1 ignition electrode 2 fuel nozzle 6.23 burner.

Page 54

54 english 5.906-432.0 rev. 00 (06/15) 1 ignition electrodes 2 fuel nozzle holder 3 fuel nozzle 4 spray angle 45° or 60°, depending on the type of appli- ance 5 screw 6 burner cover burner there is a strong spark created between the two ignition electrodes to ensure that the injected fuel will ignit...

Page 55

English 5.906-432.0 rev. 00 (06/15) 55 1 floor plate 2 output of flow-type heater 3 temperature sensor water 4 clamping bracket 5 chassis 6 connecting cable temperature sensor 7 input of flow-type heater 8 bottom booster heater 9 pressure line of the safety block 6.25 output, booster heater.

Page 56

56 english 5.906-432.0 rev. 00 (06/15) 1 lock trigger gun 2 casing shell 3 hand lever 4 high pressure hose 5 hose guide 6 safety clip 7 needle bearing 8 coupling high-pressure hose/trigger gun 9 o ring 10 node piece function when the manual lever is actuated, the valve in the node piece opens and th...

Page 57

English 5.906-432.0 rev. 00 (06/15) 57 1 connection trigger gun 2 connecting pin 3 ceramic disc on gun side 4 ceramic disc on spray pipe side 5 casing of rotating regulator 6 handle of rotary regulator 7 spray lance connection the pressure and volume regulation is designed as a rota- ry regulator be...

Page 58

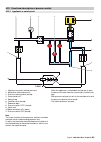

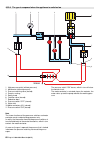

58 english 5.906-432.0 rev. 00 (06/15) 6.28 functional diagram of pressure water operation (water-cooled motor).

Page 59

English 5.906-432.0 rev. 00 (06/15) 59 1 detergent tank 1, volume 10 l 2 detergent suction hose with filter 3 level sensor, detergent tank 1 (option) 4 detergent suction hose with filter 5 level sensor, detergent tank 2 (option) 6 detergent tank 2, volume 20 l 7 dosage valve for detergent 8 suction ...

Page 60

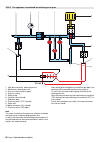

60 english 5.906-432.0 rev. 00 (06/15) 6.29 functional diagram vacuuming operation.

Page 61

English 5.906-432.0 rev. 00 (06/15) 61 1 detergent tank 1 2 detergent suction hose with filter 3 level sensor, detergent tank 1 4 detergent suction hose with filter 5 level sensor, detergent tank 2 6 detergent tank 2 7 suction hose with filter and check valve 8 open container 9 dosage valve for dete...

Page 62

62 english 5.906-432.0 rev. 00 (06/15) note if the appliance is used for vacuuming, the rinse hose of the detergent dosing valve must be plugged onto the re- spective plug to prevent erroneous air suction. Furthermore, the fine filter must be uninstalled and the wa- ter supply hose must be connected...

Page 63

English 5.906-432.0 rev. 00 (06/15) 63 1 threaded pin, max. Pressure setting 2 locknut threaded pin 3 semiload spindle 4 half-load stop sleeve 5 pressure spring 6 overflow piston 7 high pressure valve (3x) 8 pump piston (3x) 9 suction valve (3x) 10 detergent infeed with backflow valve 11 suction jum...

Page 64

64 english 5.906-432.0 rev. 00 (06/15) manually with a pressure regulator on the high pres- sure pump the pressure and volume regulation via the handle on the high pressure pump is used to relieve the motor with most- ly partial load operation. Turning the spindle anticlockwise lowers the pretension...

Page 65

English 5.906-432.0 rev. 00 (06/15) 65 1 high pressure outlet (without pressure) 2 manometer (without pressure) 3 pressure retaining valve (closed) 4 pump stands still 5 rotary knob 6 overflow valve (closed) 7 reduction bore 8 pressure switch "off" (closed) 9 water inlet 10 motor contactors (k1) (op...

Page 66

66 english 5.906-432.0 rev. 00 (06/15) 1 high pressure outlet, working pressure 2 manometer, working pressure 3 pressure retaining valve (open) 4 pump is running 5 rotary knob 6 overflow valve (closed) 7 reduction bore 8 pressure switch "off" (closed) 9 water inlet 10 motor contactors (k1) (closed) ...

Page 67

English 5.906-432.0 rev. 00 (06/15) 67 1 high pressure outlet, shut-off pressure 2 manometer, shut-off pressure 3 pressure retaining valve (closed) 4 pump stands still 5 rotary knob 6 overflow valve 7 reduction bore 8 pressure switch "off" (open) 9 water inlet 10 motor contactors (k1) (open) 11 pres...

Page 68

68 english 5.906-432.0 rev. 00 (06/15) 1 high pressure outlet (without pressure) 2 manometer (without pressure) 3 pressure retaining valve (closed) 4 pump is running 5 rotary knob 6 overflow valve (closed) 7 reduction bore 8 pressure switch "off" (closed) 9 water inlet 10 motor contactors (k1) (clos...

Page 69

English 5.906-432.0 rev. 00 (06/15) 69 1 casing shell, hose reel 2 screws release pressure. Unwind the hp hose from the hose reel. Unscrew the screws. Remove the casing shell. 1 clip lever out the clamp. Pull out the hose. Take a new hose through the hose guide and the de- flection pulley. Slide the...

Page 70

70 english 5.906-432.0 rev. 00 (06/15) 7.1.1uninstall / install high-pressure hose 1 screw 2 casing shell, hose reel loosen screws. Turn the hose reel. 1 casing shell, hose reel 2 screws unscrew the screws. 1 screws 2 bearing block unscrew the screws. 7.1.2 renew o-rings axle, hose reel.

Page 71

English 5.906-432.0 rev. 00 (06/15) 71 1 casing shell, hose reel 2 bearing block 3 crank remove the front part of the hose reel. 1 hose drum 2 safety ring 3 pipeline with axle 4 node piece 5 pliers remove the retaining ring. Remove the knot. Remove the rear part of the hose reel. 1 rear bearing bloc...

Page 72

72 english 5.906-432.0 rev. 00 (06/15) 7.1.2renew o-rings axle, hose reel 1 rear bearing block 2 screws 3 o rings 4 pipeline with axle note align the pipeline with axle at a right angle to the rear bear- ing block. 1 pipeline with axle 2 screw connection 3 wrench disconnect screw connection. Remove ...

Page 73

English 5.906-432.0 rev. 00 (06/15) 73 1 manometer unscrew the screws on the control panel. Manually push in the left clip. 1 manometer 2 screwdriver push in the right clip by means of a screwdriver. 1 screw connection 2 manometer 3 clips remove the pressure gauge. Disconnect screw connection. 7.2 u...

Page 74

74 english 5.906-432.0 rev. 00 (06/15) 1 turning handle screw in the twist grip of the pressure and volume reg- ulation on the pump all the way to the stop (towards "+"). Pull off the rotary handle. 1 adjusting screw 2 counter-nut loosen counter-nut. Completely screw in the adjustment screw. Install...

Page 75

English 5.906-432.0 rev. 00 (06/15) 75 1 setting, water temperature service mode if the service switch is in the "service" position (screwdriv- er symbol) upon switching on the device, the service mode of the device is activated (pump is not running). Selection of the service functions the available...

Page 76

76 english 5.906-432.0 rev. 00 (06/15) 7.5 set up the switching off process function adjustments led indicator important 30 °c (30/30 °c) on30min behaviour of device after 30 minutes of continuous operation. The setting will be saved. The device switches off after 30 minutes of continuous operation....

Page 77

English 5.906-432.0 rev. 00 (06/15) 77 7.7 brightness value of the flame sensor function adjustments led indicator important 45 °c (40/35 °c) ldrtest display of the brightness value measured by the flame sensor. The value is displayed digit by digit by the leds, with every led standing for a numeric...

Page 78

78 english 5.906-432.0 rev. 00 (06/15) 7.8 rfid query function adjustments led indicator important 45 °c + „set“ (40/-- °c + „set“) rfidonoff information to the printed circuit board whether the device is equipped with feed via rfid. Device with rfid menu access: select 45°c switch off device. Hold ...

Page 79

English 5.906-432.0 rev. 00 (06/15) 79 7.10 testing the water temperature setting and the programme switch function adjustments led indicator important 55 °c (46/38 °c) encprogtest with this function, the pro- gramme switch and the controller for the water temperature setting can be tested. Upon swi...

Page 80

80 english 5.906-432.0 rev. 00 (06/15) function adjustments led indicator important 55 °c (46/38 °c) 80 °c (58/46 °c) 85 °c (60/48 °c) 90 °c (63/50 °c) 95 °c (66/52 °c) 100 °c (68/54 °c) 112 °c (70/55 °c) 125 °c (74/56 °c) 140 °c (77/58 °c) 155 °c (80/60 °c) the temperature setting must finally be s...

Page 81

English 5.906-432.0 rev. 00 (06/15) 81 function adjustments led indicator important 55 °c (46/38 °c) encprogtest by operating the pushbut- ton function of the service switch (continue to turn to "set" position and re- lease) again, the test for the programme switch is started. The led display depend...

Page 82

82 english 5.906-432.0 rev. 00 (06/15) 7.11 testing the service switch function adjustments led indicator important 60 °c (48/40 °c) encdgttest service switch setting dis- play. Service switch position "off" service switch position "1" service switch position "2" service switch position "3" service ...

Page 83

English 5.906-432.0 rev. 00 (06/15) 83 7.12 testing the sensor function adjustments led indicator important 65 °c (50/42 °c) inputtest use this function to dis- play the status of the dif- ferent sensors. Every led displays the status of a certain sensor. Therefore, several leds can be on at the sam...

Page 84

84 english 5.906-432.0 rev. 00 (06/15) 7.13 error memory function adjustments led indicator important 70 °c (52/44 °c) errors this functions serves to read the fault memory. The faults are displayed in 2 steps: 1 led display of the fault type (see on the right). 2 display of the pump run time in hou...

Page 85

English 5.906-432.0 rev. 00 (06/15) 85 function adjustments led indicator important 70 °c (52/44 °c) temperature sensor fault. Short circuit or cable break. Flame sensor recognises no or not enough light. Flame sensor recognises light. Rfid write-read electronics defective. End of the fault memory. ...

Page 86

86 english 5.906-432.0 rev. 00 (06/15) 7.14 operating hours function adjustments led indicator important 75 °c (55/45 °c) stundenpwr indication of the con- sumed rm 110/111 bot- tles. The value is displayed digit by digit by the leds, with every led standing for a numeric value from 0 - 9 in accorda...

Page 87

English 5.906-432.0 rev. 00 (06/15) 87 7.15 gun switching operations since gun service function adjustments led indicator important 80 °c (58/46 °c) si_pistole display of the gun switch- ings since the most recent gun service. The value is displayed digit by digit by the leds, with every led standin...

Page 88

88 english 5.906-432.0 rev. 00 (06/15) 7.16 gun services function adjustments led indicator important 85 °c (60/48 °c) sctr_pistole display of gun services. The value is displayed digit by digit by the leds, with every led standing for a numeric value from 0 - 9 in accordance with its number. The di...

Page 89

English 5.906-432.0 rev. 00 (06/15) 89 85 °c + „set“ (60/48 °c + „set“) when switching on the device, the gun switching operations since the gun service (si_pistole) are reset to "0", the service counter gun (sctr_pistole) is increased by 1 and the fault memory is deleted. Function adjustments led i...

Page 90

90 english 5.906-432.0 rev. 00 (06/15) 7.17 gun switches since initial startup function adjustments led indicator important 90°c (63/50 °c) totalpistole display of the gun switch- ings since device was first started up. The value is displayed digit by digit by the leds, with every led standing for a...

Page 91

English 5.906-432.0 rev. 00 (06/15) 91 7.18 operation duration of the burner since burner service function adjustments led indicator important 95°c (66/52 °c) si_brenner display of the operation duration of the burner in hours since the last burn- er service. The value is displayed digit by digit by...

Page 92

92 english 5.906-432.0 rev. 00 (06/15) 7.19 burner service function adjustments led indicator important 100°c (68/54 °c) sctr_brenner display of the burner ser- vice. The value is displayed digit by digit by the leds, with every led standing for a numeric value from 0 - 9 in accordance with its numb...

Page 93

English 5.906-432.0 rev. 00 (06/15) 93 100°c + „set“ (68/54 °c + „set“) when switching on the device, the burner operation duration since the burner service (si_brenner) is reset to "0", the service counter burner (sctr_brenner) is increased by 1 and the fault memory is de- leted. Function adjustmen...

Page 94

94 english 5.906-432.0 rev. 00 (06/15) 7.20 burner operation since initial startup function adjustments led indicator important 112°c (70/55 °c) totalbrenner display of the operation duration of the burner in hours since the initial startup of the device. The value is displayed digit by digit by the...

Page 95

English 5.906-432.0 rev. 00 (06/15) 95 7.21 operating hours of the pump since pump service function adjustments led indicator important 125°c (74/56 °c) si_pumpe display of the operating time of the pump since the last pump service in hours. The value is displayed digit by digit by the leds, with ev...

Page 96

96 english 5.906-432.0 rev. 00 (06/15) 7.22 pump service function adjustments led indicator important 140°c (77/58 °c) sctr_pumpe display of the pump ser- vices. The value is displayed digit by digit by the leds, with every led standing for a numeric value from 0 - 9 in accordance with its number. T...

Page 97

English 5.906-432.0 rev. 00 (06/15) 97 140°c + „set“ (77/58 °c + „set“) when switching on the device, the pump operation duration since the pump service (si_pumpe) is reset to "0", the service counter pump (sctr_pumpe) is increased by 1 and the fault memory is deleted. Function adjustments led indic...

Page 98

98 english 5.906-432.0 rev. 00 (06/15) 7.23 pump operation since initial startup function adjustments led indicator important 155°c (80/60 °c) totalpumpe display of the operating time of the pump since the initial device startup in hours. The value is displayed digit by digit by the leds, with every...

Page 99

English 5.906-432.0 rev. 00 (06/15) 99 1 setting, water temperature service mode if the service switch is in the "service" position (screwdriv- er symbol) upon switching on the device, the service mode of the device is activated (pump is not running). Selection of the service functions the available...

Page 100

100 english 5.906-432.0 rev. 00 (06/15) 7.25 set up the switching off process display explanation remark 30°c switch-off after 30 minutes of continuous operation is activated. Switching with set switch-off after 30 minutes of continuous operation is not activated (factory setting). Switching with se...

Page 101

English 5.906-432.0 rev. 00 (06/15) 101 7.27 rfid query display explanation remark 45°c + „set“ device is equipped with rfid. Menu access: select 45°c switch off device. Hold set. Turn on the machine. Re- lease set. Select settings with set. Device is not equipped with rfid. Check the setting when r...

Page 102

102 english 5.906-432.0 rev. 00 (06/15) 7.30 testing the water temperature setting and the programme switch display explanation remark 55°c output image for temperature selector switch test. Use set to access the tem- perature selector switch test. Temperaturwahlschaltertest. Es wird die am tem- per...

Page 103

English 5.906-432.0 rev. 00 (06/15) 103 7.32 testing the sensors display explanation remark 65°c description from left to right: level stage fuel sensor (stage 7 of 8) thermal motor protection switch open. Oil refill container not empty exhaust thermostat open. Water shortage safeguard open level st...

Page 104

104 english 5.906-432.0 rev. 00 (06/15) note use set to switch over to the next fault. With switch-off - hold set - switch-on the fault memory can be deleted. 7.33 error memory display explanation remark 70°c mains voltage too high check the supply voltage. Mains voltage too low check the supply vol...

Page 105

English 5.906-432.0 rev. 00 (06/15) 105 exhaust thermostat has triggered. Decarbonize boiler. Check exhaust gas thermo- stat. Cable break or short circuit with water temperature sensor check temperature sensor. Flame sensor does not detect a flame although the burner was switched on clean the lookin...

Page 106

106 english 5.906-432.0 rev. 00 (06/15) 7.34 operating hours display explanation remark 75°c indication of the consumed rm 110/111 bottles. 7.35 gun switching operations since gun service display explanation remark 80°c number of gun switching operations since the last maintenance maintenance after ...

Page 107

English 5.906-432.0 rev. 00 (06/15) 107 7.38 operation duration of the burner since startup display explanation remark 95°c operation duration burner since the last mainte- nance maintenance after 400 burn- er hours. 7.39 burner service display explanation remark 100°c number of burner maintenances ...

Page 108

108 english 5.906-432.0 rev. 00 (06/15) 7.42 pump services display explanation remark 140°c number of pump maintenances delete service. Turn off the appliance. Hold set (2-3 seconds). Turn on the appliance. Note the fault memory is also de- leted. 7.43 pump operation since initial startup display ex...

Page 109

English 5.906-432.0 rev. 00 (06/15) 109 turn off the appliance. Make a note of the position of the service switch. Set the service switch to service. Turn on the appliance. Set temperature regulator to the relevant temperature. 30 (30/20)°c - behaviour after 30 minutes of continu- ous operation. 35 ...

Page 110

110 english 5.906-432.0 rev. 00 (06/15) read the fault memory in service mode at 70 (52/44)°c. Every fault type is saved only once, together with the passed hours since it has last occurred. Advance with "set". Oooo end of the fault memory reached. Oooo display of the software version. 7.46 overview...

Page 111

English 5.906-432.0 rev. 00 (06/15) 111 1 pressure line to the burner 2 fuel pump 3 suction hose, fuel 4 adjustment screw, fuel pressure 5 return hose to the fuel tank measure water temperature install the shut-off valve with thermometer (special tool) on the appliance outlet. Switch on the burner a...

Page 112

112 english 5.906-432.0 rev. 00 (06/15) 1 clamp ring 2 air guidance 3 exterior coat clean the air duct and the outer jacket in the installation area. Install the air duct on the outer jacket. Grease clamping ring. Insert the clamping ring up into the air duct up to the no- ticeable stop. Note when i...

Page 113

English 5.906-432.0 rev. 00 (06/15) 113 1 adjustment screw, high pressure 2 lock nut, adjustment screw, high pressure 3 spindle, pressure and quantity regulation 4 adjustment screw, low pressure 5 lock nut, adjustment screw, low pressure 6 housing, overflow valve install the test manometer (special ...

Page 114

114 english 5.906-432.0 rev. 00 (06/15) 1 adjustment screw, high pressure 2 lock nut, adjustment screw, high pressure 3 spindle, pressure and quantity regulation 4 adjustment screw, low pressure 5 lock nut, adjustment screw, low pressure 6 housing, overflow valve fasten the test manometer to the hig...

Page 115

English 5.906-432.0 rev. 00 (06/15) 115 1 adjustment screw, high pressure 2 lock nut, adjustment screw, high pressure 3 spindle, pressure and quantity regulation 4 adjustment screw, low pressure 5 lock nut, adjustment screw, low pressure 6 housing, overflow valve fasten the test manometer to the hig...

Page 116

116 english 5.906-432.0 rev. 00 (06/15) 1 adjustment screw, high pressure 2 lock nut, adjustment screw, high pressure 3 spindle, pressure and quantity regulation 4 adjustment screw, low pressure 5 lock nut, adjustment screw, low pressure 6 housing, overflow valve fasten the test manometer to the hig...

Page 117

English 5.906-432.0 rev. 00 (06/15) 117 9 troubleshooting failure measure device is not running (no led/display indication) – check/replace mains voltage, connecting cable and mains fuse. – check the fuse (f1). – check/replace the power switch. – check/replace the pressure switch – check/adjust/repl...

Page 118

118 english 5.906-432.0 rev. 00 (06/15) 9.1 error messages display explanation remark rotating field of the motor incorrect. Perform a phase inversion in the commutating pole plug. Thermal motor protection switch (wsk) in the motor has tripped. Switch off the device and al- low the motor to cool dow...

Page 119

English 5.906-432.0 rev. 00 (06/15) 119 note one display for multiple faults is used here. By reading the fault memory, the fault can possibly be localized. (service mode 70°c) 9.2 error message with service demand display explanation remark water shortage safeguard (reed switch or magnetic piston i...

Page 120

120 english 5.906-432.0 rev. 00 (06/15) 10 technical specifications appliance type appliance no. Circuit diagram operating instructions spare parts list hds 7/12-4 m 1.077-410.0 0.089-021 5.964-883.0 5.972-064.0 hds 7/12-4 mx 1.077-450.0 0.089-021 5.964-883.0 5.972-064.0 hds 8/18-4 m 1.077-609.0 0.0...

Page 121

English 5.906-432.0 rev. 00 (06/15) 121 11 special tools electric measuring appliance 6.803-022.0 shut-off valve with thermometer 2.901-030.0 removal pliers, pressure/suction valves and water sieves 4.901-062.0 installation mandrel oil seal, high-pressure seal piston diameter 18mm 5.901-062.0 instal...

Page 122

122 english 5.906-432.0 rev. 00 (06/15) soot pump soot filter paper soot pattern scale thermometer hardness indicator a indicator paper obtain recommended measuring devices, testo 320 or testo 320-2-ll - measuring device co2, directly from the supplier. Note additionally required for both measuring ...

Page 123

English 5.906-432.0 rev. 00 (06/15) 123 mounting screws for piston guide (m8 x 75) 7.304-403.0 mounting screws for piston guide (m6 x 110) 7.304-467.0

Page 124

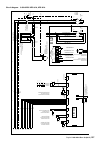

124 english 5.906-432.0 rev. 00 (06/15) note please observe the most current circuit diagrams in disis. 12 circuit diagram circuit diagram 0.089-021.0 hds 7/12.

Page 125

English 5.906-432.0 rev. 00 (06/15) 125 circuit diagram 0.089-021.0 hds 7/12.

Page 126

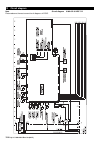

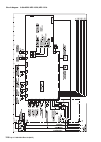

126 english 5.906-432.0 rev. 00 (06/15) circuit diagram 0.089-025.0 hds 8/18, hds 9/18.

Page 127

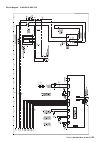

English 5.906-432.0 rev. 00 (06/15) 127 circuit diagram 0.089-025.0 hds 8/18, hds 9/18 1 23456789 10 11 12 13 l1/1.2 l2/1.2 l3/1.2 pe/1.2 1/1.13 2/1.13 4/1.13 3/1.13 5/1.13 6/1.13 7/1.13 8/1.13 +ext -on druckschalter ein pressure switch on pressosta tmarche p +ext -off druckschalter aus pressure swi...

Page 128

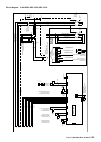

128 english 5.906-432.0 rev. 00 (06/15) circuit diagram 0.088-952.0 hds 10/20, hds 12/18.

Page 129

English 5.906-432.0 rev. 00 (06/15) 129 circuit diagram 0.088-952.0 hds 10/20, hds 12/18 1 23456789 10 11 12 13 l1/1.2 l2/1.2 l3/1.2 pe/1.2 1/1.13 2/1.13 4/1.13 3/1.13 5/1.13 6/1.13 7/1.13 8/1.13 +ext -on druckschalter ein pressure switch on pressosta tmarche p +ext -off druckschalter aus pressure s...

Page 130

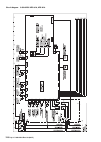

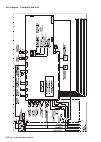

130 english 5.906-432.0 rev. 00 (06/15) circuit diagram 0.089-9026.0 hds 13/20

Page 131

English 5.906-432.0 rev. 00 (06/15) 131 circuit diagram 0.089-9026.0 hds 13/20 1 23456789 10 11 12 13 l1/1.2 l2/1.2 l3/1.2 pe/1.2 1/1.13 2/1.13 4/1.13 3/1.13 5/1.13 6/1.13 7/1.13 8/1.13 +ext -on druckschalter ein pressure switch on pressosta tmarche p +ext -off druckschalter aus pressure switch off ...