- DL manuals

- Karcher

- Pressure Washer

- HDS 2.6/30 P Cage / SGP-303037

- Operator's Manual

Karcher HDS 2.6/30 P Cage / SGP-303037 Operator's Manual

®

Model

order #

Model

HdS 2.5/20 P Cage

1.575-554.0

SGP-302017

HdS 2.8/25 P Cage

1.575-555.0

SGP-302517

HdS 2.6/30 P Cage

1.575-550.0

SGP-303037

HdS 3.5/30 P Cage

1.575-551.0

SGP-353037

HdS 3.5/30 Pe Cage

1.575-552.0

SGP-353037e

HdS 3.5/35 Pe Cage

1.575-553.0

SGP-403537e

oPerATor’S MANUAl

To locate your local Kärcher Commercial Pressure Washer Dealer nearest you,

visit www.karchercommercial.us

9.800-079.0

Summary of HDS 2.6/30 P Cage / SGP-303037

Page 1

® model order # model hds 2.5/20 p cage 1.575-554.0 sgp-302017 hds 2.8/25 p cage 1.575-555.0 sgp-302517 hds 2.6/30 p cage 1.575-550.0 sgp-303037 hds 3.5/30 p cage 1.575-551.0 sgp-353037 hds 3.5/30 pe cage 1.575-552.0 sgp-353037e hds 3.5/35 pe cage 1.575-553.0 sgp-403537e operator’s manual to locate ...

Page 2: Contents

Contents model number ______________________________ serial number ______________________________ date of purchase ____________________________ the model and serial numbers will be found on a decal attached to the pressure washer. You should record both serial number and date of purchase and keep in...

Page 3: Important Safety

9.800-079.0 • rev. 4/08 3 pressure w asher opera t or’s manu al introduction & important safety information thank you for purchasing this pressure washer. We reserve the right to make changes at any time without incurring any obligation. Owner/user responsibility: the owner and/or user must have an ...

Page 4

9.800-079.0 • rev. 4/08 opera t or’s manu al pressure w asher 4 15. Be certain all quick coupler fittings are secured before using pressure washer. Risk of injection or severe injury to persons. Keep clear of nozzle. Warning warning: high pressure devel- oped by these machines will cause personal in...

Page 5

9.800-079.0 • rev. 4/08 5 pressure w asher opera t or’s manu al important safety information 3. Machines with shut-off spray gun should not be operated with the spray gun in the off position for extensive periods of time as this may cause dam- age to the pump. 4. Protect discharge hose from vehicle ...

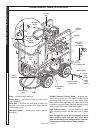

Page 6: Component Identification

9.800-079.0 • rev. 4/08 opera t or’s manu al pressure w asher 6 component identification pressure switch brass soap nozzle nozzle quick coupler spray gun high pressure hose detergent injector quick coupler collar discharge nipple water supply hose (not included) gasoline tank wand coupler variable p...

Page 7: Assembly Instructions

9.800-079.0 • rev. 4/08 7 pressure w asher opera t or’s manu al assembly instructions step 1: attach the high pressure hose to the spray gun using teflon tape on hose threads. Step 3: release the coupler collar and push the nozzle until the collar clicks. Pull the nozzle to make sure it is seated pr...

Page 8: Operating Instructions

9.800-079.0 • rev. 4/08 opera t or’s manu al pressure w asher 8 operating instructions step 1: check engine oil level. Oil level should be level with the bottom of the oil filler neck. Be sure the machine is level when checking the oil level. (refer to the engine's operating manual included with mac...

Page 9: Operating Instructions

9.800-079.0 • rev. 4/08 9 pressure w asher opera t or’s manu al safety latch operating instructions step 7: turn the engine to "run" position. Step 8: pull the starter grip. If the engine fails to start after pulls, squeeze the trigger gun to release pressure and repeat step. Return starter gently. ...

Page 10: Thermal Pump Protection

9.800-079.0 • rev. 4/08 opera t or’s manu al pressure w asher 10 warning: some detergents may be harmful if inhaled or in- gested, causing severe nausea, fainting or poisoning. The harm- ful elements may cause property damage or severe injury. Step 1: connect detergent in- jector to discharge nipple...

Page 11: Storage

9.800-079.0 • rev. 4/08 11 pressure w asher opera t or’s manu al shutting down and clean-up caution: always store your pressure washer in a location where the temperature will not fall below 32°f (0°c). The pump in this machine is susceptible to permanent damage if frozen. Freeze damage is not cover...

Page 12: Preventative Maintenance

9.800-079.0 • rev. 4/08 opera t or’s manu al pressure w asher 1 preventative maintenance 1. Check to see that the water pump is properly lubri- cated. . Follow winterizing procedures to prevent freeze damage to the pump and coils. 3. Always neutralize and flush detergent from system after use. 4. If...

Page 13: Maintenance

9.800-079.0 • rev. 4/08 13 pressure w asher opera t or’s manu al rupture disk: if pressure from pump or thermal expansion should exceed safe limits, the rupture disk will burst allow- ing high pressure to be discharged through hose to ground. When disk ruptures it will need to be replaced. The repla...

Page 14: Maintenance

9.800-079.0 • rev. 4/08 opera t or’s manu al pressure w asher 14 fuel pressure adjustment: to adjust fuel pressure, turn the adjusting screw clock- wise to increase, counterclockwise to decrease. Do not exceed 00 psi. Note: when changing the fuel pump, a bypass plug must be installed in the return p...

Page 15: Troubleshooting

9.800-079.0 • rev. 4/08 15 pressure w asher t roub leshooting guide troubleshooting problem possible cause solution low operating pressure water supply is insufficient use larger supply hose; clean filter at water inlet. Spray nozzle is old, worn or incorrect match the nozzle number to the machine a...

Page 16: Troubleshooting

9.800-079.0 • rev. 4/08 pressure w asher t roub leshooting guide 16 troubleshooting problem possible cause solution burner will not light (continued from previous page) burner nozzle is clogged clean as required. Thermostat has malfunctioned test and replace if needed. Fuel solenoid has malfunctione...

Page 17: Troubleshooting

9.800-079.0 • rev. 4/08 17 pressure w asher t roub leshooting guide troubleshooting problem possible cause solution detergent not drawing air is leaking tighten all clamps. Check detergent lines for holes. Injector head may be blocked, dirty or damaged clean and make sure ball and spring behind dete...

Page 18: Oil Change Record

9.800-079.0 • rev. 4/08 pressure w asher t roub leshooting guide 18 preventative maintenance this pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regu...

Page 19: Hose & Spray Gun Assembly

9.800-079.0 • rev. 4/08 opera t or’s manu al pressure w asher 30 hose & spray gun assembly 3 2 1 8 6 5 4 7 item part no. Description qty 1 9.80-166.0 coupler, 3/8" female 1 9.80-100.0 quick coupler o-ring lg 1 8.739-15.0 hose, 3/8" x 50', 1 wire tuff flex (all models except 553.0) 1 8.739-03.0 hose,...

Page 20

9.800-079.0 • rev. 4/08 31 pressure w asher opera t or’s manu al downstream injector assembly item part no. Description qty 1 9.80-16.0 injector, detergent, non-adjusting #3 1 9.80-15.0 injector, detergent, non-adjusting # 1 9.80-10.0 clamp, hose, uni .46 - .54 3 9.80-51.0 tube, 1/4" x 1/", clear vi...

Page 21: Hose Reel Option

9.800-079.0 • rev. 4/08 opera t or’s manu al pressure w asher 3 hose reel option hose reel parts list item part no. Description qty 1 9.80-166.0 coupler, 3/8", female, brass 1 9.80-44.0 hose, 3/8", wire pressure loop 1 3 9.80-69.0 hose reel, 100' non-pivot e-zee w/pin lock 1 4 9.80-767.0 screw, 3/" ...

Page 22

9.800-079.0 • rev. 4/08 pressure w asher w arranty what this warranty covers all kärcher commercial pressure washers are warranted by kärcher to the original purchaser to be free from defects in materials and workmanship under normal use, for the periods specified below. This limited warranty, subje...