Warning: this product can expose you to chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. For more information about this regulation: www.P65warnings.Ca.Gov 9.800-080.0-ac 09/25/17 hds series hot water - gas powered - diesel heated operator’s ma...

2 karcher hds 600-606 operator’s manual 9.800-080.0-ac machine data label.

3 table of contents machine data label . . . . . . . . . . . . . . . . . . . . . . . . . . 2 table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 how to use this manual . . . . . . . . . . . . . . . . . . . . . 4 safety introduction & safety information . . . . . . . . . . . . ....

4 how to use this manual this manual contains the following sections: • how to use this manual • safety • operations • maintenance • parts list the how to use this manual section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized d...

5 safety introduction & safety information thank you for purchasing this pressure washer. We reserve the right to make changes at any time without incurring any obligation. Owner/user responsibility: the owner and/or user must have an understanding of the manufacturer’s operating instructions and wa...

6 safety important safety information warning: to reduce the risk of injury, read operating instructions carefully before using. Avertissement: pour réduire le risque de blessures, lire attentive- ment les instructions de fonctionnement avant l'utilisation. 1. Read the owner's manual thor- oughly. F...

7 safety b. With the engine on the equipment stopped; c. With no source of ignition within 10 feet of the dispensing point; and d. With an allowance made for expansion of the fuel should the equipment be exposed to a higher ambient temperature. In an overfilling situation, additional precautions are...

8 safety warning: protect machine from freezing. Avertissement: protéger la machine contre le gel. 1. To keep machine in best operating conditions, it is important you protect machine from freezing. Failure to protect machine from freezing could cause malfunction of the machine and result in death, ...

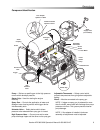

9 operations component identification pump — delivers a specific gpm to the high pressure nozzle which develops pressure. Starter grip — used for starting the engine manually. Spray gun — controls the application of water and detergent onto cleaning surface with trigger device. Includes safety latch...

10 operations assembly instructions step 1: attach wand and hose to the spray gun using teflon tape on threads to prevent leakage. Caution: never replace nozzles without engaging the safety latch on the spray gun trigger. Attention: ne jamais remplacer les buses sans d'abord mettre le dispositif de ...

11 operations battery installation due to federal regulations concerning shipment of corrosive chemicals, batteries are not shipped with this machine. Local purchase of battery will be the responsibility of the owner. Automotive type 12 volt group 24 battery is recom- mended for placement within the...

12 operations operating instructions step 3: connect garden hose to the cold water source and turn water on completely. Never use hot water. Step 2: fill gas tank with unleaded gasoline. Do not use leaded gasoline. Step 4: before installing pressure nozzle, trigger spray gun to eliminate trapped pre...

13 step 9: turn the burner switch “on”. Turn thermostat dial to the 210° mark. Step 10: (pump steam option) a. Operate machine as instructed. B. Open steam valve counterclock- wise, which will lower pressure. C. Turn thermostat knob to 250°f. D. When steam is no longer desired, turn steam valve cloc...

14 operations detergents & general cleaning techniques warning: some detergents may be harmful if inhaled or ingested, causing severe nausea, fainting or poisoning. The harmful elements may cause property damage or severe injury. Avertissement: certains détergents peuvent être dangereux s'ils sont i...

15 operations shutting down and clean up step 1: remove detergent suction tube from container and insert into one gallon of fresh water. Open detergent metering valve. Pull trigger on spray gun and siphon water for one minute. Close detergent valve. Step 4: press trigger to release water pressure st...

16 maintenance storage caution: always store your pressure washer in a location where the temperature will not fall below 32°f (0°c). The pump in this machine is susceptible to permanent damage if frozen. Freeze damage is not covered by warranty. Attention: toujours entreposer la laveuse à pression ...

17 maintenance it is advisable, periodically, to visually inspect the burner. Check air inlet to make sure it is not clogged or blocked. Wipe off any oil spills and keep equipment clean and dry. The flow of combustion and ventilating air to the burner must not be blocked or obstructed in any manner....

18 maintenance fuel use clean fuel oil that is not contaminated with water and debris. Replace fuel filter and drain tank every 100 hours of operation. Use no.1 or no 2 heating oil (astm d306) only. Never use gasoline in your burner fuel tank. Gasoline is more combustible than fuel oil and could res...

19 maintenance burner air adjustment caution: if white smoke appears from burner exhaust vent during start-up or operation, discon- tinue use and readjust air bands. Attention: si de la fumée blanche s'échappe de l'évacuation du brûleur pendant le démarrage ou le fonctionnement, cesser d'utiliser et...

20 maintenance preventive maintenance this pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative main- tenance procedures will assist i...

21 maintenance oil change record pump oil date oil changed month/day/year estimated operating hours since last oil change engine oil date oil changed month/day/year estimated operating hours since last oil change karcher hds 600-606 operator’s manual 9.800-080.0-ac.

22 maintenance troubleshooting problem possible cause solution low operating pressure faulty pressure gauge install new gauge. Insufficient water supply use larger supply hose; clean filter at water inlet. Old, worn or incorrect spray nozzle match nozzle number to machine and/or replace with new noz...

23 maintenance problem possible cause solution burner will not light (continued from previous page) flex coupling slipping on fuel pump shaft or burner motor shaft replace if needed. On-off switch defective check for electrical current reaching burner assembly with burner switch on. Heavy sooting on...

24 maintenance problem possible cause solution low water temperature improper fuel or water in fuel replace with clean and proper fuel. Low fuel pressure increase fuel pressure. Weak fuel pump check fuel pump pressure. Replace pump if needed. Fuel filter partially clogged replace as needed. Soot bui...

25 maintenance problem possible cause solution oil dripping oil seal worn check and replace if necessary. Excessive vibration in delivery line irregular functioning of the valves check and replace if necessary. Detergent not drawing air leak tighten all clamps. Check detergent lines for holes. Restr...

26 notes karcher hds 600-606 operator’s manual 9.800-080.0-ac.

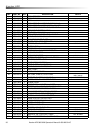

27 parts parts karcher hds hds 3.9/30 pe cage 1.575-600.0 hds 4.8/30 pe cage 1.575-601.0 hds 4.8/30 pe cage 1.575-602.0 hds 4.7/35 pe cage 1.575-603.0 hds 4.7/35 pe cage 1.575-604.0 hds 5.6/35 pe cage 1.575-605.0 hds 5.6/35 pe cage 1.575-606.0 hds 8.0/30 pe cage 1.575-611.0 hds 8.0/30 pe cage 1.575-...

28 karcher hds karcher hds 600-606 operator’s manual 9.800-080.0-ac to r ed uc e t he r isk o f inju ry , r ea d op - er ati ng in str uc tion s c are fu lly be fo re us ing . T his m ac hin e is to be us ed on ly by qu ali fi e d o pe rat ors . Lir e le m an ue l de l 'op er at eu r av an t ut ili s...

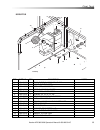

29 karcher hds 600-606 operator’s manual 9.800-080.0-ac karcher hds o t t k n a 92 46 89 90 89 55 55 56 58 57 51 55 52 59 8 2 4 3 38 40 28 44 45 15 20 21 23 106 101 122 139 139 26 140 79 16 1 7 88 88 83 34 107 25 80 112 100 to float tank to detergent valve 6 5 29 121 54 52 17 12 18 19 32 13 84 9 10 ...

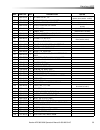

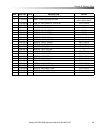

30 karcher hds ref part no. Qty description notes 1 9.803-014.0 1 coil, rodless 2 9.803-005.0 1 top wrap, ss - 9.802-071.0 2 ft. Trim not shown 3 9.802-902.0 1 insulation/blanket, die cut 28" x 24" 4 9.802-896.0 1 insulation/blanket, no foil, 24" x 57" 5 9.802-883.0 1 insulation, burner head, no hol...

31 karcher hds 600-606 operator’s manual 9.800-080.0-ac karcher hds ref part no. Qty description notes 39 9.800-026.0 1 label, open for steam 40 9.802-131.0 1 elbow, 1/2" jic x 1/2" mpt 41 9.802-129.0 1 elbow, 1/2" x 3/8, 90° 42 9.802-039.0 1 elbow, 1/2" mjic x 3/8" mnpt 43 9.802-036.0 1 nipple, 1/2...

32 karcher hds ref part no. Qty description notes 55 9.802-872.0 3 tab, belt guard - - 4 ab, belt guard (w/generator) - 9.802-753.0 6 screw, hh, nc, 1/4" x 3/4" not shown - - 7 screw, hh, nc, 1/4" x 3/4" (w/generator) 56 9.802-794.0 10 cage, nut, 1/4" x 12 gauge - - 11 cage, nut, 1/4" x 12 gauge (w/...

33 karcher hds 600-606 operator’s manual 9.800-080.0-ac karcher hds ref part no. Qty description notes - 9.802-519.0 1 strain relief, 1/2" not shown (602.0, 604.0, 605.0 - w/gen) 80 8.706-955.0 2 hose barb, 90°, 1/4" x 1/8" npt 81 9.802-039.0 1 elbow, 1/2" mjic x 3/8" mnpt (601.0, 602.0) - 9.802-154...

34 karcher hds ref part no. Qty description notes 119 9.803-559.0 1 clamp,screw, 9/16"w, 1-1/4"od, ss 120 8.706-248.0 1 plug, 3/8" 121 9.802-015.0 1 nipple, 1/2" x 4", galvanized sch 80 pipe 122 8.752-114.0 1 nipple, 1/4" 123 8.706-984.0 1 adapter, 1/2" x 1/2" brass 124 8.718-781.0 1 screw, pan head...

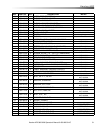

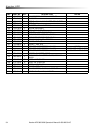

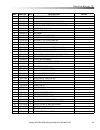

35 karcher hds 600-606 operator’s manual 9.800-080.0-ac float tank ref part no. Qty description notes 1 9.804-042.0 1 tank, float, 2-1/2 gallon, blank 2 8.749-328.0 1 valve, float plastic 3 9.802-162.0 1 strainer, 1/2" basket 4 9.802-128.0 1 nipple, 1/2" jic x 1/2" mpt 5 8.750-743.0 1 bulkhead, 1/2"...

36 control panel karcher hds 600-606 operator’s manual 9.800-080.0-ac detergent v alv e va lvu la de deter gente sou pape de detergen t to r ed uc e t he r isk o f i nju ry , r ea d op - er at ing in st ru ct ion s c ar ef ul ly be fo re us ing . T his m ac hin e is to be us ed o nly b y qu ali fi e ...

37 karcher hds 600-606 operator’s manual 9.800-080.0-ac control panel ref part no. Qty description notes 1 9.803-693.0 1 box, plastic, back 2 9.802-482.0 1 box, plastic, front, fabricated 3 8.750-094.0 1 thermostat, 302°f - 9.804-072.0 42" wire, cover, 1/4" not shown 4 9.802-700.0 4 bolt, 1/4" x 3/4...

38 hose & spray gun karcher hds 600-606 operator’s manual 9.800-080.0-ac 4 3 2 1.

39 karcher hds 600-606 operator’s manual 9.800-080.0-ac hose & spray gun ref part no. Qty description notes 1 8.739-203.0 1 hose, 3/8” x 50’, 2 wire tuff flex 2 4.775-054.0 1 easy! Force advanced kna (601.0, 602.0, 603.0, 604.0, 605.0, 606.0) - 8.710-384.0 1 gun, st-1500, 5000 psi, 10.4 gpm (611.0, ...

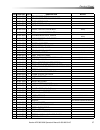

40 specifications kärcher clearfire burner model no. Burner assy no. Fuel nozzle w/ 100psi check valve igniter burner motor fuel pump solenoid coil electrode 1.575-600.0 8.918-919.0 8.754-889.0 8.919-116.0 8.751-074.0 8.754-705.0 9.802-562.0 8.751-342.0 1.575-601.0 8.918-919.0 8.754-889.0 8.919-116....

41 karcher hds 600-606 operator’s manual 9.800-080.0-ac specifications pump engine generator * with generator model pump model # part # unloader pully pully part # bushing bushing part # 1.575-600.0 kt4540 8.921-714.0 8.715-483.0 2bk100h 9.802-391.0 25mm 9.802-403.0 1.575-601.0 kt6036 8.921-716.0 8....

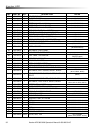

42 clearfire burner “s” karcher hds 600-606 operator’s manual 9.800-080.0-ac for best performance specify genuine kna replacement parts 8.918-919.0 28 36 36 1 1 31 36 47 30 16 15 22 33 33 40 17 14 3 27 5 5 48 45 49 29 46 39 39 7 7 8 9 2 38 32 36 4 44 6 36 36 12 11 13 3 39 39 23 21 20 18 19 10 35 34 ...

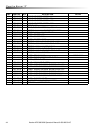

43 karcher hds 600-606 operator’s manual 9.800-080.0-ac clearfire burner “s” ref part no. Qty description notes 1 8.919-050.0 1 burner housing assembly 2 8.751-160.0 1 air guide 3 8.754-705.0 1 fuel pump, suntec ol35 12-24 v sol - 8.754-706.0 1 fuel pump, suntec ol35 120 v sol - 8.700-760.0 1 fuel p...

44 clearfire burner “s” ref part no. Qty description notes 30 8.750-817.0 2 light, indicator, green,14v - 8.750-818.0 1 light, indicator, green, 28v - 8.750-819.0 1 light, indicator, green, 125v - 8.750-820.0 1 light, indicator, green, 250v 31 8.750-784.0 1 site glass 32 8.750-785.0 1 ring, push on ...

45 karcher hds 600-606 operator’s manual 9.800-080.0-ac clearfire burner “m / l” ref part no. Qty description notes 1 8.919-865.0 1 burnerhousing assembly-ml 2 8.754-905.0 1 gasket, kna burner pump suntec 3 8.754-705.0 1 fuel pump, suntec ol35 12-24 v sol - 8.754-706.0 1 fuel pump, suntec ol35 120 v...

46 clearfire burner “m / l” ref part no. Qty description notes 6 8.752-919.0 1 air band m/l 7 8.752-933.0 1 motor, 1/5 hp 13.5vdc ametek n1cpm-156 - 8.752-932.0 1 motor, 1/7 hp 115v emerson k41 - 8.753-054.0 1 motor, 1/7 hp 230v emerson k41 8 8.753-061.0 1 coupling, flex, 1/2" x 5/16" x 3-7/8" l - 8...

47 karcher hds 600-606 operator’s manual 9.800-080.0-ac clearfire burner “m / l” ref part no. Qty description notes 32 8.750-785.0 1 ring, push on internal 33 8.733-001.0 2 screw 8 x 1/4” hi low thread cut 34 8.718-762.0 2 screw, 8-32 x 1/2”, mph rdh pl medium - - 4 screw, 8-32 x 1/2”, mph rdh pl la...

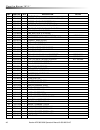

48 kt.2 series pump ref part no. Qty description notes 1 8.752-825.0 1 crankcase 2* - 3 plunger oil seal see kits table 3* - 3 o-ring Ø1.78 x 37.82 see kits table 4* - 3 pressure ring, 18mm see kits table 5* - 3 u-seal, 18mm see kits table 6* - 3 intermediate ring, 18mm see kits table 7* - 3 u-seal,...

49 karcher hds 600-606 operator’s manual 9.800-080.0-ac kt.2 series pump ref part no. Qty description notes 21* - 6 valve spring see kits table 22* - 6 valve cage see kits table 23 8.752-830.0 8 hex screw 24 9.802-884.0 8 washer 25 9.803-182.0 1 closed bearing housing 26 9.803-186.0 2 o-ring Ø2.62 x...

50 vrt3 unloader ref part no. Qty description notes 25 8.750-713.0 1 outlet fitting 18 8.750-712.0 1 knob, unloader - 8.750-709.0 - repair kit, vrt3, 2320/3630 psi - 8.750-710.0 - repair kit, vrt3, 4500 psi - - - (kit items: 3, 4, 6, 9-12, 21, 24) karcher hds 600-606 operator’s manual 9.800-080.0-ac...

51 karcher hds 600-606 operator’s manual 9.800-080.0-ac vrt3 unloader unloader adjustment procedures 1. Remove lock nut (item 19). 2. Remove adjustment knob (item 18). 3. Loosen the two (2) nuts (item 15), move them upward on stem (item 8) until you see 4 or more threads below the nut. 4. Re-attach ...

9 . 8 00-0 8 0.0 • printed in u.S.A..