- DL manuals

- Karcher

- Pressure Washer

- HDS 4.0/32 Pe Cage

- Operator's Manual

Karcher HDS 4.0/32 Pe Cage Operator's Manual

Summary of HDS 4.0/32 Pe Cage

Page 1

9.800-103.0 hds 4.0/32 pe cage - 1.575-615.0 hds 5.0/32 pe cage - 1.575-616.0 hds 5.5/35 pe cage - 1.575-617.0 operator’s manual to locate your local kärcher commercial pressure washer dealer nearest you, please visit www.Karchercommercial.Us.

Page 3: Contents

3 contents model number ______________________________ serial number ______________________________ date of purchase ___________________________ the model and serial numbers will be found on a decal attached to the pressure washer. You should record both serial number and date of purchase and keep i...

Page 4: Important Safety

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 4 introduction & important safety information thank you for purchasing our pressure washer. This manual covers the operation and maintenance of your pressure washer. All information in this manual is based on the latest product information...

Page 5: Pre-Operation Check

9.800-103.0 • rev. 1/07 5 pressure w asher opera tor’s manu al important safety information 8. High pressure developed by these machines will cause personal injury or equipment damage. Use caution when operating. Do not direct discharge stream at people, or severe injury or death will result. Warnin...

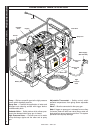

Page 6: Component Identification

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 6 component identification pump — delivers a specific gpm to the high pressure nozzle which develops pressure. Spray gun — controls the application of water and detergent onto cleaning surface with trigger device. Includes safety latch. Un...

Page 7: Assembly Instructions

9.800-103.0 • rev. 1/07 7 pressure w asher opera tor’s manu al assembly instructions step 1: attach the high pressure hose to the spray gun using teflon tape on hose threads. Step 2: remove wand end and first place the o-ring followed by the high pressure nozzle as shown. Replace end of wand. Step 3...

Page 8: Operation Instructions

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 8 step 6: pull the starter grip. If the engine fails to start after 2 pulls, squeeze the trigger gun to release pressure and repeat step. Return starter gently. After the engine warms up enough to run smoothly, move choke to run position a...

Page 9: Operation Instructions

9.800-103.0 • rev. 1/07 9 pressure w asher opera tor’s manu al operation instructions warning! Never replace nozzle without engaging the safety latch on the spray gun trigger. Safety latch step 9: turn the burner “on”. Turn thermostat dial to the 210° mark. Burner control step 7: (electric start mod...

Page 10: Thermal Pump

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 10 warning: some detergents may be harmful if inhaled or ingested, causing severe nau- sea, fainting or poisoning. The harmful elements may cause property damage or severe injury. Step 1: use detergent designed specifically for pressure wa...

Page 11: Storage

9.800-103.0 • rev. 1/07 11 pressure w asher opera tor’s manu al shutting down and clean-up storage caution: always store your pressure washer in a location where the temperature will not fall below 32°f (0°c). The pump in this machine is susceptible to permanent damage if frozen. Freeze damage is no...

Page 12: Maintenance

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 12 maintenance preventative maintenance 1. Check to see that water pump is properly lubri- cated. 2. Follow winterizing instructions to prevent freeze damage to pump and coils. 3. Always neutralize and flush detergent from system after use...

Page 13: Maintenance & Service

9.800-103.0 • rev. 1/07 13 pressure w asher opera tor’s manu al maintenance & service rupture disk: if pressure from pump or thermal expansion should exceed safe limits, the rupture disk will burst allowing high pressure to be discharged through hose to ground. When disk ruptures it will need to be ...

Page 14: Troubleshooting

9.800-103.0 • rev. 1/07 pressure w asher tr oub leshooting guide 14 troubleshooting problem possible cause solution low operating pressure faulty pressure gauge install new gauge. Insufficient water supply use larger supply hose; clean filter at water inlet. Old, worn or incorrect spray nozzle match...

Page 15: Troubleshooting

9.800-103.0 • rev. 1/07 15 pressure w asher tr oub leshooting guide troubleshooting problem possible cause solution burner will not light (continued from previous page) flex coupling slipping on fuel pump shaft or burner motor shaft replace if needed. On-off switch defective check for electrical cur...

Page 16: Troubleshooting

9.800-103.0 • rev. 1/07 pressure w asher tr oub leshooting guide 16 troubleshooting problem possible cause solution low water temperature improper fuel or water in fuel replace with clean and proper fuel. Low fuel pressure increase fuel pressure. Weak fuel pump check fuel pump pressure. Replace pump...

Page 17: Troubleshooting

9.800-103.0 • rev. 1/07 17 pressure w asher tr oub leshooting guide troubleshooting problem possible cause solution oil dripping oil seal worn check and replace if necessary. Excessive vibration in delivery line irregular functioning of the valves check and replace if necessary. Detergent not drawin...

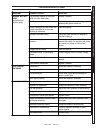

Page 18: Preventative Maintenance

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 18 date oil changed month/day/year no. Of operating hours since last oil change brand name and type of oil (see above) this pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner...

Page 19: Preventative Maintenance

9.800-103.0 • rev. 1/07 19 pressure w asher opera tor’s manu al maintenance operation every 8 hrs or daily 25 hrs or weekly 50 hrs or monthly 100 hrs or yearly yearly check oil pump x engine x change oil pump x engine x air cleaner check clean spark plug x check valve clearance x fuel tank filter x ...

Page 20: Exploded View - Left Side

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 20 exploded view - left side see control box illus. For detail 96 74 73 72 77 71 79 78 80 70 48 81 69 82 57 58 50 49 52 54 51 52 55 66 65 64 56 60 62 63 61 59 83 84 to coil inlet to coil outlet 102 47 45 67 76 89 18 68 93 95 94 2 see burne...

Page 21

9.800-103.0 • rev. 1/07 21 pressure w asher opera tor’s manu al ch au d! Ex po sed pu lle ys an d be lts ca n c au se inj ur y pr ec au cio n/a ve rt iss em en t wa rn ing van guard 16 hp v-twin van gua rd exp osed pu lley s a nd bel ts ca n c ause injur y pr ec au cio n/a ve rt iss em en t wa rn in...

Page 22: Exploded View Parts List

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 22 exploded view parts list item part no. Description qty 1 9.802-779.0 nut, 3/8" esna, nc 8 2 9.802-807.0 washer, 3/8” sae, flat 11 3 engine, please see specification pages 4 9.802-727.0 bolt, 3/8" x 1-3/4", tap 4 5 9.802-781.0 nut 1 6 9....

Page 23: Exploded View Parts List

9.800-103.0 • rev. 1/07 23 pressure w asher opera tor’s manu al exploded view parts list item part no. Description qty 46 9.802-261.0 hose, 3/4" push-on 14” 47 9.803-559.0 clamp, screw, #12 2 48 9.803-518.0 cage, hds weld assembly 1 49 9.803-677.0 base, coil mount 1 50 9.802-767.0 screw, 3/8" x 3/4"...

Page 24: Exploded View Parts List

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 24 item part no. Description qty 89 9.802-512.0 cable, tie, 45" 4 90 9.802-053.0 bushing, rubber, nitrite 3 91 9.803-531.0 elbow, 1/4" h x std pipe, 90° 2 92 9.802-054.0 elbow, fuel tank, zinc 1 93 9.803-541.0 screw, 5/16-18 x 1/2" cs soc ...

Page 25: Float Tank Assembly

9.800-103.0 • rev. 1/07 25 pressure w asher opera tor’s manu al float tank assembly float tank parts list item part no. Description qty 1 3.593-054.0 float tank w/valve 1 2 4.070-094.0 tank, scale inhibtor 1 3 4.730-071.0 filter, water, complete 1 4 5.063-226.0 lid, scale inhibitor tank 1 5 5.310-06...

Page 26: Control Box

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 26 control box control box parts list item part no. Description qty 1 9.803-512.0 box, electrical 1 2 9.803-513.0 cover, electrical box 1 3 9.803-514.0 control panel 1 4 9.800-138.0 label, control panel 1 5 9.802-251.0 tube, 1/4” id x 1/2”...

Page 27: Control Box Parts List

9.800-103.0 • rev. 1/07 27 pressure w asher opera tor’s manu al item part no. Description qty 13 9.803-606.0 spacer, nylon 2 14 9.803-607.0 spacer, phenolic, #10 x 5/16" x 3/4" 4 15 9.800-094.0 label, warning 1 16 4.580-231.0 valve, chemical 1 17 5.321-379.0 knob, metering valve 1 18 5.337-021.0 spr...

Page 28: Pump Assembly

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 28 pump assembly pump assembly parts list item part no. Description qty 1 9.802-039.0 elbow, 1/2" jic x 3/8", 90° pipe 1 2 9.803-555.0 elbow, 3/4" street 1 3 9-802-122.0 tee, 1/2" street 1 4 9.802-127.0 nipple, 1/2" jic x 1/2" mpt pipe 1 5...

Page 29: Unloader Assembly

9.800-103.0 • rev. 1/07 29 pressure w asher opera tor’s manu al unloader assembly unloader parts list item part no. Description qty 1 9.803-552.0 tee, 3/8” male, branch 1 2 9.802-036.0 nipple, 1/2” jic, 3/8” pipe 2 3 9.802-039.0 elbow, 1/2” jic, 3/8”, 90° 1 4 9.802-870.0 block, unloader, 3/8” x 3/8”...

Page 30: Blower Assembly

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 30 blower assembly blower parts list item part no. Description qty 1 5.063-274.0 cover 1 2 5.110-306.0 sleeve 3 3 5.112-602.0 bushing 1 4 5.178-032.0 cloth collar 1 5 5.379-011.0 ring, rubber 3 6 5.471-060.0 element, coupling 1 7 5.600-021...

Page 31: Blower Parts List

9.800-103.0 • rev. 1/07 31 pressure w asher opera tor’s manu al blower parts list item part no. Description qty 17 7.306-090.0 screw, m6 x 16 1 18 7.310-100.0 nut, km8 1 19 7.312-264.0 washer, r 5.5 3 20 7.312-278.0 washer, 5.3 1 21 7.343-231.0 clip, spring, 32 x 1.2 2 22 7.401-115.0 bearing, ball, ...

Page 32: Burner & Coil Assembly

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 32 burner & coil assembly item part no. Description qty 1 3.640-148.0 heater, flow 1 2 4.654-182.0 cover d.K. 1 3 7.311-380.0 nut, cap, m 6 4 4 7.312-167.0 washer, lock, a 6.4 4 5 2.880-177.0 ▲ electrodes, spare parts kit 1 6 9.803-624.0 ▲...

Page 33: Coil & Blower Assembly

9.800-103.0 • rev. 1/07 33 pressure w asher opera tor’s manu al coil & blower assembly item part no. Description qty 1 6.647-527.0 bracket 1 2 9.802-042.0 elbow, 1/2" jic x 3/8" female, 90° 1 3 5.423-234.0 tubing 1 4 6-389-262.0 nut, union, a 4-ll 2 5 6.389-263.0 ring, cutting, d.4 2 6 9.802-769.0 s...

Page 34: Hose & Spray Gun Assembly

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 34 hose & spray gun assembly hose & spray gun parts list 1 2 3 4 5 item part no. Description qty 1 6.389-709.0 hp hose, id8, 50', 5800 psi 1 2 4.775-466.0 gun, shut-off 1 3 9.311-034.0 lance, spray, insulated 1 4 9-7.362-501.0 o-ring, powe...

Page 35: Fuel Tanks Assembly

9.800-103.0 • rev. 1/07 35 pressure w asher opera tor’s manu al item part no. Description qty 1 9.803-534.0 tank, fuel, 11 gallon, red 1 2 9.803-533.0 tank, fuel, 11 gallon, black 1 3 9.802-053.0 bushing, rubber, nitrile (616.0, 617.0) 1 (615.0) 2 4 9.803-531.0 diptube, plastic, 10.00" long 1 5 n/a ...

Page 36: Engine Assemblies

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 36 engine assemblies 615.0 models 616.0 models 617.0 models 9 8 7 6 3 2 1 4 5 10 9 8 7 6 5 4 3 2 1 10 19 9 15 21 13 11 20 14 15 3 18 17 1 2 4 5 16 12 22 24 23 25 26 30 31 32 13 29 21 27 28 27 21 return to fuel tank 33 14 16 18 16 34 17 19 ...

Page 37

9.800-103.0 • rev. 1/07 37 pressure w asher opera tor’s manu al engine assemblies parts list item part no. Description qty 1 9.802-154.0 plug, push-on drain, honda (615.0) 1 9.802-039.0 elbow, 1/2" jic, 3/4", 90° (616.0) 1 9.802-130.0 elbow, 1/2" jic x 1/4", 90° (617.0) 1 2 9.802-200.0 clamp, screw,...

Page 38: Specifications

9.800-103.0 • rev. 1/07 pressure w asher specifications 38 part specifications engine pump specifications machine pump pulley bushing engine engine model engine pulley bushing belt belt belt belt model model part # unloader pulley part # bushing part # size part# cont. Pulley part# bushing part # si...

Page 39: Specifications

9.800-103.0 • rev. 1/07 39 pressure w asher specifications specifications machine pump pulley bushing engine engine model engine pulley bushing belt belt belt belt model model part # unloader pulley part # bushing part # size part# cont. Pulley part# bushing part # size part # size part # 1.575-615....

Page 40

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 40 item part no. Description qty 1 9.804-604.0 crankcase 1 2 9.803-195.0 plunger guide 3 3 * see kit below plunger oil seal 3 4 * 9.803-190.0 o-ring Ø1.78 x 31, 47 3 5 * see kit below "v" seal, plunger 6 see kit below "v" seal plunger 6 6 ...

Page 41

9.800-103.0 • rev. 1/07 41 pressure w asher opera tor’s manu al item part no. Description qty 33 9.803-177.0 shim 2 34 9.803-181.0 bearing housing 1 35 * 9.803-235.0 plunger bolt 3 36 * 9.802-886.0 copper spacer 3 37 * 9.803-187.0 o-ring Ø1.78 x10.82 3 38 * 9.803-154.0 teflon ring 3 39 * see kit bel...

Page 42

9.800-103.0 • rev. 1/07 opera tor’s manu al pressure w asher 42 ar - al 607 #9.802-367.0 7-8 gpm, 4200 psi item part no. Description qty 1 83-005150010 check connector 1 2 83-005060108 ‡ o-ring 2068 3 3 83-005100002 shutter spring 1 4 83-004120000 shutter 1 5 83-004060109 ‡ o-ring 631290 sh 1 6 83-0...

Page 43

9.800-103.0 • rev. 1/07 pressure w asher w arranty what this warranty covers all kärcher commercial pressure washers are warranted by kärcher to the original purchaser to be free from defects in materials and workmanship under normal use, for the periods specified below. This limited warranty, subje...

Page 44

Form #9.800-103.0 • revised 1/07 • printed in u.S.A..