- DL manuals

- Karcher

- Floor Machine

- ICC 1 S D

- Service Manual

Karcher ICC 1 S D Service Manual

Summary of ICC 1 S D

Page 1

Icc 1 s d 1.142-... Service manual 5.905-432 03.01.

Page 2

2 foreword icc 1 s d foreword good servicing requires extensive and relevant training as well as comprehensible refer- ence documents. We therefore regularly offer all service technician both basic and advanced training courses for the full range of our products. In addition we produce service handb...

Page 3: Table of Contents

3 icc 1 s d table of contents table of contents unit functions ................................................................................... 5 - 24 technical features .................................................................................................... 5 equipment features ........

Page 4

4 table of contents icc 1 s d hydraulic system ............................................................................................. 45 - 52 hydraulic fluid ................................................................................................................ ..... 45 hydraulic flu...

Page 5

5 icc 1 s d unit functions technical features the icc 1 s d is a high-performance sweeping machine designed for professional use in indus- trial service and municipal fleet applications. The unit may be licensed for road traffic. Depending on the country of operation, single- unit approval by the re...

Page 6

6 unit functions icc 1 s d equipment features – front view 10 9 8 7 6 5 4 3 2 1 11 1 cover, debris container 2 debris container 3 dual-circuit radiator (hydraulic fluid / engine coolant) 4 operator seat 5 support caster, vacuum intake 6 side brush, lh 7 bumper 8 turn signals 9 side brush, rh 10 head...

Page 7

7 icc 1 s d unit functions equipment features – sidebrush view 1 pressurized gas spring, side brush 2 stop screw, side brush bottom position 3 adjusting screws, side brush sweeping pattern 4 hydraulic motor, lf side brush 5 lh side brush 6 rh side brush 7 bumper.

Page 8

8 unit functions icc 1 s d equipment features – rear view 1 safety beacon 2 filler neck, fuel tank 3 rh side brush 4 side cover panel 5 rear cover panel 6 water tank 7 filler neck, water tank 1 2 3 4 5 6 7.

Page 9

9 icc 1 s d unit functions equipment features – raised debris container view 1 debris container 2 air exhaust 3 debris container cover 4 water tank 5 rear cover panel 1 2 3 4 5 6 7 8 6 removable grille, dual-circuit radiator (hydraulic fluid / engine coolant) 7 lh side brush 8 vacuum channel.

Page 10

10 unit functions icc 1 s d equipment features – control elements 1 switch, four-way flashers (s12) 2 combination instrument (p1) 3 steering wheel 4 ignition switch (s1) 5 combination switch (s13) 6 switch (s16), working spotlights (option) 7 switch, windshield wiper (s6) 8 switch, cabin heater fan ...

Page 11

11 icc 1 s d unit functions equipment features – combination instrument indicator lights and displays 1 debris container raised 2 pre-glow cycle activated 3 excessive engine coolant temperature 4 spare 5 low charging current warning 6 low engine oil pressure warning 7 blocked air cleaner warning 8 h...

Page 12

12 unit functions icc 1 s d equipment features – fuse box fuses f1 ignition switch f2 four-way flashers f3 impeller fan brake f4 magnetic clutch f5 water pump f6 fan, cabin heater f7 windshield wiper f8 turn signals / horn f9 headlamps f10 position lamps, rh f11 position lamps, lh f12 engine stop so...

Page 13

13 icc 1 s d unit functions equipment features – control console, open view d2 control module, engine shut-off solenoid s14 switch, safety beacon s15 switch, windshield defroster fan s7 switch, cabin heater fan s6 switch, windshield wiper s16 switch, working spotlights (option) s13 combination switc...

Page 14

14 unit functions icc 1 s d equipment features – side console, open view 1 mounting thread for lever, raise / lower debris container 2 mounting thread for lever, raise / lower side brush and vacuum intake 3 pressure relief valve 4 bowden cable, coarse debris flap 5 hydraulic line, lower debris conta...

Page 15

15 icc 1 s d unit functions equipment features – engine compartment, view from left 1 magnetic clutch, vacuum impeller fan 2 filler neck, engine oil 3 glow plug 4 injector nozzle 5 injection pump 6 oil dip stick 7 air intake hose 8 fuel filter 9 engine 10 tension roller, v-belt 11 v-belt 12 magnetic...

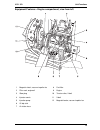

Page 16

16 unit functions icc 1 s d equipment features – engine compartment, view from right 1 oil dip stick 2 coolant radiator electric fan 3 adjustment screw, v-belt tension 4 magnetic brake, vacuum impeller fan 5 exhaust manifold 6 starter 7 oil filler neck 8 alternator.

Page 17

17 icc 1 s d unit functions equipment features – engine compartment, view toward rear 1 rh limit switch, debris container (s10) 2 lh limit switch, debris container (s11) 3 air cleaner 4 engine cover 5 lh stop screw, debris container 6 rh stop screw, debris container.

Page 18

18 unit functions icc 1 s d equipment features – fuel tank 1 fuel level sensor 2 fuel filler neck 3 fuel tank 1 2 3.

Page 19

19 icc 1 s d unit functions equipment features – heater 1 hot water supply hose 2 heat exchanger 3 warm water return hose 4 heater fan shroud.

Page 20

20 unit functions icc 1 s d equipment features – engine compartment, view from rear.

Page 21

21 icc 1 s d unit functions equipment features – engine compartment, view from rear 1 relay, radiator fan (k9) 2 control module, pre-glow (d1) 3 fuse, radiator fan (f18) 4 fuse, glow plugs (f17) 5 splash water guard 6 hydraulic line, to hydraulic motor, rr wheel 7 battery 8 hydraulic line, to steeri...

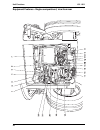

Page 22

22 unit functions icc 1 s d 1 grille plate, deflection plate 2 air exhaust 3 chain curtain 4 deflection plate 5 cover 6 debris container 7 fresh water tank 8 engine 9 impeller fan function groups – sweeping & vacuum system 10 vacuum duct 11 support casters 12 vacuum inlet 13 side brush 14 spray nozz...

Page 23

23 icc 1 s d unit functions function groups – water system 1 water tank 2 shut-off valve 3 water filter 4 water pump 5 non-return valve * 6 metering valve, vacuum channel 7 spray nozzle, vacuum channel 8 spray nozzle (2x), side brushes 9 metering valve, side brushes 10 tank fill level indicator in o...

Page 24

24 unit functions icc 1 s d 1 shut-off valve 2 water filter 3 water pump 4 solenoid valve, water pump function groups – water system.

Page 25

25 icc 1 s d basic settings and service procedures engine – fuel cleaning fuel filter – close fuel shut-off valve (1) by turning counter-clockwise one-quarter turn. – loosen and unscrew knurled retaining ring (2), and remove fuel filter bowl (3) complete with contents. – replace fuel filter insert (...

Page 26

26 basic settings and service procedures icc 1 s d engine – cooling checking / topping up engine coolant prior to checking coolant level, allow engine to cool. The proportion of antifreeze in the engine coolant must not exceed 50 percent. – raise the debris container. – check coolant level in expans...

Page 27

27 icc 1 s d basic settings and service procedures checking engine coolant temperature switch checking engine coolant temperature switch – start engine. – if the "engine coolant temperature" indicator light on the combination instrument illuminates also when the engine is cold, the connecting cable ...

Page 28

28 basic settings and service procedures icc 1 s d adjusting idle speed – push manual throttle lever on right-hand side panel all the way in. – adjust bowden cable (8) in such a way that throttle lever (5) contacts adjusting screw (3). Make necessary corrections on clamp bolt (6) or adjusting nut (7...

Page 29

29 icc 1 s d basic settings and service procedures engine – engine shut-off solenoid valve in the event that the solenoid valve (1) fails to shut off the fuel supply when the ignition key is set to position "0", the solenoid valve can also be actuated manually. Shut off engine: – move engine shut-of...

Page 30

30 basic settings and service procedures icc 1 s d checking / replacing air cleaner when the "air cleaner warning" indicator light in the combination instrument illuminates, the air cleaner must be cleaned or its cartridge replaced. – detach air cleaner cover (5), and clean together with air cleaner...

Page 31

31 icc 1 s d basic settings and service procedures engine – engine oil checking engine oil level – after shutting off engine, allow at least five minutes to pass before checking oil level. – oil level must be between "min" and "max" marks on oil dip stick (arrow). – if oil level is found to be below...

Page 32

32 basic settings and service procedures icc 1 s d engine – drive pump belt changing drive pump belt – loosen and remove six mounting bolts (1). – pull pumps (2) far enough toward the rear to separate coupling sleeve (3) from engine drive shaft (gap wide enough to allow drive belt to be passed throu...

Page 33

33 icc 1 s d basic settings and service procedures checking sweeping pattern the sweeping pattern should be formed like a moon-shaped sickle (approx. 120° to 150°). – raise side brushes. – drive sweeping machine onto flat and level ground that is evenly covered with dust. – lower side brushes, and a...

Page 34

34 basic settings and service procedures icc 1 s d sweeping mechanism – spray nozzles cleaning spray nozzles on side brush – loosen union nut (1), and remove nozzle. – blow out spray nozzle with pressurized air from front (2). Replace as required. – install spray nozzle (2), and tighten union nut (1...

Page 35

35 icc 1 s d basic settings and service procedures adjusting vacuum intake – lower vacuum intake. – loosen clamp bolts (3) on both sides. – loosen lock nuts (5) on both sides. – using adjustment screws (4), adjust vacuum intake in such a way that the front sealing lip (2) at the coarse dirt flap (1)...

Page 36

36 basic settings and service procedures icc 1 s d sweeping mechanism – warning buzzer, debris container adjusting warning buzzer switch – pull knobs off control levers (2, 3). – remove panel mounting screws (4). – detach bowden cable at injection pump (see page 28). – lift cover panel (5). – unscre...

Page 37

37 icc 1 s d basic settings and service procedures sweeping mechanism – debris container removing debris container – raise debris container until level, and shut off engine. – attach rope slings to crane hook and debris container as shown. – carefully raise crane hook until rope is taut. – remove re...

Page 38

38 basic settings and service procedures icc 1 s d running gear – grease fittings lubricating steering knuckles – lubricate grease fittings on both steering knuckles (arrow) on front axle with 3-5 shots from grease gun. Lubricating axle mounting – lubricate grease fittings (arrow) on front axle moun...

Page 39

39 icc 1 s d basic settings and service procedures running gear – brake adjusting brakes note: parking barke and operating brake act on both front wheels via brake cables (drum brake). Braking action on rear wheels is by hydraulics only. The bowden brake cables are adjusted by means of the adjusting...

Page 40

40 basic settings and service procedures icc 1 s d running gear – brake (view from below) replacing stop light switch – remove actuating spring from eyelet (2). – pull off protective cap (3) from stop light switch. – remove electrical cable. – replace stop light switch. 1 floor panel 2 actuating spr...

Page 41

41 icc 1 s d basic settings and service procedures running gear – wheel change / steering wheel changing front wheel – secure unit to prevent rolling, and loosen wheel bolts. – place hydraulic jack under front axle near wheel to be changed, and jack up unit. – support unit with block. – change wheel...

Page 42

42 basic settings and service procedures icc 1 s d running gear – toe-in adjustment measuring front wheel toe-in adjusting toe-in – set steering wheel for straight-ahead travel. – hook measuring tape into one of the tire tread grooves. – pass measuring tape under unit and across to opposite wheel. –...

Page 43

43 icc 1 s d basic settings and service procedures running gear – shock absorber replacing shock absorber – move unit with one wheel onto loading ramp (2) of approx. 150 mm height. – turn steering wheel to the left or right. – remove upper shock absorber mounting bolt (1). – remove lower shock absor...

Page 44

44 basic settings and service procedures icc 1 s d running gear – towing and transport – attach tow rope to towing eye (arrow). – winch unit onto transport vehicle, and secure to tie-down points. Important: the unit may be towed only with bypass valve open. Towing with closed bypass valve will damag...

Page 45

45 icc 1 s d basic settings and service procedures hydraulic system – hydraulic fluid checking hydraulic fluid level the inspection glass for checking the level in the hydraulic fluid tank is located in the front left wheel well. Topping up hydraulic fluid the filler neck is located beneath the oper...

Page 46

46 basic settings and service procedures icc 1 s d hydraulic system – hydraulic fluid filter 1 2 3 – tilt up operator seat. – unscrew filler neck cover. – remove filter element (1) with protective tube (2) by pulling both out of filler neck (3). – insert new filter element (1) in protective tube (2)...

Page 47

47 icc 1 s d basic settings and service procedures hydraulic system – emergency pump (option) raise / lower debris container to carry out repairs, the emergency pump (1) can be used to raise the debris container without the need to start the engine. – to raise debris container, set the "debris conta...

Page 48

48 basic settings and service procedures icc 1 s d hydraulic system – drive pedal setting neutral on hydraulic drive pump if the unit creeps forward or backward without drive pedals being actuated, setting the neutral position on the hydraulic drive pump will be required. – loosen lock nut on cam bo...

Page 49

49 icc 1 s d basic settings and service procedures hydraulic system – checking working pressures 1 connecting union on testing setup 2 t-joint 3 connecting union on bypass line 4 bypass line 5 connecting union on bypass valve 6 bypass valve 7 testing set (special tool) 8 hydraulic drive pump checkin...

Page 50

50 basic settings and service procedures icc 1 s d hydraulic system – checking working pressures (continued) 1 pressure-side connection 2 t-joint 3 pressure line to control block, side console 4 testing set (special tool) 5 hydraulic pump, side brushes and debris container checking hydraulic pressur...

Page 51

51 icc 1 s d basic settings and service procedures hydraulic system – pressure relief valve adjusting pressure relief valve the pressure relief valve is used to adjust the working pressure for functions such as "raise / lower debris container" and raising / lowering side brushes and vacuum intake. –...

Page 52

52 basic settings and service procedures icc 1 s d hydraulic system – pumps removing hydraulic pumps the hydraulic pumps powering the working hydraulics and steering are mounted beneath the battery (3) as an extension of the engine drive shaft. – drain hydraulic fluid into clean container. – remove ...

Page 53

53 icc 1 s d basic settings and service procedures impeller fan changing impeller fan – raise front of unit approx. 200 mm or drive on inclined ramp. – raise debris container to highest position and secure. – loosen and remove bolts (5) on strut (6) attached to front axle carrier (3). – remove heate...

Page 54

54 basic settings and service procedures icc 1 s d 1 2 impeller fan (continued) changing impeller fan (continued) – deflect steering all the way to the left. – remove hydraulic lines from steering cylinder. – detach accelerator cable at side panel (see page 36). – slide out impeller fan front panel ...

Page 55

55 icc 1 s d basic settings and service procedures impeller fan adjusting magnetic brake to ensure proper functioning of the magnetic brake, the air gap (1) between brake lining (2) and drive plate must be adjusted. An adjustment will be required only if the magnetic brake has been replaced. – using...

Page 56

56 troubleshooting icc 1 s d troubleshooting problem remedy starter fails to turn engine – check / replace fuse f1 – check ground connection between engine and chassis – check battery g1 (voltage, electrolyte level & density) – check / replace ignition switch s1 – check voltage at starter relay – ch...

Page 57

57 icc 1 s d troubleshooting troubleshooting problem remedy engine cannot be shut off – check engine shutoff control module d2 – check / replace ignition switch s1 – check / replace engine shutoff solenoid valve y1 no fuel tank level indication – check / replace fuel level sensor b1 brushes fail to ...

Page 58

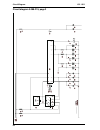

58 circuit diagram icc 1 s d circuit diagram 0.088-215, page 1 - + -g1 -m1 m b-/2.1 b+/2.1 15/2.1 -m4 m -k6 30 87a 87 -k6 85 86 1 2 -s6 -y1 x1 x2 -d2 1 2 4 3 -x1 26 -s18 -s17 -b1 -x1 4 -p1 12 1 4 3 8 7 10 6 15 2 11 5 -v1 -s4 p -s3 -s2 p -v2 -x1 5 -x1 6 -x1 7 8 k5/3.3 s5/2.1 e3/3.7 p1/1.2 -r3 -r2 -r4...

Page 59

59 icc 1 s d circuit diagram circuit diagram 0.088-215, page 1 pos designation installed location b1 level sensor fuel tank d1 module, preglow rear fuse box d2 module, engine shutoff control console f1 fuse, ignition switch front fuse box f7 fuse, windshield wiper front fuse box f12 fuse, engine shu...

Page 60

60 circuit diagram icc 1 s d circuit diagram 0.088-215, page 2.

Page 61

61 icc 1 s d circuit diagram circuit diagram 0.088-215, page 2 pos designation installed location s5 switch, folding seat cab, under seat s7 switch, heater fan control console s8 switch, water pump control console s9 switch, magnetic clutch side console s10 lh limit switch, debris container water ta...

Page 62

62 circuit diagram icc 1 s d circuit diagram 0.088-215, page 3 b+/2.13 -h1 -h2 -h3 -h4 -e3 -e4 -e5 -e6 31 -x1 20 -x1 18 -x1 19 -x1 21 -x1 15 -s12 15 30 l r 49 49a -k5 49 31 49a k5/1.9 -s13 6 9 5 3 2 1 4 7 8 -f1 1 -f10 -x1 16 e3/1.9 -e1 -b2 -x1 17 -e2 -f9 k1/2.13 -f8 -f2 -f15 -s19 -h8 -h9 l r o horn ...

Page 63

63 icc 1 s d circuit diagram circuit diagram 0.088-215, page 3 pos designation installed location k5 relay, turn signals front fuse box s12 switch, four-way flashers instrument panel s13 combination switch instrument panel s19 switch, stop lights brake pedal assy. X1 plug connector fuse box, right s...

Page 64

64 circuit diagram icc 1 s d circuit diagram – search list pos designation installed location c/d b1 level sensor, fuel fuel tank 1 b2 horn front bumper 3 d1 control module, preglow rear fuse box 1 d2 control module, engine shutoff control console 1 d3 control module, impeller fan brake side console...

Page 65

65 icc 1 s d circuit diagram circuit diagram – search list pos designation installed location c/d m1 starter engine compart. 1 m2 water pump engine compart. 2 m3 heater fan, cab cab rear wall 2 m4 windshield wiper cab 1 m5 fan, windshield defroster cab 2 m6 radiator fan engine compart. 1 r glow plug...

Page 66

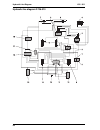

66 hydraulic block diagram icc 1 s d hydraulic block diagram 0.088-258.

Page 67

67 icc 1 s d hydraulic block diagram 1 hydraulic fluid tank 2 hydraulic fluid filter, return line 3 oil cooler 4 combustion engine 5 assembly, drive components 5.1 precharge valve 5.2 precharge pump 5.3 hydraulic pump, drive 5.4 non-return valve 5.5 control valve, low acceleration 6 bypass valve 7 h...

Page 68

68 hydraulic line diagram icc 1 s d hydraulic line diagram 2.706-010

Page 69

69 icc 1 s d hydraulic line diagram 1 hydraulic motor, lh side brush 2 steering valve 3 hydraulic motor, rh side brush 4 hydraulic cylinder, steering 5 valve block, steering 6 control block, side console 7 hydraulic pump, steering 8 hydraulic pump, side brushes and debris container 9 hydraulic cylin...

Page 70

70 specifications icc 1 s d specifications diesel engine ................................................................................... Type kubota d722 operating speed ............................................................................... Rpm 2650 – 2800 idle speed ......................

Page 71

71 icc 1 s d specifications special tools testing equipment ................................................................................... 2.639-387 tachometer ............................................................................................. 6.491-361 magnetic field tester ............