Summary of KM 130/300 R LPG

Page 1

Www .Kaercher .Com/register-and-win km 130/300 r lpg 59641380 08/13.

Page 2

2.

Page 3

- 1 please read and comply with these original instructions prior to the initial operation of your appliance and store them for later use or subsequent own- ers. Before first start-up it is definitely neces- sary to read the safety indications no. 5.956-250! Your sales outlet should be informed abou...

Page 4

- 2 – propellant-operated units are to be checked at regular intervals, at least once a year, by an expert against leaks (according to bgg 936) and ensure that the unit is functioning properly. – the inspection must be certified and documented. The inspection guidelines are § 33 and § 37 uvv (occupa...

Page 5

- 3 danger immediate danger that can cause severe injury or even death. 몇 warning possible hazardous situation that could lead to severe injury or even death. Caution possible hazardous situation that could lead to mild injury to persons or damage to property. The sweeper operates using the sweep- s...

Page 6

- 4 1 driver cabin (optional) 2 cabin door (option) 3 tank lid 4 lashing point (4x) 5 roller brush access 6 front wheel 7 side brushes 8 lighting system (optional) 9 waste container 10 lock of appliance hood 11 windshield wiper (option) 12 engine cover 13 gas cylinder 14 cab lock 15 beacon lamp 16 c...

Page 7

- 5 1 operating hour counter 2 charge warning lamp 3 oil pressure warning lamp 4 cooling water temperature warning lamp 5 motor suction air 6 warning lamp fuel reserve - blinks for reserve - illuminates when gas bottle is empty 7 indicator lamp (not connected) 8 indicator lamp (not connected) 9 indi...

Page 8

- 6 replace the gas cylinder. Observe the installation position of the gas cylinder. The connection / ring opening must point downwards. unscrew the protective cap from the connecting valve of the gas cylinder. close the bracket closure. screw the gas hose to the connecting valve of the gas ...

Page 9

- 7 switch on the blower. set the programme switch to sweep with sweeping brush when cleaning surfaces. set the programme switch to sweep with sweeping brush and side brush when cleaning edges. switch off the blower. set the programme switch to sweep with sweeping brush when cleaning surfa...

Page 10

- 8 observe the inspection checklist 5.950- 647.0! Note: the elapsed-time counter shows the timing of the maintenance intervals. Note: where maintenance is carried out by the customer, all service and maintenance work must be undertaken by a qualified specialist. If required, a specialised kärch- er...

Page 11

- 9 insert battery in battery mount. screw on mounts on battery base. connect pole terminal (red cable) to positive pole (+). connect pole terminal to negative pole (-). Note: check that the battery pole and pole terminals are adequately protected with pole grease. Caution regularly check th...

Page 12

- 10 note the waste container must not be raised. open engine cover. 1 looking glass 2 manometer 3 screw cap, oil fill opening check hydraulic oil level in the looking glass. – the oil level must lie between “min“ and “max“ marking. – add hydraulic oil if the oil level is below the "min" marking...

Page 13

- 11 the width of the sweeping track should lie between 40-50 mm. set the sweeping track using the two adjusting screws. check sweeping mirror. check tyre pressure. drive the waste container up and se- cure it with the safety rod. Danger risk of injury! Always apply the safety bar when the w...

Page 14

- 12 unscrew the head lamps. take out the head lamps and pull out the plug. Note: note the positions of the plugs. dismantle the head lamps. dismantle the head lamp casing and hold it horizontally because the lamp unit is not fastened. unlock the bracked and take out the bulb. insert new...

Page 15

- 13 troubleshooting fault remedy appliance cannot be started sit on the driver seat, the seat contact switch gets activated. Charging or replacing battery gas bottle empty - replace gas bottle. Gas removal valve closed - open the valve by turning it in anti-clockwise direction. Gas valve iced - ple...

Page 16

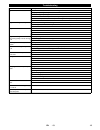

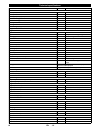

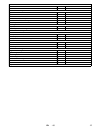

- 14 technical specifications km 130/300 r lpg machine data drive speed, forward km/h 10 drive speed, reverse km/h 10 climbing capability (max.) -- 18% surface cleaning performance without side brushes m 2 /h 10000 surface cleaning performance with 1 side brushes m 2 /h 13000 working width without s...

Page 17

- 15 brake front wheels -- mechanical rear wheel -- hydrostatic filter and vacuum system type -- flat fold filter speed 1/min 2800 filter surface area, fine dust filter m 2 5,2 nominal vacuum, suction system mbar 15,5 nominal volume flow, suction system m 3 /h 800 vibrator system -- electric motor w...

Page 19

Http://www.Kaercher.Com/dealersearch.