- DL manuals

- Karcher

- Water Pump

- SHD-R 3000

- Operating Instructions Manual

Karcher SHD-R 3000 Operating Instructions Manual

Summary of SHD-R 3000

Page 1

5.956-486 a2005937 (06/03) shd-r 3000 betriebsanleitung ! Www.Karcher.Com.

Page 2

Operating instructions to be handed to the operator read these instructions carefully before starting up the unit retain for future reference notes about these operating instructions before starting up the interior cleaner for the first time, please carefully read through these instructions. In part...

Page 3

English shd-r 3000 5.956-486 a2005937 (06/03) a. For your safety 1. Safety information and instructions 2. Noise protection 3. Authorized operators 4. Personal protective equipment 5. Emergency drill 6. Safety devices 7. Applicable regulations 8. Using the system for its intended purpose 9. Special ...

Page 4

Shd-r 3000 english 5.956-486 a2005937 (06/03) 1. Safety information and instructions the following symbols are used throughout these operating instructions: ! Danger! Denotes an immediate and present danger. Failure to observe this notice could lead to severe injury or death. Caution! Denotes a pote...

Page 5

English shd-r 3000 5.956-486 a2005937 (06/03) a2 a. For your safety 5. Emergency drill turn mains supply voltage off at system master switch. Turn off supply of cleaning liquid. If a handgun is being used, release any remaining pressure in the system by pressing the lever on the handgun. 6. Safety d...

Page 6

Shd-r 3000 english 5.956-486 a2005937 (06/03) a3 8. Using the system for its intended purpose this system is used for pumping a cleaning liquid at high-pressure, for the purpose of: with the handgun attached – cleaning containers, boxes, cases and equipment parts, etc. With the interior cleaner atta...

Page 7

English shd-r 3000 5.956-486 a2005937 (06/03) a4 a. For your safety 10. Schematic diagram of area classification.

Page 8

Shd-r 3000 english 5.956-486 a2005937 (06/03) a5 a. For your safety 11. Area classification in the betrsichv and en 1127-1, hazardous (potentially explosive) areas are classified into zones according to the frequency and duration of the occurrence of hazardous, potentially explosive atmospheres. It ...

Page 9

English shd-r 3000 5.956-486 a2005937 (06/03) 1. Types of system static or mobile systems the static system is intended to be installed on a base, has been mounted onto a rigid steel frame, is most suitable for use in conjunction with fixed-installation high-pressure lines. B. Types of system, and o...

Page 10

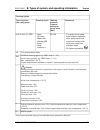

Shd-r 3000 english 5.956-486 a2005937 (06/03) b2 b. Types of system, and operating information cleaning liquids type of system (see rating plate) cleaning liquid working pressure/ pressure setting for safety valve [bar] comments shd-r 3000 (f) - water - ve -water * - water with kärcher-rm 50/65 stan...

Page 11

English shd-r 3000 5.956-486 a2005937 (06/03) b3 b. Types of system, and operating information cleaning liquids type of system (see rating plate) cleaning liquid working pressure/ pressure setting for safety valve [bar] comments shd-r 3000 (f) ssr - water - ve -water - water with kärcher-rm - acids ...

Page 12

Shd-r 3000 english 5.956-486 a2005937 (06/03) b. Types of system, and operating information b4 cleaning liquids type of system (see rating plate) cleaning liquid working pressure/ pressure setting for safety valve [bar] comments shd-r 3000 (f) sla – water – ve water* – water with kärcher-rm – alkali...

Page 13

English shd-r 3000 5.956-486 a2005937 (06/03) b5 b. Types of system, and operating information 2. System start-up emergency drill turn mains supply voltage of at system master switch. Turn off supply of cleaning liquid. If a handgun is being used, release any remaining pressure in the system by pres...

Page 14

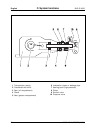

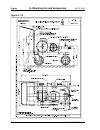

Shd-r 3000 english 5.956-486 a2005937 (06/03) c1 c. System functions 1 transmission casing 2 crankshaft with drive 3 seal (oil compartment) 4 gland 5 seal (grease compartment) 6 lubrication nipple or leakage pipe 7 sealing pack (high-pressure) 8 piston 9 suction valve 10 pressure valve.

Page 15

English shd-r 3000 5.956-486 a2005937 (06/03) c2 c. System functions operational sequence of the high- pressure pump cleaning liquid is taken in by the piston. Suction valves (9) prevent cleaning liquid from flowing backwards. Action of piston pumps cleaning liquid onwards. Pressure valves (10) prev...

Page 16

Shd-r 3000 english 5.956-486 a2005937 (06/03) d1 d. Technical specifications unit shd-r 3000 (f) shd-r 3000 (f) s shd-r 3000 (f) ssr 1) shd-r 3000 (f) sla 1) shd-r 3000 (f) sva shd-r 3000 (f) lm electrical connection type of current frequency hz 3~ 50* 3~ 50* 3~ 50* voltage v 400** 400** 400** motor...

Page 17

English shd-r 3000 5.956-486 a2005937 (06/03) e1 e. Care and maintenance 1. General information it is a fundamental requirement for ensuring that this system functions safely and reliably that maintenance is carried out regularly in accordance with the following schedule. Use only original spare par...

Page 18

Shd-r 3000 english 5.956-486 a2005937 (06/03) e2 e. Care and maintenance 2. Maintenance schedule frequency type of pump shd-r 3000 (f) action procedure by whom? 1, 2, 4, 10 hours after initial start- up. Lm sla ssr regulate tension in compression glands see maintenance tasks operator once only after...

Page 19

English shd-r 3000 5.956-486 a2005937 (06/03) e3 e. Care and maintenance 2. Maintenance schedule frequency type of pump shd-r 3000 (f) action procedure by whom? Monthly or after every 160 operating hours standard s / sva check pump for leaks if during operation more than 5 droplets per minute leak f...

Page 20

Shd-r 3000 english 5.956-486 a2005937 (06/03) e4 e. Care and maintenance 3. Maintenance tasks changing the oil ! Danger! Burns hazard due to hot oil and hot system components. Allow pump to cool down for 15 minutes before changing oil. I important! Waste oil may only be disposed of by the operators ...

Page 21

English shd-r 3000 5.956-486 a2005937 (06/03) e5 e. Care and maintenance v-belt test tension of v-belt and adjust as follows: switch off system, and ensure that it cannot be switched back on again unintentionally. Remove guard over v-belt. Test belt tension. Press down on belt which should not move ...

Page 22

Shd-r 3000 english 5.956-486 a2005937 (06/03) f1 f. Troubleshooting who is permitted to repair faults on the system? Operator tasks that are marked “operator” may only be carried out by persons who have been instructed in the safe operation and maintenance of high-pressure systems. Qualified electri...

Page 23

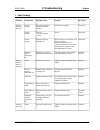

English shd-r 3000 5.956-486 a2005937 (06/03) f. Troubleshooting f2 1. Fault-finding problem component possible cause remedy by whom? System does not start up control circuitry no voltage supply to system or control circuitry check mains voltage electrician control circuitry fault on – motor contact...

Page 24

Shd-r 3000 english 5.956-486 a2005937 (06/03) f3 f. Troubleshooting 1. Fault-finding problem component possible cause remedy by whom? Knocking noise v-belt v-belt has snapped replace v-belt (see maintenance tasks) operator detergent metering on suction side of pump (accessory kit) pump is taking in ...

Page 25

English shd-r 3000 5.956-486 a2005937 (06/03) ! Hazard! The following mounting and accessory kits must not be used for operation with solvents or in a hazardous (potentially explosive atmosphere) area. 1. Mounting kits (non-hazardous area) float tank with float valve function the float valve fitted ...

Page 26

Shd-r 3000 english 5.956-486 a2005937 (06/03) g2 pressure-relief valve function the pressure-relief valve is an integrated solenoid valve. The pressure-relief valve is only active during the start-up phase when the system is configured for star-delta starting. When the pressure-relief valve is opene...

Page 27

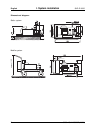

English shd-r 3000 5.956-486 a2005937 (06/03) g3 g. Mounting kits and accessories figure a 170/1.

Page 28

Shd-r 3000 english 5.956-486 a2005937 (06/03) g4 g. Mounting kits and accessories figure a 172.

Page 29

English shd-r 3000 5.956-486 a2005937 (06/03) g5 g. Mounting kits and accessories figure a 173.

Page 30

Shd-r 3000 english 5.956-486 a2005937 (06/03) g6 g. Mounting kits and accessories figure a 161.

Page 31

English shd-r 3000 5.956-486 a2005937 (06/03) g7 g. Mounting kits and accessories figure a 154.

Page 32

Shd-r 3000 english 5.956-486 a2005937 (06/03) h1 h. Warranty the applicable warranty conditions in different countries are issued by the respective national distributor of kÄrcher products. In the event of a warranty claim, please contact your original dealer or the nearest authorized customer servi...

Page 33

English shd-r 3000 5.956-486 a2005937 (06/03) i1 i. System installation this system should only be installed by kärcher customer service engineers, persons who have been specially authorized by kärcher. Unpacking the system unpack the system and deliver the packag- ing materials to an appropriate co...

Page 34

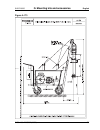

Shd-r 3000 english 5.956-486 a2005937 (06/03) i. System installation i2 dimensional diagram: static system mobile system approx. 1100

Page 35

English shd-r 3000 5.956-486 a2005937 (06/03) j1 j. Declaration of conformity ec declaration of conformity we herewith declare that the design and type of machine named in the following as well as the model marketed by us complies with the relevant fundamental health and safety requirements of the e...

Page 36

Shd-r 3000 english 5.956-486 a2005937 (06/03) j2 j. Declaration of conformity ec declaration of conformity we herewith declare that the design and type of machine named in the following as well as the model marketed by us complies with the relevant fundamental health and safety requirements of the e...

Page 37

English shd-r 3000 5.956-486 a2005937 (06/03) k1 k. Test record type no.: factory no.: commissioned on: tests carried out on: .............................................................................................................. Results ....................................... Signature tests...