- DL manuals

- Katronic Technologies

- Measuring Instruments

- KATflow 230

- Operating Instructions Manual

Katronic Technologies KATflow 230 Operating Instructions Manual

Summary of KATflow 230

Page 1

Operating instructions portable ultrasonic flowmeter ka tflow 230

Page 2

Katronic technologies ltd. 23 cross street leamington spa warwickshire cv32 4px united kingdom tel. +44 (0)1926 882954 fax +44 (0)1926 338649 internet www.Katronic.Co.Uk e-mail mail@katronic.Co.Uk operating instructions katflow 230 version v09e1108 copyright © 2008 all rights reserved..

Page 3

Katflow 230 table of content katflow 230 operating instructions table of content page 1 safety instructions, legal requirements, warranty, return policy..................7 1.1 symbols used in these operating instructions...............................................7 1.2 safety instructions...........

Page 4

Katflow 230 table of content 5.4.2 analogue current output 0/4 ... 20 ma...................................................35 5.4.3 digital open-collector output.................................................................35 5.4.4 digital relay output................................................

Page 5: •

Katflow 230 1 safety instructions, legal requirements, warranty, return policy 1 safety instructions, legal requirements, war- ranty, return policy 1.1 symbols used in these operating instructions danger this symbol represents an immediate hazardous situation which could result in a serious injury, ...

Page 6

Katflow 230 1 safety instructions, legal requirements, warranty, return policy 1.3 warranty ● any product purchased from katronic is warranted in accordance with the relevant product documentation and as specified in the sales contract provided it has been used for the purpose for which it has been ...

Page 7

Katflow 230 2 introduction 2 introduction the katflow 230 is a portable, battery operated ultrasonic flowmeter utilising clamp-on sensors for the measurement of liquids in full closed pipes. Flow meas- urements can be undertaken without interrupting of the process or interfering with the integrity o...

Page 8

Katflow 230 3 installation 3 installation 3.1 unpacking and storage 3.1.1 unpacking care should be taken when opening the box containing the flowmeter, any mark- ings or warnings shown on the parcel should be observed prior to opening. The fol- lowing steps should then be taken: ● unpack the flowmet...

Page 9

Katflow 230 3 installation 3.2 clamp-on sensor installation the correct selection of the sensor location is crucial for achieving reliable meas- urements and a high accuracy. Measurement must take place on a pipe in which sound can propagate (see acoustic propagation) and in which a rotationally sym...

Page 10

Katflow 230 3 installation correct disadvantageous for a vertical pipe: select the measuring point at a location where the liquid flows upward to insure that the pipe is completely filled. Correct incorrect look for a sensor installation location with sufficient straight pipe to obtain accurate meas...

Page 11

Katflow 230 3 installation disturbance source: t-section inlet outlet l ≥ 50 d l ≥ 10 d disturbance source: diffuser inlet outlet l ≥ 30 d l ≥ 5 d disturbance source: reducer inlet outlet l ≥ 10 d l ≥ 5 d disturbance source: valve inlet outlet l ≥ 40 d l ≥ 10 d disturbance source: pump inlet l ≥ 50 ...

Page 12

Katflow 230 3 installation 3.5 clamp-on sensor mounting configurations and separation distance the most common clamp-on sensor mounting configuration is the reflection mode, also known as v-mode (see illustration 3, sketch (1). Here the ultrasonic signal pass twice through the medium (2 signal passe...

Page 13

Katflow 230 3 installation 3.6 flowmeter installation 3.6.1 outline dimensions the katflow 230 is a portable, battery operated device with the following outline di- mensions. 13 272 266 222 15 5 7 13 37 32 168 shock protectors 080610_1 process i/o connector drawing 1: outline dimensions katflow 230 ...

Page 14

Katflow 230 3 installation 14 drawing 2: transducers k1 type transducer 1500 2500 080609_1 1000 1500 080609_1 k4 type transducer.

Page 15

Katflow 230 3 installation 3.6.2 electrical interconnections 3.7 clamp-on sensor mounting before the sensors can be mounted ● the installation location should have been determined, ● a sensor mounting method should be chosen, ● the flowmeter batteries must be sufficiently charged, ● the sensors must...

Page 16

Katflow 230 3 installation 3.7.2 acoustic coupling gel in order to obtain acoustical contact between the pipe and the sensors, apply a bead of acoustic coupling gel lengthwise down the centre of the contact area of the sensors. 16 illustration 4: sensor pipe mounting configurations illustration 5: a...

Page 17

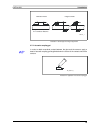

Katflow 230 3 installation 3.7.3 correct positioning of the sensors always mount the transducer pair such that the free front edges of the sensors face each other. There is a different engraving on the top of each transducer. The transducers are mounted correctly if the engravings on the two transdu...

Page 18

Katflow 230 3 installation ● take the spring end of the chain in one hand and insert the last ball ele- ment in the vertical slot of the retaining clip. Mount the chain around the pipe. ● pull the chain firmly around the pipe and fasten it in the lateral slot of the retaining clip. There should be n...

Page 19

Katflow 230 4 operation 4 operation 4.1 switching on/off the flowmeter is switched on by the key for more than 2 seconds continu- ously. Equally it can be switched off by pressing the key for more than 2 seconds. 4.2 battery charging the internal batteries can be recharged with the supplied external...

Page 20

Katflow 230 4 operation 4.3 keypad and display 4.3.1 keypad key functions key main function secondary function alphanumerical entry: 1 (1 short key stroke) , (2 short key strokes) . (3 short key strokes) _ (4 short key strokes) show next available item alphanumerical entry: a b c 2 / q on = start to...

Page 21

Katflow 230 4 operation alphanumerical entry: j k l 5 > alphanumerical entry: m n o 6 $ q + = show positive total value alphanumerical entry: p q r s 7 toggle multiplexer (for multi-chan- nel functionalities) alphanumerical entry: t u v 8 * q off = stop totaliser function alphanumerical entry: w x y...

Page 22

Katflow 230 4 operation 4.3.2 display functions display icon function on icon not used off on datalogger recording off datalogger switched off on 1 segment = 33% battery power available 2 segments = 66% battery power available 3 segments = 100% battery power available off outline blinking battery ch...

Page 23

Katflow 230 4 operation on rtc operating off rtc failure on error recorded in error log off no error detected on serial output rs 232 switched on off serial output rs 232 switched off 4.4 quick setup wizard the quick setup wizard allows for a speedy setup of the most important parameters in order to...

Page 24

Katflow 230 4 operation select fluid using cursor keys. Confirm by pressing enter>. Enter process temperature using alphanumer- ical keys and confirm by pressing enter>. Use key up> as character backspace clear to correct for data entry errors. Select pipe lining material using cursor keys. Confirm ...

Page 25

Katflow 230 4 operation 4.5 measurements 4.5.1 main process value (pv) display the measurements are started either through the quick setup wizard or the menu structure by selecting start measurement upon first power on. Once all the para- meters are programmed, any subsequent power-on sequences will...

Page 26

Katflow 230 4 operation 4.5.4 totalisers the totaliser displays will only be shown when the totalisers are activated. Display screen operation the flow totaliser can be started by press- ing on >. Pressing + > shows the total accumu- lated flow in positive flow direction. Pressing shows the total ac...

Page 27

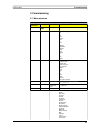

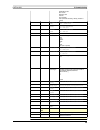

Katflow 230 5 commissioning 5 commissioning 5.1 menu structure main menu menu level 1 menu level 2 description/settings quick start setup wizard single units select from list ↑↓ m/s f/s in/s m3/h m3/min m3/s l/h l/min l/s usgall/h usgall/min usgall/s bbl/d bbl/h bbl/min g/s t/h kg/h kg/min pipe mate...

Page 28

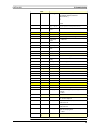

Katflow 230 5 commissioning hydrochloric acid sour cream sulphuric acid toluene vinyl chloride user (kinematic viscosity, density, medium c- speed) kinematic vis- cosity only if user fluid selected 0.001 ... 30000 mm 2 /s density only if user fluid selected 100 ... 2000 kg/m 3 medium c- speed only i...

Page 29

Katflow 230 5 commissioning ment sensor type indication of sensor type and serial number if automatically detected, otherwise select from list ↑↓ k1 k4 m q special sp 1 ... Sp 8 only for special, unrecognised sensors sensor place- ment installation pipe material select from pipe material list ↑↓ out...

Page 30

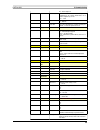

Katflow 230 5 commissioning no – pulse output off pulse value totaliser value of selected pv at which a pulse is generated, e.G. Pv = [m3/h], pulse value = 10, a pulse is output every 10 m3 0.01 ... 1000 pulse width width of the pulse 30 ... 999 ms calc. Max this is the calculated max. Number of pul...

Page 31

Katflow 230 5 commissioning user identifier example: pump p3a 9 alphanumeric character string tag no. Example: 1ft-3011 9 alphanumeric character string test test mode control system simulation: 60 second ramping up of flow velocity in m/s from 0 to programmed max f cut and subsequent 60 second rampi...

Page 32

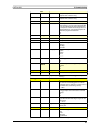

Katflow 230 5 commissioning 2400 9600 (default) 19200 parity select from list ↑↓ none even (default) odd type select from list ↑↓ none rs232 5.2 diagnostics diagnostic screens can be accessed directly during measurement or through the menu structure. 5.3 display settings customer specific settings f...

Page 33

Katflow 230 5 commissioning 5.4.1 serial interface rs 232 the rs 232 serial interface can be used to transmit data on-line or to download the integral datalogger content. The settings can be found in submenu serial comm. 5.4.2 analogue current output 0/4 ... 20 ma the analogue current output operate...

Page 34

Katflow 230 5 commissioning wiring electrical characterist- ics form c (spdt-co) contacts v = 48 v i max = 250 ma 5.5 input configurations there are two 4-wire circuit pt100 inputs available at the bottom of the enclosure. 5.5.1 pt100 inputs wiring electrical characterist- ics pt100 4-wire circuit m...

Page 35

Katflow 230 7 troubleshooting 7 troubleshooting should there be the need to call customer service, please let us know the following details: ● model code ● serial number ● sw, hw revision ● error log list possible error messages may include the following: error message group description error handli...

Page 36

Katflow 230 7 troubleshooting error call customer support comm read ave err hardware internal communication error power on/off, otherwise call customer support comm read raw err hardware internal communication error power on/off, otherwise call customer support comm read his- tory err hardware inter...

Page 37

Katflow 230 7 troubleshooting 8 technical data sound speed* shear wave (at 25 ºc) material m/s ft/s steel, 1% carbon, hardened 3,150 10,335 carbon steel 3,230 10,598 mild steel 3,235 10,614 steel, 1% carbon 3,220 10,565 302 stainless steel 3,120 10,236 303 stainless steel 3,120 10,236 304 stainless ...

Page 38

Katflow 230 8 technical data all data given at 25 ºc (77 ºf) unless otherwise stated sound speed change v/ºc kinematic viscosity x10-6 substance chemical formula specific gravity m/s ft/s m/s/ºc m 2 /s ft 2 /s acetic anhydride (ch3co)2o 1.082 (20 ºc) 1,180 3,871.4 2.5 0.769 8.274 acetic acid, anhydr...

Page 39

Katflow 230 8 technical data (-89 ºc) (-128 ºf) methanol ch4o 0.791 (20 ºc) 1,076 3,530.2 292 0.695 7.478 methyl acetate c3h6o2 0.934 1,211 3,973.1 0.407 4.379 methyl alcohol ch4o 0.791 1,076 3,530.2 292 0.695 7.478 methyl benzene c7h8 0.867 1,328 (20 ºc) 4,357 (68 ºf) 4.27 0.644 7.144 milk, homogen...

Page 40

Katflow 230 8 technical data tetrachloro-methane ccl4 1.595 (20 ºc) 926 3,038.1 0.607 6.531 tetrafluoro-methane (freon 14) cf4 1.75 (-150 ºc) 875.24 (-150 ºc) 2,871.5 (-283 ºf) 6.61 toluene c7h8 0.867 (20 ºc) 1,328 (20 ºc) 4,357 (68 ºf) 4.27 0.644 6.929 toluol c7h8 0.866 1,308 4,291.3 4.2 0.58 6.24 ...

Page 41

Katflow 230 8 technical data 37 98.6 1523 4990 38 100.4 1525 4997 39 102.2 1527 5010 40 104.0 1528 5013 41 105.8 1530 5020 42 107.6 1532 5026 43 109.4 1534 5033 44 111.2 1535 5036 45 113.0 1536 5040 46 114.8 1538 5046 47 116.6 1538 5049 48 118.4 1540 5053 49 120.2 1541 5056 50 122.0 1543 5063 51 123...

Page 42

Katflow 230 8 technical data 91 195.8 1549 5082 92 197.6 1549 5082 93 199.4 1548 5079 94 201.2 1547 5076 95 203.0 1547 5076 96 204.8 1546 5072 97 206.6 1545 5069 98 208.4 1544 5066 99 210.2 1543 5063 100 212.0 1543 5063 104 220.0 1538 5046 110 230.0 1532 5026 116 240.0 1524 5000 121 250.0 1526 5007 ...

Page 43

Katflow 230 9 specification 9 specification 43 • transit-time correlation measurement • dual dsp-technology, coded signals for better measurement accuracy • two channel portable unit with graphic display • easy to install clamp-on sensors with no process interruption • non-invasive flow measurement ...

Page 44

Katflow 230 9 specification 44 flowmeter (cont.) power consumption : signal damping : 0 ... 99 s measurement rate : 10 ... 1000 s -1 operating languages : english, german, french, spanish, russian response time : 1 s, faster rates upon request calculation functions : average/difference/sum quantity ...