- DL manuals

- Kauo Heng

- Sewing Machine

- KH-300

- Operation Manual

Kauo Heng KH-300 Operation Manual

Summary of KH-300

Page 1

Kauoheng kh-300 operation manual 電腦橫編織機 kh computerized flat knitting machine.

Page 2: Contents

Contents i. Outline 1. Introduction of kh-300………………………………………………… 1 2. Specification……………………………………………………………. 2 3. Installation / environmental conditions………………………………. 3 4. Transportation, movement and installation…………………………. 4 5. Installation work……………………………………………………….. 5 6. Overall view…………………………………...

Page 3: Outline

Kauo heng computerized flat knitting machine kh-300 operation manual 1 i. Outline 1. Introduction of kh-300 the kh-300 is a flat knitting machine, developed and manufactured in keeping with the following concepts. ▓ compact ▓ light-weight ▓ space-saving ▓ high-performance ▓ efficient ▓ economical on...

Page 4

Kauo heng computerized flat knitting machine kh-300 operation manual 2 2. Specification model kh-300 gauge 3g, 3.5g, 4g 5g, 7g, 10g, 12g, 14g 46”(117cm) 60”(152cm) knitting width 80”(203cm) 80”(203cm) 60”:double system one carriage single system, twin carriage 80”:single system, twin carriage. Cam s...

Page 5

Kauo heng computerized flat knitting machine 3. Installation / environmental conditions please install the machine as below instructions, in order to use and keep this machine good working condition. Do not install the machine at a place subject to direct sunshine and/or adjacent to a heat generatio...

Page 6

Kauo heng computerized flat knitting machine 4. Transportation, movement and installation transportation(package) weight:1830 kgs (12g x 80”) transportation(unpackage) weight:1350 kgs (12g x 80”) kh-300 operation manual 4.

Page 7

Kauo heng computerized flat knitting machine 5. Installation work a. The space required for the installation of the machine is as follows : to facilitate access to the machine to pull out the carriages, the distance from any object such as from a wall to the machine must be at least 400 mm. B. Balan...

Page 8

Kauo heng computerized flat knitting machine 6. Overall view 1. Yarn carrier selection 7. Main motor 2. Carriage 8. Side tension equipment 3. Operation bar 9. Top tension 4. Main cover 10. Side cover 5. Fabric take-down roller 11. Fabric take-down roller bar 6. Controller kh-300 operation manual 6.

Page 9

Kauo heng computerized flat knitting machine 7. Main units and names 7.1 top tension a. Electronic top tensions are easy to thread the yarn through. The large knot causes machine stop. The small knot causes slow speed then automatically resume at set speed. B. Top tension springs should have the cor...

Page 10

Kauo heng computerized flat knitting machine 7.2 fabric take-down system in principle of the take-down tension strength must be small and average. The take-down system is controlled by torque motor. Each roller can be adjusted individually. The pressure of roller gets larger and the speed of take-do...

Page 11

Kauo heng computerized flat knitting machine kh-300 operation manual 9 in in out out in in out out 7.3 yarn feed unit (5g~14g) auto, positive feeding device on each left and right side ( fig.7.3.1, fig.7.3.2, fig.7.3.3 ) are showing the ways of passing through the yarn. Fig. 7.3.1 i n (5g~14g) 1. Ya...

Page 12

Kauo heng computerized flat knitting machine the steps of passing through the yarn of side tension (3.5g yarn feed unit included) (fig. 7.3.4) (3.5g) 1. Yarn guide 2. Yarn roller 3. Side tension 4. Yarn guide in out fig. 7.3.4 kh-300 operation manual 10

Page 13

Kauo heng computerized flat knitting machine 7.4 yarn feeder the position of carrier is adjusted according to the desired knitting width, correctly make yarn feeder beside the end working needle by 10 mm. The yarn feeder must be in the central position between front and rear needles, also check its ...

Page 14

Kauo heng computerized flat knitting machine 7.5 the latch brush the latch brush is important to open needle latch and prohibit the needle latch to close in knitting, and the correct brush setting is illustrated in fig.7.5.1. Kh-300 operation manual 12 fig.7.5.1 correct position of brush 7.6 cam pla...

Page 15

Kauo heng computerized flat knitting machine 7.7 remove carriage when it becomes necessary to remove the carriage, it can be remove from the left hand side or the right hand side. The procedures are as following: a. Turn off the power firstly. B. Remove the side cover. C. Disconnect the two plugs on...

Page 16

Kauo heng computerized flat knitting machine 7.8. Carriage combination and separation two carriages, you can choose in use of combination or separation by yourself for different knitting production. Please operate combination or separation as follows: a. Turn off power. B. Fig.7.8.1 is a top overvie...

Page 17

Kauo heng computerized flat knitting machine d. In separation position, the connecting- pole must be replaced the longer one. Refer to fig. 7.8.3 (the distance between the two fabrics should be over 12”, from the middle of needle bed is each 6” to left and right side.) kh-300 operation manual 15 fig...

Page 18

Kauo heng computerized flat knitting machine 7.9 replaceable segment needle bed the replaceable segment needle bed is with the same transfer needle on front and rear bed also includes moveable sinker equipment. Kh-300 operation manual 16 fig.7.9.1 the structure of front and rear needle beds needle p...

Page 19

Kauo heng computerized flat knitting machine 7.10 racking mechanism the rear bed can be racked four(4)inch(left right each 2 inches), the initial position”0”. See the left selvedge of needle bed, the corresponding position that the first needle of rear is on the left hand side of the first needle of...

Page 20

Kauo heng computerized flat knitting machine 8. Front and rear cam system (3.5g) kh-300 the cam system of front and rear beds is the same. Kh-300 operation manual 18 fig 8.1 (3.5g) a transfer guide cam i needle guide cam q selector guide cam b transfer raising cam j needle guide cam r selector guide...

Page 21

Kauo heng computerized flat knitting machine front and rear cam system (5g~14g) kh-300 the cam system of front and rear beds is the same. Fig 8.2 (5g~14g) a transfer guide cam i tuck presser cam b transfer raising cam j presser cam c transfer receive cam k presser cam d needle raising cam l selector...

Page 22

Kauo heng computerized flat knitting machine 9. Cam action (3.5g) in graphs show the usual kinds of cam active situation. “arrow” is the direction of carriage. “cross-line” is out of action. Kh-300 operation manual 20 fig.9.1 knit & tuck jack jack fig.9.2 knit & tuck.

Page 23

Kauo heng computerized flat knitting machine cam action (3.5g) kh-300 operation manual 21 fig.9.3 transfer & receipt jack jack fig.9.4 transfer & receipt.

Page 24

Kauo heng computerized flat knitting machine cam action (3.5g) jack fig.9.5 knit jack fig.9.6 miss kh-300 operation manual 22.

Page 25

Kauo heng computerized flat knitting machine cam action (3.5g) jack fig.9.7 tuck kh-300 operation manual 23.

Page 26

Kauo heng computerized flat knitting machine cam action (5g~14g) in graphs show the usual kinds of cam active situation. “arrow” is the direction of carriage. “cross-line” is out of action jack fig 9.8 knit & tuck jack fig 9.9 knit & tuck kh-300 operation manual 24.

Page 27

Kauo heng computerized flat knitting machine cam action (5g~14g) kh-300 operation manual 25 jack fig 9.10 transfer & receipt jack fig 9.11 transfer & receipt.

Page 28

Kauo heng computerized flat knitting machine cam action (5g~14g) kh-300 operation manual 26 fig 9.12 knit jack jack fig 9.13miss.

Page 29

Kauo heng computerized flat knitting machine cam action (5g~14g) jack fig 9.14 tuck kh-300 operation manual 27.

Page 30

Kauo heng computerized flat knitting machine 10. Cleaning maintenance: daily a. Clean the yarn dust on the needle, sinker, yarn carrier, yarn carrier rail, carriage, latch brush and top tension and clean the filter. B. Clean up the needle bed daily and clean out the yarn dust on the needle bed. C. C...

Page 31

Kauo heng computerized flat knitting machine 11. Controller as fig.11.1 front side of controller, easily find two switches, one fluorescent lamp switch and one breaker/power switch. Fig upward is “on” and downward is “off”. Kh-300 operation manual 29 fluorescent lamp breaker/power switch fig 11.1con...

Page 32

Kauo heng computerized flat knitting machine 12. Operation bar kh-300 operation manual 30 fig.12.1 inching and starting in c h in g s ta rtin g fig.12.2 stop a. Inching:when turn forward of the operation bar, machine operates slowly and stops when you loosen. S top s to p b. Starting:when turn backw...

Page 33: II.

Kauo heng computerized flat knitting machine kh-300 operation manual 31 ii. Operation ◎ main menu a. Flip the breaker switch on the front side of the controller to on. Then display main menu. B. Press on green key to start servo motor. C. How select each required menu: use arrow key ↑ ↓ ← → to move ...

Page 34

Kauo heng computerized flat knitting machine █ preparation for machine running 1. Switch on the power ↓ 2. Press the green button on(main servo motor) ↓ 3. Move the carriage to the left / yarn feeders return to zero position (1-8 four systems) ↓ 4. Main menu → 1. Re-start knitting → press enter key ...

Page 35: ◎ Re-Start Knitting

Kauo heng computerized flat knitting machine ◎ re-start knitting move cursor to “1.Re-start knitting” and press enter key. Screen appears “start operation bar”. Turn the operation bar, in carriages the cam, stitch and racking etc. Come to zero position automatically and appears “knitting mode” scree...

Page 36

Kauo heng computerized flat knitting machine kh-300 operation manual 34 █ detail for knitting mode 1. Step:working step position 2. →:direction 3. Piece:set piece / finished piece ※ press :『shift + number』 4. Course:total course / working course 5. Time:total time / working time 6. Ndl.Pos:needle re...

Page 37: Edit Main Control

Kauo heng computerized flat knitting machine ◎ edit main control edit and change the programming data in the required knitting. Move cursor to “3.Edit main control” and press enter key. Kh-300 operation manual 35 it will enter “control data “screen. ** control data ** [ ] tab= keyfunc step:1 system ...

Page 38

Kauo heng computerized flat knitting machine kh-300 operation manual 36 █ explanation for edit main control when edit new main-program it must be in the step no.1 of main program and preset racking and sub-program then can do exit. P.Set–r, p.Set–f, yarn stop, turn adj, stitch, speed, t.Down / sub.T...

Page 39

Kauo heng computerized flat knitting machine kh-300 operation manual 37 13. Economy :(a)set jump for repeat. (b)set end for end of program 14. Step : jump to required step number for repeat, available repeat in single step 15. Count : how many time of repeat 16. Stitch : set stitch data, range from ...

Page 40

Kauo heng computerized flat knitting machine █ tab key function show function key in edit main program. Control data function code : kh-300 operation manual 38 *** control data function code *** f1 : stitch data f2 : speed data f3 : pattern set f4 : turn / yarn stop f5 : pattern data f6 : jump to an...

Page 41

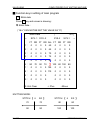

Kauo heng computerized flat knitting machine █ function key in editing of main program f1 : stitch data press f1 key and screen is showing : ▼ stitch data : ( “all” can not be set the value as “0”) *** stitch data *** [ .Sti ] kh-300 operation manual 39 ← sys -1 sys -2 sys-2 sys-1 → ft rr ft rr all ...

Page 42

Kauo heng computerized flat knitting machine ▼ stitch data: 1. If set stitch value in all then value of left & right systems are same two of all. *** stitch data *** [ .Sti ] ← sys -1 sys -2 sys -1 sys-2 → ft rr ft rr all ft rr ft rr 1: 0 0 0 0 60 0 0 0 0 2: 0 0 0 0 65 0 0 0 0 3: 0 0 0 0 70 0 0 0 0 ...

Page 43

Kauo heng computerized flat knitting machine ■ f2 : speed data press f2 key and screen is showing: ▼ main speed / take down speed / sub take down speed : *** main speed / take down *** file name:[ .Abs ] – – speed data ( 1~120 ) – – 1:80 12:1 23:1 2:70 13:1 24:1 3:1 14:1 25:1 4:1 15:1 26:1 5:1 16:1 ...

Page 44

Kauo heng computerized flat knitting machine ▼ main take down screen : *** main take down *** file name:[ .Abs ] – – maintakedown ( 0~99 ) turn ( 0~99 ) – – 1:30 / 35 12:0 /0 23:0 /0 2:40 /45 13:0 /0 24:0 /0 3:0 /0 14:0 /0 25:0 /0 4:0 /0 15:0 /0 26:0 /0 5:0 /0 16:0 /0 27:0 /0 6:0 /0 17:0 /0 28:0 /0 ...

Page 45

Kauo heng computerized flat knitting machine press pgdn : ▼ sub take down / open close screen : *** sub take down / open close *** file name:[ .Abs ] – – subtakedown ( 0~99 ) s.T.D.Open ( 0~99 ) – – 1:65 12:0 23:0 1:60 12:0 23:0 2:70 13:0 24:0 2:60 13:0 24:0 3:0 14:0 25:0 3:0 14:0 25:0 4:0 15:0 26:0...

Page 46

Kauo heng computerized flat knitting machine ▼ auto take down / open close screen : *** auto take down *** file name:[ .Abs ] needle speed m.T.D s.T.D open no. Min–max min–max mn –mx mn –mx mn –mx 33:0 – 0 1 – 1 0 – 0 0 – 0 0 – 0 34:0 – 0 1 – 1 0 – 0 0 – 0 0 – 0 35:0 – 0 1 – 1 0 – 0 0 – 0 0 – 0 36:0...

Page 47

Kauo heng computerized flat knitting machine kh-300 operation manual 45 █ f3 : pattern set press f3 key and screen is showing : pattern setting : *** pattern setting *** [ .Pst ] no.1 code set reset start end 1: inc 1 200 1 2: 3: 4: 5: 6: 7: 8: 9: 10: 11: f1:inc f2:dec f3:rept f4:cont f9:clear 1. Us...

Page 48

Kauo heng computerized flat knitting machine kh-300 operation manual 46 ▼ code : the content of pattern, set f1- f4 f1 inc, increment : this places the pattern from the set needle to the reset needle, beginning with the star wale no. And continuing in order of wale no. F2 dec, decrement : this place...

Page 49

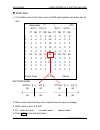

Kauo heng computerized flat knitting machine kh-300 operation manual 47 █ f4 : turn adj press f4 key and screen is showing : carriage return distance / yarn feeder set position. Carriage return distance [ .Yrn ] 1:0 2:0 3:0 4:0 yarn feeder set position ← 1 st 2 nd all 2 nd 1 st → 6: 0 0 6 0 0 5: 0 0...

Page 50: █ Function

Kauo heng computerized flat knitting machine kh-300 operation manual 48 █ function f5:pattern data press f5 key and be shown on screen. F6:jump to any step input the required step no. To jump. Shown on screen : jump step → ___ f7:copy any step input the required step no. To copy. Shown one screen : ...

Page 51: Edit Pattern

Kauo heng computerized flat knitting machine kh-300 operation manual 49 ◎ edit pattern select 4. Edit pattern in main menu, press enter key and be shown on screen. X:1 y:1 file name: [ .Des ] start: 1 , 1 end: 1 , 1 → · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ...

Page 52

Kauo heng computerized flat knitting machine kh-300 operation manual 50 █ explanation for edit pattern key board operation and function as below. 1. Edit new program. 2. Press 2 key and be shown on screen. Wale ________ course ________ y/n ? If press n key and be shown on screen. Input wale? Press e...

Page 53

Kauo heng computerized flat knitting machine ▼ key board operation and function as below. F1 jump:input the required wale and course to jump. F2 chg:change color, after present area (start: x, y; end: x, y) press f2 key to select the code for change. For example: input 4 in 1 of area, then all the 1...

Page 54: Edit Piece Area

Kauo heng computerized flat knitting machine kh-300 operation manual 52 ◎ edit piece area in main menu, select 5. Piece area and press enter key, screen be shown. *** piece area (auto ) *** [ .Pcs ] piece start end yarn 1: 2: 3: 4: 5: 6: 7: 8: f9 : all clear piece area (auto):can separate 1~4 fabric...

Page 55: Yarn Feeder Start Postion

Kauo heng computerized flat knitting machine kh-300 operation manual 53 ◎ yarn feeder start postion in main menu, select 6.Yarn feeder start position and press enter key, screen be shown. *** yarn feeder stop point *** page:1 file name:[ .Yrn ] left system right system l r l r 6: 4 4 4 4 5: 8 8 8 8 ...

Page 56: Disk Service

Kauo heng computerized flat knitting machine kh-300 operation manual 54 ◎ disk service in main menu select 7.Disk service and press enter key, screen be shown: ************************************************ ** disk service ** ************************************************ please select: 1. File ...

Page 57

Kauo heng computerized flat knitting machine kh-300 operation manual 55 ▼file load select 1.File load by cursor and press enter key, screen be shown: *** file load *** page:1 kauoheng .Bmp 258k t4 .Pst 6k kauoheng .Pxp 2k t4 .Cnt 2k kauoheng .Opt 60k t4 .Des 30k kauoheng .Pst 6k c1 .Pst 6k kauoheng ...

Page 58

Kauo heng computerized flat knitting machine kh-300 operation manual 56 ▼file save select 2.File save by cursor and press enter key, screen be shown: *** file save *** page:1 kauoheng .Bmp 258k t4 .Pst 6k kauoheng .Pxp 2k t4 .Cnt 2k kauoheng .Opt 60k t4 .Des 30k kauoheng .Pst 6k c1 .Pst 6k kauoheng ...

Page 59

Kauo heng computerized flat knitting machine kh-300 operation manual 57 ▼ rename select 3. Rename by cursor and press enter key, screen be shown: *** file rename *** page:1 kauoheng .Bmp 258k t4 .Pst 6k kauoheng .Pxp 2k t4 .Cnt 2k kauoheng .Opt 60k t4 .Des 30k kauoheng .Pst 6k c1 .Pst 6k kauoheng .C...

Page 60

Kauo heng computerized flat knitting machine kh-300 operation manual 58 ▼file delete select 4.File delete by cursor and press enter key, screen be shown: *** file delete *** page:1 kauoheng .Bmp 258k t4 .Pst 6k kauoheng .Pxp 2k t4 .Cnt 2k kauoheng .Opt 60k t4 .Des 30k kauoheng .Pst 6k c1 .Pst 6k kau...

Page 61

Kauo heng computerized flat knitting machine kh-300 operation manual 59 ▼file compare select 8.File compare by cursor and press enter key: *** file compare *** page:1 kauoheng .Bmp 258k t4 .Pst 6k kauoheng .Pxp 2k t4 .Cnt 2k kauoheng .Opt 60k t4 .Des 30k kauoheng .Pst 6k c1 .Pst 6k kauoheng .Cnt 9k ...

Page 62

Kauo heng computerized flat knitting machine kh-300 operation manual 60 ▼directory select 6. Directory by cursor and press enter key. *** directory *** page:1 kauoheng .Bmp 258k t4 .Pst 6k kauoheng .Pxp 2k t4 .Cnt 2k kauoheng .Opt 60k t4 .Des 30k kauoheng .Pst 6k c1 .Pst 6k kauoheng .Cnt 9k c1 .Cnt ...

Page 63: Demo Execution

Kauo heng computerized flat knitting machine ◎ demo execution use arrow key to move cursor to 8. Demo execution, then press enter key to the screen. 1. Press enter to demo execution automatically. 2. Press pause break to stop temporarily and press enter to continue. 3. Press space to start demo exec...

Page 64: Diagnostic Input

Kauo heng computerized flat knitting machine kh-300 operation manual 62 ◎ diagnostic input in main menu, select 9. Diagnostic input and press enter key for test of input. *** diagnostic input *** system – 1 system - 2 stitch origin rear:˙ rear:˙ front:˙ front:˙ cam origin rear:- rear:˙ front:˙ front...

Page 65: Diagnstic Output

Kauo heng computerized flat knitting machine kh-300 operation manual 63 ◎ diagnstic output move cursor to “10 re-start knitting “ and press enter key. Screen appears “start operation bar”. Turn the operation bar, in carriages the cam, stitch and racking etc. *** diagnostic output *** system -1 syste...

Page 66

Kauo heng computerized flat knitting machine kh-300 operation manual 64 █ reference stitch :key in 0~220 to test. Cam :key in 0~4 to test. Needle :key in 0~3 to test. Time :the speed of test to selection actuator. Yarn :key in 0~6 to test. Main motor :speed test. Racking motor :key in racking value ...

Page 67: ◎ System Setting

Kauo heng computerized flat knitting machine kh-300 operation manual 65 ◎ system setting key in 8 characters 『k a u o h e n g』 in main menu to enter in the screen “system setting” . *** system setting *** language :1 t.Down :0 empty : 120 buzzer :1 left off :0 right off : 0 cover :0 tr stitch :50 ke...

Page 68: ◎ Function Key

Kauo heng computerized flat knitting machine kh-300 operation manual 66 ◎ function key f1:stitch f2:main speed / take – down speed/ sub t.Down speed f3:pattern set f4:turn adj f5:pattern data f6:jump to any step f7:copy any step f8:step delete f9:step clear f10:n~n step clear shift+f9:step insert sh...

Page 69: Error Message Table

Kauo heng computerized flat knitting machine kh-300 operation manual 67 error message table error message solutioin main servo error: start servo-motor, green on key, clear the error signal. Shock: check if needles in fault ,then press r key after solution. Yarn breakage: check if top-tension in fau...

Page 70

高亨精機工業有限公司 kauo heng precision machinery industrial co., ltd. 台灣省台北縣板橋市和平路 14 巷 20 號 address:no. 20, lane 14, ho ping road, panchiao, taipei, taiwan tel:+ 886-2-29559258 fax:+ 886-2-29629153 http:// www.Kauoheng.Com.Tw e-mail:kauoheng@ms58.Hinet.Net.