- DL manuals

- Kauo Heng

- Sewing Machine

- KH-323 SERIES – V2

- Operation Manual

Kauo Heng KH-323 SERIES – V2 Operation Manual

Summary of KH-323 SERIES – V2

Page 1

Kauoheng kh-323 series – v2 operation manual 電腦橫編織機 kh computerized flat knitting machine.

Page 2: Dear Customer

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 1 dear customer : welcome to be an owner of kh-323 series-v2 computerized flat knitting machine as kauo heng endeavors to maintain a high standard of this machine, we also pleased for your cooperation to make the machin...

Page 3: Overview of Kh-323 Series-V2

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 2 overview of kh-323 series-v2 1. Yarn carrier selection 2. Carriage 3. Operation bar 4. Main cover 5. Fabric take-down roller 6. Controller 7. Main motor 8. Side tension 9. Top tension 10. Side cover.

Page 4: Contents

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 3 contents 1. Points to observe 4 2. Installation 6 3. Operation 10 3.1 power switch 10 3.2 operation bar 10 3.3 yarn feeder 11 3.4 top tension 12 3.5 latch brush 13 4. Cleaning filter 13 5. Needle bed 14 6. Cam plate d...

Page 5: 1. Points To Observe

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 4 1. Points to observe ○ 1 installation environmental conditions please install the machine as below instructions in order to use this machine in the best condition for a long period of time. Do not install the machine ...

Page 6

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 5 ○ 2 fig.1.1 illustrates the correct position of jacking while moving the machine. It is very important when moving the machine. The yarn carrier rail shall never be used to push the machine since it will distort the r...

Page 7: 2. Installation

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 6 2. Installation ○ 1 after unpacking and locating the machine in the factory, it must be leveled carefully with a spirit-level to avoid machine distortion in running. We recommend the machine to be leveled with rubber ...

Page 8

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 7 where to clean interval cams inside carriage every 3 months filter in front cover of main motor every 8-12 hours filter in front cover of controller every 8-12 hours internal controller once a month.

Page 9

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 8 ※ oil lubrication where to clean interval open the cover of main motor to clean once a year open back side of controller to clean open once a year where to oil oil type interval carriage rail sae 10w-10 oil every 8-12...

Page 10

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 9 ○ 2 raise the yarn stand till the end of the tubes is leveled with the base plate, tighten the screws and connect the plug of stop motion situated at the left rear end. Where to oil oil type interval needle beds (fron...

Page 11: 3. Operation

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 10 inching starting 3. Operation 3.1 power switch as fig.3.1 front side of controller, easily find two switches. Flip upward is “on” and downward is “off”. Fig.3.1 front side of controller 3.2 operation bar 3.2.1 inchin...

Page 12

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 11 kau o heng 高亨 精機 3.3 yarn feeder the position of carrier is adjusted according to the desired knitting width, correctly make yarn feeder beside the end working needle by 10 ㎜ .The yarn feeder must be in the central p...

Page 13

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 12 3.4 top tension top tension springs should have the correct tension, the opening of the knot-catcher must be set according to the yarn count that is being knitted. Fig.3.5 top tension tension adjust dial knot catcher...

Page 14: 4. Clear Filter

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 13 3.5 the latch brush latch brush is important to prohibit the needle latch to close in knitting, the correct brush setting is illustrated in fig.3.6. Fig.3.6 correct position of brush 4. Clear filter filters are equip...

Page 15: 5. Needle Bed

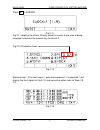

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 14 5. Needle bed 5.1 kh-323d-v2 needle bed kh-323d-v2 the structure of front and rear needle bed is the same with regular needle high butt and low butt. Fig.5.1 the structure of front & rear needle bed for the knitting ...

Page 16

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 15 5.2 kh-323dj&dtj&n-v2 needle bed the structure of the front and rear needle bed is the same. Kh-323dj&n-v2 is with regular needles high butt and low butt. Kh-323dtj-v2 is with transfer needles high butt and low butt....

Page 17: 6. Cam Plate Distance

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 16 stepped screw bearing pin 6. Cam plate distance the distance between cam plate and needle bed is maximum 0.1 ㎜ , fig.6.1 shows how to check and adjust. Please check it by every 3 months, loosen the stepped screw and ...

Page 18: 8. Fabric Take-Down System

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 17 press-off detector 8. Fabric take-down system in principle of the take-down tension strength must be small and average. The take-down system is controlled by torque motor. There are two important things to adjust the...

Page 19: 9. Racking Mechanism

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 18 left rear left front rea r n eed le bed 9. Racking mechanism ○ 1 the rear bed can be racked five ( 5 ) pitches, the initial position”0”. See the left selvedge of needle bed, the corresponding position that the first ...

Page 20

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 19 step p ed screw s r ig h t rear r ig h t fro n t ○ 5 if the corresponding position of needle bed is not proper, loosen the stepped screws and adjust the rear bed to correct position, then tighten the stepped screws a...

Page 21

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 20 10. Carriage combination and separation kh-323 series-v2 is equipped with two carriages, you can choose in use of combination or separation by yourself for different knitting production. Please operate combination or...

Page 22: Instruction Manual

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 21 0 9 8 7 6 5 4 3 2 1 + f4 f5 f3 f2 f1 instruction manual 0.Start 26 1.Edit 26 2.Run 31 3.File 40 4.Function 43 5.Test 45.

Page 23

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 22 kh-323d-v2 instruction explanation yarn carrier 0. None yarn carrier yarn carrier-1 : 1 ~ 6 ; yarn carrier-2 : 1 ~ 6 cam 0. Miss 1. Knit 2. Tuck 3. High butt knit 4. High butt knit low butt tuck 5. High butt tuck kni...

Page 24

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 23 kh-323dj-v2 instruction explanation yarn carrier 0. None yarn carrier yarn carrier-1 : 1 ~ 6 ; yarn carrier-2 : 1 ~ 6 cam 0. Miss 1. Knit 2. Tuck 3. High butt knit 4. High butt knit low butt tuck 5. High butt tuck 6....

Page 25

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 24 kh-323dtj-v2 instruction explanation yarn carrier 0. None yarn carrier yarn carrier-1 : 1 ~ 6 ; yarn carrier-2 : 1 ~ 6 cam 0. Miss 1. Knit 2. Tuck 3. High butt knit 4. High butt knit low butt tuck 5. High butt tuck 6...

Page 26

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 25 kh-323n-v2 instruction explanation yarn carrier 0. None yarn carrier yarn carrier-1 : 1 ~ 6 ; yarn carrier-2 : 1 ~ 6 cam 0. Miss 1. Knit 2. Tuck 3. High butt knit 4. High butt knit low butt tuck 5. High butt tuck 6. ...

Page 27: 0. Start

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 26 0. Start fig.0-1 when turning on the machine, it will appear this screen and display main menu after you press any key. When you switch on the machine, then it displays 【 memory error 】 or 【 file error 】 , you must s...

Page 28

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 27 1.1 open : open file press in edit menu, and then the screen displays as fig.1-2. Fig.1-2 remark : in screen there are five small squares, each one corresponds to ~ on keyboard, blank means out of function. For examp...

Page 29: Instruction Explanation

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 28 instruction explanation file : insert a file. Fig.1-5 insert file line : after current editing line inset a “ blank line ”, and the following lines are backward. Jump : this function is allowed jump to any line. If t...

Page 30

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 29 del : delete indicated lines. Fig.1-7 exit : press exit then the system will ask you to save this file, if it is not a new file, directly press sure to use the same file name to save. The screen displays as fig.1-9 ;...

Page 31

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 30 1.2 new : open file after you edit the first line, press to insert blank line and go on editing. Fig.1-11 1.3 yarn feed : quickly edit the working yarn carriers of any file. Fig.1-12 1.4 stitch : quickly edit the wor...

Page 32: 2. Run

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 31 2. Run fig.2-0 press ☉ enter run mode, if any of cam or stitch is error, it displays as fig.2-1. You should go to the test mode, correct it then come back to run mode. Fig.2-1 fig.2-2 enter fig.2-2, display will show...

Page 33: Error Message

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 32 error message after you finish inputting the instruction for the program that occurs incorrect action or wrong instruction to the function of machine, it will automatically appear error message on run mode. Error mes...

Page 34: Message Explanation

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 33 error message table message explanation speed over with racking in racking, the maximum of knitting speed is no.6 start needle error the number of start-needle must be smaller than the number of end-needle. End needl...

Page 35

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 34 file name : (912 set pcs : (9999 finished pcs : (0055 after finishing checking the system and confirming the program executive then the screen displays as fig.2-3. Fig.2-3 in fig.2-3, column 1 displays total ( total ...

Page 36

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 35 edit : fig.2-5 edit press in stitch fig.2-6 stitch fig.2-6 displays all the used stitch value of file. Directly move the cursor to the area of being changed, and press the numeric key to correct it. For example, in f...

Page 37

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 36 press in take down fig.2-8 take down fig.2-8 displays the entire used take down value of file. Directly move the cursor to the area of being changed, and press the numeric key to correct it. Press in repeat fig.2-9 r...

Page 38

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 37 press in shock fig.2-11 fig.2-11 displays the shock. Directly move the cursor to the area of being changed, and press the numeric key to correct it. Fig.2-12 production times fig.2-12 machine stop : if the fault sign...

Page 39

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 38 tab.2-3 machine stop signal & corrective action ten top check if yarn breakage, tension loose or yarn knot is occurred with top tension. If yes, please do the action to correct it. Sten l check if yarn breakage or ya...

Page 40

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 39 tab.2-4 machine stop signal & corrective action lmt l check if left limit sensor (kce2201), encoder or plastic in blue on connecting ring is damaged. If yes, please do the action to correct it. Lmt r check if right l...

Page 41: 3. File

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 40 3. File fig.3-1 3.1 disp : display select file location from ram or usb. Fig.3-2 fig.3-3 move cursor to select the displayed file name, and press sure the system will execute program once simultaneously, and display ...

Page 42

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 41 3.2 del : delete the input file name, and press for sure. Fig.3-5 3.3 copy : input source file name and target file name, and press for sure. Fig.3-6 3.4 trans : save file to usb floppy. Fig.3-7 3.5 read : load file ...

Page 43

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 42 3.6 clear : clear all files. Fig.3-9 fig.3-10 fig.3-11 enter code no : 555.

Page 44: 4. Function

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 43 4. Function fig.4-1 4.1 stitc : stitch parameters, directly adjust with numeric. ( machine has two sets of stitch parameters ; one is for separation system and the other is for combination system. ) fig.4-2 fig.4-3.

Page 45

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 44 4.2 buzz : setting buzzer function in action or not. Fig.4-4 4.3 mode : setting display mode in english and in chinese. Fig.4.5 4.4 system : setting left and right carriage system is open or not. Fig.4.6 2 1.

Page 46: 5. Test

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 45 5. Test fig.5-1 5.1 racking : fig.5-2 5.2 main motor : fig.5-3.

Page 47

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 46 5.3 in/out : signal. Test when they are switched on. There should be with a small dot appeared in the front. Fig.5-4 fig.5-5 l.Sys : left system r.Sys : right system stitch org : stitch origin cam pos : cam position ...

Page 48

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 47 5.4 cam : move cursor to make the cam or the yarn feeder solenoid in action. Fig.5-6 5.5 take down : setting the speed of fabric take-down then turning the operation bar to test. Fig.5-7 5.6 stitc : stitch. Setting t...

Page 49: 6. Operating Procedures

Kauo heng computerized flat knitting machine 6. Operating procedures kh-323 series – v2 operation manual 48 welcome to kauoheng system 1.Edit file not found! Open new file! File jump line del exit file name: save-file: renameor sure to save! File already exist! Resave this file? File isn't to save 1...

Page 50: Operating Procedures

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 49 operating procedures to: from: (del) to: (jump) course: file name: (file) run edit (912 org 1pcs (0055 exit (9999 del jump file 2.Run sure exit sure exit sure exit sure exit sure exit stitch org: cam pos: cam org: l....

Page 51: Operating Procedures

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 50 operating procedures 2.Run 3.Take down 5.Width 1.Stitch 4.Repeat 6.Shock 2.Speed exit 02:15 00 12 11 20 sure exit 30 __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ 1.Stit...

Page 52: Operating Procedures

Kauo heng computerized flat knitting machine kh-323 series – v2 operation manual 51 operating procedures 24349 bytes free 912 913 914 915 04 file 00483 bytes del-name: ram: usb: save to usb: load from usb: are you sure? Please input password:555 3.File 1.Disp 2.Del 3.Copy 4.Trans 5.Read 6.Clear sure...

Page 53: Operating Procedures

Kauo heng computerized flat knitting machine operating procedures 4.System 2.Buzz 3.Mode 1.Stitc 6.Stitch 4.Cam 2.Main motor 5.Take down 3.In/out 1.Racking sure exit sure exit sure exit sure exit next exit sure exit sure exit sure exit 5. 4. 2.English 1.中文 3. Sure exit stitch org: cam pos: cam org: ...

Page 55

高 亨 精 機 工 業 有 限 公 司 kauo heng precision machinery industrial co., ltd. 台灣省台北縣板橋市和平路 14 巷 20 號 address : no. 20, lane 14, ho ping road, panchiao, taipei, taiwan tel : + 886-2-29559258 fax : + 886-2-29629153 http : // www.Kauoheng.Com.Tw e-mail : kauoheng@ms58.Hinet.Net.