- DL manuals

- Kawasaki

- Other

- ER-5 - SERVICE

- Service Manual

Kawasaki ER-5 - SERVICE Service Manual

Summary of ER-5 - SERVICE

Page 3: Quick Reference Guide

This quick reference guide will assist you in locating a desired topic or pro- cedure. •bend the pages back to match the black tab of the desired chapter num- ber with the black tab on the edge at each table of contents page. •refer to the sectional table of contents for the exact pages to locate th...

Page 5: Er-5

Er-5 motorcycle service manual all rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of quality assurance departme...

Page 6

List of abbreviations a ampere(s) lb pound(s) abdc after bottom dead center m meter(s) ac alternating current min minute(s) atdc after top dead center n newton(s) bbdc before bottom dead center pa pascal(s) bdc bottom dead center ps horsepower btdc before top dead center psi pound(s) per square inch...

Page 7

Emission control information to protect the environment in which we all live, kawasaki has incorporated crankcase emis- sion (1) and exhaust emission (2) control systems in compliance with applicable regulations of the united states environmental protection agency and california air resources board....

Page 8

Tampering with noise control system prohibited federal law prohibits the following acts or the causing thereof: (1) the removal or rendering inoperative by any person other than for purposes of maintenance, repair, or replacement, of any device or element of design incorporated into any new vehicle ...

Page 9: Foreword

Foreword this manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic in- formation to make it useful to the owner who de- sires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the prope...

Page 11: General Information

General information 1-1 1 general information table of contents before servicing ..................................................................................................................... 1-2 model identification................................................................................

Page 12

1-2 general information before servicing before starting to perform an inspection service or carry out a disassembly and reassembly opera- tion on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustra- tions, photographs, cautions, and detailed descriptions...

Page 13

General information 1-3 before servicing (10)liquid gasket, locking agent clean and prepare surfaces where liquid gasket or non-permanent locking agent will be used. Apply them sparingly. Excessive amount may block engine oil passages and cause serious dam- age. (11)press when using a press or drive...

Page 14

1-4 general information before servicing two-color electrical (19)inspection when parts have been disassembled, visually inspect these parts for the following conditions or other damage. If there is any doubt as to the condition of them, replace them with new ones. Abrasion crack hardening warp bent...

Page 15

General information 1-5 model identification er500-c1, d1 left side view er500-c1, d1 right side view.

Page 16

1-6 general information general specifications items en500-c1 ∼ c2 en500-c3 ∼ en500-d1 dimensions overall length 2 070 mm (81.5 in.) ← ← overall width 730 mm (28.74 in.) ← ← overall height 1 070 mm (42.13 in.) ← ← wheelbase 1 430 mm (56.3 in.) ← ← road clearance 125 mm (4.92 in.) ← ← seat height 800...

Page 17

General information 1-7 general specifications items en500-c1 ∼ c2 en500-c3 ∼ en500-d1 lubrication system forced lubrication ← ← engine oil: grade api se, sf, sg or api sh or sj with jaso ma ← ← viscosity sae10w-40 ← ← capacity 3.4 l (3.6 us at) ← ← drive train primary reduction system: type chain ←...

Page 18

1-8 general information general specifications items en500-c1 ∼ c2 en500-c3 ∼ en500-d1 electrical equipment battery 12 v 10 ah ← ← headlight: type semi-sealed beam ← ← bulb 12 v 60/55 w (quartz-halogen) ← ← tail/brake light 12 v 5/21 w × 2 ← ← alternator: type three-phase ac ← ← rated output 17 a × ...

Page 19

General information 1-9 periodic maintenance chart the scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running condition. The initial maintenance is vitally important and must not be neglected. Frequency whichever comes first * odometer reading × 1 000...

Page 20

1-10 general information periodic maintenance chart frequency whichever comes first * odometer reading × 1 000 km (× 1 000 mile) 1 6 12 18 24 30 36 inspection every (0.6) (4) (7.5) (12) (15) (20) (24) remarks engine oil - change # year • • • • • • • oil filter - replace • • • • brake fluid - change ...

Page 21

General information 1-11 torque and locking agent tighten all bolts and nuts to the proper torque using an accurate torque wrench. An insufficiently tightened bolt or nut may become damaged or fall off, possibly resulting in damage to the motorcycle and injury to the rider. A bolt or nut which is ov...

Page 22

1-12 general information torque and locking agent torque fastener n·m kgf·m ft·lb remarks water pipe bolts 9.8 1.0 87 in·lb l cylinder head jacket plug 9.8 1.0 87 in·lb l air suction valve cover bolts 11 1.1 95 in·lb coolant drain plug 11 1.1 95 in·lb engine top end spark plugs 14 1.4 10 cylinder he...

Page 23

General information 1-13 torque and locking agent torque fastener n·m kgf·m ft·lb remarks engine oil drain plug 29 3.0 22 oil pan mounting bolts 11 1.1 95 in·lb oil pump mounting bolts 11 1.1 95 in·lb breather body bolt 5.9 0.6 52 in·lb engine removal/installation downtube bolts 44 4.5 33 engine mou...

Page 24

1-14 general information torque and locking agent torque fastener n·m kgf·m ft·lb remarks front brake light switch mounting screw 1.2 0.12 10 in·lb caliper mounting bolts 34 3.5 25 caliper bleed valves 7.8 0.8 69 in·lb brake disc mounting bolts 27 2.8 20 l brake pedal bolt 8.8 0.9 78 in·lb torque li...

Page 25

General information 1-15 torque and locking agent torque fastener n·m kgf·m ft·lb remarks starter clutch allen bolts 34 3.5 25 l sidestand switch mounting screw 3.9 0.4 35 in·lb l sidestand mounting bolt 44 4.5 33 starter motor terminal locknut 6.9 0.70 61 in·lb starter relay terminal bolt 4.9 0.50 ...

Page 26

1-16 general information special tools and sealants piston ring pliers: 57001-115 oil pressure gauge, 5 kgf/cm²: 57001-125 bearing puller: 57001-135 bearing puller adapter: 57001-136 steering stem bearing driver: 57001-137 inside circlip pliers: 57001-143 outside circlip pliers: 57001-144 bearing pu...

Page 27

General information 1-17 special tools and sealants valve spring compressor assembly: 57001-241 bearing puller adapter: 57001-317 bearing driver, 32: 57001-382 piston pin puller assembly: 57001-910 fuel level gauge: 57001-1017 valve guide arbor, 5.5: 57001-1021 spark plug wrench, hex 18: 57001-1024 ...

Page 28

1-18 general information special tools and sealants bead breaker assembly: 57001-1072 steering stem bearing driver adapter, 34.5: 57001-1074 head pipe outer race press shaft: 57001-1075 head pipe outer race driver, 51.5: 57001-1076 valve guide reamer, 5.5: 57001-1079 piston ring compressor grip: 570...

Page 29

General information 1-19 special tools and sealants valve seat cutter, 32° - 25: 57001-1118 valve seat cutter, 32° - 30: 57001-1120 valve seat cutter, 60° - 30: 57001-1123 valve seat cutter holder, 5.5: 57001-1125 valve seat cutter holder bar: 57001-1128 bearing driver set: 57001-1129 compression ga...

Page 30

1-20 general information special tools and sealants rotor puller, m16/m18/m20/m22 × 1.5: 57001-1216 fork outer tube weight: 57001-1218 front fork oil seal driver: 57001-1219 jack: 57001-1238 timing light: 57001-1241 clutch holder: 57001-1243 oil filter wrench: 57001-1249 bearing remover head, 15 × 1...

Page 31

General information 1-21 special tools and sealants valve seat cutter, 60° - 25: 57001-1328 pilot screw adjuster adapter, 5: 57001-1372 pilot screw adjuster driver: 57001-1373 bearing remover shaft, 13: 57001-1377 igniter checker assembly: 57001-1378 harness adapter #1: 57001-1381 hand tester: 57001...

Page 32

1-22 general information special tools and sealants kawasaki bond (silicone sealant): 56019-120 kawasaki bond (liquid gasket - black) tb1105: 92104-1003.

Page 33

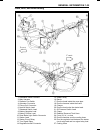

General information 1-23 cable, wire, and hose routing 1. Vacuum hose 2. Air hose 3. Fuel hose 4. Throttle and choke cables 5. Fuel filters 6. Fuel tap 7. To the air suction valve. 8. To the vacuum switch valve. 9. Clamp 10. To the fuel tap. 11. To the left carburetor. 12. To the right carburetor..

Page 34

1-24 general information cable, wire, and hose routing 1. Throttle cables 2. Choke cable 3. Right handlebar switch leads 4. Horn 5. Clutch cable 6. Left handlebar switch leads 7. Brake hose 8. Speedometer cable 9. Run the cables outside. 10. Run the clutch cable inside the cross pipe. 11. Bands 12. ...

Page 35

General information 1-25 cable, wire, and hose routing 1. Handlebar switch harness 2. Main harness 3. Radiator fan switch 4. Alternator connector 5. Pickup coil connector 6. Neutral switch lead 7. Sidestand switch lead 8. Battery negative lead 9. Battery positive lead 10. Rear brake light switch con...

Page 36

1-26 general information cable, wire, and hose routing 1. Radiator 2. Thermostat housing 3. Coolant filter 4. Carburetor 5. Reserve tank 6. Coolant valve 7. Reserve tank overflow hose 8. Air cleaner drain hose 9. Cross pipe 10. Damper 11. Radiator cover 12. Face the white mark upward and to the radi...

Page 37

General information 1-27 cable, wire, and hose routing 1. Reserve tank 2. Reserve tank overflow hose 3. Clamps.

Page 38

1-28 general information cable, wire, and hose routing 1. Starter motor 2. Positive lead 3. Negative lead 4. Plate 5. Pickup coil 6. Pickup coil mounting bolts 7. Tighten the starter motor negative lead terminal with the rear starter mounting bolt. 8. To the battery negative terminal. 9. To the star...

Page 39

General information 1-29 cable, wire, and hose routing 1. #1 ignition coil connectors 2. Radiator fan switch connector 3. Left handlebar switch connectors 4. Water temperature switch ground termi- nal 5. Water temperature switch 6. Battery negative lead 7. Igniter connectors 8. #2 ignition coil conn...

Page 40

1-30 general information cable, wire, and hose routing 1. Fuel tank 2. Fuel tank upper drain hose 3. Catch tank 4. Reserve tank hose 5. Main harness 6. Fuel tank lower drain hose 7. Plug 8. Reserve tank overflow hose 9. Air cleaner drain hose 10. Bind the edge of the hose bend 11. About 70 mm 12. Fr...

Page 41: Fuel System

Fuel system 2-1 2 fuel system table of contents exploded view........................................................................................................................ 2-2 specifications ......................................................................................................

Page 42

2-2 fuel system exploded view 1. Throttle cable (accelerator) 2. Throttle cable (decelerator) 3. Choke cable 4. Pilot screw 5. Pilot (slow) jet 6. Needle jet 7. Needle jet holder 8. Main jet 9. Jet needle cl: apply cable lubricant. G: apply grease..

Page 43

Fuel system 2-3 exploded view 1. Vacuum switch valve 2. Air cleaner housing 3. Air cleaner element t1: 0.8 n·m (0.08 kgf·m, 7 in·lb) t2: 1.0 n·m (0.10 kgf·m, 9 in·lb) t3: 6.9 n·m (0.7 kgf·m, 61 in·lb) t4: 2.5 n·m (0.25 kgf·m, 22 in·lb).

Page 44

2-4 fuel system specifications item standard throttle grip free play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) choke cable free play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) carburetors mark, type keihin cvk34 idle speed 1 200 ±50 r/min (rpm) pilot screw (turns out) (1 1/4 ±1/4 for reference) synchronization vacuum 2.7 kpa (2 c...

Page 45

Fuel system 2-5 throttle grip and cables throttle cable inspection throttle grip free play inspection • check throttle grip play [a] by lightly turning the throttle grip back and forth. If the free play is improper, adjust the throttle cable. Throttle grip free play standard: 2 ∼ 3 mm (0.08 ∼ 0.12 i...

Page 46

2-6 fuel system throttle grip and cables • check that the throttle pulley [a] stops against the idle adjusting screw [b], with the throttle grip released and stops against the carburetor stopper with the throttle grip opened. • turn the handlebar from side to side while idling the en- gine. If idle ...

Page 47

Fuel system 2-7 choke cable free play inspection • push the choke lever [a] all the way to the front. • check choke cable free play [b]. ○ determine the amount of choke cable play at the choke lever. Pull the choke lever until the starter plunger lever [c] at the carburetor touches the starter plung...

Page 48

2-8 fuel system carburetors idle speed inspection idle speed inspection • start the engine and warm it up thoroughly. • with the engine idling, turn the handlebar to both sides. If handlebar movement changes the idle speed, the throt- tle cable may be improperly adjusted or incorrectly routed, or it...

Page 49

Fuel system 2-9 carburetors carburetor removal warning gasoline is extremely flammable and can be ex- plosive under certain conditions. Turn the ignition switch off. Do not smoke. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a pi...

Page 50

2-10 fuel system carburetors • install the holder clamps [a] as shown being careful of the screw position and the screw head [b] direction. Warning install the clamp screws horizontally as shown. Otherwise the screws could come in contact with the vacuum adjusting screws, resulting in an un- safe ri...

Page 51

Fuel system 2-11 carburetors • connect fuel level gauge [a] to the rubber hose. Special tool - fuel level gauge: 57001-1017 • hold the gauge vertically against the side of the carburetor body so that the "middle" line [b] is several millimeters higher than the bottom edge [d] of the carburetor body....

Page 52

2-12 fuel system carburetors • bend the tang [a] on the float arm very slightly to change the float height. Increasing the float height lowers the fuel level and decreasing the float height raises the fuel level. Float height 17.0 ±2.0 mm (0.67 ±0.08 in.) note ○ do not push the needle rod [a] in dur...

Page 53

Fuel system 2-13 carburetors • turn in the pilot screw and count the number of turns until it seats fully but not tightly, and then remove the screw. This is to set the screw to its original position when as- sembling. • after installing the upper chamber cover, check that the vacuum piston slides u...

Page 54

2-14 fuel system carburetors • slip the jet needle through the hole in the center of the vacuum piston, and put the spring seat [a] on the top of the needle. Turn the seat so that it does not block the hole [b] at the bottom of the vacuum piston. Carburetor separation/assembly • read the warnings in...

Page 55

Fuel system 2-15 carburetors caution do not use compressed air on an assembled car- buretor, or the floats may be crushed by the pres- sure, and the vacuum piston diaphragms may be damaged. Remove as many rubber or plastic parts from the carburetor as possible before cleaning the carburetor with a c...

Page 56

2-16 fuel system carburetors • disassemble the carburetors. • clean the carburetors. • check that the o-rings on the float bowl and drain plug and the diaphragm on the vacuum piston are in good con- dition. If any of the o-rings or diaphragms are not in good con- dition, replace them. • check the pl...

Page 57

Fuel system 2-17 air cleaner element removal • remove: left side cover (see frame chapter) screws [a] nut [b] inlet pipe [c] • remove the element [a]. • push a clean, lint-free towel into the carburetor intake to keep dirt or other foreign material from entering. Warning if dirt or dust is allowed t...

Page 58

2-18 fuel system air cleaner air cleaner draining a drain hose [a] is provided beneath the air cleaner hos- ing, and catches the water or oil from the bottom of the hose. Usually water or oil does not collect at the bottom of the hose. In the event that rain water is drawn in through the air cleaner...

Page 59

Fuel system 2-19 fuel tank fuel tank removal warning gasoline is extremely flammable and can be ex- plosive under certain conditions. Turn the ignition switch off. Do not smoke. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a pilo...

Page 60

2-20 fuel system fuel tank • remove the fuel tank [a]. • drain the fuel tank. ○ place a suitable container under the fuel tank. ○ turn the fuel tap to the pri position to drain the fuel into the container. Fuel tank installation • read the warning in the fuel tank removal section. • check the rubber...

Page 61

Fuel system 2-21 fuel tank fuel tank and tap cleaning • remove the fuel tank and drain it. • pour some high flash-point solvent into the fuel tank and shake the tank to remove dirt and fuel deposits. Warning clean the tank in a well-ventilated area, and take care that there are no sparks or flame an...

Page 62

2-22 fuel system fuel hose fuel hose and connection inspection ○ check the fuel hose periodically in accordance with the periodic maintenance chart, and if the motorcycle is not properly handled, the inside the fuel line can cause fuel to leak [a] or the hose to burst. Remove the fuel tank and check...

Page 63: Cooling System

Cooling system 3-1 3 cooling system table of contents exploded view........................................................................................................................ 3-2 specifications ................................................................................................

Page 64

3-2 cooling system exploded view 1. Radiator fan switch 2. Water temperature switch 3. Thermostat 4. Coolant drain plug t1: 2.5 n·m (0.25 kgf·m, 22 in·lb) t2: 7.8 n·m (0.8 kgf·m, 69 in·lb) t3: 11 n·m (1.1 kgf·m, 95 in·lb) t4: 9.8 n·m (1.0 kgf·m, 7.0 ft·lb) t5: 18 n·m (1.8 kgf·m, 13.0 ft·lb) t6: 25 n...

Page 65

Cooling system 3-3 specifications item standard coolant provided when shipping type (recommended) permanent type antifreeze (soft water and ethylene glycol plus corrosion and rust inhibitor chemicals for aluminum engines and radiators) color green mixed ratio soft water 50%, coolant 50% freezing poi...

Page 66

3-4 cooling system coolant flow chart permanent type antifreeze is used as a coolant to protect the cooling system from rust and corrosion. When the engine starts, the water pump turns and the coolant circulates. The thermostat is a wax pellet type which opens or closes with coolant temperature chan...

Page 67

Cooling system 3-5 coolant coolant deterioration inspection • visually inspect the coolant in the reservoir tank. ○ if whitish cotton-like wafts are observed, aluminum parts in the cooling system are corroded. If the coolant is brown, iron or steel parts are rusting. In either case flush the cooling...

Page 68

3-6 cooling system coolant coolant filling • install the drain plug [a]. Always replace the gasket with a new one, if it is damaged. • tighten the drain plug. Torque - coolant drain plug: 11 n·m (1.1 kgf·m, 95 in·lb) • fill [a] the radiator up to the bottom of the radiator filler neck [b] with coola...

Page 69

Cooling system 3-7 coolant • remove the reserve tank cap. • fill the reserve tank up to the f level [a] with coolant and install the cap. Caution do not add more coolant above the f level. • install the fuel tank. • install the seat. Visual leak inspection any time the system slowly loses water, ins...

Page 70

3-8 cooling system coolant flushing over a period of time, the cooling system accumulates rust, scale, and lime in the water jacket and radiator. When this accumulation is suspected or observed, flush the cool- ing system. If this accumulation is not removed, it will clog up the water passages and c...

Page 71

Cooling system 3-9 water pump water pump removal • drain the coolant. • loosen the clamp and remove the radiator hose [a] from the water pump cover [b]. • remove the four cover bolts [c]. • with the water pipe [d] attached, remove the water pump cover. • install the right footpeg assembly. Note ○ th...

Page 72

3-10 cooling system water pump • be sure to install the water pipe o-rings [a], and apply high temperature grease to them. • install the water pump cover with the water pipe, being careful of the two knock pins [b]. Torque - water pump cover bolts: 11 n·m (1.1 kgf·m, 95 in·lb) mechanical seal inspec...

Page 73

Cooling system 3-11 water pump impeller assembly • clean the sliding surface of the mechanical seal with a high flash-point solvent, and apply a little coolant to the sliding surface to give the mechanical seal initial lubrica- tion. • apply coolant to the surfaces of the rubber seal [a] and sealing...

Page 74

3-12 cooling system radiator, radiator fan warning the radiator fan is connected directly to the bat- tery. The radiator fan may start even if the ignition switch is off. Never touch the radiator fan until the radiator fan connector is dis- connected. Touching the fan before the connector is disconn...

Page 75

Cooling system 3-13 radiator, radiator fan caution when cleaning the radiator with steam cleaner, be careful of the following to prevent radiator damage. 1) keep the steam gun [a] away more than 0.5 m (20 in.) [b] from the radiator core. 2) hold the steam gun perpendicular to the core sur- face. 3) ...

Page 76

3-14 cooling system radiator, radiator fan radiator hose and connection inspection ○ the high pressure inside the radiator hose can cause coolant to leak [a] or the hose to burst if the line is not properly maintained. Visually inspect the hoses for signs of deterioration. Squeeze the hoses. A hose ...

Page 77

Cooling system 3-15 thermostat thermostat removal • remove: coolant (draining) seat (see frame chapter) fuel tank (see fuel system chapter) • unscrew the thermostat housing bolts [a]. • separate the housing from the housing cover [b]. • pull out the thermostat [a]. Thermostat installation • install ...

Page 78

3-16 cooling system radiator fan switch, water temperature switch caution the fan switch or the water temperature switch should never be allowed to fall on a hard surface. Such a shock to these parts can damage them. Radiator fan switch removal • pull out the cover [a]. • disconnect the fan switch c...

Page 79: Engine Top End

Engine top end 4-1 4 engine top end table of contents exploded view................................... 4-2 specifications .................................... 4-4 clean air system............................... 4-6 vacuum switch valve removal ... 4-6 vacuum switch valve installation 4-6 air suction ...

Page 80

4-2 engine top end exploded view 1. Closed coil end faces downward. 2. Arrow points to the front (er500-c1 ∼ c4). Install the piston so that the circle mark on the top of the piston come to front side of the engine (er500-c5). 3. “n” marked side faces up. L: apply a non-permanent locking agent. M: a...

Page 81

Engine top end 4-3 exploded view t1: 13 n·m (1.3 kgf·m, 9.5 ft·lb) t2: 9.8 n·m (1.0 kgf·m, 87 in·lb) t3: 11 n·m (1.1 kgf·m, 95 in·lb) t4: 12 n·m (1.2 kgf·m, 8.5 ft·lb) t5: 15 n·m (1.5 kgf·m, 11.0 ft·lb) t6: 20 n·m (2.0 kgf·m, 14.5 ft·lb) t7: 25 n·m (2.5 kgf·m, 18.0 ft·lb) t8: 39 n·m (4.0 kgf·m, 29 f...

Page 82

4-4 engine top end specifications item standard service limit clean air system vacuum switch valve closing pressure open → close 57 ∼ 65 kpa (430 ∼ 490 mmhg) – – – camshafts cam height: exhaust 35.475 ∼ 35.591 mm (1.3967 ∼ 1.4012 in.) 35.38 mm (1.3929 in.) inlet 35.474 ∼ 35.590 mm (1.3966 ∼ 1.4012 i...

Page 83

Engine top end 4-5 specifications item standard service limit outside diameter: exhaust 24.0 ∼ 24.2 mm (0.945 ∼ 0.953 in.) – – – inlet 28.3 ∼ 28.5 mm (1.114 ∼ 1.122 in.) – – – valve spring free length: inner 36.3 mm (1.429 in.) 35 mm (1.3780 in.) outer 40.4 mm (1.591 in.) 39 mm (1.5354 in.) cylinder...

Page 84

4-6 engine top end clean air system vacuum switch valve removal • remove: fuel tank (see fuel system chapter) • remove the clamps [a] and take off the vacuum switch valve [b]. Vacuum switch valve installation • install the vacuum switch valve so that the air hole [a] faces downwards. Air suction val...

Page 85

Engine top end 4-7 clean air system clean air system hose inspection • be certain that all the hoses are routed without being flat- tened or kinked, and are connected correctly to the air cleaner housing, silencer, vacuum switch valve, carbure- tors, and air suction valve covers. If they are not, co...

Page 86

4-8 engine top end cylinder head cover cylinder head cover removal • drain the coolant (see cooling system chapter). • remove: fuel tank (see fuel system chapter) choke cable lower end [a] throttle cable lower ends [b] spark plug caps [c] vacuum switch valve [d] thermostat housing [e] • unscrew the ...

Page 87

Engine top end 4-9 camshaft chain tensioner camshaft chain tensioner removal caution this is a non-return type cam chain tensioner. The push rod does not return to its original position once it moves out to take up cam chain slack. Ob- serve all the rules listed below: when removing the tensioner, d...

Page 88

4-10 engine top end camshaft, camshaft chain camshaft removal • remove the cylinder head cover. • position the crankshaft at #2 piston tdc. ○ using a wrench on the crankshaft rotation bolt turn the crankshaft clockwise until the "c" mark line [a] on the rotor is aligned with the notch [b] in the edg...

Page 89

Engine top end 4-11 camshaft, camshaft chain • engage the camshaft chain with the camshaft sprockets. ○ pull the tension side [a] (inlet side) of the chain taut to install the chain. ○ the timing marks [b] on the inlet sprocket [c] must be aligned with the cylinder head upper surface [d]. • pull the...

Page 90

4-12 engine top end camshaft, camshaft chain camshaft, camshaft cap wear the journal wear is measured using plastigage (press gauge), which is inserted into the clearance to be mea- sured. The plastigage indicates the clearance by the amount it is compressed and widened when the parts are assembled....

Page 91

Engine top end 4-13 rocker shaft, rocker arm rocker shaft, rocker arm removal • remove the camshafts (see camshaft removal). • unscrew the rocker shafts [a] and remove the rocker arms [b] and springs [c]. ○ mark and record the rocker arm locations so that the rocker arm can be reinstalled in their o...

Page 92

4-14 engine top end oil pipe cylinder head oil pipe removal • remove the oil pipe mounting bolts [a] and pull the oil pipes [b] and o-rings out of the cylinder head. Cylinder head oil pipe installation • flush out the oil pipes with a high flash-point solvent. • check that the o-rings are in good co...

Page 93

Engine top end 4-15 cylinder head compression measurement • remove the seat (see frame chapter). • thoroughly warm up the engine so that the engine oil be- tween the piston and cylinder wall will help seal compres- sion as it does during normal running. • stop the engine, remove the fuel tank, ignit...

Page 94

4-16 engine top end cylinder head cylinder head removal • remove: cylinder head cover (see cylinder head cover re- moval) exhaust pipes and mufflers (see crankshaft/transmis- sion chapter) cam chain tensioner (see chain tensioner removal) camshafts (see camshaft removal) carburetors (see fuel system...

Page 95

Engine top end 4-17 cylinder head • install a new cylinder head gasket with "up" [a] marked side positioning to the right. Note ○ the camshaft caps are machined with the cylinder head so if a new cylinder head is installed, use the caps that are supplied with the new head. • tighten the 10 mm cylind...

Page 96

4-18 engine top end cylinder head • using compressed air, blow out any particles which may obstruct the oil passage [a] in the cylinder head. • install the valves (see valve installation)..

Page 97

Engine top end 4-19 valves valve clearance inspection valve clearance inspection note ○ valve clearance must be checked and adjusted when the engine is cold (room temperature). • remove the cylinder head cover (see cylinder head cover removal). • remove the cylinder head oil pipes (see cylinder head...

Page 98

4-20 engine top end valves • measure the clearance of each valve by inserting a thick- ness gauge [a] between the adjusting screw [b] and the valve stem. Valve clearance (when cold) inlet 0.13 ∼ 0.18 mm (0.0051 ∼ 0.0071 in.) exhaust 0.18 ∼ 0.23 mm (0.0070 ∼ 0.0090 in.) valve clearance adjustment if ...

Page 99

Engine top end 4-21 valves valve guide removal • remove: valve (see valve removal) oil seal spring seats • heat the area around the valve guide to about 120 ∼ 150°c (248 ∼ 302°f), and hammer lightly on the valve guide arbor [a] to remove the guide from the top of the head. Special tool - valve guide...

Page 100

4-22 engine top end valves if the width is too wide, too narrow or uneven, repair the seat (see valve seat repair). [f] good [g] too wide [h] too narrow [j] uneven valve seating surface width inlet 0.5 ∼ 1.0 mm (0.020 ∼ 0.039 in.) exhaust 0.5 ∼ 1.0 mm (0.020 ∼ 0.039 in.) measuring valve-to-guide cle...

Page 101

Engine top end 4-23 valves seat cutter operating cares 1. This valve seat cutter is developed to grind the valve for repair. Therefore the cutter must not be used for other purposes than seat repair. 2. Do not drop or shock the valve seat cutter, or the dia- mond particles may fall off. 3. Do not fa...

Page 102

4-24 engine top end valves • measure the outside diameter (o.D.) of the seating sur- face with a vernier caliper. If the outside diameter of the seating surface is too small, repeat the 45° grind [a] until the diameter is within the specified range. Original seating surface [b] note ○ remove all pit...

Page 103

Engine top end 4-25 valves • lap the valve to the seat, once the seat width and o.D. Are within the ranges specified above. ○ put a little coarse grinding compound on the face of the valve in a number of places around the valve head. ○ spin the valve against the seat until the grinding com- pound pr...

Page 104

4-26 engine top end valves.

Page 105

Engine top end 4-27 cylinder, piston cylinder removal • remove the cylinder head (see cylinder head removal). • remove the main oil pipe mounting bolt. • remove the bolts [a] and pull out the water pipe with wa- ter pump cover [b] (see cooling system chapter). • take out the cylinder block so as not...

Page 106

4-28 engine top end cylinder, piston piston installation • install the oil ring expander [a] in the piston oil ring groove so that the expander ends [b] butt together, never overlap. • install the upper and lower steel rails. There is no up or down to the rails. They can be installed either way. • d...

Page 107

Engine top end 4-29 cylinder, piston piston ring, piston ring groove wear • check for uneven groove wear by inspecting the ring seat- ing. The rings should fit perfectly parallel to the groove sur- faces. If not, the piston must be replaced. • with the piston rings in their grooves, make several mea...

Page 108

4-30 engine top end cylinder, piston piston diameter • measure the outside diameter [a] of each piston 5 mm [b] up from the bottom of the piston at a right angle to the direction of the piston pin. If the measurement is under the service limit, replace the piston. Piston diameter standard: 73.942 ∼ ...

Page 109

Engine top end 4-31 carburetor holder carburetor holder installation • install the carburetor holders. The projection [a] faces upwards. • install the holder clamps [a] as shown being careful of the screw position and the screw head [b] direction. Warning install the clamp screws horizontally. Other...

Page 110

4-32 engine top end muffler muffler removal • unscrew the muffler mounting bolt and nut [a]. • remove the exhaust pipe holder nuts [a]. • take off the muffler [a]. Muffler installation • replace the exhaust pipe holder gaskets with new ones. • first, all the bolts and nuts to a snag fit. • secondary...

Page 111: Clutch

Clutch 5-1 5 clutch table of contents exploded view........................................................................................................................ 5-2 specifications ................................................................................................................

Page 112

5-2 clutch exploded view 1. Starter lockout switch cl: apply cable lubricant. G: apply high temperature grease. M: apply molybdenum disulfide grease. O: apply engine oil. Ss: apply silicone sealant..

Page 113

Clutch 5-3 exploded view t1: 1.5 n·m (0.15 kgf·m, 13 in·lb) t2: 9.3 n·m (0.95 kgf·m, 82 in·lb) t3: 11 n·m (1.1 kgf·m, 95 in·lb) t4: 132 n·m (13.5 kgf·m, 98 ft·lb).

Page 114

5-4 clutch specifications item standard service limit clutch lever position non-adjustable – – – clutch lever free play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) – – – clutch friction plate thickness 2.9 ∼ 3.1 mm (0.114 ∼ 0.122 in.) 2.75 mm (0.1082 in.) friction and steel plate warp 0.2 mm (0.008 in.) or less 0.3 ...

Page 115

Clutch 5-5 clutch lever and cable due to friction plate wear and clutch cable stretch over a long period of use, the clutch must be adjusted in accor- dance with the periodic maintenance chart. Warning to avoid a serious burn, never touch the engine or exhaust pipe during clutch adjustment. Clutch a...

Page 116

5-6 clutch clutch lever and cable cable lubrication whenever the clutch cable is removed, lubricate the clutch cable as follows. • apply a thin coating of grease to the cable upper and lower ends. • lubricate the cable with a penetrating rust inhibitor..

Page 117

Clutch 5-7 right engine cover clutch cover removal • drain the engine oil (see engine lubrication system chapter). • remove: clutch cable right footpeg assembly clutch cover bolts [a] • turn the release lever [b] toward the front as shown, and remove the clutch cover. Clutch cover installation • app...

Page 118

5-8 clutch right engine cover • free the clutch inner cable tip from the clutch release lever [a]. • turn the release lever toward the rear [b] as shown in the figure. • pull the lever and shaft assembly out of the clutch cover. Clutch release installation caution always install a new oil seal when ...

Page 119

Clutch 5-9 clutch clutch removal • drain the engine oil (see engine lubrication system chapter). • remove the clutch cover (see clutch cover removal). • remove the clutch spring bolts [a], washers [b] and springs. • remove the clutch spring plate [c] with the thrust ball bearing [d] and pusher [e]. ...

Page 120

5-10 clutch clutch ○ the grooves [a] on the friction plate surfaces are cut tan- gentially and radially, install the friction plates so that the grooves run toward the center in the direction of the clutch housing rotation (counterclockwise viewed from the en- gine right side). Caution if new dry st...

Page 121

Clutch 5-11 clutch clutch spring free length measurement • measure the free length of the clutch spring [a]. If any spring is shorter than the service limit, it must be replaced. Clutch spring free length standard: 34.2 mm (1.346 in.) service limit: 33.1 mm (1.303 in.) clutch housing finger inspecti...

Page 123: Engine Lubrication System

Engine lubrication system 6-1 6 engine lubrication system table of contents exploded view........................................................................................................................ 6-2 engine oil flow chart....................................................................

Page 124

6-2 engine lubrication system exploded view 1. Oil filter 2. Main oil passage plug 3. Oil pump drive gear 4. Oil pump 5. Oil screen 6. Oil pressure relief valve 7. Oil pressure switch 8. Engine oil drain plug.

Page 125

Engine lubrication system 6-3 exploded view t1: 1.5 n·m (0.15 kgf·m, 13 in·lb) t2: 7.8 n·m (0.80 kgf·m, 69 in·lb) t3: 11 n·m (1.1 kgf·m, 95 in·lb) t4: 12 n·m (1.2 kgf·m, 8.5 ft·lb) t5: 15 n·m (1.5 kgf·m, 11.0 ft·lb) t6: 17 n·m (1.75 kgf·m, 12.5 ft·lb) t7: 18 n·m (1.8 kgf·m, 13 ft·lb) t8: 20 n·m (2.0...

Page 126

6-4 engine lubrication system engine oil flow chart.

Page 127

Engine lubrication system 6-5 specifications item standard engine oil grade api se, sf, sg or api sh or sj jaso ma viscosity sae 10w-40 capacity 2.8 l (when filter is not removed) 3.0 l (when filter is removed) 3.4 l (when engine is completely dry) level between upper and lower level lines oil press...

Page 128

6-6 engine lubrication system engine oil and oil filter warning motorcycle operation with insufficient, deteri- orated, or contaminated engine oil will cause accelerated wear and may result in engine or trans- mission seizure, accident, and injury. Engine oil level inspection • if the oil has just b...

Page 129

Engine lubrication system 6-7 engine oil and oil filter • fill the engine with a good quality motor oil specified in the table. • check the oil level. Engine oil grade: api se, sf, sg or api sh or sj with jaso ma viscosity: sae 10w40 capacity: 2.8 l (when filter is not removed) 3.0 l (when filter is...

Page 130

6-8 engine lubrication system oil pan and relief valve oil pan removal • drain the engine oil (see engine oil change). • disconnect the oil pressure switch lead. • remove the oil pan mounting bolts [a] and the oil pan from the crankcase. Oil pan installation • check that the o-rings for the outlet s...

Page 131

Engine lubrication system 6-9 oil pan and relief valve relief valve inspection • remove the relief valve. • check to see if the steel ball inside the valve slides smoothly when pushing it in with a wooden or other soft rod, and see if it comes back to its seat by valve spring pressure. Note ○ inspec...

Page 132

6-10 engine lubrication system oil pump oil pump removal • drain the coolant (see cooling system chapter). • drain the engine oil (see engine oil change). • remove the engine (see engine removal/installation chapter). • remove: water pump (see cooling system chapter) clutch cover (see clutch chapter...

Page 133

Engine lubrication system 6-11 oil pump • be sure to install the oil pump and outer oil pipe o-rings [a], and apply engine oil to them. • install the oil pump outer oil pipe [b] and oil screen. ○ apply a non-permanent locking agent to the oil pipe bolt and tighten it. Torque - oil pump outer oil pip...

Page 134

6-12 engine lubrication system oil pressure measurement oil pressure measurement note ○ measure the oil pressure after the engine is warmed up. • remove: right footpeg assembly oil passage plug warning if the oil passage plug is removed while the engine is warm, hot engine oil will drain through the...

Page 135: Engine Removal/installation

Engine removal/installation 7-1 7 engine removal/installation table of contents exploded view........................................................................................................................ 7-2 engine removal/installation .........................................................

Page 136

7-2 engine removal/installation exploded view t1: 44 n·m (4.5 kgf·m, 33 ft·lb) t2: 25 n·m (2.5 kgf·m, 18 ft·lb).

Page 137

Engine removal/installation 7-3 engine removal/installation engine removal • set the motorcycle up on its center stand. • squeeze the brake lever slowly and hold it with a band [a]. Warning be sure to hold the front brake when removing the engine, or the motorcycle may fall over. It could cause an a...

Page 138

7-4 engine removal/installation engine removal/installation • remove: battery negative lead [a] starter motor lead [b] • remove: oil pressure switch lead [a] neutral switch lead [b] sidestand switch lead connector [c] • support the engine with a stand or jack [a]. • remove the engine mounting bolts ...

Page 139

Engine removal/installation 7-5 engine removal/installation • insert the rear mounting bolts from the left side of the engine. • tighten the rear engine upper mounting bolt and nut first to eliminate the gap between the engine and frame bracket, and then the rear engine lower mounting bolt and nut. ...

Page 141: Crankshaft/transmission

Crankshaft/transmission 8-1 8 crankshaft/transmission table of contents exploded view........................................................................................................................ 8-2 specifications ..............................................................................

Page 142

8-2 crankshaft/transmission exploded view 1. 8 mm bolt (55 mm l.) 2. 6 mm bolts (60 mm l.) 3. 6 mm bolts (80 mm l.) 4. 6 mm bolts (40 mm l.) 5. 8 mm bolts (80 mm l.) 6. 8 mm bolts (40 mm l.) 7. Neutral switch t1: 8.8 n·m (0.9 kgf·m, 78 in·lb) t2: 11 n·m (1.1 kgf·m, 95 in·lb) t3: 12 n·m (1.2 kgf·m, 8...

Page 143

Crankshaft/transmission 8-3 exploded view g: apply high temperature grease. L: apply a non-permanent locking agent. Lg: apply liquid gasket-black. M: apply a thin coat of molybdenum disulfide grease. O: apply engine oil. S: follow the specific tightening sequence. Ss: apply silicone sealant. Wl: app...

Page 144

8-4 crankshaft/transmission specifications item standard service limit crankshaft, connecting rods connecting rod bend – – – 0.2/100 mm (0.0079/4 in.) connecting rod twist – – – 0.2/100 mm 0.0079/4 in.) connecting rod big end side clearance 0.13 ∼ 0.38 mm (0.0051 ∼ 0.0150 in.) 0.50 mm (0.02 in.) con...

Page 145

Crankshaft/transmission 8-5 specifications item standard service limit crankshaft main bearing insert thickness: brown 1.490 ∼ 1.494 mm (0.0587 ∼ 0.0588 in.) – – – black 1.494 ∼ 1.498 mm (0.0588 ∼ 0.0590 in.) – – – blue 1.498 ∼ 1.502 mm (0.0590 ∼ 0.0591 in.) – – – crankshaft main bearing insert sele...

Page 146

8-6 crankshaft/transmission specifications item standard service limit shift fork ear thickness 4.9 ∼ 5.0 mm (0.193 ∼ 0.197 in.) 4.8 mm (0.189 in.) shift fork guide pin diameter 7.900 ∼ 8.000 mm (0.3110 ∼ 3150 in.) 7.8 mm (0.307 in.) shift fork dowel pin diameter 7.985 ∼ 8.000 mm (0.3144 ∼ 0.3150 in...

Page 147

Crankshaft/transmission 8-7 crankcase splitting crankcase splitting • remove the engine (see engine removal/installation chapter). • set the engine on a clean surface and hold the engine steady while parts are being removed. • remove: shift lever (see external shift mechanism removal) starter motor ...

Page 148

8-8 crankshaft/transmission crankcase splitting crankcase assembly caution the upper crankcase half and the lower crankcase half are machined at the factory in the assembled state, so the crankcase halves must be replaced to- gether as a set. • using compressed air, blow out the oil passages [a] in ...

Page 149

Crankshaft/transmission 8-9 crankcase splitting • tighten the lower crankcase-half bolts using the following 3 steps: ○ tighten all lower crankcase-half bolts to a snug fit. Following the sequence numbers on the lower crankcase half, torque the 8 mm bolts first to about one half of the specification...

Page 150

8-10 crankshaft/transmission clutch housing/primary chain clutch housing/primary chain removal • remove the engine. • remove: cylinder head, cylinder and pistons (see engine top end chapter) starter clutch sprocket (see electrical system chapter) clutch (except the clutch housing) • split the crankc...

Page 151

Crankshaft/transmission 8-11 crankshaft/connecting rods crankshaft removal • split the crankcase (see crankcase splitting). • remove the clutch housing and the primary chain. • remove the crankshaft with the camshaft chain and pri- mary chain. Crankshaft installation caution if the crankshaft, beari...

Page 152

8-12 crankshaft/transmission crankshaft/connecting rods big end cap [a] connecting rod [b] weight mark, alphabet [c] diameter mark [d] • apply engine oil to the inner surface of the upper and lower bearing inserts [a]. • apply a small amount of engine oil to the threads [b] and seating surface [c] o...

Page 153

Crankshaft/transmission 8-13 crankshaft/connecting rods • measure the connecting rod twist. ○ with the big-end arbor [a] still on v blocks [c], hold the connecting rod horizontal and measure the difference in the height of the arbor [b] above the surface plate over a 100 mm (4 in.) length of the arb...

Page 154

8-14 crankshaft/transmission crankshaft/connecting rods if the clearance is within the standard, no bearing insert replacement is required. If the clearance is between 0.066 mm and the service limit (0.10 mm, 0.0039 in.), replace the bearing inserts [a] with inserts painted blue [b] check insert/cra...

Page 155

Crankshaft/transmission 8-15 crankshaft/connecting rods • select the proper bearing insert in accordance with the combination of the connecting rod and crankshaft coding. • install the new insert in the connecting rod and check in- sert/journal clearance with a plastigage. Connecting rod big end bea...

Page 156

8-16 crankshaft/transmission crankshaft/connecting rods if the clearance is within the standard, no bearing insert replacement is required. If the clearance is between 0.044 mm and the service limit (0.08 mm), replace the bearing inserts [a] with in- serts painted blue [b] check insert/journal clear...

Page 157

Crankshaft/transmission 8-17 crankshaft/connecting rods crankshaft main bearing insert selection bearing insert* crankcase main bearing bore diameter mark crankshaft main journal diameter mark size color part number journal nos 92028-1102 2, 3 ○ 1 brown 92028-1274 1, 4 92028-1100 2, 3 none none blue...

Page 158

8-18 crankshaft/transmission balancer balancer removal • split the crankcase (see crankcase splitting). • pull the balancer shaft with the balancer gear out of the crankcase. Balancer installation • apply oil to the inside of the balancer shaft bearing insert. • align the timing mark [a] on the bala...

Page 159

Crankshaft/transmission 8-19 balancer if either journal has worn past the service limit, replace the balancer shaft with a new one. If the measured journal diameters are not less than the service limit, but do not coincide with the original diameter markings on the balancer shaft, write new marks on...

Page 160

8-20 crankshaft/transmission transmission external shift mechanism removal • remove: engine sprocket (see final drive chapter) chain guard [a] neutral switch lead connector [b] • place an oil pan beneath the external shift mechanism cover [a]. • remove the external shift mechanism cover bolts [b]. •...

Page 161

Crankshaft/transmission 8-21 transmission • apply high temperature grease to the seal lips. • insert the shift shaft into the cover [a], and then fit the shift mechanism arm [b] to the shift drum [c]. • tighten the cover bolts. Torque - external shift mechanism cover bolts: 11 n·m (1.1 kgf·m. 95 in·...

Page 162

8-22 crankshaft/transmission transmission transmission shaft installation • with a high flash-point solvent, clean off the outer cir- cumferences of the transmission ball bearings and needle bearings, and their bearing housings, and wipe dry. • check to see that the set rings [a] and set pins [b] ar...

Page 163

Crankshaft/transmission 8-23 transmission drive shaft assembly • apply engine oil liberally to the drive shaft, gears, bear- ings and bushing. • install the drive shaft ball bearing using the bearing driver [a]. Special tool - bearing driver, 32: 57001-382 • replace any circlips that were removed wi...

Page 164

8-24 crankshaft/transmission transmission output shaft assembly • assembly is the reverse of disassembly. Note the follow- ing. • apply engine oil liberally to the output shaft, gears, bear- ings, bushing and o-ring. • install the output shaft ball bearing, o-ring and collar us- ing the bearing driv...

Page 165

Crankshaft/transmission 8-25 transmission • the output shaft gears can be identified by size: the largest diameter gear is 1st gear, and the smallest is 6th. Be sure that all parts are put back in the correct sequence and facing the proper direction, and that all circlips and washers are properly in...

Page 166

8-26 crankshaft/transmission transmission shift drum and fork installation • insert the shift drum [a] into the crankcase part way, install the 3rd/4th shift fork [b] with the longer side [c] facing the neutral switch, i.E., the longer side goes onto the drum first. • push the shift drum in the rest...

Page 167

Crankshaft/transmission 8-27 transmission shift drum disassembly • remove the screw [a] and the pin plate [b]. • pull out the shift drum cam [c]. • take off the ball bearing [d]. • pull off the dowel pin [e]. Shift drum assembly • set the dowel pin into larger hole of the two which is the farthest h...

Page 168

8-28 crankshaft/transmission transmission ball and needle bearing wear • check the following ball bearings: shift drum lh, drive shaft rh, and output shaft lh. ○ since the ball bearings are made to extremely close toler- ances, the wear must be judged by feel rather than mea- surement. Clean each be...

Page 169: Wheels/tires

Wheels/tires 9-1 9 wheels/tires table of contents exploded view........................................................................................................................ 9-2 specifications ....................................................................................................

Page 170

9-2 wheels/tires exploded view t1: 20 n·m (2.0 kgf·m, 14.5 ft·lb) t2: 88 n·m (9.0 kgf·m, 65 ft·lb) t3: 98 n·m (10.0 kgf·m, 72 ft·lb) g: apply grease. R: replacement parts s: follow the specific tightening sequence. Wl: apply soap and water solution or rubber lubricant..

Page 171

Wheels/tires 9-3 specifications standard item en500-c1 ∼ c2, d1 en500-c3 ∼ service limit wheels (rims) rim runout: radial – – – – – – 0.5 mm (0.02 in.) axial – – – – – – 0.8 mm (0.03 in.) axle runout/100 mm (3.94 in.) 0.1 mm (0.004 in.) or less ← 0.2 mm (0.008 in.) wheel balance 10 g (0.35 us oz) or...

Page 172

9-4 wheels/tires wheels (rims) front wheel removal • remove the speedometer cable lower end [a]. • loosen the front axle nut [b]. • raise the front wheel off the ground. Special tool - jack: 57001-1238 • loosen the axle clamp bolt [a]. • pull out the axle [b] to the right, and remove the front wheel...

Page 173

Wheels/tires 9-5 wheels (rims) rear wheel removal • remove: cotter pin [a] rear axle nut [b] (loosen) • raise the rear wheel off the ground using the center stand. • remove: cotter pin [a] torque link nut and bolt [b] adjuster [c] and brake rod [d] rear axle nut • pull out the rear axle to the right...

Page 174

9-6 wheels/tires wheels (rims) • insert a new cotter pin [a]. Note ○ when inserting the cotter pin, if the slots in the nut do not align with the cotter pin hole in the axel, tighten the nut clockwise [b] up to next alignment. ○ it should be within 30 degree. ○ loosen once and tighten again when the...

Page 175

Wheels/tires 9-7 wheels (rims) axle inspection • visually inspect the front and rear axle for damages. If the axle is damaged or bent, replace it. • measure the axle runout with a dial gauge. If axle runout exceeds the service limit, replace the axle. Axle runout/100 mm (3.94 in.) standard: less tha...

Page 176

9-8 wheels/tires wheels (rims) • repeat the entire procedure as many times as necessary to achieve correct wheel balance. • permanently install the balance weight. Balance weight part number weight: g (us oz) 41075-1059 10 (0.35) 41075-1060 20 (0.71) 41075-1061 30 (1.06) note ○ balance weights are a...

Page 177

Wheels/tires 9-9 wheels (rims) • check that the weight [a] and clip [b] are fully seated on the rim [c] and that the clip is hooked over the rib [d]. Warning if the balance weight has any play on the rim, the clip of the weight has been stretched. Replace the loose balance weight. Do not reuse balan...

Page 178

9-10 wheels/tires tires air pressure inspection/adjustment • measure the tire air pressure with an air pressure gauge [a] when the tires are cold (that is, when the motorcycle has not been ridden more than a mile during the past 3 hours). Adjust the tire air pressure according to the specifications ...

Page 179

Wheels/tires 9-11 tires tire removal caution do not lay the front wheel on the ground with the disc facing down. This can damage or warp the disc. Place blocks under the wheel so that the disc does not touch the ground. • remove the wheel. • to maintain wheel balance, mark the valve stem position on...

Page 180

9-12 wheels/tires tires tire installation • inspect the rim and the tire, and replace them if neces- sary. • clean the sealing surfaces of the rim and tire, and smooth the sealing surfaces of the rim with a fine emery cloth if necessary. • remove the air valve and discard it. Caution replace the air...

Page 181

Wheels/tires 9-13 tires • position the tire on the rim so that the valve [a] is at the tire balance mark [b] (the chalk mark made during removal, or the yellow paint mark on a new tire). • install the tire bead on the rim using a suitable commer- cially available tire changer. • lubricate the tire b...

Page 182

9-14 wheels/tires hub bearing hub bearing removal • remove the wheel, and take out the following. Caution do not lay the wheel on the ground with the disc facing down. This can damage or warp the disc. Place blocks under the wheel so that the disc does not touch the ground. Front grease seal [a] cir...

Page 183

Wheels/tires 9-15 hub bearing • replace the circlips with new ones. Special tool - inside circlip pliers: 57001-143 • replace the grease seal with new ones. • press in the grease seals so that the seal surface flush with the end of the hole. ○ apply high temperature grease to the grease seal lips. S...

Page 184

9-16 wheels/tires speedometer gear disassembly and assembly note ○ it is recommended that the assembly be replaced rather than attempting to repair the components. • install the speedometer gear so that it fits in the speedometer gear drive notches (see front wheel installation). Lubrication • clean...

Page 185: Final Drive

Final drive 10-1 10 final drive table of contents exploded view........................................................................................................................ 10-2 specifications ...................................................................................................

Page 186

10-2 final drive exploded view 1. Drive chain joint (er500-c4 ∼ ) t1: 11 n·m (1.1 kgf·m, 95 in·lb) t2: 127 n·m (13.0 kgf·m, 94 ft·lb) t3: 59 n·m (6.0 kgf·m, 43 ft·lb) t4: 98 n·m (10.0 kgf·m, 72 ft·lb) co: apply chain oil. G: apply grease. L: apply non-permanent locking agent. O: apply oil. R: replac...

Page 187

Final drive 10-3 specifications item standard service limit drive chain chain slack 35 ∼ 40 mm (1.4 ∼ 1.6 in.) – – – 20-link length 317.5 ∼ 318.2 mm (12.50 ∼ 12.53 in.) 323 mm (12.7 in.) standard chain make enuma – – – type ek520sx-o, endless – – – ek520mvxl (er500-c4 ∼ ) link 106 links – – – sprock...

Page 188

10-4 final drive drive chain drive chain slack inspection drive chain slack inspection note ○ check the slack with the motorcycle setting on its center stand. ○ clean the chain if it is dirty, and lubricate it if it appears dry. • check the wheel alignment (see wheel alignment inspec- tion). • rotat...

Page 189

Final drive 10-5 drive chain • bend the cotter pin [a] over the nut [b]. • turn the wheel, measure the chain slack again at the tight- est position, and readjust if necessary. • tighten the torque link nut. Torque - torque link nut: 34 n·m (3.5 kgf·m, 25 ft·lb) • install a new cotter pin to the rear...

Page 190

10-6 final drive drive chain drive chain wear inspection • remove: chain cover • rotate the rear wheel to inspect the drive chain for dam- aged rollers, loose pins and links. If there is any irregularity, replace the drive chain. Lubricate the drive chain if it appears dry. • stretch the chain taut ...

Page 191

Final drive 10-7 drive chain caution the o-rings between the side plates seal in the lu- bricant between the pin and the bushing. To avoid damaging the o-rings and resultant loss of lubri- cant, observe the following rules: use only kerosene or diesel oil for cleaning an o -ring drive chain. Any oth...

Page 192

10-8 final drive drive chain • grind [a] pin head to make it flat. • set cutting and rivetting pin [b] as shown. • screw pin holder until it touches the link pin. • be sure that the cutting pin hits center of the link pin. • screw the handlebar [a] into the body. • turn the pin holder with the wrenc...

Page 193

Final drive 10-9 drive chain • fit the plate holder (a) to the link plate. • turn the pin holder by hand until the plate holder (b) touches the other link plate. • turn the pin holder by a wrench clockwise until two pins of link come into groove of the plate holder (a). • take off the plate holder. ...

Page 194

10-10 final drive drive chain • after staking, check the staked area of the link pin for cracks. • measure the outside diameter [a] of the link pin and link plates width [b]. Link pin outside diameter standard: 5.6 ∼ 6.0 mm (0.22 ∼ 0.24 in.) link plates outside width standard: 17.45 ∼ 17.60 mm (0.68...

Page 195

Final drive 10-11 sprocket, coupling engine sprocket removal • remove the bolts [a]. • pull the engine sprocket cover [b]. • flatten out the bended washer [a]. • remove the engine sprocket nut [b] and washer. Note ○ when loosening the engine sprocket nut, hold the rear brake on. • loosen the drive c...

Page 196

10-12 final drive sprocket, coupling rear sprocket removal • remove the rear wheel (see wheel/tires chapter). • remove the rear sprocket nuts [a]. • remove the rear sprocket [b]. Rear sprocket installation • install the sprocket facing the tooth number marking [a] outward. • tighten the rear sprocke...

Page 197

Final drive 10-13 sprocket, coupling coupling bearing removal • remove: coupling grease seal [a] • remove the bearing by tapping from the brake drum side. Special tool - bearing driver set: 57001-1129 [a] coupling bearing installation • replace the bearing with a new one. • press in the bearing unti...

Page 198

10-14 final drive sprocket, coupling coupling bearing inspection and lubrication note ○ it is not necessary to remove the coupling bearing for inspection and lubrication. If the bearing is removed, it will need to be replaced with a new one. • spin the bearing by hand to check its condition. If it i...

Page 199: Brakes

Brakes 11-1 11 brakes table of contents exploded view................................... 11-2 specifications .................................... 11-4 brake lever ....................................... 11-5 lever position adjustment ........... 11-5 caliper ............................................

Page 200

11-2 brakes exploded view t1: 7.8 n·m (0.80 kgf·m, 69 in·lb) t2: 25 n·m (2.5 kgf·m, 18.0 ft·lb) t3: 11 n·m (1.1 kgf·m, 95 in·lb) t4: 1.0 n·m (0.10 kgf·m, 9 in·lb) t5: 5.9 n·m (0.60 kgf·m, 52 in·lb) t6: 1.5 n·m (0.15 kgf·m, 13 in·lb) t7: 1.2 n·m (0.12 kgf·m, 10 in·lb) t8: 8.8 n·m (0.90 kgf·m, 78 in·l...

Page 201

Brakes 11-3 exploded view.

Page 202

11-4 brakes specifications item standard service limit front brake brake lever position 4-way adjustable (to suit rider) – – – 5-way adjustable (to suit rider): er500-c4 ∼ brake lever free play non-adjustable – – – pad lining thickness 4.5 mm (0.177 in.) 1 mm (0.04 in.) disc thickness 4.8 ∼ 5.2 mm (...

Page 203

Brakes 11-5 brake lever lever position adjustment the adjuster has 4 positions so that the brake lever posi- tion can be adjusted to suit the operator’s hand. • push the lever forward and turn the adjuster [a] to align the number with the arrow mark [b] on the lever holder. ○ the distance from the g...

Page 204

11-6 brakes caliper caliper removal • drain the brake fluid. • loosen the banjo bolt [a] at the brake hose lower end, and tighten it loosely. • unscrew the caliper mounting bolts [b], and detach the caliper [c] from the disc. • unscrew the banjo bolt and remove the brake hose [d] from the caliper. N...

Page 205

Brakes 11-7 caliper • insert a wooden board [a] 5 mm thick inside the caliper opening. • pump the brake lever until the pistons [b] push the wooden board. • remove the wooden board and pull out the piston by hand. • remove the other parts of the caliper. • the pistons can be removed by compressed ai...

Page 206

11-8 brakes caliper • apply brake fluid to the outside of the piston, and push the piston into the cylinder by hand. Take care that neither the cylinder nor the piston skirt get scratched. • replace the shaft rubber friction boot [a] and dust cover [b] with new ones if they are damaged. • apply a th...

Page 207

Brakes 11-9 brake pads brake pad removal • remove the caliper with the hose installed. • remove the clip and take off the pad pin. • remove: piston side pad [a] • remove the other pad [a]. Brake pad installation • push the caliper piston in by hand as far as it will go. • install the anti-rattle spr...

Page 208

11-10 brakes master cylinder master cylinder removal • disconnect the front brake switch wires [a]. • remove the banjo bolt [b] to disconnect the upper brake hose end from the master cylinder [c]. There is a flat washer [d] on each side of the hose fitting. • remove the clamp bolts [e] and take off ...

Page 209

Brakes 11-11 master cylinder master cylinder assembly • before assembly, clean all parts including the master cylinder with brake fluid or alcohol. Caution except for the disc pads and disc, use only disc brake fluid, isopropyl alcohol, or ethyl alcohol, for cleaning brake parts. Do not use any othe...

Page 210

11-12 brakes brake disc brake disc removal • remove the wheel (see wheels/tires chapter). • unscrew the mounting allen bolts [a], and take off the disc [b]. Brake disc installation • install the brake disc on the wheel so that the marked side [a] faces out. • tighten the mounting allen bolts. Torque...

Page 211

Brakes 11-13 brake fluid level inspection • check that the brake fluid level in the front brake reservoir [a] is above the lower level line [b]. Note ○ hold the reservoir horizontal by turning the handlebar when checking brake fluid level. If the fluid level is lower than the lower level line, fill ...

Page 212

11-14 brakes brake fluid bleeding the brake line the brake fluid has a very low compression coefficient so that almost all the movement of the brake lever is transmit- ted directly to the caliper for braking action. Air, however, is easily compressed. When air enters the brake line, brake lever move...

Page 213

Brakes 11-15 brake fluid • install the reservoir cap. • remove the rubber cap from the bleed valve on the caliper. • attach a clear plastic hose to the bleed valve on the caliper, and run the other end of the hose into a con- tainer. • bleed the air from the caliper as follows: • repeat this operati...

Page 214

11-16 brakes brake fluid warning when working with the disc brake, observe the pre- cautions listed below. 1. Never reuse old brake fluid. 2. Do not use fluid from a container that has been left unsealed or that has been open for a long time. 3. Do not mix two types and brands of fluid for use in th...

Page 215

Brakes 11-17 brake hose brake hoses and connections inspection • inspect the brake hose and fittings for deterioration, cracks and signs of leakage. ○ the high pressure inside the brake line can cause fluid to leak [a] or the hose to burst if the line is not properly main- tained. Bend and twist the...

Page 216

11-18 brakes brake pedal and cable brake play inspection brake pedal position inspection • with the brake pedal [a] in the correct position, inspect the brake pedal position [b] as shown. Footpeg [c] pedal position standard: about 20 mm (0.79 in.) below footpeg (from top of the footpeg to top of the...

Page 217

Brakes 11-19 brake pedal and cable brake pedal removal • remove: adjuster [a] clevis pin [b] return spring [c] • remove the brake rod rear end. • loosen the locknut and turn in the adjusting bolt to keep the pedal free from it. • unscrew the right footpeg bracket bolts [a]. • remove rear brake light...

Page 218

11-20 brakes brake panel and drum brake lining wear inspection • check that the brake lining wear indicator [a] points within the usable range [b] when the rear brake is fully ap- plied. If does not, the shoes must be immediately replaced and the other brake parts examined. Cam lever angle inspectio...

Page 219

Brakes 11-21 brake panel and drum brake panel removal • remove the rear wheel (see wheels/tires chapter). • separate the brake panel [a] from the wheel. Brake panel installation • installation is the reverse of removal. Note the following. • adjust the brake pedal free play (see brake pedal free pla...

Page 220

11-22 brakes brake panel and drum • link the brake shoes together with the springs, and push them onto the panel in the reverse of removal. • put the dust seal over the end of the cam shaft. • install the return spring. • install the indicator [a] on the serration so that it points to the extreme ri...

Page 221

Brakes 11-23 brake panel and drum brake camshaft and camshaft hole wear • remove the brake camshaft (see brake panel disassem- bly). • measure the shaft diameter [a]. ○ use a micrometer at the point shown. If any measurement is less than the service limit, replace the camshaft. Camshaft diameter sta...

Page 222

11-24 brakes brake panel and drum • lubricate the brake pedal by applying a multi-purpose grease to the brake shaft pivot groove [a]. • clean any excess grease from the parts before assembly. • lubricate the brake cable (see brake cable lubrication)..

Page 223: Suspension

Suspension 12-1 12 suspension table of contents exploded view........................................................................................................................ 12-2 specifications .....................................................................................................

Page 224

12-2 suspension exploded view fo: apply fork oil. L: apply a non-permanent locking agent. R: replacement parts s: follow he specific tightening sequence. T1: 20 n·m (2.0 kgf·m, 14.5 ft·lb) t2: 35 n·m (3.6 kgf·m, 26 ft·lb).

Page 225

Suspension 12-3 exploded view 1. Needle bearings: face the manufacturer’s marks out. T3: 34 n·m (3.5 kgf·m, 25 ft·lb) t4: 88 n·m (9.0 kgf·m, 65 ft·lb) g: apply grease..

Page 226

12-4 suspension specifications item standard service limit front fork (per one unit) fork inner tube diameter 37 mm (1.46 in.) fork spring setting non-adjustable air pressure atmospheric pressure (non-adjustable) rebound damper setting non-adjustable compression damper setting non-adjustable fork oi...

Page 227

Suspension 12-5 front fork fork oil change the oil should be changed in accordance with the periodic maintenance chart. • remove the front fork (see fork removal). • hold the outer tube vertically in a vise. • remove the cap. • push the top plug [a] down to remove the plug retaining ring [b], and th...

Page 228

12-6 suspension front fork • install the fork spring with the smaller diameter end [a] facing down. • install: fork spring seat spacer • install the front fork (see front fork installation). • repeat the same procedure for another front fork. Fork removal • remove: brake hose clamps [a] (left front ...

Page 229

Suspension 12-7 front fork • hold the front fork horizontally in a vise [a]. • stop the cylinder unit [b] from turning by using the special tools. • unscrew the allen bolt [c], and take the gasket out of the bottom of the outer tube. Special tools - fork cylinder holder handle: 57001-183 [d] fork cy...

Page 230

12-8 suspension front fork • put the cylinder unit [a] with the spring into the inner tube [b] protruding from the inner tube, and install the cylinder base [c] onto the bottom end of the cylinder unit. ○ install the cylinder base with the tapered end [d] up. • install the inner tube, cylinder unit,...

Page 231

Suspension 12-9 front fork inner tube, outer tube inspection • visually inspect the inner tube [a] for scoring or scratches on the outer surface of it and repair any damage. • nick or rust damage can sometimes be repaired by using a wet- stone to remove sharp edges or raised areas which cause seal d...

Page 232

12-10 suspension rear shock absorber spring preload adjustment the spring preload adjuster on each rear shock absorber has 5 positions so that the spring tension can be adjusted for different road and loading conditions. • using the hook wrench [a], turn the adjuster to adjust the spring tension. ○ ...

Page 233

Suspension 12-11 rear shock absorber bushing wear • visually inspect the rubber bushings [a]. If they show any signs of damage, replace them. Rear shock absorber oil leak inspection • visually inspect the shock absorber for oil leakage. If the oil leakage is found on it, replace the shock absorber w...

Page 234

12-12 suspension swingarm caution do not tap the swingarm pivot shaft when removing or installing. Push or pull the pivot shaft while turn- ing the shaft. Tapping on the shaft could damage the needle bearings in the swingarm. Swingarm removal • remove: rear wheel (see wheels/tires chapter) rear shoc...

Page 235

Suspension 12-13 swingarm swingarm installation • installation is the reverse of removal. • tighten the pivot shaft nut. Torque - swingarm pivot nut: 88 n·m (9.0 kgf·m, 65 ft·lb) • tighten the torque link nut. Torque - torque link nut: 34 n·m (3.5 kgf·m, 25 ft·lb) • move the swingarm up and down [a]...

Page 237: Steering

Steering 13-1 13 steering table of contents exploded view........................................................................................................................ 13-2 specifications .........................................................................................................

Page 238

13-2 steering exploded view t1: 44 n·m (4.5 kgf·m, 33 ft·lb) t2: hand-tight t3: 25 n·m (2.5 kgf·m, 18 ft·lb) t4: 3.4 n·m (0.35 kgf·m, 30 in·lb) t5: 20 n·m (2.0 kgf·m, 14.5 ft·lb) t6: 29 n·m (3.0 kgf·m, 22 ft·lb) ad: apply adhesive. G: apply grease. L: apply a non-permanent locking agent. S: follow t...

Page 239

Steering 13-3 specifications special tools - jack: 57001-1238 steering stem wrench: 57001-1100 head pipe outer race press shaft: 57001-1075 bearing puller: 57001-158 head pipe outer race driver, 46.5: 57001-1106 head pipe outer race driver, 51.5: 57001-1076 steering stem bearing driver: 57001-137 st...

Page 240

13-4 steering handlebar handlebar removal • remove: clutch cable upper end right and left handlebar switch housing throttle grip brake master cylinder • unscrew the handlebar mounting bolts [a] and remove the handlebar [b] and clamp [c]. Handlebar installation • install the handlebar clamps so that ...

Page 241

Steering 13-5 handlebar rear view mirrors (left and right) installation • screw the mounting area of the right rear view mirror into the holder all the way, and tighten the lower hexagonal area for tightening securely. [a] lower hexagonal area for tightening [b] upper hexagonal area (adapter) [c] re...

Page 242

13-6 steering steering steering inspection steering inspection • check the steering. ○ lift the front wheel off the ground using the jack. Special tool - jack: 57001-1238 ○ with the front wheel pointing straight ahead, alternately tap each end of the handlebar. The front wheel should swing fully lef...

Page 243

Steering 13-7 steering • tighten the steering stem head bolt [a] and fork lower clamp bolts [b]. Torque - steering stem head bolt: 44 n·m (4.5 kgf·m, 33 ft·lb) fork lower clamp bolts: 29 n·m (3.0 kgf·m, 22 ft·lb) • check the steering again. If the steering is still too tight or too loose, repeat the...

Page 244

13-8 steering steering stem steering stem removal • remove the handlebar. Loosen the stem head bolt [a] remove the front fork [b] (see suspension chapter) • remove: headlight turn signal light bracket bolts [a] headlight housing bolts [b] meter unit • remove the stem head bolt [a] and lift up the st...

Page 245

Steering 13-9 steering stem • install the stem cap [a], and hand tighten the stem nut [b]. Torque - steering stem nut: 4.9 n·m (0.50 kgf·m, 43 in·lb, for reference) note ○ install the steering stem nut so that the recess side [c] faces down. • install the front fork (see suspension chapter). Note ○ ...

Page 246

13-10 steering steering stem bearing stem bearing removal • remove the steering stem (see this chapter). • to remove the outer races [a] pressed in the head pipe [b], insert a bar [c] into the head pipe, and hammer evenly around the circumference of the opposite race to drive it out. • remove the lo...

Page 247

Steering 13-11 steering stem bearing • settle the inner races in place as follows. ○ using the steering stem nut wrench, tighten the stem nut 20 n·m (2.0 kgf·m, 14.5 ft·lb) of torque. To tighten the steering stem nut to the specified torque, hook the wrench on the stem nut, and pull the wrench at th...

Page 249: Frame

Frame 14-1 14 frame table of contents exploded view........................................................................................................................ 14-2 specifications ...............................................................................................................

Page 250

14-2 frame exploded view t1: 34 n·m (3.5 kgf·m, 25 ft·lb) t2: 44 n·m (4.5 kgf·m, 33 ft·lb) t3: 25 n·m (2.5 kgf·m, 18 ft·lb) o: apply oil. G: apply grease..

Page 251

Frame 14-3 exploded view.

Page 252

14-4 frame specifications special tool - jack: 57001-1238.

Page 253

Frame 14-5 seat seat removal • insert the ignition switch key [a] into the seat lock. • turn the ignition switch key clockwise. • swing open the seat and remove it. Seat installation • slip the hook [a] of the seat under the brace [b] on the fuel tank. • push down [a] the rear part of the seat until...

Page 254

14-6 frame side covers side cover removal • remove the seat (see this chapter). • remove the screw [a]. • pull the rear part and front part of the side cover [a] evenly outward to clear the stoppers [b]. • remove the side cover. • remove the other side cover in the same manner..

Page 255

Frame 14-7 seat cover seat cover removal • remove the seat (see this chapter). • remove both side covers (see this chapter). • unscrew the mounting bolts [a] and remove the tail grip [b]. • remove the screws [a]. • with the tail of the seat covers joined, bend open the seat cover [a] and pull them o...

Page 256

14-8 frame fenders front fender removal • remove the front wheel (see wheels/tires chapter). • remove the bolts [a] and take off the front fender [b] rear- ward. Rear fender removal • remove: seat (see frame chapter) battery (see electrical system chapter) regulator/rectifier (see electrical system ...

Page 257

Frame 14-9 frame frame inspection • visually inspect the frame [a] for cracks, dents, bending, or warp. If there is any damage to the frame, replace it. Warning a repaired frame may fail in use, possibly causing an accident. If the frame is bent, dented, cracked, or warped, replace it. Battery case ...

Page 259: Electrical System

Electrical system 15-1 15 electrical system table of contents parts location.................................... 15-3 exploded view................................... 15-4 specifications ................................... 15-8 er500-c1 ∼ c2, d1 wiring diagram (other than australia) ...................

Page 260

15-2 electrical system radiator fan switch inspection ... 15-62 water temperature switch inspection.................................. 15-63 fuel gauge operation inspection 15-63 fuel level sensor inspection....... 15-64 fuses................................................. 15-66 30 ampere fuse remo...

Page 261

Electrical system 15-3 parts location 1. Starter lockout switch 2. Horn 3. Radiator fan switch 4. #1 ignition coil 5. Spark plugs 6. Water temperature switch 7. Starter motor 8. Mf battery 9. Ic igniter 10. Fuse box 11. Alternator 12. Pickup coil 13. Oil pressure switch 14. Neutral switch 15. Sidest...

Page 262

15-4 electrical system exploded view 1. Starter lockout switch 2. Front brake light switch 3. Horns 4. City light (other than australia) t1: 1.2 n·m (0.12 kgf·m, 10 in·lb) t2: 3.4 n·m (0.35 kgf·m, 30 in·lb) l: apply a non-permanent locking agent..

Page 263

Electrical system 15-5 exploded view 1. Regulator/rectifier 2. Fuse box 3. Turn signal relay 4. Rectifiers 5. Ic igniter 6. Starter circuit relay 7. Diode t1: 5.9 n·m (0.6 kgf·m, 52 in·lb).

Page 264

15-6 electrical system exploded view.

Page 265

Electrical system 15-7 exploded view 1. Ignition switch 2. Water temperature switch 3. Radiator fan 4. Radiator fan switch 5. Ignition coils 6. Spark plugs 7. Rear brake light switch 8. Alternator starter 9. Pickup coil 10. Starter motor 11. 30 a main fuse 12. Starter relay 13. Sidestand switch 14. ...

Page 266