- DL manuals

- Kawasaki

- Engine

- FH451V

- Service Manual

Kawasaki FH451V Service Manual

FH451V,FH500V,FH531V

FH601V,FH641V,FH680V

FH721V

4–stroke air cooled v-twin gasoline engine

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of

Quality Assurance Department/Consumer Products & Machinery Group/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care has been

taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to make such

changes to products manufactured previously.

All information contained in this publication is based on the latest product information available at the time of publication.

Illustrations and photographs in this publication are intended for reference use only and may not depict actual model

component parts.

© Kawasaki Heavy Industries, Ltd., 1999, 2000

Third Edition (1) : Nov. 20, 2000 (K)

Summary of FH451V

Page 1

Fh451v,fh500v,fh531v fh601v,fh641v,fh680v fh721v 4–stroke air cooled v-twin gasoline engine service manual all rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or o...

Page 2

List of abbreviations a ampere(s) lb pound(s) abdc after bottom dead center m meter(s) ac alternating current min minute(s) atdc after top dead center n newton(s) bbdc before bottom dead center pa pascal(s) bdc bottom dead center ps horsepower btdc before top dead center psi pound(s) per square inch...

Page 3

Emission control information to protect the environment in which we all live, kawasaki has incorporated crankcase emission (1) and exhaust emission (2) control systems (em) in compliance with applicable regulations of the united states environmental protection agency and california air resources boa...

Page 4: Foreword

Foreword this manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the proper us...

Page 5: General Information

General information 1-1 general information table of contents 1 before servicing.................................................................................................................................................................1-2 model identification .....................................

Page 6

1-2 general information before servicing before starting to service the engine, carefully read the applicable section to eliminate unnecessary work. Photographs, diagrams, notes, cautions, warnings, and detailed descriptions have been included wherever necessary. Nevertheless, even a detailed accoun...

Page 7

General information 1-3 before servicing (15) cotter pin replace any cotter pins that were removed with new ones, as removal deforms and breaks them. (16) lubrication engine wear is generally at its maximum while the engine is warming up and before all the rubbing surfaces have an adequate lubricati...

Page 8

1-4 general information model identification electric starter model-fh500v recoil starter model-fh500v cylinder number designation: no.1 cylinder is the left-hand cylinder viewed from the air cleaner. No.2 cylinder is the right-hand cylinder viewed from the air cleaner..

Page 9

General information 1-5 model identification electric starter model-fh680v.

Page 10

1-6 general information general specifications items fh451v, fh500v, fh531v fh601v, fh641v, fh680v fh721v type of engine forced air-cooled, vertical shaft, ohv, 4-stroke gasoline engine. Cylinder layout 90 v-twin bore x stroke 68 mm x 68 mm (2.68 in x 2.68 in) 75.2 mm x 76 mm (2.96 in x 2.99 in) pis...

Page 11

General information 1-7 periodic maintenance chart to ensure satisfactory operation over an extended period of time, any engine requires normal maintenance regular intervals. The periodic maintenance chart below shows periodic inspection and maintenance items and suitable intervals. The bullet mark ...

Page 12

1-8 general information periodic maintenance chart fh601v, fh641v, fh680v, fh721v operation interval daily first 8 hr. Every 25 hr. Every 50 hr. Every 100 hr. Every 200 hr. Every 300 hr. Check or clean air intake screen • check and add engine oil • check for fuel and oil leakage • check for loose or...

Page 13

General information 1-9 torque and locking agent the following tables lists the tightening torque for the major fasteners, and the parts requiring use of a non-permanent locking agent or liquid gasket. Letters used in the "remarks" column mean: l : apply a non-permanent locking agent to the threads....

Page 14

1-10 general information torque and locking agent fh451v, fh500v, fh531v fastener torque remarks n 1 m kg 1 m ft 1 lb lubrication system: engine drian plugs (plastic) 6.9 0.70 61 in 1 lb engine drain plug (metal) 20 2.0 14.5 engine drain plug joint (plastic) 17 1.7 12.0 engine drain plug joint (meta...

Page 15

General information 1-11 torque and locking agent fh601v, fh641v, fh680v, fh721v fh601v, fh641v, fh680v, fh721v fasteners torque remarks n 1 m kg 1 m ft 1 lb fuel system: choke valve screw 1.0 0.10 8.9 in 1 lb = l throttle valve screws 1.0 0.10 8.9 in 1 lb = l pilot jet – – – main jet – – - plug, ma...

Page 16

1-12 general information torque and locking agent fh601v, fh641v, fh680v, fh721v fastener torque remarks n 1 m kg 1 m ft 1 lb lubrication system: engine drian plugs (plastic) 6.9 0.7 61 in 1 lb engine drain plug (metal) 20 2.0 14.5 engine drain plug joint (plastic) 17 1.7 12 engine drain plug joint ...

Page 17

General information 1-13 special tools compression gauge: 57001–221 piston ring pliers: 57001–115 piston ring compression grip: 57001–1095 piston ring compression belt, Ø67 -Ø79: 57001–1097 valve seat cutter holder bar: 57001–1128 valve seat cutter holder Ø6: 57001–1360 valve seat cutter, 45 - Ø35.0...

Page 18

1-14 general information special tools oil filter wrench : 57001–1249 hand tester: 57001–1394 kawasaki bond (silicone sealant) : 56019–120

Page 19: Fuel System

Fuel system 2-1 fuel system table of contents 2 exploded view.............................................................2-2 specifications...............................................................2-8 governor link mechanism .......................................... 2-9 control panel assembly...

Page 20

2-2 fuel system exploded view [fh451v, fh500v, fh531v].

Page 21

Fuel system 2-3 exploded view [fh451v, fh500v, fh531v] 1. Pilot screw 2. Pilot air jet 3. Main air jet 4. Main jet 5. Pilot jet 6. Solenoid valve t1: 0.7 n 1 m (0.07 kg 1 m, 6 in 1 lb) t2: 1.0 n 1 m (0.10 kg 1 m, 9 in 1 lb) t3: 1.3 n 1 m (0.13 kg 1 m, 11 in 1 lb) t4: 1.7 n 1 m (0.17 kg 1 m, 15 in 1 ...

Page 22

2-4 fuel system exploded view [fh601v, fh641v, fh680v, fh721v].

Page 23

Fuel system 2-5 exploded view [fh601v, fh641v, fh680v, fh721v] 1. Pilot screw 2. Pilot air jet 3. Main air jet 4. Main jet 5. Pilot jet 6. Solenoid valve t1: 1.0 n 1 m (0.10 kg 1 m, 9 in 1 lb) t2: 3.9 n 1 m (0.40 kg 1 m, 35 in 1 lb) t3: 2.0 n 1 m (0.20 kg 1 m, 18 in 1 lb) t4: 19 n 1 m (1.9 kg 1 m, 1...

Page 24

2-6 fuel system exploded view.

Page 25

Fuel system 2-7 exploded view [fh451v, fh500v, fh531v] t5: 2.0 n 1 m (0.20 kg 1 m , 17 in 1 lb) t8: 5.9 n 1 m (0.60 kg 1 m , 52 in 1 lb) t9: 7.8 n 1 m (0.80 kg 1 m , 69 in 1 lb) [fh601v, fh641v, fh680v, fh721v] t5: 2.0 n 1 m (0.20 kg 1 m , 17 in 1 lb) t8: 5.9 n 1 m (0.60 kg 1 m , 52 in 1 lb) t9: 7.8...

Page 26

2-8 fuel system specifications standard item fh451v, fh500v, fh531v fh601v, fh641v, fh680v, fh721v caburetors specifications: make/ type mikuni b24t1 nikki 621266 throttle bore diameter 24 mm (0.94 in.) 26 mm (1.02 in.) venturi diameter 16 mm (0.63 in.) 18 mm (0.71 in.) 21 mm (0.83 in.) main jet (mj...

Page 27

Fuel system 2-9 governor link mechanism control panel assembly removal • remove: air cleaner (see cleaner body removal) air cleaner mount bracket bolts [a] air cleaner mount bracket [b] earth lead (starter model) control panel mounting bolts [c] • remove the control panel assembly [a] while unhookin...

Page 28

2-10 fuel system governor link mechanism governor arm installation • install the governor arm [a] onto the governor shaft [b] temporarily. • be sure the link spring [c] around the throttle link rod [d] is inplace and that it pulls the governor arm and throttle lever [e] each other. • loosen the clam...

Page 29

Fuel system 2-11 governor link mechanism governor assembly inspection visually check all governor parts for wear and damage. If any parts are worm or damaged, replace them. Governor shaft removal • split the crankcase (see camshaft/crankcase chapter). • unscrew the governor shaft plate screws [a], a...

Page 30

2-12 fuel system carburetor fuel and air flow the main system of the carburetor consists of the main jet [a], valve seat [b] main nozzle [c], and the main air passage [d] (main air jet [e]). The main system meters fuel to the engine during moderate to heavy load conditions. Fuel flows through the ma...

Page 31

Fuel system 2-13 carburetor fuel shut off solenoid valve (electric starter model) to avoid after firing when stopping the engine, a solenoid actuated fuel shut off solenoid valve [a] is installed in the carburetor bowl. The valve shuts off the fuel supply to the valve seat [b] simultaneously when th...

Page 32

2-14 fuel system carburetor always keep your hands clear of the moving parts. • move the throttle lever at a dash to the high idle position and match the lever hole position with the panel hole by inserting 6 mm dia., pin or bolt [a]. • loosen two m6 control panel mounting bolts [b] enough to move t...

Page 33

Fuel system 2-15 carburetor • using a proper blade screw driver, carefully replace the main jet (a) with a new one for altitude expected. • tighten the main jet to the specification (see carburetor disassembly assembly notes). • install the float chamber, gasket and solenoid valve.– fh451v, 500v, 53...

Page 34

2-16 fuel system carburetor carburetor removal gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition switch off. Do not smoke. Make sure the area is well- ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light...

Page 35

Fuel system 2-17 carburetor carburetor disassembly/assembly - fh451v, 500v, 531v • refer to the illustration shown for disassembly and assembly. • there are several passage plugs (ball plugs) in the carburetor body. Do not remove. • before disassembly, mark the out side of choke valve and throttle v...

Page 36

2-18 fuel system carburetor carburetor disassembly/assembly- fh601v, 641v, 680v, 721v. • refer to the illustration shown for disassembly and assembly. • there are several passage plugs (ball plugs) in the carburetor body. Do not remove. • before disassembly, mark the out side of choke valve and thro...

Page 37

Fuel system 2-19 carburetor • drive the float pin so that it’s big diameter side faces the throttle shaft lever side. • the fuel inlet valve seat is pressed into the carburetor body and is not replacable. • assemble carburetor parts which recommended tightening torque. (see exploded view) carburetor...

Page 38

2-20 fuel system carburetor carburetor inspection gasoline is extremely flammable and can be explosive under certain. Turn the ignition switch off. Do not smoke. Make sure the area is well ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. • inspe...

Page 39

Fuel system 2-21 carburetor fuel shut-off solenoid valve test (electric starter model) • unscrew the fuel shut off valve and remove the valve. • connect a 12 vdc source to the solenoid as shown. If the actuate solenoid plunger (needle valve) does not pop in when the test voltage is applied, replace ...

Page 40

2-22 fuel system intake manifold intake manifold removal • remove: air cleaner (see cleaner body removal) engine upper cover • cut off the band [a] and harness and/or wire lead are released from intake manifold. • unscrew the manifold mounting bolts [b]. • then lifting up the intake manifold middle ...

Page 41

Fuel system 2-23 intake manifold intake manifold inspection • inspect the intake manifold for cracks or porous casting. • cracks not visible to the eye may be detected by coating the suspected area with mixture of 25% kerosene and 75% light engine oil. • wipe the area dry and immediately apply a coa...

Page 42

2-24 fuel system fuel pump, fuel filter the fuel pump cannot be disassembled, if any damage for the pump is noticed replace it with a new one. Fuel pump inspection • check the vent hole [a] and filter [b] for plugging or clogging. If vent hole and filter are plugged or clogged, remove the foreign ma...

Page 43

Fuel system 2-25 air cleaner element removal - fh451v, 500v, 531v • pull the hooks [a] to outside and remove the air cleaner cover [b]. • remove: wing bolt [a] foam element [b] paper element [c] element removal - fh601v, 641v, 680v, 721v • remove air cleaner case nut air cleaner case wing nut [a] fo...

Page 44

2-26 fuel system air cleaner • clean the paper element [a] by tapping it gently on a flat surface to remove dust. If the element is very dirty, replace it with a new one. Caution do not use compressed air to clean the paper element. Do not oil the paper or foam element. Element cleaning and inspecti...

Page 45

Fuel system 2-27 air cleaner cleaner body removal - fh601v, fh641v, fh680v, fh721v • remove the element. (see element removal). • remove the clamp [a], and take off the breather tube [b]. • loosen nuts [c] and remove the solenoid valve wire [d]. • unscrew the bolts [e] and remove the intake pipe [f]...

Page 46

2-28 fuel system air cleaner housing (case and body) inspection • clean the housing with detergent and water and dry thoroughly. • check the housing for deformation or other damage. The housing must seal well and permit only filtered air to reach the carburetor. If the housing is damaged, it must be...

Page 47: Cooling System

Cooling system 3-1 cooling system table of contents 3 exploded view....................................................................................................................................................................3-2 cooling fan ........................................................

Page 48

3-2 cooling system exploded view.

Page 49

Cooling system 3-3 exploded view [fh451v, fh500v, fh531v] t1: 3.9 n 1 m (0.40 kg 1 m, 35 in 1 lb) t2: 5.9 n 1 m (0.60 kg 1 m, 52 in 1 lb) t3: 17 n 1 m (1.7 kg 1 m, 12.0 ft 1 lb) t4: 56 n 1 m (5.7 kg 1 m, 41 ft 1 lb) t5: 7.8 n 1 m (0.8 kg 1 m, 69 in 1 lb) [fh601v, fh641v, fh680v, fh721v] t1: 3.9 n 1 ...

Page 50

3-4 cooling system cooling fan cooling fan removal • refer to flywheel removal in electrical system chapter. Cooling fan installation • refer to flywheel installation in electrical system chapter. Cooling fan inspection • visually inspect the blades [a] in the cooling fan [b]. If they are any cracks...

Page 51

Cooling system 3-5 cooling fan screen clearance adjustment • check clearance between screen [a] and fan housing [b]. If clearance is less than 1 mm, add proper number of spacer [c] between screen and bracket comp [d] to adjust clearance [g] 1 3 mm. F: screws g: clearance 1 3 mm.

Page 53: Engine Top End

Engine top end 4-1 engine top end table of contents 4 exploded view....................................................................................................................................................................4-2 specifications .....................................................

Page 54

4-2 engine top end exploded view.

Page 55

Engine top end 4-3 exploded view [fh451v, fh500v, fh531v] t1: 5.9 n 1 m (0.60 kg 1 m, 52 in 1 lb) t2: 5.9 n 1 m (0.60 kg 1 m, 52 in 1 lb) t3: 25 n 1 m (2.6 kg 1 m, 19.5 ft 1 lb) t4: 28 n 1 m (2.8 kg 1 m, 20 ft 1 lb) t5: 22 n 1 m (2.2 kg 1 m, 16 ft 1 lb) [fh601v, fh641v, fh680v, fh721v] t1: 21 n 1 m ...

Page 56

4-4 engine top end exploded view.

Page 57

Engine top end 4-5 exploded view [fh451v, fh500v, fh531v] t2: 15 n 1 m (1.5 kg 1 m, 11.0 ft 1 lb) [fh601v, fh641v, fh680v, fh721v] t2: 15 n 1 m (1.5 kg 1 m, 11.0 ft 1 lb).

Page 58

4-6 engine top end specifications item service limit fh451v, fh500v, fh531v cylinder head: cylinder compression (min) [390 kpa (57 psi)] (min) cylinder head warp 0.05 mm (0.002 in.) valves: valve head thickness intake, exhaust 0.35 mm (0.014 in.) valve stem runout intake, exhaust 0.05 mm (0.002 in.)...

Page 59

Engine top end 4-7 specifications item service limit fh601v, fh641v, fh680v, fh721v cylinder head: cylinder compression (min) [390 kpa (57 psi)] (min) cylinder head warp 0.05 mm (0.002 in.) valves: valve head thickness intake, exhaust 0.35 mm (0.014 in.) valve stem runout intake, exhaust 0.05 mm (0....

Page 60

4-8 engine top end specifications special tools - compression gauge : 57001 - 221 compression gauge adapter m14 x 1.25: 57001–1159 piston ring pliers: 57001 - 115 piston ring compression grip: 57001 - 1095 piston ring compression belt, 67 - 79: 57001–1097 valve seat cutter holder bar: 57001–1128 val...

Page 61

Engine top end 4-9 cylinder head compression measurement • before measuring compression, do the following. Be sure the battery is fully charged. Thoroughly warm up the engine so that engine oil between the piston and cylinder wall will help seal compression as it does during normal running. Stop the...

Page 62

4-10 engine top end cylinder head cylinder head assembly removal • remove: air cleaner and carburetor (see fuel system chapter) muffler (see muffler exhaust pipe removal) intake manifold (see fuel system chapter) spark plug • unscrew the rocker cover mounting bolts [a], and remove the cover [b] and ...

Page 63

Engine top end 4-11 cylinder head • tighten the cylinder head bolts following the tightening sequence. Torque - cylinder head bolts: 25 n 1 m (2.6 kg 1 m, 19.0 ft 1 lb) caution a torque wrench must be used to assure proper torque. Improper tightening of the head bolts can result in warping of the cy...

Page 64

4-12 engine top end cylinder head push rod inspection • place the rocker arm push rod in v blocks that are as far apart as possible, and set a dial gauge on the rod at a point halfway between the blocks. Turn the rod to measure the runout. The difference between highest and the lowest dial readings ...

Page 65

Engine top end 4-13 cylinder head cleaning and inspection • scrape the carbon deposits from the head and exhaust port with a suitable tool [a]. • to avoid gouging, use scrapers that are made of a material that will not cause damage. • clean the head in a bath of high flash-point solvent and dry it w...

Page 66

4-14 engine top end valves valve clearance inspection note valve clearance must be checked when the engine is cold (at room temperature). • remove the rocker cover (see cylinder head removal). • place the piston at top dead center (tdc) of the compression stroke turning the crankshaft clockwise faci...

Page 67

Engine top end 4-15 valves valve seat inspection • remove the valve. (see valve mechanism removal/installation) • inspect the valve seats for damage. If the seats are warped or distorted beyond reconditioning, replace the cylinder head. • pitted or worn valve seats can be refaced. Lap the valves to ...

Page 68

4-16 engine top end valves seat cutter operating cares: 1. This valve seat cutter is designed only for valve seat repair. Therefore the cutter must not be used for other purposes. 2. Do not drop or hit the valve seat cutter, or the diamond particles may fall off. 3. Do not fail to apply engine oil t...

Page 69

Engine top end 4-17 valves • use a 30 seat cutter [a] to narrow the seat width to the std width. Turn the seat cutter one turn at a time while pressing down very lightly. Check the seat width after each turn. Caution the 30 cutter removes material very quickly. Check the seat width frequently to pre...

Page 70

4-18 engine top end valves valve stem runout • support the valve in v blocks at each end of the stem. • position a dial gauge perpendicular to the stem. • turn the valve and read the variation on the dial gauge. If the stem runout is greater than service limit, replace the valve. Valve stem runout s...

Page 71

Engine top end 4-19 cylinder, piston piston removal • split the crankcase (see camshaft/crankshaft chapter). • remove the camshaft (see camshaft/crankshaft chapter). • turn the crankshaft to expose the connecting rod cap bolts [a]. • remove the bolts and take off the connecting rod caps [b]. Note no...

Page 72

4-20 engine top end cylinder, piston piston installation • install the expander [a] in the piston oil ring groove so that the expander ends [b] touch together, never overlap. • install the upper and lower steel rails. There is no up or down to the rails. They can be installed either way. • do not mi...

Page 73

Engine top end 4-21 cylinder, piston • apply engine oil to the piston skirt and the cylinder bore. Using the piston ring compressor grip [a] and the belt [b], lightly tap the top of the piston with a plastic mallet [c] to insert the piston and connecting rod into the cylinder. Special tool - piston ...

Page 74

4-22 engine top end cylinder, piston piston cleaning • remove the piston and piston rings (see piston removal). Caution never clean the piston head with the engine assembled. Carbon particles will fall between the piston and cylinder, and damage the crankshaft bearings. • scrape the carbon off [a] t...

Page 75

Engine top end 4-23 cylinder, piston • measure the piston ring thickness [a]. Use a micrometer to measure at several points around the rings. If any of the measurement are less than the service limit, replace the entire set of rings. Piston ring thickness service limit top, second 1.40 mm (0.055 in....

Page 76

4-24 engine top end cylinder, piston • measure the inside diameter [a] of the small end of the connecting rod at several points. Use a dial bore gauge. If the inside diameter is more than the service limit, replace the connecting rod. Connecting rod small end inside diameter service limit: 16.05 mm ...

Page 77

Engine top end 4-25 cylinder, piston cylinder boring and honing always resize to exactly 0.5 mm (0.02 in.) over the standard bore size. If this is done accurately, the stock oversize rings and piston will fit perfectly and proper clearance will be maintained. Resizing the cylinder bore can be done b...

Page 78

4-26 engine top end cylinder, piston caution stop the drill press before measuring and remove the hone from the cylinder. Note the finish should not be smooth, but have a 40 to 60 degree crosshatch pattern. • hone the cylinder until it is about 0.007 to 0.009 mm (0.0003 to 0.0004 in) large to allow ...

Page 79

Engine top end 4-27 muffler/exhaust pipe installation muffler/exhaust pipe removal • loosen the clamp nut [a]. • remove the bolt [b] on the muffler bracket and take off the muffler. • unscrew the exhaust pipe flange nuts [a], and remove the exhaust pipe [b] with pipe cover [c]. Use a penetrating oil...

Page 81: Lubrication System

Lubrication system 5-1 lubrication system table of contents 5 exploded view....................................................................................................................................................................5-2 engine oil flow chart.......................................

Page 82

5-2 lubrication system exploded view.

Page 83

Lubrication system 5-3 exploded view [fh451v, fh500v, fh531v] t1: 3.9 n 1 m (0.40 kg 1 m, 35 in 1 lb) t2: 6.9 n 1 m (0.7 kg 1 m, 61 in 1 lb) t3: 9.8 n 1 m (1.0 kg 1 m, 87 in 1 lb) t4: 20 n 1 m (2.0 kg 1 m, 14.5 ft 1 lb) t5: 39 n 1 m (4.0 kg 1 m, 29 ft 1 lb) t6: 17 n 1 m (1.7 kg 1 m, 12.0 ft 1 lb) t7...

Page 84

5-4 lubrication system engine oil flow chart.

Page 85

Lubrication system 5-5 specifications item standard engine oil: grade sf, sg, sh or sj class viscosity sae40, sae30, sae10w-30 / sae10w-40, or sae5w-20 capacity [when filter is not removed] 1.5 l (1.6 us qt) [when filter is removed] 1.7 l (1.8 us qt) 111 except fh721v 1.8 l (1.9 us-qt) 111 fh721v le...

Page 86

5-6 lubrication system engine oil, oil filter, and oil cooler caution engine operation with insufficient, deteriorated, or contami- nated engine oil will cause accelerated wear and may result in engine seizure and accident. Before starting the engine for the first time, add oil: the engine is shippe...

Page 87

Lubrication system 5-7 engine oil, oil filter, and oil cooler • remove the oil filler cap and pour in the specified type and amount of oil. Engine oil : grade: sf, sg, sh or sj class viscosity: sae40, sae30, sae10w-30/sae10w-40, or sae5w-20 capacity: [when filter is not removed] 1.5 l (1.6 us qt) [w...

Page 88

5-8 lubrication system pressurized lubrication system the engine lubrication circuit is a pressurized system consisting of a positive displacement pump which picks up oil through a filter screen from the crankcase. The oil is pumped to a replaceable oil filter cartridge, through the engine’s oil pas...

Page 89

Lubrication system 5-9 oil pump, relief valve oil pump, relief valve removal • remove the crankcase cover (see camshaft/crankshaft chapter). • unscrew the mounting bolts and remove the oil pump parts assembly (pump gear, pump cover plate, pump shaft, pins and rotors). • take off the relief valve spr...

Page 90

5-10 lubrication system oil pump, relief valve • measure the inside diameter [a] of the pump housing with a inside micrometer at several points. If the inside diameter is more than the service limit, replace the crankcase cover. Pump housing inside diameter service limit: 40.801 mm (1.6063 in.) • me...

Page 91

Lubrication system 5-11 oil pump, relief valve if cleaning does not solve the problem, replace the relief valve parts. If necessary, put the ball in position and lightly tap the ball with a suitable tools to form a perfect seat. • measure free length [a] of the spring with a vernier caliper. If the ...

Page 92

5-12 lubrication system oil screen oil screen removal • remove the crankcase cover (see camshaft/crankcase chapter). • unscrew the mounting bolts [a] and remove the oil pump parts assembly. • remove the oil screen [b]. Oil screen installation • clean the oil screen thoroughly whenever it is removed ...

Page 93: Camshaft/crankshaft

Camshaft/crankshaft 6-1 camshaft/crankshaft table of contents 6 exploded view....................................................................................................................................................................6-2 specifications ...........................................

Page 94

6-2 camshaft/crankshaft exploded view.

Page 95

Camshaft/crankshaft 6-3 exploded view [fh451v, fh500v, fh531v] t1: 5.9 n 1 m (0.6 kg 1 m, 52 in 1 lb) t2: 25 n 1 m (2.6 kg 1 m, 19.0 ft 1 lb) t3: see engine top end chapter. [fh601v, fh641v, fh680v, fh721v] t1: 5.9 n 1 m (0.6 kg 1 m, 52 in 1 lb) t2: 25 n 1 m (2.6 kg 1 m, 19.0 ft 1 lb) t3: see engine...

Page 96

6-4 camshaft/crankshaft specifications service limit item fh451v, 500v, 531v fh601v, 641v, 680v, 721v camshaft, tappet: cam lobe height intake 29.131 mm (1.1469 in.) 29.621 mm (1.166 in.) exhaust 29.131 mm (1.1469 in.) 29.621 mm (1.166 in.) camshaft journal diameter pto side 15.985 mm (0.6293 in.) f...

Page 97

Camshaft/crankshaft 6-5 crankcase crankcase cover removal • set the engine on a clean surface while parts are being removed. • drain the oil (see lubrication system chapter). • remove: exhaust pipe and muffler (see engine top end chapter) control panel (see fuel system chapter) governor arm (see fue...

Page 98

6-6 camshaft/crankshaft crankcase • check to see that the crankcase dowel pins [a] are in place on the crankcase. • install the gasket on the crankcase. • install the crankcase cover and tighten the crankcase cover bolts following the tightening sequence shown - fh451v, 500v, 531v. Torque - crankcas...

Page 99

Camshaft/crankshaft 6-7 crankcase cleaning • remove: camshaft and tappets (see camshaft, tappet removal) crankshaft (see crankshaft removal) • clean up the crankcase and cover with a high flash-point solvent, and blow out any foreign particles that may be in the pockets inside of the crankcase with ...

Page 100

6-8 camshaft/crankshaft breather the function of the breather is to create a vacuum in the crankcase which prevents oil from being forced out of the engine through the piston rings, oil seals or gaskets. A sealed-type crankcase emission control system is used to eliminate blow-by gases. The blow-by ...

Page 101

Camshaft/crankshaft 6-9 breather breather element removal - fh451v, 500v, 531v • remove the bolts [a] and breather chamber cover [b]. • remove the element [a]. • check to see that the plate [b] is in place under the element [a]. D breather element installation - fh451v, 500v, 531v • apply sealant [a...

Page 102

6-10 camshaft/crankshaft camshaft, tappet camshaft, tappet removal • set the engine on a clean surface while parts are being removed. • drain the oil (see lubrication system chapter). • remove: muffler (see engine top end chapter) throttle control panel (see fuel system chapter) carburetor (see fuel...

Page 103

Camshaft/crankshaft 6-11 camshaft, tappet camshaft disassembly • remove the governor assembly (see fuel system chapter). • remove: spring [a] do not remove the acr (automatic compression release) weight [b]. Camshaft assembly • install the governor assembly (see fuel system chapter). • after assembl...

Page 104

6-12 camshaft/crankshaft camshaft, tappet • measure both camshaft journals at several points around the journal circumference. If the journal diameter is less than the service limit, replace the camshaft. Pto side camshaft journal diameter service limit: 15.985 mm (0.6293 in.) flywheel side camshaft...

Page 105

Camshaft/crankshaft 6-13 crankshaft, connecting rod connecting rod removal • remove: piston (see engine top end chapter) connecting rod installation • install: piston (see engine top end chapter) crankshaft removal • set the engine on a clean surface while parts are being removed. • drain the oil (s...

Page 106

6-14 camshaft/crankshaft crankshaft, connecting rod • measure connection rod twist. With the big-end arbor still on the v blocks, hold the connection rod horizontally and measure the amount that the small end arbor varies from being parallel with the surface plate over a 100 mm length of the arbor t...

Page 107

Camshaft/crankshaft 6-15 crankshaft, connecting rod • measure the crankpin outside diameter [a]. Use a micrometer to measure several points around the crankpin circumference. If the crankpin diameter is less than the service limit, replace the crankshaft with a new one. Crankpin outside diameter mod...

Page 108

6-16 camshaft/crankshaft crankshaft, connecting rod crankpin resizing crankpin can be resized to accept 34.5 mm (1.3583 in.) dia under size connecting rod. The crankpin should be reground if the crankpin is so much undersize and so much scored that a lapping operation will prove unsatisfactory. Regr...

Page 109: Electrical System

Electrical system 7-1 electrical system table of contents 7 exploded view....................................................................................................................................................................7-2 specifications ...............................................

Page 110

7-2 electrical system exploded view.

Page 111

Electrical system 7-3 exploded view [fh451v, fh500v, fh531v] t1: 3.9 n 1 m (0.40 kg 1 m, 35 in 1 lb) t2: 5.9 n 1 m (0.60 kg 1 m, 52 in 1 lb) t3: 7.8 n 1 m (0.80 kg 1 m, 69 in 1 lb) t5: 56 n 1 m (5.7 kg 1 m, 41 ft 1 lb) t6: 22 n 1 m (2.2 kg 1 m, 16 ft 1 lb) [fh601v, fh641v, fh680v, fh721v] t1: 3.9 n ...

Page 112

7-4 electrical system exploded view [fh451v, fh500v, fh531v].

Page 113

Electrical system 7-5 exploded view [fh451v, fh500v, fh531v] t2: 5.9 n 1 m (0.60 kg 1 m, 52 in 1 lb) t3: 7.8 n 1 m (0.80 kg 1 m, 69 in 1 lb) t4: 17 n 1 m (1.7 kg 1 m, 12 ft 1 lb) g: apply grease..

Page 114

7-6 electrical system specifications standard item fh451v, 500v, 531v fh601v, 641v, 680v, 721v service limit charging system: regulated output voltage 14.1 v dc 15 v dc alternator stator coil resistance in the text – – – unregulated stator output 28.4 v ac/3000 rpm 26v ac/3000 rpm regulator resistan...

Page 115

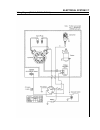

Electrical system 7-7 wiring diagram [fh451v, fh500v, fh531v].

Page 116

7-8 electrical system wiring diagram [fh451v, fh500v, fh531v].

Page 117

Electrical system 7-9 wiring diagram [fh451v, fh500v, fh531v].

Page 118

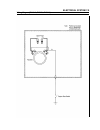

7-10 electrical system wiring diagram [fh601v, fh641v, fh680v, fh721v].

Page 119

Electrical system 7-11 precautions there are a number of important precautions that are musts when servicing electrical systems. Learn and observe all the rules below. Do not reverse the battery lead connections. This will burn out the diodes in the electrical parts. Always check battery condition b...

Page 120

7-12 electrical system charging, ignition system flywheel, stator coil removal • remove: recoil starter (see recoil starter removal) nuts [a] and guard [b] bolts [c] and screen [d] spacer [e] • loosen the fan housing bolts [a] and remove the fan housing [b]. • remove: ignition coils (see ignition co...

Page 121

Electrical system 7-13 charging, ignition system • remove: woodruff key [a] stator coil lead connector [b] stator coil screw [c] stator coil [d] flywheel, stator coil installation • install the stator coil and tighten the screws. Torque - stator coil screws: 3.4 n 1 m (0.35 kg 1 m, 30 in 1 lb) • usi...

Page 122

7-14 electrical system charging, ignition system • install the fan housing and tight the bolts. Torque - fan housing bolts: 5.9 n 1 m (0.6 kg 1 m, 52 in 1 lb) • install: recoil starter (see recoil starter installation) • install: spacer [a] screen [b] position three sets [c] of screen notches around...

Page 123

Electrical system 7-15 charging, ignition system stator coil resistance • disconnect the connector [a]. • measure the stator coil resistance. (electric starter model) connect an ohmmeter between stator pins [b]. Stator coil resistance (electric starter model) 0.01 to 0.1 (recoil starter model with e...

Page 124

7-16 electrical system charging, ignition system regulator resistance • set the kawasaki hand tester selector switch to the r 2 100 position. • connect the test leads to the points shown on the chart and read the resistance. There are two(2) types of regulator on fh engines as follows: (with out cha...

Page 125

Electrical system 7-17 charging, ignition system this engine ignition is controlled by a solid state ignition assembly and requires no periodic maintenance except for the spark plugs. The system consists of the following: inductive ignition assemblies permanent magnet flywheel spark plugs stop switc...

Page 126

7-18 electrical system charging, ignition system ignition coil removal • remove: fan housing (see flywheel, stator coil removal) spark plug cap [a] stop switch lead connector [b] bolts [c] ignition coil [d] ignition coil installation • install ignition coil on crankcase so that the stop switch lead ...

Page 127

Electrical system 7-19 charging, ignition system ignition coil inspection • remove the ignition coils (see ignition coil removal). • measure the winding resistance as follows: set the hand tester to the r 2 1 k range. Special tool - hand tester: 57001–1394 make the measurements shown in the table. I...

Page 128

7-20 electrical system starter system starter motor removal • remove the mounting bolts [a] and pull the starter motor [b] from the engine. Starter motor installation • clean the starter motor and engine mounting flanges to ensure good electrical contact and tighten the mounting bolts. Torque - star...

Page 129

Electrical system 7-21 starter system starter motor assembly • assembly is the reverse of disassembly. • apply a small amount of grease [a] to the armature shaft. • do not reuse the snap ring [b]. Replace it with a new one. • check the cap and replace it with a new one if damaged. • fit the projecti...

Page 130

7-22 electrical system starter system • measure the depth of the grooves between the commutator segments. If the grooves are shallower than the specified limit, replace the armature with a new one. If the grooves are only dirty, clean them carefully. Commutator groove depth limit less than 0.9 mm (0...

Page 131

Electrical system 7-23 starter system • test the armature winding for shorts. Place the armature on a growler [a]. Hold a thin metal strip (e.G., hack saw blade) on top of the armature. Turn on the growler and rotate the armature one complete turn. If the metal strip vibrates, the windings are inter...

Page 132

7-24 electrical system starter system recoil starter removal • remove: recoil starter mounting nuts [a] recoil starter [b] recoil starter installation • install the recoil starter and tighten the mounting nuts. Torque - recoil starter mounting nuts: 5.9 n 1 m (0.6 kg 1 m, 52 in 1 lb) recoil starter ...

Page 133

Electrical system 7-25 starter system when removing the reel [a], be careful that the recoil spring [b] under the reel does not fly loose and cause injury. The spring is under great pressure. Note there should be no spring tension on the reel when removing it. If tension is felt, push the reel back ...

Page 134

7-26 electrical system starter system • lightly grease the shaft [a]. • put the reel into the case, with the round peg [b] aligned with the spring inner tongue [c]. • turn the reel clockwise until you feel the hang hook on the catch. • install: return springs [a] and pawls [b] washer [c] and center ...

Page 135: Troubleshooting

Troubleshooting 8-1 troubleshooting table of contents 8 engine troubleshooting guide ...........................................................................................................................................8-2 starter motor troubleshooting guide........................................

Page 136

8-2 troubleshooting engine troubleshooting guide if the engine malfunctions, check if the way the engine is used is correct. If engine malfunctions even if engine is used correctly, systematically carry out troubleshooting starting with simple points. This chart describes typical troubleshooting pro...

Page 137

Troubleshooting 8-3 engine troubleshooting guide.

Page 138

8-4 troubleshooting engine troubleshooting guide.

Page 139

Troubleshooting 8-5 engine troubleshooting guide.

Page 140

8-6 troubleshooting starter motor troubleshooting guide 1. Disconnect spark plug caps from the spark plugs. 2. Turn engine switch to “start” position and check condition. Engine may be cranked in this test. Do not touch any rotating parts of engine and equipment during test. Caution if starter does ...