- DL manuals

- Kawasaki

- Other

- KFX 450R - BROCHURE 2009

- Service Manual

Kawasaki KFX 450R - BROCHURE 2009 Service Manual

Summary of KFX 450R - BROCHURE 2009

Page 1

Kfx450r all terrain vehicle service manual.

Page 3: Quick Reference Guide

This quick reference guide will assist you in locating a desired topic or pro- cedure. •bend the pages back to match the black tab of the desired chapter num- ber with the black tab on the edge at each table of contents page. •refer to the sectional table of contents for the exact pages to locate th...

Page 5: Kfx450R

Kfx450r all terrain vehicle service manual all rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of quality assura...

Page 6

List of abbreviations a ampere(s) lb pounds(s) abdc after bottom dead center m meter(s) ac alternating current min minute(s) atdc after top dead center n newton(s) bbdc before bottom dead center pa pascal(s) bdc bottom dead center ps horsepower btdc before top dead center psi pound(s) per square inc...

Page 7

Emission control information to protect the environment in which we all live, kawasaki has incorporated crankcase emission (1) and exhaust emission (2) control systems in compliance with applicable regulations of the united states environmental protection agency and california air resources board. A...

Page 8

We recommend that all dealers observe these provisions of federal law, the violation of which is punishable by civil penalties not exceeding $10,000 per violation..

Page 9

Please do not tamper with noise control system (us model only) tampering with emission control system prohibited: federal regulations and california state law prohibit the following acts or the causing thereof: (1) the removal or rendering inoperative by any person other than for purposes of mainten...

Page 10: Foreword

Foreword this manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic in- formation to make it useful to the owner who de- sires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the prope...

Page 11: General Information

General information 1-1 1 general information table of contents before servicing ..................................................................................................................... 1-2 model identification................................................................................

Page 12

1-2 general information before servicing before starting to perform an inspection service or carry out a disassembly and reassembly oper- ation on a vehicle, read the precautions given below. To facilitate actual operations, notes, illustra- tions, photographs, cautions, and detailed descriptions ha...

Page 13

General information 1-3 before servicing arrangement and cleaning of removed parts disassembled parts are easy to confuse. Arrange the parts according to the order the parts were disassembled and clean the parts in order prior to assembly. Storage of removed parts after all the parts including subas...

Page 14

1-4 general information before servicing tightening sequence generally, when installing a part with several bolts, nuts, or screws, start them all in their holes and tighten them to a snug fit. Then tighten them according to the specified se- quence to prevent case warpage or deformation which can l...

Page 15

General information 1-5 before servicing press for items such as bearings or oil seals that must be pressed into place, apply small amount of oil to the con- tact area. Be sure to maintain proper alignment and use smooth movements when installing. Ball bearing and needle bearing do not remove presse...

Page 16

1-6 general information before servicing lubrication it is important to lubricate rotating or sliding parts during assembly to minimize wear during initial operation. Lubri- cation points are called out throughout this manual, apply the specific oil or grease as specified. Direction of engine rotati...

Page 17

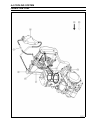

General information 1-7 model identification ksf450b8f left side view ksf450b8f right side view frame number [a] frame number [b] left suspension arm engine number [a] engine number [b] shift pedal.

Page 18

1-8 general information general specifications items ksf450b8f ∼, ksf450b8fa ∼ dimensions overall length 1 806 mm (71.10 in.) overall width 1 170 mm (46.06 in.) overall height 1 064 mm (41.89 in.) wheelbase 1 255 mm (49.41 in.) ground clearance 108 mm (4.25 in.) seat height 786 mm (30.94 in.) dry ma...

Page 19

General information 1-9 general specifications items ksf450b8f ∼, ksf450b8fa ∼ lubrication system forced lubrication (semi dry sump) engine oil: type api sf or sg api sh, sj or sl with jaso ma, ma1 or ma2 viscosity sae 10w-40 capacity 1.35 l (1.43 us qt) drive train primary reduction system: type ge...

Page 20

1-10 general information general specifications items ksf450b8f ∼, ksf450b8fa ∼ suspension: front: type double wishbone wheel travel 215 mm (8.46 in.) rear: type swingarm wheel travel 254 mm (10.0 in.) brake: front disc × 2 rear disc parking brake disc (mechanical) electrical equipment battery 12 v ...

Page 21

General information 1-11 unit conversion table prefixes for units: prefix symbol power mega m × 1 000 000 kilo k × 1 000 centi c × 0.01 milli m × 0.001 micro μ × 0.000001 units of mass: kg × 2.205 = lb g × 0.03527 = oz units of volume: l × 0.2642 = gal (us) l × 0.2200 = gal (imp) l × 1.057 = qt (us)...

Page 23: Periodic Maintenance

Periodic maintenance 2-1 2 periodic maintenance table of contents periodic maintenance chart ................................................................................................... 2-3 torque and locking agent..................................................................................

Page 24

2-2 periodic maintenance steering inspection ........................................................................................................... 2-35 knuckle joint boot inspection........................................................................................... 2-35 tie-rod end boot...

Page 25

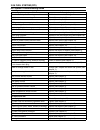

Periodic maintenance 2-3 periodic maintenance chart the scheduled maintenance must be done in accordance with this chart to keep the vehicle in good running condition. The initial maintenance is vitally important and must not be neglected. Frequency first service regular service operation after 10 h...

Page 26

2-4 periodic maintenance periodic maintenance chart frequency first service regular service operation after 10 hrs. Or 100 km (60 mi.) of use every 10 days or 200 km (120 mi.) of use every 30 days or 600 km (360 mi.) of use every 90 days or 1 700 km (1 100 mi.) of use every year of use see page brak...

Page 27

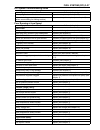

Periodic maintenance 2-5 torque and locking agent the following tables list the tightening torque for the major fasteners, and the parts requiring use of a non-permanent locking agent or liquid gasket. Letters used in the “remarks” column mean: l: apply a non-permanent locking agent. Lh: left-hand t...

Page 28

2-6 periodic maintenance torque and locking agent torque fastener n·m kgf·m ft·lb remarks cylinder bolts 12 1.2 106 in·lb chain tensioner mounting bolts 9.8 1.0 87 in·lb chain tensioner cap bolt 5.0 0.51 44 in·lb rear camshaft chain guide bolt 15 1.5 11 eo camshaft sprocket bolts 12 1.2 106 in·lb l ...

Page 29

Periodic maintenance 2-7 torque and locking agent torque fastener n·m kgf·m ft·lb remarks reverse cable cap bolt 8.8 0.90 78 in·lb crankcase bolts 9.8 1.0 87 in·lb s bearing retaining bolts 19 1.9 14 l piston oil nozzle 2.9 0.30 26 in·lb st wheels/tires front wheel nuts 79 8.0 58 s rear wheel nuts 7...

Page 30

2-8 periodic maintenance torque and locking agent torque fastener n·m kgf·m ft·lb remarks suspension swingarm pivot shaft nut 90.5 9.2 67 swingarm adjusting locknut 31.5 3.2 23 l suspension arm pivot nuts 36.5 3.7 27 knuckle joint nuts 29 3.0 21 tie-rod mounting nut 71.5 7.3 53 rocker arm pivot nut ...

Page 31

Periodic maintenance 2-9 torque and locking agent torque fastener n·m kgf·m ft·lb remarks starter motor terminal nut 9.8 1.0 87 in·lb spark plug 13 1.3 115 in·lb regulator/rectifier bolts 8.8 0.90 78 in·lb starter relay cable terminal bolts 4.0 0.41 35 in·lb ignition coil nuts 8.8 0.90 78 in·lb star...

Page 32

2-10 periodic maintenance torque and locking agent the tables below, relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the values are for use with dry solvent-c...

Page 33

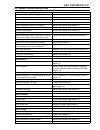

Periodic maintenance 2-11 specifications item standard service limit fuel system throttle lever free play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) – – – idle speed 1 800 ±100 r/min (rpm) – – – air cleaner element oil high-quality foam air filter oil – – – cooling system coolant: type (recommended) permanent type ...

Page 34

2-12 periodic maintenance specifications item standard service limit final drive drive chain slack 40 ∼ 50 mm (1.57 ∼ 1.97 in.) – – – drive chain 20 link length 317.5 ∼ 318.2 mm (12.50 ∼ 12.53 in.) 323 mm (12.7 in.) rear sprocket warp 0.4 mm (0.016 in.) or less 0.5 mm (0.02 in.) brakes brake lever f...

Page 35

Periodic maintenance 2-13 special tool filler cap driver: 57001-1454.

Page 36

2-14 periodic maintenance periodic maintenance procedures fuel system throttle lever free play inspection • check that the throttle lever [a] moves smoothly from full open to close, and the throttle closes quickly and com- pletely in all steering positions by the return spring. If the throttle lever...

Page 37

Periodic maintenance 2-15 periodic maintenance procedures idle speed adjustment • remove: left side cover (see side cover removal in the frame chapter) • start the engine and warm it up thoroughly. • turn the idle adjuster [a] until the idle speed is correct. ○ open and close the throttle a few time...

Page 38

2-16 periodic maintenance periodic maintenance procedures air cleaner draining • if any water or oil accumulates in the tube, drain it by tak- ing off the drain plug [a]. After draining, be sure to install the drain plug and clamp firmly. Fuel hose inspection (fuel leak, damage, installation conditi...

Page 39

Periodic maintenance 2-17 periodic maintenance procedures • twist the screwdriver to disconnect the joint lock [a]. • pull [b] the fuel hose joint [c] out of the delivery pipe. Warning be prepared for fuel spillage; any spilled fuel must be completely wiped up immediately. When the fuel hose is disc...

Page 40

2-18 periodic maintenance periodic maintenance procedures • clean the radiator. Caution when cleaning the radiator with steam cleaner, be careful of the following to prevent radiator damage. Keep the steam gun away more than 0.5 m (20 in.) from the radiator core [a]. Hold the steam gun perpendicular...

Page 41

Periodic maintenance 2-19 periodic maintenance procedures • place a container under the drain bolt [a] at the bottom of the water pump cover, then remove the drain plug. • remove the radiator cap [a] in two steps. First turn the cap counterclockwise to the first step. Then push and turn it further i...

Page 42

2-20 periodic maintenance periodic maintenance procedures caution soft or distilled water must be used with the an- tifreeze in the cooling system. If hard water is used in the system, it causes scale accumulation in the water passages, considerably reducing the efficiency of the cooling system. Wat...

Page 43

Periodic maintenance 2-21 periodic maintenance procedures • first, bring the piston to the top-dead-center of its com- pression stroke to inspect the valve clearance (the posi- tion at the end of the compression stroke), when the cam lobe faces outside of the camshaft. ○ place a wrench over the alte...

Page 44

2-22 periodic maintenance periodic maintenance procedures • clean the shim to remove any dust or oil. • measure the thickness of the removed shim [a]. • select a new shim thickness calculation as follows. A = (b – c) + d [a] replace shim thickness [b] measured valve clearance [c] specified valve cle...

Page 45

Periodic maintenance 2-23 periodic maintenance procedures • when installing the shim, face the marked side [a] toward the valve lifter [b]. At this time, apply engine oil to the shim or the valve lifter to keep the shim in place during camshaft installation. Caution do not put shim stock under the s...

Page 46

2-24 periodic maintenance periodic maintenance procedures engine right side clutch lever free play check • slide the clutch lever dust cover [a] out of place. • check that the clutch cable upper end is fully seated in the adjusting bolt [b]. • check that the clutch lever [c] has 5 ∼ 10 mm (0.2 ∼ 0.4...

Page 47

Periodic maintenance 2-25 periodic maintenance procedures • remove the engine oil drain bolts on the bottom of the engine, and let the oil drain completely. Drain bolt (m6) [a] drain bolt (m12) [b] note ○ hold the vehicle upright so that the oil may drain com- pletely. • replace the gaskets at the d...

Page 48

2-26 periodic maintenance periodic maintenance procedures • remove the oil filter [a]. • install the spring [a] to the right engine cover. • apply grease to the grommet [b]. • be sure to install the filter with the grommet facing outside as shown. Caution inside out installation stop oil flow, causi...

Page 49

Periodic maintenance 2-27 periodic maintenance procedures wheels/tires tire inspection • examine the tire for damage and wear. If the tire is cut or cracked, replace it. ○ lumps or high spots on the tread or sidewalls indicate internal damage requiring tire replacement. ○ remove any foreign objects ...

Page 50

2-28 periodic maintenance periodic maintenance procedures • using the hook wrench [a] in the owner’s tool, hock the it to the groove of the bearing housing and turn it upward or downward until the drive chain has the correct amount of chain slack. Caution do not overtighten the chain. Overtightening...

Page 51

Periodic maintenance 2-29 periodic maintenance procedures drive chain lubrication ○ the chain should be lubricated with a lubricant which will both prevent the exterior from rusting and reduce friction in the interior of the chain. If the chain is especially dirty, it should be washed in diesel oil ...

Page 52

2-30 periodic maintenance periodic maintenance procedures chain guide inspection • remove: swingarm (see swingarm removal in the suspension chapter) rear bottom guard (see rear bottom guard removal in the frame chapter) • visually inspect the chain guides [a]. Replace the chain guide if it shows any...

Page 53

Periodic maintenance 2-31 periodic maintenance procedures brake hose replacement • pump the brake fluid out of the line as explained in the brake fluid change (see brake flude change). • remove the banjo bolts at both ends of the brake hose, and pull the hose off the vehicle. • immediately wipe up a...

Page 54

2-32 periodic maintenance periodic maintenance procedures brake fluid level inspection • check the brake fluid level in the front or rear brake reser- voir [a]. Note ○ hold the reservoir horizontal when checking brake fluid level. • the front or rear reservoir must be kept above the lower level line...

Page 55

Periodic maintenance 2-33 periodic maintenance procedures brake fluid change note ○ the procedure to change the front brake fluid. Chang- ing the rear brake fluid is the same as for the front brake. • remove the reservoir cap and the rubber cap on the bleed valve. • attach a clear plastic hose to th...

Page 56

2-34 periodic maintenance periodic maintenance procedures master cylinder piston assembly and dust cover replacement front • disassemble: master cylinder (see front master cylinder disassem- bly in the brakes chapter) • replace: master cylinder piston assembly [a] dust cover [b] circlip [c] • assemb...

Page 57

Periodic maintenance 2-35 periodic maintenance procedures steering steering inspection • turn the handlebar left and right, and check the steering action. If the steering action is not smooth, or if the steering binds or catches before the stop, lubricate the steering stem bearing. Note ○ the cables...

Page 58

2-36 periodic maintenance periodic maintenance procedures spark plug gap inspection • measure the gap [a] with a wire-type thickness gauge. If the gap is incorrect, carefully bend the side electrode [b] with a suitable tool to obtain the correct gap. Spark plug gap 0.8 ∼ 0.9 mm (0.03 ∼ 0.04 in.) bra...

Page 59

Periodic maintenance 2-37 periodic maintenance procedures cables: lubricate with cable lubricant parking brake cable throttle cable clutch cable reverse cable • lubricate the cables by seeping the oil between the cable and housing. ○ the cable may be lubricated by using a pressure cable luber with a...

Page 60

2-38 periodic maintenance periodic maintenance procedures bolts and nuts tightening tightness inspection • check the tightness of the bolts and nuts listed here in accordance with the periodic maintenance chart. Also, check to see that each cotter pin is in place and in good condition. If there are ...

Page 61: Fuel System (Dfi)

Fuel system (dfi) 3-1 3 fuel system (dfi) table of contents exploded view........................................................................................................................ 3-3 dfi system...............................................................................................

Page 62

3-2 fuel system (dfi) injector signal test............................................................................................................ 3-60 injector resistance inspection .......................................................................................... 3-61 injector unit tes...

Page 63

Fuel system (dfi) 3-3 exploded view dummy page.

Page 64

3-4 fuel system (dfi) exploded view.

Page 65

Fuel system (dfi) 3-5 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 fuel tank mounting bolts 9.3 0.95 82 in·lb 2 fuel pump bolts 9.8 1.0 87 in·lb l 3 ecu mounting bolts 8.8 0.90 78 in·lb 4 inlet air pressure sensor bracket mounting bolt 8.8 0.90 78 in·lb 5 throttle case cover screws 2....

Page 66

3-6 fuel system (dfi) exploded view.

Page 67

Fuel system (dfi) 3-7 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 air cleaner housing bolts 8.8 0.90 78 in·lb 2 rear air cleaner duct clamp screw 1.4 0.14 12 in·lb 3 front air cleaner duct clamp screws 1.4 0.14 12 in·lb 4 inlet air temperature sensor mounting screw 4.9 0.50 43 in·lb ...

Page 68

3-8 fuel system (dfi) dfi system dfi system.

Page 69

Fuel system (dfi) 3-9 dfi system 1. Inlet air pressure sensor 2. Crankshaft sensor 3. Injector 4. Main throttle sensor 5. Delivery pipe 6. Main throttle valve 7. Fuel pump 8. Pressure regulator 9. Fuel tank 10. Air cleaner element 11. Inlet air temperature sensor 12. Air cleaner housing 13. Vehicle-...

Page 70

3-10 fuel system (dfi) dfi system dfi system wiring diagram part name 1. Ignition switch 2. Frame ground 3. Fuel pump 4. Fuel pump relay 5. Fuel pump fuse 10 a 6. Main throttle sensor 7. Inlet air pressure sensor 8. Fuel injector 9. Water temperature sensor 10. Inlet air temperature sensor 11. Crank...

Page 71

Fuel system (dfi) 3-11 dfi system terminal names 1. Ignition coil #1 signal 2. Radiator fan relay signal 3. Fi indicator light/water temperature warn- ing light 4. Unused 5. Unused 6. External communication line (mode switch) 7. Communication line b 8. Communication line a 9. Ground for sensors 10. ...

Page 72

3-12 fuel system (dfi) dfi parts location fi indicator (water temperature warning) light [a] ignition coil [a] fuel pump [b] battery 12 v 6 ah [a] crankshaft sensor [b] water temperature sensor [a] inlet air pressure sensor [a] main throttle sensor [b] fuel injector [c].

Page 73

Fuel system (dfi) 3-13 dfi parts location inlet air temperature sensor [a] fuel pump relay [a] kawasaki diagnostic system connector [a] self diagnosis terminal [b] ecu (electronic control unit) [c] vehicle-down sensor [d].

Page 74

3-14 fuel system (dfi) specifications item standard digital fuel injection system idle speed 1 800 ±100 r/min (rpm) throttle body assy: type single barrel type bore 42 mm (1.65 in.) ecu (electronic control unit): make mitsubishi electric type digital memory type, with built in ic igniter, sealed wit...

Page 75

Fuel system (dfi) 3-15 special tools and sealant oil pressure gauge, 5 kgf/cm²: 57001-125 fork oil level gauge: 57001-1290 hand tester: 57001-1394 needle adapter set: 57001-1457 throttle sensor setting adapter: 57001-1538 sensor harness adapter: 57001-1561 fuel pressure gauge adapter: 57001-1593 fue...

Page 76

3-16 fuel system (dfi) dfi servicing precautions dfi servicing precautions there are a number of important precautions that should be followed servicing the dfi system. ○ this dfi system is designed to be used with a 12 v sealed battery as its power source. Do not use any other battery except for a ...

Page 77

Fuel system (dfi) 3-17 dfi servicing precautions ○ to maintain the correct fuel/air mixture (f/a), there must be no inlet air leaks in the dfi system. Be sure to install the oil filler plug [a] after filling the engine oil. Clutch cover [b].

Page 78

3-18 fuel system (dfi) troubleshooting the dfi system outline when an abnormality in the dfi system occurs, the fi in- dicator light goes on to alert the rider on the meter panel. In addition, the condition of the problem is stored in the mem- ory of the ecu (electronic control unit). With the engin...

Page 79

Fuel system (dfi) 3-19 troubleshooting the dfi system ○ the dfi part connectors [a] have seals [b], including the ecu. • join the connector and insert the needle adapters [c] inside the seals [b] from behind the connector until the adapter reaches the terminal. Special tool - needle adapter set: 570...

Page 80

3-20 fuel system (dfi) troubleshooting the dfi system • pull each connector [a] apart and inspect it for corrosion, dirt, and damage. If the connector is corroded or dirty, clean it carefully. If it is damaged, replace it. Connect the connectors securely. • check the wiring for continuity. ○ use the...

Page 81

Fuel system (dfi) 3-21 troubleshooting the dfi system ○ there are two ways to inspect the dfi system. One is voltage check method and the other is resistance check method. (voltage check method) ○ this method is conducted by measuring the input voltage [b] to a sensor [a] first, and then the output ...

Page 82

3-22 fuel system (dfi) troubleshooting the dfi system dfi diagnosis flow chart inquiries to rider inquiries to rider ○ each rider reacts to problems in different ways, so it is important to confirm what kind of symptoms the rider has encountered. ○ try to find out exactly what problem occurred under...

Page 83

Fuel system (dfi) 3-23 troubleshooting the dfi system sample diagnosis sheet rider name: registration no. (license plate no.): year of initial registration: model: engine no.: frame no.: date problem occurred: mileage: environment when problem occurred. Weather □ fine, □ cloudy, □ rain, □ snow, □ al...

Page 84

3-24 fuel system (dfi) troubleshooting the dfi system □ other □ spark plug loose (tighten it) □ spark plug dirty, broken, or gap maladjusted (remedy it) □ spark plug incorrect (replace it) □ knocking (fuel poor quality or incorrect) □ brake dragging □ clutch slipping □ engine overheating □ engine oi...

Page 85

Fuel system (dfi) 3-25 dfi system troubleshooting guide note ○ this is not an exhaustive list, giving every possible cause for each problem listed. It is meant simply as a rough guide to assist the troubleshooting for some of the more common difficulties. ○ the ecu may be involved in the dfi electri...

Page 86

3-26 fuel system (dfi) dfi system troubleshooting guide symptoms or possible causes actions (chapter) clutch lever not pulled in and gear not in neutral pull the lever in and shift the gear in neutral. Vehicle-down sensor coming off reinstall (see chapter 3). Vehicle-down sensor trouble inspect (see...

Page 87

Fuel system (dfi) 3-27 dfi system troubleshooting guide symptoms or possible causes actions (chapter) valve spring broken or weak inspect and replace (see chapter 5). Valve not seating properly (valve bent, worn or carbon accumulating on seating surface) inspect and repair or replace (see chapter 5)...

Page 88

3-28 fuel system (dfi) dfi system troubleshooting guide symptoms or possible causes actions (chapter) main throttle sensor trouble inspect (see chapter 3). Fuel pressure too low or too high inspect (see chapter 3). Inlet air pressure sensor trouble inspect (see chapter 3). Water temperature sensor t...

Page 89

Fuel system (dfi) 3-29 dfi system troubleshooting guide symptoms or possible causes actions (chapter) water or foreign matter in fuel change fuel. Inspect and clean fuel system (see chapter 3). Clogged fuel filter or pump screen inspect and replace fuel pump (see chapter 3). Fuel pump trouble inspec...

Page 90

3-30 fuel system (dfi) dfi system troubleshooting guide symptoms or possible causes actions (chapter) engine overheating (see overheating of troubleshooting guide, see chapter 17) other: engine oil viscosity too high change (see chapter 2). Drive train trouble inspect drive chain (see chapter 2) and...

Page 91

Fuel system (dfi) 3-31 dfi system troubleshooting guide symptoms or possible causes actions (chapter) cylinder head not sufficiently tightened down tighten (see chapter 5). No valve clearance adjust (see chapter 2). Cylinder, piston worn inspect and replace (see chapter 5). Piston ring bad (worn, we...

Page 92

3-32 fuel system (dfi) dfi system troubleshooting guide symptoms or possible causes actions (chapter) (brown smoke) air cleaner duct loose reinstall (see chapter 3). Air cleaner o-ring damaged replace (see chapter 3). Too low fuel pressure inspect fuel line and fuel pump (see chapter 3). Water tempe...

Page 93

Fuel system (dfi) 3-33 self-diagnosis self-diagnosis outline the self-diagnosis system has two modes and can be switched to another mode by grounding the self-diagnosis terminal. User mode the ecu notifies the rider of troubles in dfi system and ignition system by lighting the fi indicator when dfi ...

Page 94

3-34 fuel system (dfi) self-diagnosis.

Page 95

Fuel system (dfi) 3-35 self-diagnosis how to read service codes ○ service codes are shown by a series of long and short blinks of the fi indicator light as shown below. ○ read 10th digit and unit digit as the fi indicator light blinks. ○ when there are a number of problems, all the service codes can...

Page 96

3-36 fuel system (dfi) self-diagnosis service code table ser- vice code fi indicator light problems 11 main throttle sensor malfunction, wiring open or short 12 inlet air pressure sensor malfunction, wiring open or short 13 inlet air temperature sensor malfunction, wiring open or short 14 water temp...

Page 97

Fuel system (dfi) 3-37 self-diagnosis backups ○ the ecu takes the following measures to prevent engine damage when the dfi or the ignition system parts have troubles. Service codes parts output signal usable range or criteria backups by ecu 11 main throttle sensor main throttle sensor output voltage...

Page 98

3-38 fuel system (dfi) main throttle sensor (service code 11) caution never drop the throttle body assy, especially on a hard surface. Such a shock to the sensor can dam- age it. Main throttle sensor replacement note ○ these procedures are explained on the assumption that the inlet and exhaust syste...

Page 99

Fuel system (dfi) 3-39 main throttle sensor (service code 11) • turn the main throttle sensor counterclockwise [a] until the sensor screw hole aligns with screw hole in the body. • tighten the torx screw [b] lightly. • connect the throttle sensor setting adapter [a] between the harness connector and...

Page 100

3-40 fuel system (dfi) main throttle sensor (service code 11) main throttle sensor input voltage inspection note ○ be sure the battery is fully charged. • turn the ignition switch off. • remove the left upper engine bracket. • disconnect the main throttle sensor connector with the needle nose pliers...

Page 101

Fuel system (dfi) 3-41 main throttle sensor (service code 11) main throttle sensor output voltage inspection • measure the output voltage at the main throttle sensor in the same way as input voltage inspection, note the following. ○ disconnect the main throttle sensor connector and con- nect the har...

Page 102

3-42 fuel system (dfi) main throttle sensor (service code 11) if the output voltage is normal, check the wiring for conti- nuity. ○ disconnect the ecu and sensor connectors. Wiring connection ecu connector [a] ←→ main throttle sensor connector [b] y/w lead (ecu terminal 17) br/bk lead (ecu terminal ...

Page 103

Fuel system (dfi) 3-43 main throttle sensor (service code 11) main throttle sensor circuit 1. Ecu (electronic control unit) 2. Main throttle sensor.

Page 104

3-44 fuel system (dfi) inlet air pressure sensor (service code 12) caution never drop the sensor, especially on a hard surface. Such a shock to the part can damage it. Inlet air pressure sensor removal • remove: seat (see seat removal in the frame chapter) fuel tank (see fuel tank removal) bolt [a] ...

Page 105

Fuel system (dfi) 3-45 inlet air pressure sensor (service code 12) inlet air pressure sensor output voltage inspection note ○ the output voltage changes according to the local at- mospheric pressure. • measure the output voltage at the ecu in the same way as input voltage inspection. Note the follow...

Page 106

3-46 fuel system (dfi) inlet air pressure sensor (service code 12) suppose: pg: vacuum pressure (gauge) to sensor pl: local atmospheric pressure (absolute) measured by a barometer pv: vacuum pressure (absolute) to sensor vv: sensor output voltage (v) then pv = pl – pg for example, suppose the follow...

Page 107

Fuel system (dfi) 3-47 inlet air pressure sensor (service code 12) id: idling ps: standard atmospheric pressure (absolute) pv: throttle vacuum pressure (absolute) st: standard of sensor output voltage (v) to: throttle full open ur: usable range of sensor output voltage (v) vv: inlet air pressure sen...

Page 108

3-48 fuel system (dfi) inlet air pressure sensor (service code 12) inlet air pressure sensor circuit 1. Ecu (electronic control unit) 2. Inlet air pressure sensor.

Page 109

Fuel system (dfi) 3-49 inlet air temperature sensor (service code 13) inlet air temperature sensor removal/installation caution never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. • remove the seat (see seat removal in the frame chap- ter). • disconnect the...

Page 110

3-50 fuel system (dfi) inlet air temperature sensor (service code 13) inlet air temperature sensor output voltage inspection note ○ be sure the battery is fully charged. ○ the output voltage changes according to the inlet air temperature. • remove the ecu (see ecu removal). ○ do not disconnect the e...

Page 111

Fuel system (dfi) 3-51 inlet air temperature sensor (service code 13) inlet air temperature sensor resistance inspection • remove the inlet air temperature sensor (see inlet air temperature sensor removal/installation). • suspend the sensor [a] in a container of machine oil so that the heat-sensitiv...

Page 112

3-52 fuel system (dfi) water temperature sensor (service code 14) water temperature sensor removal/installation caution never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. • remove the right upper engine bracket. • drain the coolant (see coolant change in t...

Page 113

Fuel system (dfi) 3-53 water temperature sensor (service code 14) water temperature sensor circuit 1. Ecu (electronic control unit) 2. Water temperature sensor.

Page 114

3-54 fuel system (dfi) crankshaft sensor (service code 21) start the engine and switch the diagnosis mode to dealer 1 mode to know all the problem that the dfi system has at the time of self-diagnosis. If the engine cannot be started, the self-diagnosis system does not detect dynamic condi- tion of ...

Page 115

Fuel system (dfi) 3-55 vehicle-down sensor (service code 31) vehicle-down sensor removal caution never drop the vehicle-down sensor, especially on a hard surface. Such a shock to the sensor can damage it. • remove: upper cover (see upper cover removal in the frame chapter) vehicle-down sensor [a] co...

Page 116

3-56 fuel system (dfi) vehicle-down sensor (service code 31) • remove the vehicle-down sensor (see vehicle-down sensor removal). ○ do not disconnect the sensor connector. • connect a digital meter [a] to the connector [b] with nee- dle adapter set [c]. Special tool - needle adapter set: 57001-1457 v...

Page 117

Fuel system (dfi) 3-57 vehicle-down sensor (service code 31) vehicle-down sensor circuit 1. Ecu (electronic control unit) 2. Vehicle-down sensor.

Page 118

3-58 fuel system (dfi) fuel injector (service code 41) fuel injector removal • remove: seat (see seat removal in the frame chapter) fuel hose (see fuel hose replacement in the periodic maintenance chapter) connector [a] screw [b] delivery pipe [c] fuel injector [d] fuel injector installation • repla...

Page 119

Fuel system (dfi) 3-59 fuel injector (service code 41) audible inspection • start the engine. • apply the tip of a screwdriver [a] to the injector [b]. Put the grip end onto your ear, and listen whether the injector is clicking or not. ○ a sound scope [c] can also be used. • do the same for the othe...

Page 120

3-60 fuel system (dfi) fuel injector (service code 41) fuel injector output voltage inspection • disconnect the injector connector [a] and connect the in- sulated auxiliary leads [b] between injector [c] and injec- tor connector. Caution do not short each terminals. • connect a digital meter [d] as ...

Page 121

Fuel system (dfi) 3-61 fuel injector (service code 41) • remove: fuel tank (see fuel tank removal) • disconnect the connectors for injector [a]. • connect each test light set [b] to the injector sub harness connector [c]. • turn the ignition switch on. • while cranking the engine with the starter mo...

Page 122

3-62 fuel system (dfi) fuel injector (service code 41) injector fuel line inspection • remove the fuel tank (see fuel tank removal). • be sure to place a piece of cloth around the fuel hose joint and the delivery pipe. • insert a minus screwdriver [a] into the slit on the joint lock [b]. • turn the ...

Page 123

Fuel system (dfi) 3-63 fuel injector (service code 41) fuel injector circuit 1. Ecu (electronic control unit) 2. Ignition switch 3. Engine stop switch 4. Fuel pump relay 5. Fuel pump fuse 10 a 6. Main fuse 30 a 7. Battery 12 v 6 ah 8. Fuel injector.

Page 124

3-64 fuel system (dfi) fuel pump relay (service code 46) fuel pump relay removal • remove: upper cover (see upper cover removal in the frame chapter) fuel pump relay [a] fuel pump relay inspection • refer to the relay inspection in the electrical system chapter. Fuel pump relay circuit 1. Ecu (elect...

Page 125

Fuel system (dfi) 3-65 fi indicator light fi indicator light inspection • remove the upper cover (see upper cover removal in the frame chapter). • using two auxiliary leads, supply battery power to the fi indicator light. 12 v battery [a] fi indicator light check connector: indicator unit connector ...

Page 126

3-66 fuel system (dfi) ecu caution never drop the ecu, especially on a hard surface. Such a shock to the ecu can damage it. Ecu removal • remove the upper cover (see upper cover removal in the frame chapter). • remove: bolts [a] ecu [b] • disconnect the ecu connector [c]. Ecu installation • connect ...

Page 127

Fuel system (dfi) 3-67 ecu • check the ecu power source voltage with a digital meter [a]. ○ position the terminal in accordance with terminal numbers of ecu connector [b] in this chapter figure. Battery [c] ecu power source inspection meter connections: between terminal 13 (w) and battery (–) termin...

Page 128

3-68 fuel system (dfi) fuel line fuel pressure inspection note ○ this inspection can determine which trouble the dfi system has, mechanical or electrical trouble. ○ it is preferable to measure the fuel pressure while run- ning the vehicle just when trouble occurred in order to know symptom well. ○ b...

Page 129

Fuel system (dfi) 3-69 fuel line note ○ the gauge needle will fluctuate. Read the pressure at the average of the maximum and minimum indications. If the fuel pressure is much lower than specified, the fuel pressure regulator in the fuel pump have been clogged or stuck. Replace the fuel pump (see fue...

Page 130

3-70 fuel system (dfi) fuel line warning be prepared for fuel spillage; any spilled fuel must be completely wiped up immediately. When the fuel hose is disconnected, fuel spills out from the hose and the pipe because of residual pressure. Cover the hose connection with a piece of clean cloth to prev...

Page 131

Fuel system (dfi) 3-71 fuel pump fuel pump removal caution never drop the fuel pump, especially on a hard sur- face. Such a shock to the pump can damage it. Warning gasoline is extremely flammable and can be explo- sive under certain conditions. Make sure the area is well-ventilated and free from an...

Page 132

3-72 fuel system (dfi) fuel pump • replace the o-ring [a] with a new one. • apply a non-permanent locking agent to the threads of the fuel pump bolts. • tighten the fuel pump bolts to a snug fit, tighten them alternating diagonally. Torque - fuel pump bolts: 9.8 n·m (1.0 kgf·m, 87 in·lb) • tighten t...

Page 133

Fuel system (dfi) 3-73 fuel pump • connect the hand tester (× dc 25 v) to the fuel pump connector [a] with needle adapter set. Special tools - hand tester: 57001-1394 needle adapter set: 57001-1457 pump operating voltage at pump connections to pump connectors tester (+) → w/r lead tester (–) → bk/y ...

Page 134

3-74 fuel system (dfi) fuel pump fuel pump circuit 1. Ecu (electronic control unit) 2. Ignition switch 3. Engine stop switch 4. Fuel pump relay 5. Fuel pump fuse 10 a 6. Main fuse 30 a 7. Battery 12 v 6 ah 8. Fuel pump.

Page 135

Fuel system (dfi) 3-75 throttle lever and cable throttle lever free play inspection • refer to the throttle lever free play inspection in the periodic maintenance chapter. Throttle lever free play adjustment • refer to the throttle lever free play adjustment in the periodic maintenance chapter. Thro...

Page 136

3-76 fuel system (dfi) throttle lever and cable throttle case removal/disassembly • remove: screws [a] cover [b] • remove: bolts [a] • separate the reverse cable bracket [b] and throttle lever assy. • remove the screw [a] to free the reverse cable [b]. • remove the throttle cable guide [a] and gromm...

Page 137

Fuel system (dfi) 3-77 throttle lever and cable • lubricate the throttle cable (see lubrication in the peri- odic maintenance chapter). • apply grease to the throttle cable end [a]. • install the throttle cable end to the throttle lever. • install the cable guide [b] and grommet [c] to the throttle ...

Page 138

3-78 fuel system (dfi) throttle body assy idle speed inspection • refer to the idle speed inspection in the periodic main- tenance chapter. Throttle body assy removal warning gasoline is extremely flammable and can be ex- plosive under certain conditions. Turn the ignition switch off. Disconnect the...

Page 139

Fuel system (dfi) 3-79 throttle body assy • loosen the nut [a]. • remove the throttle cable lower end [b] from the throttle pulley. • pull off the throttle body assy. • after removing the throttle body assy, stuff pieces of lint -free, clean cloths into the throttle body assy holder. Caution if dirt...

Page 140

3-80 fuel system (dfi) throttle body assy • tighten the throttle cable nut [a] securely so that the claw [b] of the washer faces as shown. • check the throttle lever free play (see throttle lever free play inspection in the periodic maintenance chapter). Warning operation with an incorrectly routed ...

Page 141

Fuel system (dfi) 3-81 throttle body assy throttle body assy assembly • replace the o-ring [a] and seal [b] with a new one. • before assembling, blow away dirt or dust from the throttle body and delivery pipe by applying compressed air. • apply grease to the new o-ring of the injector [c], and inser...

Page 142

3-82 fuel system (dfi) air cleaner air cleaner element removal • remove: seat (see seat removal in the frame chapter) mud guard plate [a] clips [b] air cleaner housing cap [c] • loosen the thumb screw [a] to remove the element [b]. • separate the element [a] and holder [b]. Air cleaner element insta...

Page 143

Fuel system (dfi) 3-83 air cleaner • hook the clips [a]. • install the mud guard plate [b] so that the "up mark" [c] faces upward. Air cleaner element cleaning and inspection • refer to the air cleaner element cleaning and inspection in the periodic maintenance chapter. Air cleaner draining • refer ...

Page 144

3-84 fuel system (dfi) air cleaner air cleaner housing installation • install the air cleaner housing. • tighten: torque - rear air cleaner duct clamp screw [a]: 1.4 n·m (0.14 kgf·m, 12 in·lb) air cleaner housing bolts [b]: 8.8 n·m (0.90 kgf·m, 78 in·lb) air cleaner duct and resonator tank removal •...

Page 145

Fuel system (dfi) 3-85 air cleaner air cleaner duct and resonator tank installation • install the resonator tank holder [a] so that the "upper" mark [b] faces tank side and slit [c] on the holder fit to the projection [d] on the duct. • install the resonator tank so that the projection [a] fit to th...

Page 146

3-86 fuel system (dfi) fuel tank fuel tank removal warning gasoline is extremely flammable and can be explo- sive under certain conditions. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. Do not smoke. Turn the igniti...

Page 147

Fuel system (dfi) 3-87 fuel tank • be sure to place a piece of cloth [a] around the fuel hose joint. • insert a minus screwdriver [b] into the slit [c] on the joint lock. • turn the driver [a] to disconnect the joint lock [b]. • pull the fuel hose joint out [c] of the outlet pipe. Warning be prepare...

Page 148

3-88 fuel system (dfi) fuel tank • insert [a] the fuel hose joint [b] straight onto the delivery pipe until the hose joint clicks. • push the joint lock [c] . • push and pull [a] the hose joint [b] back and forth more than two times and make sure it is locked and doesn’t come off. Warning make sure ...

Page 149: Cooling System

Cooling system 4-1 4 cooling system table of contents exploded view........................................................................................................................ 4-2 coolant flow chart.............................................................................................

Page 150

4-2 cooling system exploded view.

Page 151

Cooling system 4-3 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 radiator hose fitting bolts 9.8 1.0 87 in·lb 2 coolant drain bolt 7.0 0.71 62 in·lb 3 water pump impeller bolt 9.8 1.0 87 in·lb 4 water pump cover bolts 9.8 1.0 87 in·lb 5 reserve tank screws 3.5 0.36 31 in·lb 6 radiator ...

Page 152

4-4 cooling system coolant flow chart.

Page 153

Cooling system 4-5 coolant flow chart permanent type antifreeze is used as a coolant to protect the cooling system from rust and corrosion. When the engine starts, the water pump turns and the coolant circulates. When the coolant temperature goes up beyond 100°c (212°f), the radiator fan relay condu...

Page 154

4-6 cooling system specifications item service limit coolant type permanent type antifreeze for aluminum engines and radiators color green mixed ratio soft water 50%, antifreeze 50% freezing point -35°c (-31°f) total amount 1.4 l (1.5 us qt.) (reserve tank full level, including radiator and engine) ...

Page 155

Cooling system 4-7 special tools outside circlip pliers: 57001-144 bearing driver set: 57001-1129.

Page 156

4-8 cooling system coolant coolant deterioration inspection • visually inspect the coolant in the reserve tank [a]. If whitish cotton-like wafts are observed, aluminum parts in the cooling system are corroded. If the coolant is brown, iron or steel parts are rusting. In either case, flush the coolin...

Page 157

Cooling system 4-9 coolant • remove the radiator cap [a]. Note ○ remove the radiator cap in two steps. First turn the cap counterclockwise to the first stop and wait there for a few seconds. Then push down and turn it further in the same direction and remove the cap. • place a container under the co...

Page 158

4-10 cooling system coolant • fill the radiator up to the bottom of the radiator filler neck [b] with coolant [a], and install the cap, turning it clockwise about 1/4 turn. ○ lean the vehicle slightly to the right until the radiator filler neck is level to the ground so that the filler neck is locat...

Page 159

Cooling system 4-11 coolant cooling system flushing over a period of time, the cooling system accumulates rust, scale, and lime in the water jacket and radiator. When this accumulation is suspected or observed, flush the cool- ing system. If this accumulation is not removed, it will clog up the wate...

Page 160

4-12 cooling system water pump water pump cover removal • unscrew the drain bolt [a], and drain the coolant (see coolant draining). • loosen the clamp screw [b], and remove the radiator hose [c] from the water pump cover. • unscrew the cover bolts [d]. • using the pry point [a], remove the pump cove...

Page 161

Cooling system 4-13 water pump impeller removal • drain: coolant (see coolant draining) • remove: water pump cover (see water pump cover removal) impeller bolt [a] impeller [b] impeller installation • install: impeller [a] • tighten: torque - water pump impeller bolt [b]: 9.8 n·m (1.0 kgf·m, 87 in·l...

Page 162

4-14 cooling system water pump • insert a bar [a] into the water pump shaft hole from the outside of the right engine cover, and remove the ball bearing [b] by tapping [c] evenly around the bearing in- ner race. • remove the spacer [d]. • remove the ball bearing [e] and oil seal [f] from the right e...

Page 163

Cooling system 4-15 radiator radiator removal • drain the coolant (see coolant draining) • remove: fuel tank (see fuel tank removal in the fuel system (dfi) chapter battery case • loosen: clamp screws [a] • remove: radiator hoses [b] radiator fan connection [c] (disconnect) • remove: clamp [a] hose ...

Page 164

4-16 cooling system radiator radiator installation • assemble the radiator, and install it. • tighten: torque - radiator hose clamp screws: 2.0 n·m (0.20 kgf·m, 18 in·lb) radiator mounting bolts: 8.8 n·m (0.90 kgf·m, 78 in·lb) radiator screen screws: 3.5 n·m (0.36 kgf·m, 31 in·lb) • route the radiat...

Page 165

Cooling system 4-17 radiator radiator inspection • check the radiator core. If there are obstructions to air flow, remove the radiator and remove obstructions. If the corrugated fins [a] are deformed, carefully straighten them. If the air passages of the radiator core are blocked more than 20% by un...

Page 166

4-18 cooling system radiator radiator hoses installation • install the radiator hoses being careful to follow the per- formed bends (see cable, wire, and hose routing sec- tion in the appendix chapter). Avoid sharp bending, kink- ing, flattening, or twisting. • tighten the hose clamps securely. Torq...

Page 167: Engine Top End

Engine top end 5-1 5 engine top end table of contents exploded view........................................................................................................................ 5-2 specifications ................................................................................................

Page 168

5-2 engine top end exploded view.

Page 169

Engine top end 5-3 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 cylinder head cover bolts 9.8 1.0 87 in·lb 2 cylinder head bolts (m10) 59 6.0 44 s, mo 3 cylinder head bolts (m6) 12 1.2 106 in·lb s 4 cylinder bolt 12 1.2 106 in·lb 5 camshaft cap bolts 12 1.2 106 in·lb s 6 camshaft spro...

Page 170

5-4 engine top end exploded view.

Page 171

Engine top end 5-5 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 exhaust pipe cover bolts 12 1.2 106 in·lb 2 exhaust pipe holder nuts 20 2.0 15 3 muffler mounting bolts 35 3.6 26 4 muffler joint clamp bolt 20 2.0 15 5 muffler body end cover bolts 8.8 0.90 78 in·lb r: replacement parts.

Page 172

5-6 engine top end specifications item standard service limit camshafts cam height: exhaust 35.546 ∼ 35.654 mm (1.3994 ∼ 1.4037 in.) 35.45 mm (1.396 in.) inlet 35.946 ∼ 36.054 mm (1.4152 ∼ 1.4194 in.) 35.85 mm (1.411 in.) camshaft journal clearance 0.020 ∼ 0.062 mm (0.00079 ∼ 0.0024 in.) 0.15 mm (0....

Page 173

Engine top end 5-7 specifications item standard service limit inlet outer 39.28 mm (1.546 in.) 37.8 mm (1.49 in.) inner 36.05 mm (1.419 in.) 34.5 mm (1.36 in.) cylinder and pistons cylinder inside diameter 96.000 ∼ 96.012 mm (3.7795 ∼ 3.7800 in.) 96.10 mm (3.783 in.) piston diameter 95.964 ∼ 95.979 ...

Page 174

5-8 engine top end specifications cam height cam height [a] camshaft runout valve stem diameter valve stem diameter [a] 45° [b] valve stem bend dial gauge [a].

Page 175

Engine top end 5-9 special tools and sealant compression gauge, 20 kgf/cm²: 57001-221 valve spring compressor assembly: 57001-241 valve guide arbor, 5.5: 57001-1021 valve guide reamer, 5.5: 57001-1079 piston ring compressor grip: 57001-1095 valve seat cutter, 45° - 35: 57001-1116 valve seat cutter, ...

Page 176

5-10 engine top end special tools and sealant valve seat cutter, 55° - 35: 57001-1247 spark plug wrench, hex 16: 57001-1262 compression gauge adapter, m10 × 1.0: 57001-1317 piston ring compressor belt, 95 ∼ 108: 57001-1358 filler cap driver: 57001-1454 valve seat cutter, 45° - 40: 57001-1496 valve s...

Page 177

Engine top end 5-11 special tools and sealant valve guide driver attachment d: 57001-1659 kawasaki bond (liquid gasket-gray): 92104-1063.

Page 178

5-12 engine top end cylinder head cover cylinder head cover removal • remove: fuel tank (see fuel tank removal in the fuel system (dfi) chapter) spark plug cap • remove the cylinder head cover bolts [a] and remove the cylinder head cover [b]. Cylinder head cover installation • make sure that the upp...

Page 179

Engine top end 5-13 camshaft chain tensioner camshaft chain tensioner removal caution this is a non-return type camshaft chain tensioner. The push rod does not return to its original position once it moves out to take up camshaft chain slack. Observe all the rules listed below: when removing the ten...

Page 180

5-14 engine top end camshaft chain tensioner • replace the chain tensioner gasket with a new one. • tighten: torque - chain tensioner mounting bolts [a]: 9.8 n·m (1.0 kgf·m, 87 in·lb) • take out the holder plate [b]. • install the o-ring and tighten the cap bolt. Torque - chain tensioner cap bolt: 5...

Page 181

Engine top end 5-15 camshaft camshaft removal • remove: cylinder head cover (see cylinder head cover re- moval) timing inspection cap [a] alternator rotor nut cap [b] special tool - filler cap driver: 57001-1454 • first, bring the piston to the tdc (of either the compres- sion or exhaust stroke). ○ ...

Page 182

5-16 engine top end camshaft • remove: bolt [a] auto-decompressor [b] (with the sprocket) • remove: circlips [a] camshaft installation • assemble the auto-decompressor weights [a] and spring [b] to install it to the sprocket [c]. • replace the circlips [d] with new ones, and install them so that the...

Page 183

Engine top end 5-17 camshaft • engage the camshaft chain with the camshaft sprockets. ○ pull the tension side (exhaust side) of the chain taut to install the chain. ○ the timing marks on the sprocket must be aligned with the cylinder head upper surface. • pull the chain taut and fit it onto the cams...

Page 184

5-18 engine top end camshaft • apply grease to the rubber portions of the oil pipes. • assemble: camshaft caps [a] oil pipes [b] • while keeping parallel, install them. • uniformly tighten all bolts and after the camshaft has set- tled, uniformly tighten all the bolts. ○ following the sequence numbe...

Page 185

Engine top end 5-19 camshaft camshaft and camshaft cap wear • measure each clearance between the camshaft journal and camshaft cap using plastigauge (press gauge) [a]. • install the camshaft caps (see camshaft installation) note ○ do not turn the camshaft when the plastigauge is be- tween the journa...

Page 186

5-20 engine top end cylinder head cylinder compression measurement • start the engine. • thoroughly warm up the engine so that the engine oil be- tween the piston and cylinder wall will help seal compres- sion as it does during normal running. • stop the engine. • remove: fuel tank (see fuel tank re...

Page 187

Engine top end 5-21 cylinder head problem diagnosis remedy (action) carbon accumulation on piston and in cylinder head (combustion chamber) is suspected due to damaged valve stem or piston oil rings. Remove the carbon deposits and replace damaged parts if necessary. The cylinder compression is highe...

Page 188

5-22 engine top end cylinder head • remove the 10 mm cylinder head bolts following the tight- ening sequence as shown. • tap lightly up with a plastic mallet [a] to separate the cylin- der head [b] from the cylinder. • pull the cylinder head forward to separate the throttle body holder from the thro...

Page 189

Engine top end 5-23 cylinder head • install the cylinder head so that the throttle body holder recess [a] fit the throttle body projection [b]. • tighten the 10 mm cylinder head bolts in the numbered sequence [1 ∼ 4]. Torque - cylinder head bolts (m10): 59 n·m (6.0 kgf·m, 44 ft·lb) • tighten: torque...

Page 190

5-24 engine top end cylinder head cylinder head warp inspection • remove the cylinder head (see cylinder head removal). • lay a straightedge [a] across the lower surface of the head at several different points, and measure warp by inserting a thickness gauge between the straightedge and the head. If...

Page 191

Engine top end 5-25 valves valve clearance inspection • refer to the valve clearance inspection in the periodic maintenance chapter. Valve removal • remove the cylinder head (see cylinder head removal). • remove the valve lifter and the shim from the valve. Note ○ use the valve spring compressor ass...

Page 192

5-26 engine top end valves valve guide removal • remove: valve (see valve removal) oil seal spring seat • heat the area around the valve guide up to 120 ∼ 150°c (248 ∼ 302°f). Caution do not heat the cylinder head with a torch. This will warp the cylinder head. Soak the cylinder head and heat the oi...

Page 193

Engine top end 5-27 valves • ream the valve guide with valve guide reamer [a], even if the old guide is reused. Special tool - valve guide reamer, 5.5: 57001-1079 valve/valve guide clearance measurement (wobble method) ○ if a small bore gauge is not available, inspect the valve guide wear by measuri...

Page 194

5-28 engine top end valves valve seat inspection • remove the valve (see valve removal). • check the valve seating surface [a] between the valve [b] and valve seat [c]. • measure the outside diameter [d] of the seating pattern on the valve seat. If the outside diameter is too large or too small, rep...

Page 195

Engine top end 5-29 valves seat cutter operation care 1. This valve seat cutter is developed to grind the vale for repair. Therefore the cutter must not be used for other purposes than seat repair. 2. Do not drop or shock the valve seat cutter, or the dia- mond particles may fall off. 3. Do not fail...

Page 196

5-30 engine top end valves • measure the outside diameter of the seating surface with a vernier caliper. If the outside diameter of the seating surface is too small, repeat the 45° grind until the diameter is within the spec- ified range. Original seating surface [b] ○ remove all pittings of flaws f...

Page 197

Engine top end 5-31 valves • the seating area should be marked about in the middle of the valve face. If the seat area is not in the right place on the valve, check to be sure the valve is the correct part. If it is, it may have been refaced too much; replace it. • when the engine is assembled, be s...

Page 198

5-32 engine top end valves valve seat repair.

Page 199

Engine top end 5-33 cylinder and piston cylinder removal • remove: cylinder head (see cylinder head removal) front camshaft chain guide [a] cylinder bolt [b] • disconnect the water temperature sensor connector [c]. • tap lightly up with a plastic mallet to separate the cylinder from the crankcase. •...

Page 200

5-34 engine top end cylinder and piston • do not mix up the top ring and second ring. • install the top ring [a] so that the “r” mark [b] faces up. • install the second ring [c] so that the “rn” mark [d] faces up. Note ○ if a new piston or cylinder is used, check piston to cylin- der clearance (see ...

Page 201

Engine top end 5-35 cylinder and piston • apply engine oil to the cylinder bore. • determine the position of the piston ring ends. • install the cylinder while compressing the piston rings with your fingers or the special tools. Special tools - piston ring compressor grip [a]: 57001 -1095 piston rin...

Page 202

5-36 engine top end cylinder and piston piston ring/ring groove clearance • check for uneven groove wear by inspecting the ring seat- ing. The rings should fit perfectly parallel to groove surfaces. If not, replace the piston and all the piston rings. • with the piston rings in their grooves, make s...

Page 203

Engine top end 5-37 cylinder and piston piston ring end gap measurement • place the piston ring [a] inside the cylinder, using the pis- ton to locate the ring squarely in place. Place the piston ring close to the bottom of the cylinder, where cylinder wear is minimal • measure the gap [b] between th...

Page 204

5-38 engine top end throttle body holder throttle body holder installation • install the throttle body holder [a] with the marked [b] side facing toward the cylinder head outside. ○ install the holder clamp [c] with its screw head [d] facing as shown. • fit the recess [a] of the holder into the proj...

Page 205

Engine top end 5-39 muffler warning to avoid a serious burn, do not remove the muffler when the engine is still hot. Wait until the muffler cools down. Muffler removal • remove the rear exhaust cover bolt [a] and cover [b]. • loosen the muffler joint clamp bolt [c]. • remove: exhaust pipe holder nut...

Page 206

5-40 engine top end muffler • first tighten all the bolts and nuts to a snug fit. • next tighten the exhaust pipe holder nuts evenly to avoid exhaust leaks. • lastly, tighten the rest of the bolts and clamp bolt. Torque - exhaust pipe holder nuts: 20 n·m (2.0 kgf·m, 15 ft·lb) muffler mounting bolts:...

Page 207: Engine Right Side

Engine right side 6-1 6 engine right side table of contents exploded view........................................................................................................................ 6-2 specifications ..........................................................................................

Page 208

6-2 engine right side exploded view.

Page 209

Engine right side 6-3 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 primary gear nut 98 10 72 lh 2 clutch cover bolts 9.8 1.0 87 in·lb 3 right engine cover bolts 9.8 1.0 87 in·lb 4 clutch spring bolts 8.8 0.90 78 in·lb 5 clutch hub nut 98 10 72 6. Friction plate (lining block: 45 slots...

Page 210

6-4 engine right side exploded view.

Page 211

Engine right side 6-5 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 shift pedal bolt 9.8 1.0 87 in·lb 2 upper ratchet plate mounting bolt 9.8 1.0 87 in·lb s 3 lower ratchet plate mounting bolt 15 1.5 11 l, s 4 gear positioning lever nut 8.8 0.90 78 in·lb 5 shift drum cam bolt 29 3.0 21...

Page 212

6-6 engine right side specifications item standard service limit clutch lever clutch lever free play 5 ∼ 10 mm (0.2 ∼ 0.4 in.) – – – clutch friction plate thickness 2.92 ∼ 3.08 mm (0.115 ∼ 0.121 in.) 2.7 mm (0.11 in.) friction plate warp 0.15 mm (0.0059 in.) or less 0.3 mm (0.01 in.) steel plate war...

Page 213

Engine right side 6-7 special tools clutch holder: 57001-1243 gear holder, m2.0: 57001-1557.

Page 214

6-8 engine right side clutch lever and cable due to friction plate wear and clutch cable stretch over a long period of use, the clutch must be adjusted in accor- dance with the periodic maintenance chart. Warning to avoid a serious burn, never touch the hot engine or exhaust chamber during clutch ad...

Page 215

Engine right side 6-9 clutch lever and cable • slide the dust cover [a] out of place. • screw the adjuster [b] at the clutch lever fully. • line up the slots [c] in the clutch lever and adjuster and then free the cable from the lever. • remove the clutch cable holder mounting bolts [a]. • free the c...

Page 216

6-10 engine right side clutch cover and right engine cover clutch cover removal • drain the engine oil (see engine oil change in the peri- odic maintenance chapter). • remove the brake pedal (from the return spring and brake light switch spring). • remove the clutch cover bolts [a] and remove the cl...

Page 217

Engine right side 6-11 clutch cover and right engine cover • remove: water pump cover (see water pump cover removal in the cooling system chapter) oil filter (see oil filter change in the periodic mainte- nance chapter) right engine cover bolts [a] • loosen the these cover bolts [b] fully. • remove ...

Page 218

6-12 engine right side clutch cover and right engine cover release shaft removal • remove the clutch (see clutch removal). • remove the clutch cable upper end (see clutch cable removal). • remove the breather hose [a] and clutch cable holder mounting bolts [b]. • remove the tips [c] of the clutch ca...

Page 219

Engine right side 6-13 clutch clutch removal • drain the engine oil (see engine oil change in the peri- odic maintenance chapter). • remove the clutch cover (see clutch cover removal). • remove: clutch spring bolts [a] clutch spring clutch spring plate [b] • remove: adjusting washer [a] needle beari...

Page 220

6-14 engine right side clutch • install the washer so that stamp mark [a] facing the out- side. • hold the clutch hub [a] with the clutch holder [b]. Special tool - clutch holder: 57001-1243 • tighten torque - clutch hub nut [c]: 98 n·m (10 kgf·m, 72 ft·lb) • install the spring seat [a] and spring [...

Page 221

Engine right side 6-15 clutch • apply molybdenum disulfide grease to the rubbing portion [a] of the push rod holder. • install the push rod [b] and push rod holder. • apply molybdenum disulfide grease to the needle bearing [c] and adjusting washer [d], and install them. • tighten: torque - clutch sp...

Page 222

6-16 engine right side clutch clutch plate assembly free play inspection/ad- justment • assemble the following parts. Clutch hub [a] spring seat [b] spring [c] friction plate [d] steel plate [e] friction plates [f] friction plate [g] spring plate [h] springs [i] bolts [j] torque - clutch spring bolt...

Page 223

Engine right side 6-17 clutch friction and steel plate warp inspection • remove the clutch plate (see clutch removal). • place each friction plate or steel plate on a surface plate, and measure the gap between the surface plate [a] and each friction plate or steel plate [b] with a thickness gauge [c...

Page 224

6-18 engine right side clutch clutch hub spline damage • visually inspect the areas of the clutch hub splines that come in contact with the teeth of the steel plates. If there are notches worn into the clutch hub splines [a], replace the clutch hub. Replace the steel plates if their teeth are damage...

Page 225

Engine right side 6-19 primary gear primary gear removal • remove: right engine cover (see right engine cover removal) oil pump idle shaft and gear • temporarily install the clutch housing [a]. • using the gear holder [b], secure the primary gear. Special tool - gear holder, m2.0: 57001-1557 • loose...

Page 226

6-20 engine right side external shift mechanism external shift mechanism removal • remove: shift pedal bolt [a] shift pedal [b] • remove: right engine cover (see right engine cover removal) • pull out the shift shaft [a]. • remove the bolts [b] and take off the shift ratchet assem- bly [c] with ratc...

Page 227

Engine right side 6-21 external shift mechanism • install the gear positioning lever [a]. • tighten the gear positioning lever nut [b]. Torque - gear positioning lever nut: 8.8 n·m (0.90 kgf·m, 78 in·lb) • holding the gear positioning lever with the screwdriver [c] and install the shift drum cam [d]...

Page 228

6-22 engine right side external shift mechanism • install the shift pedal so that the split portion [a] on the pedal and punch mark [b] on the shift align. • tighten: torque - shift pedal bolt: 9.8 n·m (1.0 kgf·m, 87 in·lb) external shift mechanism inspection • check the shift shaft [a] for bending ...

Page 229: Engine Lubrication System

Engine lubrication system 7-1 7 engine lubrication system table of contents exploded view........................................................................................................................ 7-2 lubrication system chart ................................................................

Page 230

7-2 engine lubrication system exploded view.

Page 231

Engine lubrication system 7-3 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 engine oil drain bolt (m12) 15 1.5 11 2 engine oil drain bolt (m6) 7.0 0.71 62 in·lb 3 oil pump (scavenge) cover bolts 9.8 1.0 87 in·lb 4 oil pump (feed) cover bolts 8.8 0.90 78 in·lb 5 crankcase bolt 9.8 1.0 8...

Page 232

7-4 engine lubrication system lubrication system chart.

Page 233

Engine lubrication system 7-5 lubrication system chart 1. Oil screen (feed) 2. Oil pump (feed) 3. Oil pressure relief valve 4. Oil filter 5. Crankshaft 6. Oil pipes 7. Oil screen (scavenge) 8. Oil pump (scavenge) 9. Oil pipe 10. Piston oil nozzle 11. Oil passage (dowel pin) 12. Oil return pipe.

Page 234

7-6 engine lubrication system specifications item standard engine oil grade api sf or sg api sh, sj or sl with jaso ma, ma1 or ma2 viscosity sae 10w-40 capacity oil change - when filter is not removed 1.15 l (1.22 us qt) oil change - when filter is removed 1.20 l (1.27 us qt) when engine is complete...

Page 235

Engine lubrication system 7-7 special tools oil pressure gauge, 5 kgf/cm²: 57001-125 oil pressure gauge adapter, m10 × 1.25: 57001-1182 oil pressure cap: 57001-1656.

Page 236

7-8 engine lubrication system engine oil and oil filter warning vehicle operation with insufficient, deteriorated, or contaminated engine oil will cause accelerated wear and may result in engine or transmission seizure, accident, and injury. The engine oil level indicated in the right engine cover o...

Page 237

Engine lubrication system 7-9 engine oil and oil filter oil filter change • refer to the oil filter change in the periodic maintenance chapter. Oil screen (scavenge) removal • remove the oil pump (scavenge) cover (see oil pump (scavenge) removal). • pull out the oil screen [a] from the left crankcas...

Page 238

7-10 engine lubrication system engine oil and oil filter • apply engine oil to the rubber portion [a] on the oil screen. • install the oil screen facing the carved line [b] to the out- side. • install the oil pump covers (see oil pump (scavenge) (feed) installation) oil screen cleaning • remove the ...

Page 239

Engine lubrication system 7-11 oil pressure relief valve oil pressure relief valve removal • remove: right engine cover (see right engine cover removal in the engine right side chapter) • remove the oil pressure relief valve [a]. Oil pressure relief valve installation • apply a non-permanent locking...

Page 240

7-12 engine lubrication system oil pump oil pump (scavenge) removal • drain: engine oil (see engine oil change in the periodic main- tenance chapter) coolant (see coolant draining in the coolant system chapter) • remove: shift pedal (see external shift mechanism in the engine right side chapter) alt...

Page 241

Engine lubrication system 7-13 oil pump • install: oil pump cover [a] lower camshaft chain guide [b] • tighten: torque - oil pump (scavenge) cover bolts [c]: 9.8 n·m (1.0 kgf·m, 87 in·lb) oil pump (feed) removal • remove: right engine cover (right engine cover removal in the engine right side chapte...

Page 242

7-14 engine lubrication system oil pump • install the oil pump cover [a]. • tighten: torque - oil pump (feed) cover bolts [b]: 8.8 n·m (0.90 kgf·m, 78 in·lb) ○ thread length of the lower bolt [c] is 30 mm (1.2 in.) only. • install the oil pump idle gear [a] facing the stepped side to the outside. • ...

Page 243

Engine lubrication system 7-15 oil pipe oil pipe removal • remove: right engine cover (see right engine cover removal in the engine right side chapter) bolt [a] oil pipe [b] oil pipe installation • replace the o-rings [a] with new ones. • apply grease to the o-rings. • tighten: torque - oil pipe mou...

Page 244

7-16 engine lubrication system oil pressure oil pressure measurement • remove the oil filter cover [a]. • install the o-rings to the oil pressure cap. Special tool - oil pressure cap: 57001–1656 • install the oil pressure cap. • attach the oil pressure gauge adapter [a] and oil pressure gauge [b]. S...

Page 245: Engine Removal/installation

Engine removal/installation 8-1 8 engine removal/installation table of contents exploded view........................................................................................................................ 8-2 special tools .......................................................................

Page 246

8-2 engine removal/installation exploded view.

Page 247

Engine removal/installation 8-3 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 front engine bracket bolts 30 3.0 22 2 front engine mounting nut 46 4.7 34 s 3 lower engine bracket nut 46 4.7 34 4 lower engine mounting nut 46 4.7 34 s 5 upper engine bracket bolts 30 3.0 22 6 upper engine ...

Page 248

8-4 engine removal/installation special tools jack: 57001-1238 swingarm pivot nut wrench: 57001-1686.

Page 249

Engine removal/installation 8-5 engine removal/installation engine removal • place the jack under the frame to support the vehicle. Special tool - jack: 57001-1238 warning for engine removal, the swingarm pivot shaft must be pulled out, causing the swingarm and rear wheels assembly to become detache...

Page 250

8-6 engine removal/installation engine removal/installation • cut the clamps [a]. • disconnect: alternator lead connector [b] crankshaft sensor lead connector [c] • disconnect: neutral/reverse switch lead connector [a] • remove: breather hose lower end [a] clutch cable holder mounting bolts [b] clut...

Page 251

Engine removal/installation 8-7 engine removal/installation • remove: rear brake light switch bracket [a] • remove: radiator hoses [a] • remove: upper engine bracket bolts (left and right) [a] upper engine mounting bolt and nut (left and right) [b] upper engine brackets (left and right) [c] front en...

Page 252

8-8 engine removal/installation engine removal/installation engine installation • screw the swingarm adjusting bolt [a] until the surface is flush with the frame surface [b]. • install the lower engine bracket [a] as shown. [b] front [c] long [d] short • install the engine. • install the swingarm pi...

Page 253

Engine removal/installation 8-9 engine removal/installation • firstly, tighten the swingarm pivot shaft nut [a]. Torque - swingarm pivot shaft nut : 90.5 n·m (9.2 kgf·m, 67 ft·lb) • secondly, tighten the lower engine mounting nut [b]. Torque - lower engine mounting nut : 46 n·m (4.7 kgf·m, 34 ft·lb)...

Page 255: Crankshaft/transmission

Crankshaft/transmission 9-1 9 crankshaft/transmission table of contents exploded view........................................................................................................................ 9-2 specifications ..............................................................................

Page 256

9-2 crankshaft/transmission exploded view.

Page 257

Crankshaft/transmission 9-3 exploded view torque no. Fastener n·m kgf·m ft·lb re- marks 1 reverse cable cap bolt 8.8 0.90 78 in·lb 2 crankcase bolts (l = 50) 9.8 1.0 87 in·lb s 3 crankcase bolts (l = 60) 9.8 1.0 87 in·lb s 4 crankcase bolts (l = 80) 9.8 1.0 87 in·lb s 5 bearing retaining bolts 19 1....

Page 258

9-4 crankshaft/transmission exploded view.

Page 259

Crankshaft/transmission 9-5 exploded view torque no. Fastener n·m kgf·m ft·lb re- marks 1 balancer weight mounting nut 52 5.3 38 2 reverse idle gear holder bolts (m6) 12 1.2 106 in·lb l 3 reverse idle gear holder bolt (m8) 25 2.5 18 l 4 neutral/reverse switch screws 4.9 0.50 43 in·lb 5. Ksf450b9f/b9...

Page 260

9-6 crankshaft/transmission specifications item standard service limit connecting rods connecting rod big end radial clearance 0.002 ∼ 0.014 mm (0.00008 ∼ 0.0006 in.) 0.06 mm (0.002 in.) connecting rod big end side clearance 0.25 ∼ 0.35 mm (0.0098 ∼ 0.014 in.) 0.6 mm (0.02 in.) crankshaft runout tir...

Page 261

Crankshaft/transmission 9-7 special tools and sealant bearing puller: 57001-135 outside circlip pliers: 57001-144 bearing driver set: 57001-1129 kawasaki bond (liquid gasket - gray): 92104-1063 bearing puller adapter: 57001-1526 gear holder, m2.0: 57001-1557.

Page 262

9-8 crankshaft/transmission crankcase crankcase disassembly • remove the engine from the frame (see engine removal in the engine removal/installation chapter). • set the engine on clean surface while parts are being re- moved. • remove: alternator cover (see alternator cover removal in the electrica...

Page 263

Crankshaft/transmission 9-9 crankcase • remove: neutral/reverse switch screws [a] neutral/reverse switch [b] • remove: neutral/reverse switch finger [a] spring • remove: circlip [a] blancer drive gear [b] • remove: engine ground terminal bolt [a] • remove: stater motor mounting bolts [a] stater moto...

Page 264

9-10 crankshaft/transmission crankcase • remove the crankcase bolts [a]. • put the engine so that the left crankcase is down. • pry the points [a] to split the crankcase halves apart, and remove the right crankcase half. ○ tap lightly around the crankcase joint with a plastic mallet, and split the c...

Page 265

Crankshaft/transmission 9-11 crankcase • remove: needle bearing [a] tongue washer [b] idle gear shaft [c] caution do not remove the bearings and the oil seals unless it is necessary. Removal may damage them. Crankcase assembly caution right and left crankcase halves are machined at the factory in th...

Page 266

9-12 crankshaft/transmission crankcase • press the new output shaft bearing [a] in the left crankcase half, so that the stepped side [b] faces inside of the engine. Special tool - bearing driver set: 57001-1129 • press the new drive shaft bearings [a] in the each crankcase [b] half, so that the step...

Page 267

Crankshaft/transmission 9-13 crankcase • first, press the inside release shaft needle bearing [a] until it bottom out with the bearing driver set [b]. Special tool - bearing driver set: 57001-1129 • next, press the outside release shaft needle bearing [a] until the surface of the bearing is even wit...

Page 268

9-14 crankshaft/transmission crankcase • press the shift shaft stoppe pin [a] to the right crankcase [b] as shown. [c] less than 14.5 mm (0.571 in.) • apply engine oil to the transmission gears, bearings, shift forks, shift drum and crankshaft bearing. • install the drive shaft [a] and output shaft ...

Page 269

Crankshaft/transmission 9-15 crankcase • set the pin [a] to the idle gear shaft [b], and install them to the left crankcase half. • install the tongue washer [a] so that the projection fits the hole of the left crankcase half. • install: needle bearing [b] • install: reverse idle gear [a] dowel pin ...

Page 270

9-16 crankshaft/transmission crankcase • set the left crankcase halve on the right crankcase halve. • while turning the reverse idle gear [a] with the tip of a screw driver [b], mesh the reverse idle gear and reverse gears. • using a plastic hammer, press the rear portion of the crankcase, and tap t...

Page 271

Crankshaft/transmission 9-17 crankcase • to install the shift drum cam [a], use the driver [b] to bring the gear positioning lever [c] to the bottom of the crankcase. • mate the shift drum pin [d] into the shift drum hole. ○ fit the groove [e] of the shift drum cam on the shift drum pin. • apply non...

Page 272