- DL manuals

- Kawasaki

- Other

- KFX 50 - BROCHURE 2009

- Service Manual

Kawasaki KFX 50 - BROCHURE 2009 Service Manual

Summary of KFX 50 - BROCHURE 2009

Page 1

Kfx50 all terrain vehicle service manual.

Page 3: Kfx50

Kfx50 all terrain vehicle service manual supplement all rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of quali...

Page 4: Foreword

Foreword this kawasaki service manual supplement information provides unique to the kawasaki ksf50b7f, which is based on the kymco (kwang yang motor co., ltd.). It must be used in conjunction with the other chapters of this manual. Read both this supplement and the base manual for complete informati...

Page 5: General Information

General information 1-1 general information contents serial number ......................................................................................................... Base manual specifications........................................................................................................

Page 6

General information 1-2 specifications items ksf50b7f ~ dimensions overall length 1 400 mm (55.12 in.) overall width 880 mm (34.65 in.) overall height 910 mm (35.83 in.) wheelbase 965 mm (37.99 in.) ground clearance (at rear axle) 85 mm (3.35 in.) seat height 635 mm (25.00 in.) dry mass 105 kg (232 ...

Page 7

General information 1-3 items ksf50b7f ~ drive train primary reduction system: type belt converter reduction ratio 0.91 a 3.03 clutch type (primary) centrifugal transmission: type 1-speed oil viscosity sae 90 oil capacity 0.12 l (0.13 us gt) final drive system: type chain reduction ratio 2.0 (32/16)...

Page 8

General information 1-4 items ksf50b7f ~ electrical equipment: battery 12 v 4 ah brake light bulb 12 v 21 w alternator: type single-phase ac rated output 5 a, 14 v @5 000 r/min (rpm) specifications are subject to change without notice, and may not apply to every country..

Page 9

General information 1-5 service precautions caution if parts replacement is necessary, replace the parts with kawasaki genuine parts or their equivalent. When removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order and orienta...

Page 10

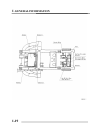

General information 1-6 model identification ksf50b7f left side view ksf50b7f right side view.

Page 11

General information 1-7 symbol throughout this manual are symbols indicating instructions and other information necessary for servicing. The meaning of each symbol is included in the table below. Where applicable, comparable kawasaki products and their part numbers have been included. Symbol kymco d...

Page 12

General information 1-8 special tools base manual tools kawasaki recommend tools a120e00001 flywheel puller 57001-y001 flywheel puller a120e00012 tappet adjuster 57001-y003 tappet adjuster a120e00014 oil seal and bearing driver 57001-1129 bearing driver set a120e00017 universal holder 57001-1605 fly...

Page 13

General information 1-9 base manual tools kawasaki recommend tools a120e00034 clutch spring compressor 57001-y006 clutch spring compressor a120e00037 bearing puller 57001-1058 oil seal & bearing remover assy for an oil seal or a bearing of smaller size (inner diameter is 13 mm or less) use a suitabl...

Page 14

General information 1-10 base manual tools kawasaki recommend tools yf-3501 tester 57001-1394 hand tester 㧙 57001-1665 pilot screw adjuster 㧙 57001-1486 compression gauge adapter, m10 × 1.0

Page 15: Base Manual

Base manual kawasaki kfx50 note: kawasaki modified kymco 4121-pwa5-s00. Use the kawasaki service manual supplement along with the kymco base manual when servicing the kawasaki kfx50 model..

Page 16: Preface

Preface this service manual describes the technical features and servicing procedures for the atv 50. Section 1 contains the precautions for all operations stated in this manual. Read them carefully before starting any operation. Section 2 is the removal/installation procedures for the frame covers ...

Page 17: . General Information

1 . General information 1-0 1 _____________________________________________________________________________________________ _____________________________________________________________________________________________ __________________________________________________________________________________...

Page 18: . General Information

1 . General information 1-1 serial number location of frame serial number location of engine serial number.

Page 19: . General Information

1 . General information 1-2 specifications name kfx50 overall length 1400 mm (55.12 in) overall width (mm) 880 mm (34.65 in) overall height (mm) 910 mm (35.83 in) wheel base (mm) 965 (37.99 in) engine type sohc displacement 49.5 cm 3 (3.02 cu-in) fuel used #92 nonleaded gasoline front wheel 53 kg (1...

Page 20: . General Information

1 . General information 1-3 service precautions make sure to install new gaskets, o-rings, circlips, cotter pins, etc. When reassembling. when tightening bolts or nuts, begin with larger-diameter to smaller ones at several times, and tighten to the specified torque diagonally. use genuine part...

Page 21: . General Information

1 . General information 1-4 apply or add designated greases and lubricants to the specified lubrication points. after reassembly, check all parts for proper tightening and operation. when two persons work together, pay attention to the mutual working safety. disconnect the battery negative (...

Page 22: . General Information

1 . General information 1-5 confirm capacity if the fuse is burned out, find the cause and repair it. Replace it with a new one according to the specified capacity. after operation, terminal caps shall be installed securely. when taking out the coupler, the lock on the coupler shall be release...

Page 23: . General Information

1 . General information 1-6 snapping! the coupler shall be inserted completely. if the double coupler has a lock, lock it at the correct position. check if there is any loose wire. before connecting a terminal, check for damaged terminal cover or loose negative terminal. check the double c...

Page 24: . General Information

1 . General information 1-7 after clamping, check each wire to make sure it is secure. do not squeeze wires against the weld or its clamp. after clamping, check each harness to make sure that it is not interfering with any moving or sliding parts. when fixing the wire harnesses, do not make ...

Page 25: . General Information

1 . General information 1-8 do not press or squeeze the wire. Do not pull too tight! route harnesses so they are neither pulled tight nor have excessive slack. protect wires and harnesses with electrical tape or tube if they contact a sharp edge or corner. when rubber protecting cover is used ...

Page 26: . General Information

1 . General information 1-9 do you understand the instrument? Is the instrument set correctly? Remove rust ! after routing, check that the wire harnesses are not twisted or kinked. wire harnesses routed along with handlebar should not be pulled tight, have excessive slack or interfere with adjac...

Page 27: . General Information

1 . General information 1-10 symbols: the following symbols represent the servicing methods and cautions included in this service manual. : apply engine oil to the specified points. (use designated engine oil for lubrication.) : apply grease for lubrication. : transmission gear oil (sae90) : this ...

Page 28: . General Information

1 . General information 1-11 torque values standard torque values item torque n·m (kgf·m, lbf·ft) item torque n·m (kgf·m, lbf·ft) 5 mm bolt and nut 6 mm bolt and nut 8 mm bolt and nut 10 mm bolt and nut 12 mm bolt and nut 14 mm bolt and nut 5(0.5, 4) 10 (1, 7) 22 (2.2, 16) 35 (3.5, 25) 55 (5.5, 40) ...

Page 29: . General Information

1 . General information 1-12 frame item q‘ty thread dia. (mm) torque n·m (kgf·m, lbf·ft) remarks steering column nut front arm nut knuckle arm nut front wheel nut rear wheel nut front axle nut rear axle nut front shock absorber upper mount bolt front shock absorber lower mount bolt rear shock absorb...

Page 30: . General Information

1 . General information 1-13 lubrication points engine lubrication points lubricant valve guide/valve stem movable part cam lobes valve rocker arm friction surface cam chain cylinder lock bolt and nut piston surroundings and piston ring grooves piston pin surroundings cylinder inside wall connecting...

Page 31: . General Information

1 . General information 1-14 throttle cable steering column lower front swing arm bush front swing arm bush frame the following is the lubrication points for the frame. Use general purpose grease for parts not listed. Apply clean engine oil or grease to cables and movable parts not specified. This w...

Page 32: . General Information

1 . General information 1-15 rear axle hub collar/oil seal/bearing driven sprocket rear swing arm axle.

Page 33: . General Information

1 . General information 1-16 cable & harness routing.

Page 34: . General Information

1 . General information 1-17.

Page 35: . General Information

1 . General information 1-18.

Page 36: . General Information

1 . General information 1-19.

Page 37: . General Information

1 . General information 1-20 troubleshooting engine will not start or is hard to start check if fuel reaches carburetor by loosening drain screw remove spark plug and install it into spark plug cap to test spark by connecting it to engine ground inspection/adjustment probable cause spark jumps norma...

Page 38: . General Information

1 . General information 1-21 engine lacks power start engine and accelerate lightly for observation inspection/adjustment symptom probable cause engine speed increases correct timing engine speed does not increase sufficiently incorrect timing check ignition timing (using a timing light) test cylind...

Page 39: . General Information

1 . General information 1-22 poor performance (especially at idle and low speeds) remove spark plug and install it into spark plug cap to test spark by connecting it to engine ground inspection/adjustment symptom probable cause check ignition timing check carburetor gasket for air leaks check carbur...

Page 40: . General Information

1 . General information 1-23 poor performance (at high speed) inspection/adjustment symptom probable cause check ignition timing check carburetor jets for clogging correct timing incorrect timing check valve spring tension check valve clearance correct incorrect not clogged clogged correctly adjuste...

Page 41: . General Information

1 . General information 1-24 poor charging (battery over discharging or overcharging) undercharging overcharging start engine and test limit voltage of battery terminals connect battery (+) wire to regulator/rectifier coupler red wire and battery (-) wire to engine ground and test voltage inspection...

Page 42: . General Information

1 . General information 1-25 no spark at spark plug replace with a new spark plug and inspect again check cdi unit coupler for looseness inspection/adjustment symptom probable cause normal abnormal normal abnormal normal abnormal abnormal measure resistance between terminals of cdi unit coupler chec...

Page 43: 2-0

2 . Frame covers/exhaust muffler/bulb 2-0 2 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ____________________________________________________________________...

Page 44: 2-1

2 . Frame covers/exhaust muffler/bulb 2-1.

Page 45: 2-2

2 . Frame covers/exhaust muffler/bulb 2-2 service information general instructions x when removing frame covers, use special care not to pull them by force because the cover joint claws may be damaged. X make sure to route cables and harnesses according to the cable & harness routing. Torque values ...

Page 46: 2-3

2 . Frame covers/exhaust muffler/bulb 2-3 frame covers seat removal to remove the seat, pull upward the seat lock lever and pull up the seat at the rear. Seat installation to install the seat, insert the hook in the hole and align the tabs on the seat with the grommets on the frame and press the sea...

Page 47: 2-4

2 . Frame covers/exhaust muffler/bulb 2-4 disconnect the front brake cables. Disconnect the front brake stop switch wires. Remove the two screws and speed limiter cover. Disconnect the throttle cable. Remove the four bolts and upper handlebar holders. Remove the handlebar. Front brake cables screws ...

Page 48: 2-5

2 . Frame covers/exhaust muffler/bulb 2-5 handlebar installation reverse the “handlebar removal” procedures. (see page 2-3) apply adhesive agent to the handlebar grip when installing it. Adhesive agent: konishi co. Ltd g103 or equivalent rubber adhesive agent footboard removal remove the eight quick...

Page 49: 2-6

2 . Frame covers/exhaust muffler/bulb 2-6 front fender installation reverse the “front fender removal” procedures. Rear fender removal remove the front fender. (see page 2-5) remove the battery. (see page 14-4) remove the starter relay and cdi unit. Remove the three bolts attaching the rear fender. ...

Page 50: 2-7

2 . Frame covers/exhaust muffler/bulb 2-7 exhaust muffler removal remove the two nuts attaching the exhaust pipe and cylinder head. Remove the two bolts attaching the exhaust pipe. Remove the bolt attaching the exhaust muffler, then remove the exhaust muffler. Inspection inspect the gasket at the fr...

Page 51: 2-8

2 . Frame covers/exhaust muffler/bulb 2-8 installation install the exhaust muffler by reversing the removal sequence. Torque: exhaust muffler lock bolts: 35 n·m (3.5 kgf·m, 25 lbf·ft) exhaust muffler lock nuts: 20 n·m (2 kgf·m, 15 lbf·ft) brake light bulb removal remove the two screws and brake ligh...

Page 52: 2-9

2 . Frame covers/exhaust muffler/bulb 2-9 installation align the projections with the grooves of the socket. Push and turn the bulb clockwise and install it. Install the lower lens as shown. Fit the projection in the notch of the lower lens. Grooves projections lower lens notch projections.

Page 53: . Inspection/adjustment

3 . Inspection/adjustment 3-0 3 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ________________________________________________________________________________...

Page 54: . Inspection/adjustment

3 . Inspection/adjustment 3-1 service information general warning xbefore running the engine, make sure that the working area is well-ventilated. Never run the engine in a closed area. The exhaust contains poisonous carbon monoxide gas which may cause death to people. Xgasoline is extremely flammabl...

Page 55: . Inspection/adjustment

3 . Inspection/adjustment 3-2 maintenance schedule this chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly over...

Page 56: . Inspection/adjustment

3 . Inspection/adjustment 3-3 fuel system fuel line check the fuel tubes and replace any parts, which show signs of deterioration, damage or leakage. Throttle lever play check the throttle to swing for smooth movement. Measure the throttle to swing free play. Free play: 1 ~ 4 mm (0.04 ~ 0.16 in) to ...

Page 57: . Inspection/adjustment

3 . Inspection/adjustment 3-4 to clean the air filter element: 1. Wash the element gently but thoroughly in solvent. Warning use parts cleaning solvent only. Never use gasoline or low flash point solvents which may lead to a fire or explosion. 2. Squeeze the excess solvent out of the filter and let ...

Page 58: . Inspection/adjustment

3 . Inspection/adjustment 3-5 fuel system cleanliness inspection warning gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition switch off. Do not smoke. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any app...

Page 59: . Inspection/adjustment

3 . Inspection/adjustment 3-6 fuel hoses and connections inspection check the fuel hoses. Replace the fuel hose if any fraying, leaks, cracks, bulges, or ozonic cracks are noticed. Check that the hoses are securely connected and clamps are installed correctly. When installing the fuel hoses, avoid s...

Page 60: . Inspection/adjustment

3 . Inspection/adjustment 3-7 turn the fuel tap to the off position. Remove the fuel tap and fuel tank. Replace the fuel hoses with new ones. When installing the fuel hose, avoid sharp bending, kinking, flattening or twisting, and route the fuel hose with a minimum of bending so that the fuel flow w...

Page 61: . Inspection/adjustment

3 . Inspection/adjustment 3-8 cylinder head cylinder compression warm up the engine before compression test. Remove the spark plug. Install a compression gauge and adapter. Special tool: compression gauge adapter, m10 × 1.0 : 57001-1486 (kawasaki) open the throttle valve fully and push the starter b...

Page 62: . Inspection/adjustment

3 . Inspection/adjustment 3-9 turn the cooling fan clockwise so that the “t” mark line on the flywheel aligns with the index mark on the crankcase to bring the round hole on the camshaft gear facing up to the top dead center on the compression stroke. Inspect and adjust the valve clearance. Valve cl...

Page 63: . Inspection/adjustment

3 . Inspection/adjustment 3-10 cylinder head cover breather system inspection check breather hose for cracks or damage. Replace if necessary. Exhaust system spark arrester cleaning be sure the exhaust pipe and muffler are cool before cleaning the spark arrester. Warning always let the exhaust system...

Page 64: . Inspection/adjustment

3 . Inspection/adjustment 3-11 exhaust system inspection check the leakage at front end of the exhaust pipe. If the exhaust gas leaks, retighten the exhaust muffler lock nut or replace the gasket with a new one. Torque: exhaust muffler lock bolt: 35 n·m (3.5 kgf·m, 25 lbf·ft) exhaust muffler lock nu...

Page 65: . Inspection/adjustment

3 . Inspection/adjustment 3-12 engine oil replacement place the machine on a level place. Warm up the engine for several minutes and stop it. Place a container under the engine. Remove the oil filler cap and drain plug to drain the oil. Reinstall the drain plug and tighten the drain plug to specific...

Page 66: . Inspection/adjustment

3 . Inspection/adjustment 3-13 engine oil replacement and oil filter cleaning a. Place the machine on a level place. B. Warm up the engine for several minutes and stop it. C. Place a container under the engine. D. Remove the oil filler cap and oil filter cap to drain the oil. E. Clean the oil strain...

Page 67: . Inspection/adjustment

3 . Inspection/adjustment 3-14 transmission oil transmission oil measurement place the machine on a level place. Remove the oil filler bolt and check the oil level. It should be up to the brim of the hole. If the level is low, add oil to raise it to the proper level. Reinstall the oil filler bolt an...

Page 68: . Inspection/adjustment

3 . Inspection/adjustment 3-15 drive belt remove the left crankcase cover. Inspect the drive belt for cracks, scaling, chipping or excessive wear. Measure the v-belt width service limit: 17 mm (0.68 in) replace the drive belt if out of specification. Brakes brake shoes the checking of brake shoes we...

Page 69: . Inspection/adjustment

3 . Inspection/adjustment 3-16 front brake lever free play inspection the brake lever free play (a) should be adjusted to 10 ~ 20 mm (0.4 ~ 0.8 in) at the tip of the brake lever. Front brake lever free play adjustment loosen the upper lock nut and fully turn in the adjusting bolt. Loosen the lower l...

Page 70: . Inspection/adjustment

3 . Inspection/adjustment 3-17 brake fluid change place the machine on a level place and set the handlebar upright. Remove the two screws attaching the brake fluid reservoir cap. Connect a transparent hose to the brake caliper bleed valve and then loosen the bleed valve nut. Use a syringe to draw th...

Page 71: . Inspection/adjustment

3 . Inspection/adjustment 3-18 brake hose replacement pump the brake fluid out of the line as explained in the brake fluid change. (see page 3-17) remove the fluid tube bolts at both ends of the brake hose, and pull the hose off the vehicle. Immediately wipe up any brake fluid that spills. Caution b...

Page 72: . Inspection/adjustment

3 . Inspection/adjustment 3-19 steering system inspection place the machine on a level place. Check the steering column bushings and bearings: move the handlebar up and down, and/or back and forth. Replace the steering column bushings and or bearings if excessive play check the tie-rod ends. Turn th...

Page 73: . Inspection/adjustment

3 . Inspection/adjustment 3-20 toe-in adjustment place the machine on a level place. Measure the toe-in. Adjust if out of specification. Toe-in measurement steps: mark both front tire tread centers. Raise the front end of the machine so that there is no weight on the front tires. Fix the handlebar s...

Page 74: . Inspection/adjustment

3 . Inspection/adjustment 3-21 wheels/tires check the tires for cuts, imbedded nails or other damages. Check the tire pressure. Tire pressure 1 rider front 25 kpa (0.25 kgf/cm², 3.6 psi) rear 25 kpa (0.25 kgf/cm², 3.6 psi) tire size front : 16 × 8-7 rear : 16 × 8-7 check the front axle nut for loose...

Page 75: . Inspection/adjustment

3 . Inspection/adjustment 3-22 inspect the wheel. Replace if damage or bends always balance the wheel when a tire or wheel has been changed or replaced. Drive chain slack inspection before checking and/or adjusting, rotate the rear wheels several revolutions and check slack at several points to find...

Page 76: . Inspection/adjustment

3 . Inspection/adjustment 3-23 turn the adjusting nut, to decrease or increase chain slack. Retighten the upper and lower axle holding bolts. Torque: 70 n·m (7 kgf·m, 50 lbf·ft) drive chain cleaning and lubrication the drive chain is equipped with rubber o-rings between the chain plates. Steam clean...

Page 77: . Inspection/adjustment

3 . Inspection/adjustment 3-24 lever lubrication lubricate the pivoting parts of each lever. Suspension lubrication inject grease into the nipples using a grease gun until slight over flow is observed from the thrust covers. Joint boot inspection tie-rod end boot inspection visually inspect the tie-...

Page 78: . Inspection/adjustment

3 . Inspection/adjustment 3-25 bolts and nuts tightening tightness inspection check the tightness of the bolts and nuts listed here in accordance with the periodic maintenance chart. Also, check to see that each cotter pin is in place and in good condition. If there are loose fasteners, retorque the...

Page 79: . Lubrication System

4 . Lubrication system 4-0 4 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ___________________________________________________________________________________...

Page 80: . Lubrication System

4 . Lubrication system 4-1 lubrication system oil pump oil filter screen crankshaft rocker arm shaft.

Page 81: . Lubrication System

4 . Lubrication system 4-2 service information general instructions x the maintenance of lubrication system can be performed with the engine installed in the frame. X use care when removing and installing the oil pump not to allow dust and foreign matters to enter the engine and oil line. X do not a...

Page 82: . Lubrication System

4 . Lubrication system 4-3 engine oil/oil filter oil level and oil change refer to the “engine oil” section in the chapter 3 to check the oil level and replacement and oil filter cleaning. Oil pump removal place a container under the engine. Remove the drain plug to drain the oil. (see page 3-12) re...

Page 83: . Lubrication System

4 . Lubrication system 4-4 remove o-rings and dowel pin. Disassembly remove the screws and disassemble the oil pump. Inspection measure the pump body-to-outer rotor clearance. Service limit: 0.25 mm (0.01 in) dowel pin o-rings bolts screws outer rotor pump body.

Page 84: . Lubrication System

4 . Lubrication system 4-5 measure the inner rotor-to-outer rotor clearance. Service limit: 0.2 mm (0.008 in) measure the rotor end-to-pump body clearance. Service limit: 0.12 mm (0.0048 in) assembly install the outer rotor, inner rotor and pump shaft into the pump body. Install the dowel pin. Insta...

Page 85: . Lubrication System

4 . Lubrication system 4-6 installation install the o-rings and dowel pin. Install the oil pump and tighten the bolts. Make sure that the pump shaft rotates freely without binding. Install the oil pump gear and tighten the nut. Inspect the o-rings and replace if damaged. Ϡ oil pump gear nut bolts oi...

Page 86: . Lubrication System

4 . Lubrication system 4-7 install the right crankcase cover and tighten the bolts. Bolts crankcase cover bolts.

Page 87: . Fuel System

5 . Fuel system 5-0 5 _____________________________________________________________________________________________ _____________________________________________________________________________________________ __________________________________________________________________________________________...

Page 88: . Fuel System

5 . Fuel system 5-1.

Page 89: . Fuel System

5 . Fuel system 5-2 service information general instructions warning gasoline is very dangerous. When working with gasoline, keep sparks and flames away from the working area. Gasoline is extremely flammable and is explosive under certain conditions. Be sure to work in a well-ventilated area. X do n...

Page 90: . Fuel System

5 . Fuel system 5-3 troubleshooting engine cranks but won’t start engine lacks power x no fuel in tank x clogged air cleaner x no fuel to carburetor x faulty carburetor x cylinder flooded with fuel x faulty ignition system x no spark at plug x clogged air cleaner lean mixture x intake air leak x clo...

Page 91: . Fuel System

5 . Fuel system 5-4 fuel tank removal warning x gasoline is extremely flammable and can be explosive under certain conditions. X keep sparks and flames away from the work area. X wipe off any spilled gasoline. Remove front fender. (see page 2-5) switch the fuel tap “off”. Disconnect the fuel outlet ...

Page 92: . Fuel System

5 . Fuel system 5-5 installation reverse the “fuel tank removal” procedures. Install the “on” fuel hose on the fitting that has screen. Fuel tap removal warning x gasoline is extremely flammable and can be explosive under certain conditions. X keep sparks and flames away from the work area. X drain ...

Page 93: . Fuel System

5 . Fuel system 5-6 remove the rubber gasket from the fuel tap body. Inspection inspect the fuel tap body for dirt and clog. Clean if necessary. Replace the rubber gasket with new ones if they are damaged or deteriorated. Replace the o-rings with new ones if they are damaged or deteriorated. Assembl...

Page 94: . Fuel System

5 . Fuel system 5-7 throttle valve disassembly remove the fuel tank. (see page 5-4) remove the carburetor cap. Pull out the throttle valve. Compress the spring to disconnect the throttle cable by hand. Remove the spring from the throttle valve. Carburetor cap throttle valve throttle cable spring.

Page 95: . Fuel System

5 . Fuel system 5-8 remove the needle clip and jet needle. Check the throttle valve and jet needle for wear or damage. Assembly reverse the “disassembly” procedures. Install the throttle valve into the carburetor body. Align the groove in the throttle valve with the throttle stop screw on the carbur...

Page 96: . Fuel System

5 . Fuel system 5-9 air cleaner cleaning refer to “air cleaner” section in the chapter 3. Removal remove front fender. (see page 2-5) disconnect the breather hose from cylinder head and frame. Remove the bolt at the air cleaner left side. Loosen the screw at the band and remove bolt at the air clean...

Page 97: . Fuel System

5 . Fuel system 5-10 carburetor removal remove the fuel tank, carburetor cap and air cleaner. (refer to chapter 5) loosen the drain plug to drain the gasoline from the float chamber. Warning x gasoline is extremely flammable and can be explosive under certain conditions. X keep sparks and flames awa...

Page 98: . Fuel System

5 . Fuel system 5-11 disassembly remove auto bystarter cap. Remove the two screws and then remove auto bystarter and plate. Remove the three float chamber screws and remove the float chamber. Pull out the float pin, then remove float and float valve. Remove the main jet, needle jet holder, and needl...

Page 99: . Fuel System

5 . Fuel system 5-12 caution x be careful not to damage the jets and jet holder when removing them. X do not force the screw against its seat to avoid seat damage. X be sure to install the o-ring in the reverse order of removal. Assembly reverse the “disassembly” procedures. Install the needle jet i...

Page 100: . Fuel System

5 . Fuel system 5-13 carburetor cleaning blow compressed air through all passages of the carburetor body. Float/float valve inspection inspect the float valve seat for wear or damage. Inspect the float for damage or fuel level inside the float chamber. Fuel reservoir o-ring check remove the o-ring. ...

Page 101: . Fuel System

5 . Fuel system 5-14 auto bystarter inspection measure the resistance between the auto bystarter wire terminals. Resistance: 5: (10 minutes minimum after stopping the engine) if the resistance exceeds 5:, replace the auto bystarter with a new one. After the engine stops for 30 minutes, connect a hos...

Page 103: . Engine Removal

6 . Engine removal 6-0 6 _____________________________________________________________________________________________ _____________________________________________________________________________________________ _______________________________________________________________________________________...

Page 104: . Engine Removal

6 . Engine removal 6-1 service information general instructions x a floor jack or other adjustable support is required to support and maneuver the engine. Be careful not to damage the machine body, cables and wires during engine removal. X use shop towels to protect the machine body during engine re...

Page 105: . Engine Removal

6 . Engine removal 6-2 engine removal drain engine oil and transmission oil. (refer to chapter 3) remove the footboards and exhaust pipe. (refer to chapter 2) remove the air cleaner and carburetor. (refer to chapter 5) remove the two bolts on the drive sprocket. Remove the drive sprocket and washer....

Page 106: . Engine Removal

6 . Engine removal 6-3 remove the engine assembly to the left side of the machine. Engine installation reverse the “removal” procedures. Torque values engine bracket bolt 27 n·m (2.7 kgf·m, 20 lbf·ft) front engine mounting bolts 45 n·m (4.5 kgf·m, 32 lbf·ft) rear engine mounting bolts 32 n·m (3.2 kg...

Page 107: . Cylinder Head/valves

7 . Cylinder head/valves 7-0 7 _____________________________________________________________________________________________ _____________________________________________________________________________________________ _________________________________________________________________________________...

Page 108: . Cylinder Head/valves

7 . Cylinder head/valves 7-1.

Page 109: . Cylinder Head/valves

7 . Cylinder head/valves 7-2 service information general instructions x the cylinder head can be serviced with the engine installed in the frame. X when assembling, apply molybdenum disulfide grease or engine oil to the valve guide movable parts, valve arm and camshaft sliding surfaces for initial l...

Page 110: . Cylinder Head/valves

7 . Cylinder head/valves 7-3 torque values cylinder head cover bolt 10 n·m (1 kgf·m, 7 lbf·ft) camshaft hold nut 14 n·m (1.4 kgf·m, 10 lbf·ft) apply engine oil to threads tappet adjusting nut 9 n·m (0.9 kgf·m, 6.5 lbf·ft) apply engine oil to threads special tools valve spring compressor a120e00040 t...

Page 111: . Cylinder Head/valves

7 . Cylinder head/valves 7-4 cylinder head cover removal disconnect the breather hose at the cylinder head cover. Remove the four bolts at the cylinder head cover, then remove the cylinder head cover. Installation install a new cylinder head cover o-ring and install the cylinder head cover. Install ...

Page 112: . Cylinder Head/valves

7 . Cylinder head/valves 7-5 remove the two screws and cam chain tensioner cover. Remove the cam chain tensioner cap/spring. Remove the lifter tensioner bolts, then remove cam chain tensioner and gasket. Remove the four camshaft holder nuts and washers. Remove the camshaft holder and dowel pins. Rem...

Page 113: . Cylinder Head/valves

7 . Cylinder head/valves 7-6 camshaft holder disassembly take out the valve rocker arm shafts using a 5 mm (0.2 in) bolt. Remove the valve rocker arms and arm shafts. Camshaft holder inspection inspect the camshaft holder for wear or damage. Inspect the rocker arm shaft for blue discoloration or gro...

Page 114: . Cylinder Head/valves

7 . Cylinder head/valves 7-7 camshaft holder assembly reverse the “camshaft holder disassembly” procedures. Camshaft inspection check each camshaft bearing for play or damage. Replace the camshaft assembly with a new one if the bearings are noisy or have excessive play. Inspect camshaft lobes for pi...

Page 115: . Cylinder Head/valves

7 . Cylinder head/valves 7-8 camshaft installation reverse the “camshaft removal” procedures. Note the following points: 1. Turn the flywheel so that the “t” mark on the flywheel aligns with the index mark on the crankcase. Keep the round hole on the camshaft gear facing up and align the punch marks...

Page 116: . Cylinder Head/valves

7 . Cylinder head/valves 7-9 install the tensioner and new gasket to cylinder. Install the lifter tensioner bolts and tighten them. Torque: 12 n·m (1.2 kgf·m, 9 lbf·ft) install the washer, spring and tensioner cap, and then tighten the tensioner cap to specified torque. Torque: 4.5 n·m (0.45 kgf·m, ...

Page 117: . Cylinder Head/valves

7 . Cylinder head/valves 7-10 cylinder head removal remove the camshaft. (see page 7-4) remove the carburetor. (refer to the “carburetor removal” section in the chapter 5) remove the exhaust muffler. (refer to the “exhaust muffler removal” section in the chapter 2) remove the two nuts and then remov...

Page 118: . Cylinder Head/valves

7 . Cylinder head/valves 7-11 remove the two cylinder head bolts. Remove the cylinder head. Cylinder head cylinder head bolts.

Page 119: . Cylinder Head/valves

7 . Cylinder head/valves 7-12 cylinder head disassembly remove the valve spring cotters, retainers, springs, spring seats, oil seals and valves using a valve spring compressor. Special tool: valve spring compressor a120e00040 valve/valve guide inspection inspect each valve for bending, burning, scra...

Page 120: . Cylinder Head/valves

7 . Cylinder head/valves 7-13 valve spring inspection measure the free length of the valve springs. Service limit: 34 mm (1.36 in) measure compressed force (valve spring) and installed length. Replace if out of specification. Standard: 19.2 ~ 22 kg at 19.65 mm (0.786 in) check the intake manifold an...

Page 121: . Cylinder Head/valves

7 . Cylinder head/valves 7-14 assembly install the valve spring seats and oil seal. Lubricate each valve with engine oil and insert the valves into the valve guides. Install the valve springs so that the closed coil end faces downwards and retainers. Compress the valve springs using the valve spring...

Page 123: . Cylinder/piston

8 . Cylinder/piston 8-0 8 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ______________________________________________________________________________________...

Page 124: . Cylinder/piston

8 . Cylinder/piston 8-1.

Page 125: . Cylinder/piston

8 . Cylinder/piston 8-2 service information general instructions x the cylinder and piston can be serviced with the engine installed in the frame. X before disassembly, clean the engine to prevent dust from entering the engine. X remove all gasket material from the mating surfaces. X do not use a dr...

Page 126: . Cylinder/piston

8 . Cylinder/piston 8-3 troubleshooting x when hard starting or poor performance at low speed occurs, check the crankcase breather for white smoke. If white smoke is found, it means that the piston rings are worn, stuck or broken. Compression too low or uneven compression excessive smoke from exhaus...

Page 127: . Cylinder/piston

8 . Cylinder/piston 8-4 cylinder/piston piston removal remove the cylinder head. (see page 7-10) remove the two dowel pins and cylinder head gasket. Remove cam chain guide and then remove cylinder. Remove the cylinder gasket and dowel pins. Clean any gasket material from the cylinder surface. Remove...

Page 128: . Cylinder/piston

8 . Cylinder/piston 8-5 piston inspection inspect the piston, piston pin and piston rings. Remove the piston rings. Clean carbon deposits from the piston ring grooves. Inspect the piston wall for wear/scratches/damage. If any defects are found, replace the piston with a new one. Install the piston r...

Page 129: . Cylinder/piston

8 . Cylinder/piston 8-6 measure the piston pin o.D. Service limit: 12.96 mm (0.5184 in) measure the piston-to-piston pin clearance. Service limit: 0.02 mm (0.0008 in) measure the piston o.D. Service limit: 38.9 mm (1.556 in) cylinder inspection inspect the cylinder bore for wear or damage. Measure t...

Page 130: . Cylinder/piston

8 . Cylinder/piston 8-7 piston ring installation install the piston rings onto the piston. Apply engine oil to each piston ring. Inspection measure the connecting rod small end i.D. Service limit: 13.06 mm (0.5224 in) measure the piston pin o.D. Service limit: 12.96 mm (0.5184 in) measure the connec...

Page 131: . Cylinder/piston

8 . Cylinder/piston 8-8 inspect the exhaust side and intake side chain guides. Wear or damage ń replace. Piston installation remove any gasket material from the crankcase surface. Install the piston, piston pin and a new piston pin clip. Cylinder installation install the dowel pins and a new cylinde...

Page 133: Drive And Driven Pulleys

9. Drive and driven pulleys 9-0 9 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ______________________________________________________________________________...

Page 134: Drive And Driven Pulleys

9. Drive and driven pulleys 9-1.

Page 135: Drive And Driven Pulleys

9. Drive and driven pulleys 9-2 service information general instructions x the drive pulley, clutch and driven pulley can be serviced with the engine installed in the frame. X avoid getting grease and oil on the drive belt and pulley faces. Remove any oil or grease from them to minimize the slipping...

Page 136: Drive And Driven Pulleys

9. Drive and driven pulleys 9-3 left crankcase cover/kick starter removal remove left footboard. (see page 2-5) remove the eight left crankcase cover bolts and left crankcase cover. Remove the gasket and dowel pins. Kick starter disassembly remove the kick lever from the kick starter spindle. Gently...

Page 137: Drive And Driven Pulleys

9. Drive and driven pulleys 9-4 remove the circlip and washer from the kick starter spindle. Inspection inspect the kick starter spindle and gear for wear or damage. Inspect the return spring for weakness or damage. Inspect the kick starter spindle bushings for wear or damage. Inspect the starter dr...

Page 138: Drive And Driven Pulleys

9. Drive and driven pulleys 9-5 assembly install the kick starter spindle bushing and return spring onto the left crankcase cover. Install the kick starter spindle. Install the starter driven gear and friction spring onto the left crankcase cover as the figure shown. Install the kick starter spindle...

Page 139: Drive And Driven Pulleys

9. Drive and driven pulleys 9-6 install the left crankcase cover and tighten the eight left crankcase cover bolts diagonally. Torque: 12 n·m (1.2 kgf·m, 9 lbf·ft) drive pulley removal remove the left crankcase cover. (refer to the “left crankcase cover removal” section in the chapter 9) hold the fly...

Page 140: Drive And Driven Pulleys

9. Drive and driven pulleys 9-7 disassembly remove the ramp plate. Remove the six weight rollers. Inspection check each weight roller for wear or damage. Measure each weight roller o.D. Service limit: 15.4 mm (0.616 in) measure the movable drive face bushing i.D. Service limit: 20.6 mm (0.824 in) ra...

Page 141: Drive And Driven Pulleys

9. Drive and driven pulleys 9-8 assembly install the weight rollers into the movable drive face. Install the slide pieces to the ramp plate. Install the ramp plate to the movable drive face. Check the drive pulley collar for wear or damage. Measure the o.D. Of the drive pulley collar sliding surface...

Page 142: Drive And Driven Pulleys

9. Drive and driven pulleys 9-9 installation install the drive pulley face assembly, drive pulley collar and maximum speed reduction collars. Warning do not remove the maximum speed reduction collar until the rider develops sufficient skills to operate the atv safely at the maximum speed with the ma...

Page 143: Drive And Driven Pulleys

9. Drive and driven pulleys 9-10 clutch/driven pulley removal remove the left crankcase cover. (refer to the “left crankcase cover removal” section in the chapter 9) remove the drive pulley. (refer to the “drive pulley removal” section in the chapter 9) remove the drive belt. Hold the clutch outer w...

Page 144: Drive And Driven Pulleys

9. Drive and driven pulleys 9-11 clutch outer inspection inspect the clutch outer for wear or damage. Measure the clutch outer i.D. Service limit: 107.5 mm (4.3 in) clutch/driven pulley disassembly hold the clutch/driven pulley assembly with the clutch spring compressor. Special tool: clutch spring ...

Page 145: Drive And Driven Pulleys

9. Drive and driven pulleys 9-12 remove the seal collar. Pull out the three guide roller pins and guide rollers. Remove the movable driven face from the driven face. Inspection measure the clutch lining thickness. Service limit: 1 mm (0.04 in) measure the driven face spring free length. Service limi...

Page 146: Drive And Driven Pulleys

9. Drive and driven pulleys 9-13 check the driven face for wear or damage. Measure the driven face o.D. Service limit: 33.94mm (1.3576 in) check the movable driven face for wear or damage. Measure the movable driven face i.D. Service limit: 34.06 mm (1.3624 in) driven pulley face bearing replacement...

Page 147: Drive And Driven Pulleys

9. Drive and driven pulleys 9-14 apply grease to the outer bearing. Drive a new outer bearing into the driven face with the sealed end facing up. Seat the snap ring in its groove. Apply grease to the driven face bore areas. Press a new needle bearing into the driven face. Special tool: oil seal and ...

Page 148: Drive And Driven Pulleys

9. Drive and driven pulleys 9-15 clutch / driven pulley assembly.

Page 149: Drive And Driven Pulleys

9. Drive and driven pulleys 9-16 install the damper rubbers on the drive plate pins. Install the clutch weights/shoes and clutch springs. Set the circlips in the groove. Clean the driven pulley faces and remove any grease from them. Apply grease onto the both oil seals and install them onto the mova...

Page 150: Drive And Driven Pulleys

9. Drive and driven pulleys 9-17 install the seal collar. Remove any excessive grease. Set the driven pulley assembly, driven face spring and clutch assembly onto the clutch spring compressor. Set the clutch spring compressor in a vice. Special tool: clutch spring compressor a120e00034 be sure to cl...

Page 151: Drive And Driven Pulleys

9. Drive and driven pulleys 9-18 compress the clutch spring compressor and tighten the clutch drive plate nut to the specified torque. Torque: 55 n·m (5.5 kgf·m, 40 lbf·ft) installation install the clutch/driven pulley and driven belt onto the drive shaft. Install the clutch outer. Hold the clutch o...

Page 153: .Transmission System

10 .Transmission system 10-0 10 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ________________________________________________________________________________...

Page 154: .Transmission System

10 .Transmission system 10-1.

Page 155: .Transmission System

10 .Transmission system 10-2 service information general instructions x the transmission system can be serviced with the engine installed in the frame. X when replacing the drive axle, use a special tool to hold the bearing inner race for this operation. Specifications specified oil: gear oil sae 90...

Page 156: .Transmission System

10 .Transmission system 10-3 transmission removal remove the drive sprocket. (see page 6-2) remove the left crankcase cover. (see page 9-3) remove the clutch/driven pulley. (see page 9-10) remove the plate attaching bolts and nut. Remove the plate. Drain the transmission gear oil into a clean contai...

Page 157: .Transmission System

10 .Transmission system 10-4 inspect the bearings for allow play in the transmission case or the bearing turns roughly. If any defects are found, replace the bearing with a new one. Primary drive axle removal remove the transmission case cover. (see page 10-3) remove the primary drive axle. Inspect ...

Page 158: .Transmission System

10 .Transmission system 10-5 installation reverse the “transmission revoval” section procedures. Install the primary drive axle into the left crankcase. Install the dowel pins and a new gasket onto the left crankcase install the final shaft into transmission case cover. Install the countershaft and ...

Page 159: .Transmission System

10 .Transmission system 10-6 install the transmission case cover assembly and tighten the transmission case cover bolt. Torque: 27 n·m (2.7 kgf·m, 19 lbf·ft) fill the engine with oil and install the oil filler bolt. (refer to the “transmission oil replacement” section in the chapter 3) specified gea...

Page 161: .Crankscase/crankshaft

11 .Crankscase/crankshaft 11-0 11 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ______________________________________________________________________________...

Page 162: .Crankscase/crankshaft

11 .Crankscase/crankshaft 11-1.

Page 163: .Crankscase/crankshaft

11 .Crankscase/crankshaft 11-2 service information general instructions x this section covers crankcase separation to service the crankshaft. The engine must be removed for this operation. X the following parts must be removed before separating the crankcase. Cylinder head (see page 7-10) cylinder/p...

Page 164: .Crankscase/crankshaft

11 .Crankscase/crankshaft 11-3 crankcase/crankshaft removal remove the crankcase attaching bolt. Separate the left and right crankcase halves. Remove the cam chain guide bolt and cam chain guide. Remove the cam chain from the sprocket. Move the crankshaft by tapping it lightly. Hold the crankshaft a...

Page 165: .Crankscase/crankshaft

11 .Crankscase/crankshaft 11-4 clean off all gasket material from the crankcase mating surfaces. Crankshaft inspection measure the connecting rod small end i.D. Service limit: 13.06 mm (0.5224 in) measure the connecting rod small end free play (a). Service limit: 0.6 mm (0.024 in) measure the cranks...

Page 166: .Crankscase/crankshaft

11 .Crankscase/crankshaft 11-5 turn the crankshaft bearings and check for excessive play. Measure the crankshaft bearing play. Service limit: axial : 0.2 mm (0.008 in) radial : 0.05 mm (0.002 in) crankcase/crankshaft installation install the cam chain into the left crankcase. Install the crankshaft ...

Page 167: .Crankscase/crankshaft

11 .Crankscase/crankshaft 11-6 install the dowel pins and a new gasket onto the left crankcase. Install the right crankcase. Tighten the crankcase attaching bolt. Torque: 10 n·m (1 kgf·m, 7 lbf·ft) cut the excessive part of the new gasket. Place the right crankcase over the crankshaft and onto the l...

Page 169: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-0 12 _____________________________________________________________________________________________ _____________________________________________________________________________________________ __________________________________________...

Page 170: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-1.

Page 171: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-2 service information general instructions x remove the machine frame covers before removing the front wheel. Jack the machine front wheel off the ground and be careful to prevent the machine from falling down. X during servicing, keep...

Page 172: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-3 special tools oil seal and bearing driver a120e00014 troubleshooting hard steering (heavy) front wheel wobbling x insufficient tire pressure x bent rim x excessive wheel bearing play steers to one side or does not track straight x be...

Page 173: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-4 front wheel removal place the machine on a level place. Remove four nuts attaching the wheel panel and front wheel. Elevate the front wheels by placing a suitable stand under the frame. Warning support the machine securely so there i...

Page 174: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-5 inspection measure the wheel run out. Replace wheel or check bearing play if out of specification rim run out limits: radial: 2 mm (0.08 in) axial: 2 mm (0.08 in) inspect the front wheel hub. Replace it if cracks or damage. Inspect t...

Page 175: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-6 front wheel hub disassembly remove the dust seal of each side. Drive the bearing a few times to make the free play. Drive the distance collar with a suitable rod and remove the front wheel hub bearings and distance collar. Wheel hub ...

Page 176: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-7 assembly apply grease to a new dust seal lip and install the dust seal. Pack all bearing cavities with grease. Drive in the outside bearing. Install the distance collar. Drive in the inside bearing. Special tool: oil seal and bearing...

Page 177: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-8 front brake removal remove the wheel hub. (see page 12-4) pull brake shoe plate out from steering knuckle. Disconnect the front brake cable from brake cam lever and remove the brake shoe plate. Inspection measure the front brake lini...

Page 178: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-9 install the brake shoe plate. Install front wheel. (see page 12-7) adjust the front brake cable free play. Refer to the “brake lever free play” section in the chapter 3. Brake cable free play: 10 ~ 20 mm (0.4 ~ 0.8 in) boss locating ...

Page 179: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-10 front suspension removal elevate the front wheels by placing a suitable stand under the frame. Warning support the machine securely so there is no danger of it falling over. Remove the front wheel, wheel hub, brake shoe plate. (refe...

Page 180: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-11 inspect the steering knuckle. Replace if cracks, pitting or damage. Check the front arm brackets of the frame. If bent, cracked or damaged, repair or replace the frame. Check the tightening torque of the front arms securing nuts. To...

Page 181: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-12 inspect the front arm. Replace if cracks, bends or damage. Inspect bushes. Replace if wear or damage. Installation reverse the “removal” procedures. Install the front arm onto the frame and tighten the bolts and nut. Torque: 45 n·m ...

Page 182: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-13 steering system handlebar removal remove the following parts: handlebar and front fender refer to the “frame covers” section in the chapter 2. Inspection inspect the handlebar. Replace it if cracks, bends or damage. Installation ins...

Page 183: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-14 steering column removal remove handlebar. (refer to the “frame cover” section in the chapter 2) remove the cotter pins and nuts attaching the tie-rods, then remove tie-rods. Remove the cotter pin and nut attaching the steering colum...

Page 184: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-15 inspect the dust seals, and bearing. Replace them if wear or damage. Remove the dust seals of each frame side. Remove the snap ring. Remove the bearing. Bearing dust seal dust seal dust seal snap ring bearing.

Page 185: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-16 installation apply grease to a new dust seal lip and install the dust seal (under frame). Pack bearing cavities with grease. Drive in the bearing and install snap ring. Apply grease to a new dust seal lip and install the dust seal. ...

Page 186: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-17 tie-rod removal remove the cotter pin and nut at the steering knuckle. Remove the cotter pin and nut at the steering column. Remove the tie-road. Inspection inspect the tie-rod. Replace it if bend or damage. Check the tie-rod end mo...

Page 187: Steering System

12 .Front wheel/front brake/front suspension/ steering system 12-18 set the rod end (steering column side) in an angle where the indentation surface of the tie-rod is parallel to the rod end shaft, and then tighten the lock nut. Torque: 35 n·m (3.5 kgf·m, 25 lbf·ft) set the other rod end (knuckle ar...

Page 189: 13-0

13 . Rear wheel/swing arm/hydraulic brake 13-0 13 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ______________________________________________________________...

Page 190: 13-1

13 . Rear wheel/swing arm/hydraulic brake 13-1.

Page 191: 13-2

13 . Rear wheel/swing arm/hydraulic brake 13-2 service information general instructions x during servicing, keep oil or grease off the brake disk and brake pads. X drain the brake fluid from the hydraulic brake system before disassembly. X contaminated brake disk or brake pads reduce stopping power....

Page 192: 13-3

13 . Rear wheel/swing arm/hydraulic brake 13-3 troubleshooting rear wheel wobbling tight brake lever x bent rim xseized piston x faulty tire xclogged hydraulic brake system x axle not tightened properly xsmooth or worn brake pad soft rear shock absorber poor brake performance x weak shock absorber s...

Page 193: 13-4

13 . Rear wheel/swing arm/hydraulic brake 13-4 rear wheel rear wheel removal place the machine on a level place. Remove four nuts attaching the wheel. Elevate the rear wheels by placing a suitable stand under the rear of frame. Warning support the machine securely so there is no danger of it falling...

Page 194: 13-5

13 . Rear wheel/swing arm/hydraulic brake 13-5 rear wheel hub removal remove rear wheel nuts. (see page 13-4) remove the wheel hub nut cover and cotter pin. Loosen nut attaching the wheel hub. Remove rear wheel. (see page 13-4) remove wheel hub nut, washer and wheel hub. Elevate the rear wheels by p...

Page 195: 13-6

13 . Rear wheel/swing arm/hydraulic brake 13-6 rear axle removal remove the rear wheel hub of the both rear wheels. (see page 13-5) remove the collars on the rear axle right and left side. Relax the drive chain. (refer to the “drive chain slack inspection” section in the chapter 3.) remove the sproc...

Page 196: 13-7

13 . Rear wheel/swing arm/hydraulic brake 13-7 remove the four bolts and rear axle hub. Inspection replace the rear axle if it is scratched (excessively) or damage. Replace it if splines and threads of the rear axle are wear or damage. Measure the rear axle run out. Service limit: less than 1.5 mm (...

Page 197: 13-8

13 . Rear wheel/swing arm/hydraulic brake 13-8 inspect the driven sprocket. Replace sprocket if more than 1/4 teeth wear or bent teeth. Replace it if the brake disk is cracks or damage. Replace it if splines of the brake disk are wear or damage. Inspect rear axle hub. Replace it if bearing allow pla...

Page 198: 13-9

13 . Rear wheel/swing arm/hydraulic brake 13-9 rear axle installation reverse the “rear axle removal” procedures. Install the rear axle hub. Install the driven sprocket so that the stepped side faces outward. Install the rear axle. Install the sprocket holder and bolts. Torque: 26 n·m (2.7 kgf·m, 20...

Page 199: 13-10

13 . Rear wheel/swing arm/hydraulic brake 13-10 swing arm rear shock absorber removal place the machine on a level place. Elevate the rear wheels by placing a suitable stand under the rear of frame. Warning support the machine securely so there is no danger of it falling over. Remove the rear wheels...

Page 200: 13-11

13 . Rear wheel/swing arm/hydraulic brake 13-11 check the swing arm side play by moving it from side to side. If side play noticeable, check the inner collar, bushing and thrust cover. Check the swing arm vertical movement by moving it up and down. If vertical movement is tight, binding or rough, to...

Page 201: 13-12

13 . Rear wheel/swing arm/hydraulic brake 13-12 swing arm removal remove the nut and pivot shaft, then remove swing arm. Remove the two screws and chain guide. Remove the four bolts and guard. Remove thrust covers and collar. Swing arm nut screws chain guide thrust covers collar guard bolts.

Page 202: 13-13

13 . Rear wheel/swing arm/hydraulic brake 13-13 inspection roll the axle on a flat surface to inspect the pivot shaft. Replace it if bends. Inspect the swing arm. Replace it if crack, bend or damage. Inspect the thrust cover, chain guide, collar and bush. Replace them if wear or damage. Inspect the ...

Page 203: 13-14

13 . Rear wheel/swing arm/hydraulic brake 13-14 installation reverse the “swing arm removal” procedure. Apply grease onto the collar, bush, pivot shaft and thrust cover. Install the swing arm and tighten the nut. Torque: 70 n·m (7 kgf·m, 50 lbf·ft) install the shock absorber and tighten the bolts. T...

Page 204: 13-15

13 . Rear wheel/swing arm/hydraulic brake 13-15 hydraulic brake brake fluid change refer to the “brake fluid change” section in the chapter 3. Brake fluid refilling connect a transparent hose and syringe to the brake caliper bleed valve and then loosen the bleed valve nut. Fill the brake reservoir w...

Page 205: 13-16

13 . Rear wheel/swing arm/hydraulic brake 13-16 push the brake caliper holder and then remove brake pad. Remove the other brake pad. Assembly assemble the brake pads in the reverse order of removal. Brake disk measure the brake disk thickness. Service limit: 3 mm (0.12 in) measure the brake disk run...

Page 206: 13-17

13 . Rear wheel/swing arm/hydraulic brake 13-17 brake master cylinder removal drain the brake fluid from the hydraulic brake system. Disconnect the brake light switch wire connectors. Remove the two master cylinder holder bolts and remove the master cylinder. Disassembly remove the piston rubber cov...

Page 207: 13-18

13 . Rear wheel/swing arm/hydraulic brake 13-18 i inspection check the cylinder inside wall, and spring for scratch, corrosion or other abnormal condition. If any abnormal condition is found, replace the inner parts or master cylinder. Assembly before assembly, apply brake fluid to all removed parts...

Page 208: 13-19

13 . Rear wheel/swing arm/hydraulic brake 13-19 place the brake master cylinder on the handlebar and install the master cylinder holder with the “up” mark facing up, aligning the tab on the holder with the hole in the handlebar. First tighten the upper bolt and then tighten the lower bolt. Torque: 1...

Page 209: 13-20

13 . Rear wheel/swing arm/hydraulic brake 13-20 remove the pistons from the brake caliper. Use compressed air to press out the pistons through the brake fluid inlet opening and place a shop towel under the caliper to avoid contamination caused by the removed pistons. Push the piston oil seals inward...

Page 210: 13-21

13 . Rear wheel/swing arm/hydraulic brake 13-21 install the piston with its outer end protruding 3 ~ 5 mm (0.12 ~ 0.2 in) beyond the brake caliper. Ϡ assembly clean all removed parts. Apply silicon grease to the pistons and oil seals. Lubricate the brake caliper cylinder inside wall with brake fluid...

Page 211: 14-0

14 . Battery/charging system/a.C. Generator 14-0 14 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ____________________________________________________________...

Page 212: 14-1

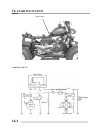

14 . Battery/charging system/a.C. Generator 14-1 charging circuit regulator/ rectifier y r g battery 12v4ah y auto bystarter g/b w g resisto r a.C. Generator regulator/rectifier a.C. Generator.

Page 213: 14-2

14 . Battery/charging system/a.C. Generator 14-2 service informationn general instructions x the battery can be charged and discharged repeatedly. If a discharged battery is not used for a long time, its service life will be shortened. Generally, the capacity of a battery will decrease after it is u...

Page 214: 14-3

14 . Battery/charging system/a.C. Generator 14-3 testing instruments electric tester: yf-3501 troubleshooting no power intermittent power x dead battery x loose battery cable connection x disconnected battery cable x loose charging system connection x fuse burned out x loose connection or short circ...

Page 215: 14-4

14 . Battery/charging system/a.C. Generator 14-4 battery removal remove seat. (see page 2-3) make sure the ignition switch is off. First disconnect the battery negative (-) cable and then the positive (+) cable. Remove the battery by removing the band. Installation the installation sequence is the r...

Page 216: 14-5

14 . Battery/charging system/a.C. Generator 14-5 charging connect the charger positive (+) cable to the battery positive (+) terminal. Connect the charger negative (-) cable to the battery negative (-) terminal. Warning x keep flames and sparks away from a charging battery. X turn power on/off at th...

Page 217: 14-6

14 . Battery/charging system/a.C. Generator 14-6 charging system short circuit test turn the ignition switch off and check for short circuit. Disconnect the ground wire from the battery and connect an ammeter across the battery negative (-) terminal and the ground wire. If any abnormality is found, ...

Page 218: 14-7

14 . Battery/charging system/a.C. Generator 14-7 regulator/rectifier main harness circuit inspection remove the regulator/rectifier 4p coupler and check for continuity between the wire harness terminals according to the following: item (wire color) judgment between battery (red) and engine ground ba...

Page 219: 14-8

14 . Battery/charging system/a.C. Generator 14-8 a.C. Generator charging coil inspection disconnect the a.C. Generator 2p connector. Measure the resistance between the a.C. Generator white wire and engine ground with an electric tester (yf-3501 tester). Standard: 1 ~ 3 : (at 20°c) replace the a.C. G...

Page 220: 14-9

14 . Battery/charging system/a.C. Generator 14-9 a.C. Generator removal remove the four bolts attaching the cooling fan cover. Remove the fan cover. Remove the cooling fan by removing the four cooling fan attaching bolts. Hold the flywheel with an universal holder. Remove the flywheel nut. Special t...

Page 221: 14-10

14 . Battery/charging system/a.C. Generator 14-10 disconnect the a.C generator wire coupler. Remove the pulser coil bolts. Remove the a.C. Generator wire rubber sleeve and pulser coil from the right crankcase. Remove the two bolts and a.C. Generator stator. Bolts bolts.

Page 222: 14-11

14 . Battery/charging system/a.C. Generator 14-11 a.C. Gnerator installation reverse the “a.C. Generator removal” procedures. Install the a.C. Generator stator and pulser coil onto the right crankcase. Install the a.C. Generator wire rubber sleeve. Tighten the stator and pulser coil bolts. Torques: ...

Page 223: 14-12

14 . Battery/charging system/a.C. Generator 14-12 hold the flywheel with the universal holder and tighten the flywheel nut. Torque: 40 n·m (4 kgf·m, 29 lbf·ft) special tool: universal holder a120e00017 install the cooling fan. Torque: 8 n·m (0.8 kgf·m, 6 lbf·ft) install the fan cover and tighten bol...

Page 225: . Ignition System

15 . Ignition system 15-0 15 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ___________________________________________________________________________________...

Page 226: . Ignition System

15 . Ignition system 15-1 a.C. Generator/pulser coil spark plug ignition coil.

Page 227: . Ignition System

15 . Ignition system 15-2 ignition circuit.

Page 228: . Ignition System

15 . Ignition system 15-3 service information general instructions x check the ignition system according to the sequence specified in the troubleshooting. X the ignition system adopts ignition unit, change gear control and the ignition timing cannot be adjusted. X if the timing is incorrect, inspect...

Page 229: . Ignition System

15 . Ignition system 15-4 troubleshooting high voltage too low no high voltage x weak battery or low engine speed x faulty ignition switch x loose ignition system connection x faulty ignition unit x faulty ignition unit x poorly connected or broken ignition unit ground wire x faulty ignition coil xd...

Page 230: . Ignition System

15 . Ignition system 15-5 cdi unit inspection remove seat. (see page 2-3) disconnect the cdi coupler and remove the cdi unit. Measure the resistance between the terminals using the electric tester. Replace the cdi unit if the readings are not within the specifications in the table. Unit: k: probe (...

Page 231: . Ignition System

15 . Ignition system 15-6 ignition coil removal remove the spark plug cap. Disconnect the ignition coil wires and remove the ignition coil bolt and ignition coil. Inspection continuity test measure the resistance between the ignition coil primary coil terminals. Resistance: 1.5 ~ 3.5 : (at 20°c) mea...

Page 232: . Ignition System

15 . Ignition system 15-7 pulser coil inspection disconnect the a.C. Generator coupler. Measure the pulser coil resistance between the blue/yellow and engine ground with an electric tester (yf-3501 tester). Standard: 100 ~ 140 : (at 20°c) replace the a.C. Generator coil assembly if the reading is no...

Page 233: . Starting System

16 . Starting system 16-0 16 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ___________________________________________________________________________________...

Page 234: . Starting System

16 . Starting system 16-1 starting circuit starter motor g g/y ignition switch fuse stop switches r y/r battery starter motor starter relay rear g r/w front g/y stoplight start switch.

Page 235: . Starting System

16 . Starting system 16-2 service information general instructions x the removal of starter motor can be accomplished with the engine installed. Troubleshooting starter motor won‘t turn lack of power x fuse burned out x weak battery x weak battery x loose wire or connection x faulty ignition switch ...

Page 236: . Starting System

16 . Starting system 16-3 starter motor removal disconnect the starter motor cable coupler. Remove the two mounting bolts at the starter motor attaching left crankcase, then remove the starter motor. Disassembly remove the two starter motor case screws, front cover, motor case and other parts. Inspe...

Page 237: . Starting System

16 . Starting system 16-4 check for continuity between pairs of the commutator segments and there should be continuity. Also, make a continuity check between individual commutator segments and the armature shaft. There should be no continuity. Starter motor case continuity inspection check to confir...

Page 238: . Starting System

16 . Starting system 16-5 check the dust seal for wear or damage. Assembly apply grease to the dust seal in the front cover. Install the brushes onto the brush holders. Apply a thin coat of grease to the end of the armature shaft. Insert the commutator into the front cover while the brushes are hold...

Page 239: . Starting System

16 . Starting system 16-6 starter motor installation check the o-ring for wear or damage and replace it if necessary. Apply grease to the o-ring and install the starter motor with the engine ground wire. Tighten the two mounting bolts. Torque: 10 n·m (1 kgf·m, 7 lbf·ft) connect the starter motor cab...

Page 240: . Starting System

16 . Starting system 16-7 starter pinion removal remove the left crankcase cover. Remove the drive pulley. (refer to chapter 9) remove the starter pinion. Inspection inspect the starter pinion seat for wear. Inspect the starter pinion for smooth operation. Inspect the starter pinion shaft forcing pa...

Page 241: . Wiring Diagrams

17 . Wiring diagrams 17-0 17 _____________________________________________________________________________________________ _____________________________________________________________________________________________ ___________________________________________________________________________________...

Page 242: . Wiring Diagrams

17 . Wiring diagrams 17-1.

Page 244

Model application year model beginning frame no. 2007 ksf50b7f rgswa04a 7b100101 (usa model) rgswa04a 7b200101 (canada model) rgswa04a 7b300101 (australia model) 2008 ksf50b8f rgswa04aغ8b100001 (usa model) rgswa04aغ8b200101 (canada model) rgswa04aغ8b300101 (australia model) rgswa04aغ8b600101 (qatar ...