- DL manuals

- Kawasaki

- Other

- KX100 -

- Service Manual

Kawasaki KX100 - Service Manual

Summary of KX100 -

Page 1

Kx85 kx85-ii kx100 motorcycle service manual.

Page 3: Quick Reference Guide

This quick reference guide will assist you in locating a desired topic or pro- cedure. •bend the pages back to match the black tab of the desired chapter num- ber with the black tab on the edge at each table of contents page. •refer to the sectional table of contents for the exact pages to locate th...

Page 5: Kx85

Kx85 kx85-ii kx100 motorcycle service manual all rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of quality assu...

Page 6

List of abbreviations a ampere(s) lb pound(s) abdc after bottom dead center m meter(s) ac alternating current min minute(s) atdc after top dead center n newton(s) bbdc before bottom dead center pa pascal(s) bdc bottom dead center ps horsepower btdc before top dead center psi pound(s) per square inch...

Page 7: Foreword

Foreword this manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic in- formation to make it useful to the owner who de- sires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the prope...

Page 9: General Information

General information 1-1 1 general information table of contents before servicing ..................................................................................................................... 1-2 model identification................................................................................

Page 10

1-2 general information before servicing before starting to perform an inspection service or carry out a disassembly and reassembly opera- tion on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustra- tions, photographs, cautions, and detailed descriptions...

Page 11

General information 1-3 before servicing (10)liquid gasket, locking agent clean and prepare surfaces where liquid gasket or non-permanent locking agent will be used. Apply them sparingly. Excessive amount may block engine oil passages and cause serious dam- age. (11) press when using a press or driv...

Page 12

1-4 general information before servicing two-color electrical (19)inspection when parts have been disassembled, visually inspect these parts for the following conditions or other damage. If there is any doubt as to the condition of them, replace them with new ones. Abrasion crack hardening warp bent...

Page 13

General information 1-5 model identification kx85-a1 left side view kx85-b1 right side view.

Page 14

1-6 general information model identification kx100-d1 left side view kx100-d1 right side view.

Page 15

General information 1-7 general specifications items kx85-a1 ∼ a5, a6f ∼ aaf kx85-b1 ∼ b5, b6f ∼ baf dimensions overall length 1 820 mm (71.7 in.) 1 910 mm (75.2 in.) overall width 735 mm (28.9 in.) ← overall height 1 055 mm (41.5 in.) 1 105 mm (43.5 in.) wheelbase 1 255 mm (49.4 in.) 1 290 mm (50.8...

Page 16

1-8 general information general specifications items kx85-a1 ∼ a5, a6f ∼ aaf kx85-b1 ∼ b5, b6f ∼ baf duration 174° (low speed) ← 187° (high speed) ← lubrication system petrol mix (32 : 1) ← drive train primary reduction system: type gear ← reduction ratio 3.400 (68/20) ← clutch type wet, multi disc ...

Page 17

General information 1-9 general specifications items kx85-a1 ∼ a5, a6f ∼ aaf kx85-b1 ∼ b5, b6f ∼ baf rear tire: size 90/100-14 49m 90/100-16, (eu) 90/100-16 52m (kx85-b5 ∼ ) 90/100-16 52m type tube ← rim size: front 17 × 1.40 19 × 1.40 rear 14 × 1.60 16 × 1.85 front suspension: type telescopic fork ...

Page 18

1-10 general information general specifications items kx100-d1 ∼ d5, d6f ∼ d9f dimmensions overall length 1 910 mm (75.2 in.) overall width 735 mm (28.9 in.) overall height 1 105 mm (43.5 in.) wheelbase 1 290 mm (50.8 in.) road clearance 380 mm (15.0 in.) seat height 870 mm (34.3 in.) dry weight (kx...

Page 19

General information 1-11 general specifications items kx100-d1 ∼ d5, d6f ∼ d9f drive train primary reduction system: type gear reduction ratio 3.400 (68/20) clutch type wet, multi disc transmission: type 6-speed, constant mesh, return shift gear tatios 1st 2.538 (33/13) 2nd 1.875 (30/16) 3rd 1.500 (...

Page 20

1-12 general information general specifications items kx100-d1 ∼ d5, d6f ∼ d9f rear suspension: type swingarm (uni-trak) wheel travel 275 mm (10.8 in.) brake type: front and rear single disc effective disc diameter: front 202 mm (8.0 in.) rear 150 mm (5.9 in.) specifications are subject to change wi...

Page 21

General information 1-13 periodic maintenance chart the maintenance must be done in accordance with this chart to keep the motorcycle in good running condition. Frequency operation each race (2.5 hr) every 3 races (7.5 hr) every 5 races (12.5 hr) every 10 races (25 hr) as required engine clutch - ad...

Page 22

1-14 general information periodic maintenance chart frequency operation each race (2.5 hr) every 3 races (7.5 hr) every 5 races (12.5 hr) every 10 races (25 hr) as required front fork oil - change 1st time after 2 races, then every 5 races nuts, bolts, fasteners - inspect † • fuel system - clean • f...

Page 23

General information 1-15 torque and locking agent the following tables list the tightening torque for the major fasteners requiring use of a non-permanent locking agent or liquid gasket. Letters used in the "remarks" column mean: l: apply a non-permanent locking agent to the threads. Lh: left-hand t...

Page 24

1-16 general information torque and locking agent torque fastener n·m kgf·m ft·lb remarks primary gear nut 49 5.0 36 lh kick lever plug screw – – – st kick lever boss mounting bolt 12 1.2 104 in·lb shift shaft return spring pin 22 2.2 16 l right engine cover bolts 8.8 0.90 78 in·lb clutch cover bolt...

Page 25

General information 1-17 torque and locking agent torque fastener n·m kgf·m ft·lb remarks brake lever pivot bolt 5.9 0.60 52 in·lb brake lever adjust locknut 4.9 0.50 43 in·lb front master cylinder clamp bolts 8.8 0.90 78 in·lb s caliper mounting bolts (front, rear) 25 2.5 18 disc bolts (front, rear...

Page 26

1-18 general information torque and locking agent the table on the right relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the values are for use with dry solve...

Page 27

General information 1-19 special tools and sealants fuel level gauge, m18 × 1.0: 57001-122 bearing puller adapter: 57001-136 inside circlip pliers: 57001-143 outside circlip pliers: 57001-144 bearing puller: 57001-158 compression gauge, 20 kgf/cm²: 57001-221 flywheel puller, m12 × 1.75: 57001-252 be...

Page 28

1-20 general information special tools and sealants bead breaker assembly: 57001-1072 head pipe outer race press shaft: 57001-1075 steering stem bearing driver adapter, 29.7: 57001-1092 crankcase splitting tool assembly: 57001-1098 steering stem nut wrench: 57001-1100 head pipe outer race driver, 46...

Page 29

General information 1-21 special tools and sealants fork outer tube weight: 57001-1218 jack: 57001-1238 clutch holder: 57001-1243 bearing remover shaft, 9: 57001-1265 bearing remover head, 10 × 12: 57001-1266 fork spring holder: 57001-1286 fork oil level gauge: 57001-1290 fork piston rod puller, m10...

Page 30

1-22 general information special tools and sealants hand tester: 57001-1394 fork cylinder holder: 57001-1413 peak voltage adapter: 57001-1415 lead wire - magneto lead adapter: 57001-1469 bearing puller adapter: 57001-1526 gear holder: 57001-1602 flywheel & pulley holder: 57001-1605 liquid gasket, tb...

Page 31

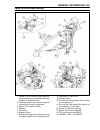

General information 1-23 cable, wire and hose routing 1. Run the throttle cable and engine stop button lead through the clamp. 2. Do not pinch the throttle cable between the fuel tank and frame. 3. Adheve the damper on the frame pipe. 4. Run the clutch cable between the clamp and upper and lower rad...

Page 32

1-24 general information cable, wire and hose routing 1. Engine stop button ground lead (b) 2. Run the engine stop button lead through the clamp for throttle cable. 3. Engine stop button lead [bk/w] 4. Cdi unit 5. Cdi unit ground lead [bk/y] 6. Cdi unit primary lead [o] 7. Cdi unit lead to engine st...

Page 33

General information 1-25 cable, wire and hose routing 1. Tighten the cdi unit and engine stop but- ton ground terminals together with lower ignition coil installation bolt. 2. Install the ignition coil so that the ignition secondary coil come to backward. 3. Ignition coil installation bolts 4. Radia...

Page 34

1-26 general information cable, wire and hose routing 1. Front brake master cylinder 2. Brake lever 3. Banjo bolt 4. Front brake hose 5. Front brake caliper 6. Brake hose cover 7. Front brake disc 8. Rear brake fluid reservoir 9. Banjo bolt 10. Rear brake master cylinder 11. Brake pedal 12. Brake ho...

Page 35

General information 1-27 cable, wire and hose routing 1. Route the water hose so that it does not touch the exhaust pipe. 2. Route the water hose between 3 engine mounting brackets. 3. Route the water hose noting the bend of it. 4. Band (radiator hose and kips chamber vent tube) 5. Kips chamber vent...

Page 37: Fuel System

Fuel system 2-1 2 fuel system table of contents exploded view........................................................................................................................ 2-2 specifications ......................................................................................................

Page 38

2-2 fuel system exploded view 1. Throttle cable 2. Pilot screw 3. Needle jet 4. Main jet holder 5. Pilot jet 6. Main jet 7. Float valve t1: 1.0 n·m (0.10 kgf·m, 9 in·lb) t2: 8.8 n·m (0.90 kgf·m, 78 in·lb) t3: 1.5 n·m (0.15 kgf·m, 13 in·lb) cl: apply cable lubricant g: apply grease o: apply oil.

Page 39

Fuel system 2-3 exploded view 1. Fuel tank cap 2. Gasket 3. Fuel filler 4. Fuel tank 5. Fuel tap 6. Air cleaner housing 7. Holder 8. Air filter plate 9. Air cleaner element holder 10. Air cleaner element 11. Air duct 12. Fuel tap (kx85a6f ∼ /b6f ∼ , kx100d6f ∼ ) t1: 0.8 n·m (0.08 kgf·m, 7 in·lb) t2:...

Page 40

2-4 fuel system specifications item standard service limit throttle grip free play and cable 2 ∼ 3 mm (0.08 ∼ 0.12 in.) – – – carburetor make/type keihin pwk28 – – – main jet: kx85a/b #140 – – – kx100d #138 – – – main air jet #60 – – – throttle valve cutaway #3.5 – – – jet needle: kx85a/b nape – – –...

Page 41

Fuel system 2-5 throttle grip and cable if the throttle grip has excessive free play due to cable stretch or misjudgments, there will be a delay in throttle re- sponse. Also, the throttle valve may not open fully at full throttle. On the other hand, if the throttle grip has no play, the throttle wil...

Page 42

2-6 fuel system throttle grip and cable installation notes • install the throttle cable in accordance with the cable, wire and hose routing section in the general informa- tion chapter. • after the installation, adjust each cable properly. Cable lubrication • refer to the general lubrication in the ...

Page 43

Fuel system 2-7 carburetor since the carburetor regulates and mixes the fuel and air going to the engine, there are two general types of carbure- tor trouble: too rich a mixture (too much fuel), and too lean a mixture (too little fuel). Such trouble can be caused by dirt, wear, maladjustment, or imp...

Page 44

2-8 fuel system carburetor • turn the fuel tap to the off position. • remove the fuel tank. • place a suitable container beneath the carburetor drain plug. • remove the carburetor (see carburetor removal). • remove the drain plug to drain the carburetor. • replace the main jet [a] with the desired o...

Page 45

Fuel system 2-9 carburetor service fuel level adjustment warning gasoline is extremely flammable and can be ex- plosive under certain conditions. Always stop the engine and do not smoke. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance wi...

Page 46

2-10 fuel system carburetor • place a suitable container beneath the carburetor. • turn the fuel tap to the off position. • remove the drain plug [a] from the bottom of the float bowl and check for water or dirt in the fuel. If any water or dirt comes out, clean the carburetor (see carburetor cleani...

Page 47

Fuel system 2-11 carburetor installation • being careful not to bend or otherwise damage the jet needle [b], insert the throttle valve assembly [a] into the carburetor body. ○ check to see that the throttle valve goes all the way down into the carburetor body, and slides smoothly. • fit the ridge [a...

Page 48

2-12 fuel system carburetor disassembly warning gasoline is extremely flammable and can be ex- plosive under certain conditions. Always stop the engine and do not smoke. Make sure the area is well ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light....

Page 49

Fuel system 2-13 carburetor cleaning warning gasoline and low-flash point solvents can be flammable and/or explosive and cause severe burns. Clean the carburetor in a well ventilated area, and take care that there are no sparks or flame anywhere near the working area; this includes any appliance wit...

Page 50

2-14 fuel system carburetor • clean the carburetor (see cleaning). • check the plastic tip [a] of the float valve needle [b]. It should be smooth without any grooves, scratches, or tears. If the plastic tip is damaged [c], replace the needle. • push the rod [d] in the valve, then release [e] it. If ...

Page 51

Fuel system 2-15 air cleaner air cleaner element removal • remove the side cover. • remove the wing bolt [a] and pull out the element [b]. Air cleaner element installation • coat the lip of the element [a] with a thick layer of all purpose grease [b] to assure a complete seal. Also, coat the air cle...

Page 52

2-16 fuel system air cleaner • remove the air cleaner element, and separate the ele- ment [a] from the frame [b]. • clean the element in a bath of a high flash-point solvent, and squeeze the element dry. • check all the parts of the element for visible damage. If any part of the element is damaged, ...

Page 53

Fuel system 2-17 fuel tank fuel tank removal • remove: seat (see frame chapter) air scoop [a] • turn the fuel tap to the off position. • pull the fuel hose off the fuel tap. Warning gasoline is extremely flammable and can be ex- plosive under certain conditions. Always stop the engine and do not smo...

Page 54

2-18 fuel system fuel tank fuel tap inspection • remove the fuel tap. • check the fuel tap filter screen for any breaks or deterio- ration. If the fuel tap screen has any breaks or is deteriorated, it may allow dirt to reach the carburetor, causing poor run- ning. Replace the fuel tap. If the fuel t...

Page 55

Fuel system 2-19 reed valve removal • remove the carburetor (see carburetor removal). • remove the carburetor holder [a] mounting bolts, and move the rearward. • take the reed valve assembly [b] out of the cylinder. Installation note torque - carburetor holder mounting bolts: 8.8 n·m (0.90 kgf·m, 78...

Page 56

2-20 fuel system fuel hose fuel hoses and connections inspection ○ check the fuel hose periodically in accordance with the periodic maintenance chart, and if the motorcycle is not properly handled, the inside the fuel line can cause fuel to leak [a] or the hose to burst. Remove the fuel tank and che...

Page 57: Cooling System

Cooling system 3-1 3 cooling system table of contents exploded view........................................................................................................................ 3-2 cooling system ................................................................................................

Page 58

3-2 cooling system exploded view 1. Air bleeder bolt 2. Radiator 3. Water hoses 4. Water pump cover 5. Impeller 6. Water pump bearing 7. Water pump seal t1: 1.5 n·m (0.15 kgf·m, 13 in·lb) t2: 8.8 n·m (0.90 kgf·m, 78 in·lb) t3: 7.0 n·m (0.70 kgf·m, 61 in·lb) t4: 5.4 n·m (0.55 kgf·m, 48 in·lb) m: appl...

Page 59

Cooling system 3-3 cooling system the cooling system is a pressurized forced circulation type. When the engine load varies, this sys- tem controls the engine temperature within narrow limits where the engine operates most efficiently. In this way the engine performs stably in various riding conditio...

Page 60

3-4 cooling system specifications item standard coolant type permanent type antifreeze (soft water and ethylene glycol plus corrosion and rust inhibitor chemicals for aluminum engines and radiators) color green mixed ratio soft water 50%, coolant 50% freezing point − 35°c (− 31°f) total capacity 0.6...

Page 61

Cooling system 3-5 coolant check the coolant level each day before riding the motor- cycle, and replenish coolant if the level is low. Change the coolant in accordance with the periodic maintenance chart (see general information chapter). Warning hot engine coolant can cause serious burns. To avoid ...

Page 62

3-6 cooling system coolant coolant draining warning coolant can be extremely hot and cause severe burns, is toxic and very slippery. Do not remove the radiator cap or attempt to change the coolant when the engine is hot; allow it cool completely. Immediately wipe any spilled coolant from tires, fram...

Page 63

Cooling system 3-7 coolant recommended coolant type: permanent type antifreeze (soft water and ethylene glycol plus corrosion and rust inhibitor chemicals for aluminum engines and radiators) color: green mixed ratio: soft water 50%, coolant 50% freezing point: − 35°c (− 31°f) total amount: 0.67 l (0...

Page 64

3-8 cooling system coolant cooling system pressure testing any time the system slowly loses coolant, inspect for leaks. Notice during pressure testing, do not exceed the pres- sure for which the system is designed to work. The maximum pressure is 125 kpa (1.25 kgf/cm², 18 psi). • remove the radiator...

Page 65

Cooling system 3-9 water pump water pump cover removal • drain the coolant (see coolant draining). • loosen the cooling hose clamps, and disconnect the cool- ing hoses [a] on the water pump cover. • remove the water pump cover bolts [b], and remove the water pump cover [c]. Water pump cover installa...

Page 66

3-10 cooling system water pump water pump shaft removal • remove: right engine cover (see engine right side chapter) primary gear [a] (see engine right side chapter) • pull out the water pump shaft [b]. Water pump seal removal • remove: impeller (see impeller removal) right engine cover (see engine ...

Page 67

Cooling system 3-11 radiator radiator removal • drain the coolant by removing the coolant drain plug (wa- ter pump) • remove: air scoop fuel tank (move back) hose clamps (loosen) breather hose upper end [a] water hose ends [b] radiator screen [c] radiator mounting bolts/screw [d] radiator [e] radiat...

Page 68

3-12 cooling system radiator radiator cap inspection • check the condition of the valve spring [b], and the top and bottom valve seals [a] of the radiator cap. If any one of them shows visible damage, replace the cap. • wet the top and bottom valve seals with water or coolant to prevent pressure lea...

Page 69: Engine Top End

Engine top end 4-1 4 engine top end table of contents exploded view........................................................................................................................ 4-2 specifications ................................................................................................

Page 70

4-2 engine top end exploded view 1: kips chamber vent tube (kx85a6f ∼ /b6f ∼ , kx100d6f ∼ ) t1: 3.9 n·m (0.40 kgf·m, 35 in·lb) t2: 5.2 n·m (0.53 kgf·m, 46 in·lb) t3: 25 n·m (2.5 kgf·m, 18 ft·lb) t4: 29 n·m (3.0 kgf·m, 22 ft·lb) t5: 8.8 n·m (0.90 kgf·m, 78 in·lb) o: apply 2 stroke-racing oil. R: repl...

Page 71

Engine top end 4-3 specifications item standard service limit cylinder head cylinder compression (usable range) – – – 825 ∼ 1 280 kpa (8.4 ∼ 13.0 kgf/cm², 119 ∼ 185 psi) cylinder head warp – – – 0.03 mm (0.0012 in.) cylinder, piston cylinder inside diameter kx85a/b 48.505 ∼ 48.520 mm* (1.9096 ∼ 1.91...

Page 72

4-4 engine top end cylinder head compression pressure measurement • start the engine. • thoroughly warm up the engine so that the engine oil be- tween the piston and cylinder wall will help seal compres- sion as it does during normal running. • stop the engine. • move the fuel tank backward with the...

Page 73

Engine top end 4-5 cylinder head installation • replace the head gasket with a new one. • scrape out any carbon and clean the head with a high flash-point solvent. • check the head water jacket for a crust of minerals and rust and remove them if necessary. • install a new cylinder head gasket with t...

Page 74

4-6 engine top end cylinder cylinder removal • drain the coolant (see cooling system chapter). Be sure to remove the cylinder drain plug. • remove the following. Cylinder head (see cylinder head removal) carburetor (see fuel system chapter) radiator hose upper end kips cover muffler holding springs ...

Page 75

Engine top end 4-7 cylinder piston removal • remove the cylinder (see cylinder removal). • stuff a clean cloth into the crankcase opening around the connecting rod so that no parts will fall into the crankcase. • remove one of the piston pin snap rings with needle nose pliers. • remove the piston by...

Page 76

4-8 engine top end cylinder ○ install the ring so that the pin [a] in the piston ring groove is between the ends of the piston ring. • apply 2-stroke engine oil to the connecting rod needle bearing and the piston pin. • install the piston so that the “in” marked on the piston side wall comes to the ...

Page 77

Engine top end 4-9 cylinder cylinder inside diameter standard: kx85a/b 48.505 ∼ 48.520 mm (1.9096 ∼ 1.9102 in.), and less than 0.01 mm (0.0004 in.) difference between any two measurements. Kx100d 52.505 ∼ 52.520 mm (2.0671 ∼ 2.0677 in.), and less than 0.01 mm (0.0004 in.) difference between any two ...

Page 78

4-10 engine top end cylinder the most accurate way to find the piston clearance is by making separate piston and cylinder diameter measure- ments and then computing the difference between the two values. Measure the piston diameter and cylinder diameter as just described. Piston/cylinder clearance k...

Page 79

Engine top end 4-11 cylinder piston ring groove width standard: top: kx85a/b 1.01 ∼ 1.03 mm (0.0398 ∼ 0.0406 in.) kx100d 1.03 ∼ 1.05 mm (0.0406 ∼ 0.0413 in.) second: 1.01 ∼ 1.03 mm (0.0398 ∼ 0.0406 in.) service limit: top: kx85a/b 1.11 mm (0.0437 in.) kx100d 1.13 mm (0.0445 in.) second: 1.11 mm (0.0...

Page 80

4-12 engine top end cylinder if there is any doubt as to the condition of a needle bear- ing, replace the bearing and piston pin. Piston pin diameter standard: kx85, kx100 14.000 ∼ 13.995 mm (0.5512 ∼ 0.5510 in.) service limit: kx85, kx100 13.965 mm (0.5498 in.) piston pin hole diameter standard: kx...

Page 81

Engine top end 4-13 exhaust valve (kips) removal • remove: carburetor cylinder head cylinder • take out the screws [a] and remove the cover [b]. • pull the valve assembly [a] out. • unscrew the bolt [a] and remove the operating rod and the lever [b]. Installation • scrape out any carbon and clean th...

Page 82

4-14 engine top end exhaust valve (kips) • install the butterfly valve [a] on the holder [b], with a pin [c]. • install the pin [d] in the slide valve [e], carefully the direc- tion of the brim [f]. • place the slide valve on the holder as shown. • install the valve assembly at fully opened conditio...

Page 83

Engine top end 4-15 muffler removal • remove the left side cover and scoop. • remove the muffler mounting bolts [a] • pull the muffler body to backward. • remove: louver exhaust pipe mounting bolt [a] exhaust pipe mounting springs [b] • pull the muffler body out of the cylinder. Installation • scrap...

Page 85: Engine Right Side

Engine right side 5-1 5 engine right side table of contents exploded view........................................................................................................................ 5-2 specifications ..........................................................................................

Page 86

5-2 engine right side exploded view 1: kx85-a1 ∼ a5/b1 ∼ b5, kx100-d1 ∼ d5 t1: 9.3 n·m (0.95 kgf·m, 82 in·lb) t2: 88 n·m (9.0 kgf·m, 65 ft·lb) t3: 49 n·m (5.0 kgf·m, 36 ft·lb) cl: apply cable lubricant. G: apply grease. Lh: left-hand threads m: apply molybdenum disulfide grease. Eo: apply engine oil...

Page 87

Engine right side 5-3 exploded view 1. Idle gear 2. Kick gear 3. Ratchet 4. Lever shaft (kx85-a1 ∼ a3/b1 ∼ b3, kx100-d1 ∼ d3) t1: 7.0 n·m (0.70 kgf·m, 61 in·lb) t2: 22 n·m (2.2 kgf·m, 16 ft·lb) t3: 8.8 n·m (0.90 kgf·m, 78 in·lb) t4: 5.2 n·m (0.53 kgf·m, 46 in·lb) t5: 1.5 n·m (0.15 kgf·m, 13 in·lb) t...

Page 88

5-4 engine right side specifications item standard service limit clutch lever free play 8 ∼ 13 mm (0.3 ∼ 0.5 in.) – – – clutch friction plate thickness 2.8 ∼ 2.9 mm (0.110 ∼ 0.114 in.) 2.7 mm (0.106 in.) friction and steel plate warp 0.15 mm (0.006 in.) or less 0.3 mm (0.012 in.) clutch spring free ...

Page 89

Engine right side 5-5 clutch cable due to friction plate wear and clutch cable stretch over a long period of use, the clutch must be adjusted in accor- dance with the periodic maintenance chart. Warning the engine and exhaust system get extremely hot during normal operation and can cause serious bur...

Page 90

5-6 engine right side clutch cable clutch release lever angle inspection and adjustment if the clutch slips or the action at the lever feels heavy despite proper clutch lever free play adjustment, inspect and adjust the clutch release lever angle. • turn the clutch release lever toward the front unt...

Page 91

Engine right side 5-7 clutch cable installation • run the clutch cable according to the cable, wire and hose routing section in the general information chapter. • adjust the clutch cable (see free play adjustment). Lubrication and inspection • lubricate the clutch cable using the pressure cable lube...

Page 92

5-8 engine right side clutch cover clutch cover removal • drain the engine oil (see transmission oil change in the engine bottom end/transmission chapter). • remove the brake pedal (see brake pedal removal in the brake chapter). • free the clutch inner cable at clutch lever side (see clutch cable re...

Page 93

Engine right side 5-9 right engine cover right engine cover removal • remove: engine oil (drain) coolant (drain) cooling hose lower end kick pedal brake pedal water pump cover impeller clutch cable • remove the kips cover from the right side of the cylinder. • remove the e-clip [a]. • put a spanner ...

Page 94

5-10 engine right side right engine cover • remove the right engine cover bolts [a] and take off the right engine cover [b] and gasket. Cover installation • there are two knock pins of the mating surfaces of the crankcase and right engine cover. • apply molybdenum disulfide grease [a] to the water p...

Page 95

Engine right side 5-11 right engine cover • run the clutch cable and the water hoses according to the cable, wire, and hose routing section in the general information chapter. • adjust the clutch cable (see clutch cable free play ad- justment). • check the clutch release lever angle (see clutch rele...

Page 96

5-12 engine right side right engine cover the advancer assembly consists of the following parts. [a] gear [b] spring [c] collar [d] circlip [e] ball bearing [f] collar [g] holder [h] shaft [i] ball [j] guide • check the advancer assembly parts for damage. Any damaged parts should be replaced with ne...

Page 97

Engine right side 5-13 clutch removal • remove the clutch cover. • remove the magneto cover. • unscrew the crankshaft sensor mounting screws and re- move the crankshaft sensor [b] from the stator. • install the flywheel holder [a] on the magneto flywheel. Note ○ use the flywheel holder to prevent th...

Page 98

5-14 engine right side clutch installation notes • apply molybdenum disulfide grease to the outside of the sleeve. • apply transmission oil to the inside of the clutch housing gear and kickstarter driven gear. • install the friction plates and steel plates, starting with a friction plate and alterna...

Page 99

Engine right side 5-15 clutch friction and steel plate warp inspection • place each friction plate or steel plate on a surface plate, and measure the gap between the surface plate [a] and each friction plate or steel plate [b] with a thickness gauge [c]. The gap is the amount of friction or steel pl...

Page 100

5-16 engine right side primary gear removal (kx85-a1 ∼ a5/b1 ∼ b5, kx100-d1 ∼ d5) • remove the right engine cover (see right engine cover removal). • remove the circlip [a], then pull out the primary gear [b]. Special tool - outside circlip pliers: 57001-144 installation (kx85-a1 ∼ a5/b1 ∼ b5, kx100...

Page 101

Engine right side 5-17 primary gear • using the gear holder [a], secure the clutch gear and the bottom of the primary gear; then, tighten the primary gear nut [b]. ○ primary gear nut is left-hand threads. Torque - primary gear nut: 49 n·m (5.0 kgf·m, 36 ft·lb) special tool - gear holder: 57001-1602 ...

Page 102

5-18 engine right side external shift mechanism removal • remove the following. Brake pedal (see brakes chapter) magneto cover shift pedal clutch (see clutch removal) • pull out the shift shaft with the shift mechanism arm and arm spring. • remove the gear set lever spring [a]. • remove the bolt, an...

Page 103

Engine right side 5-19 kickstarter removal • remove the following parts. Right engine cover (see right engine cover removal) clutch housing spring guide [a] • pull the end of the kick spring [b] out of the hole in the crankcase. • remove the ratchet guide [c] and bolts. • remove the kickstarter asse...

Page 105: Engine Removal/installation

Engine removal/installation 6-1 6 engine removal/installation table of contents exploded view........................................................................................................................ 6-2 engine removal/installation .........................................................

Page 106

6-2 engine removal/installation exploded view t1: 29 n·m (3.0 kgf·m, 22 ft·lb) t2: 69 n·m (7.0 kgf·m, 51 ft·lb).

Page 107

Engine removal/installation 6-3 engine removal/installation removal • the following parts may be removed with the engine in the frame. Clutch (see engine right side chapter) flywheel magneto (see electrical system chapter) • remove the following. Engine oil (drain, see engine bottom end/transmission...

Page 108

6-4 engine removal/installation engine removal/installation • move the engine forward and remove it from the vehicle right or left side. Installation • engine installation is the reverse of removal. • torque: torque - swingarm pivot shaft nut: 69 n·m (7.0 kgf·m, 51 ft·lb) engine mounting bracket nut...

Page 109: Table Of Contents

Engine bottom end/transmission 7-1 7 engine bottom end/transmission table of contents exploded view........................................................................................................................ 7-2 specifications ................................................................

Page 110

7-2 engine bottom end/transmission exploded view 1. Water pump gear 2. Primary gear 3. Kx85-a1 ∼ a5/b1 ∼ b5, kx100-d1 ∼ d5 t1: 29 n·m (3.0 kgf·m, 22 ft·lb) t2: 8.8 n·m (0.90 kgf·m, 78 in·lb) t3: 15 n·m (1.5 kgf·m, 11 in·lb) t4: 5.4 n·m (0.55 kgf·m, 48 in·lb) t5: 49 n·m (5.0 kgf·m, 36 ft·lb) g: apply...

Page 111

Engine bottom end/transmission 7-3 exploded view 1: kx85-a2 ∼ /b2 ∼ , kx100-d2 ∼ 2: kx85-a1 ∼ a4/b1 ∼ b4, kx100-d1 ∼ d4 t1: 23 n·m (2.3 kgf·m, 16.5 ft·lb) t2: 8.8 n·m (0.90 kgf·m, 78 in·lb) t3: 22 n·m (2.2 kgf·m, 16 ft·lb) g: apply grease. L: apply a non-permanent locking agent. R: replacement parts...

Page 112

7-4 engine bottom end/transmission specifications item standard service limit transmission oil engine oil: grade api sg, sh, sj, sl or sm with jaso ma, ma1 or ma2 – – – viscosity sae10w-40 – – – oil level in middle of level gauge – – – capacity 0.65 l (kx85-a1 ∼ a3/b1 ∼ b3, kx100-d1 ∼ d3) – – – 0.70...

Page 113

Engine bottom end/transmission 7-5 transmission oil in order for the transmission and clutch to function prop- erly, always maintain the transmission oil at the proper level and change the oil periodically. Warning vehicle operation with insufficient, deteriorated, or contaminated transmission oil w...

Page 114

7-6 engine bottom end/transmission transmission oil • check the gasket at the engine drain plug for damage. Replace the gasket with a new one if it is damaged. After the oil has completely drained out, install the engine drain plug with the gasket, and tighten it to the specified torque. Torque - en...

Page 115

Engine bottom end/transmission 7-7 crankcase crankcase splitting • the following parts may be removed with the engine in the frame. Clutch (see engine right side chapter) magneto flywheel and stator (see electrical system chapter)) • remove the engine (see the engine removal/installation chapter). •...

Page 116

7-8 engine bottom end/transmission crankcase crankcase assembly notice right and left crankcase halves are machined at the factory in the assembled state, so they must be re- placed together as a set. • chip off the old gasket from the mating surfaces of the crankcase halves, and clean off the crank...

Page 117

Engine bottom end/transmission 7-9 crankcase • the crankshaft jig must be installed between the flywheel opposite the connecting rod big end with the crankshaft at bdc. This is to protect flywheel alignment [a] crankshaft [b] connecting rod [c] crankshaft jig: 57001-1174 • using a suitable tool on t...

Page 118

7-10 engine bottom end/transmission crankshaft, connecting rod crankshaft removal • see crankcase splitting. Crankshaft installation • see crankcase assembly. Crankshaft disassembly since assembly of the crankshaft demands exacting toler- ances, the disassembly of the crankshaft can only be done by ...

Page 119

Engine bottom end/transmission 7-11 crankshaft, connecting rod connecting rod big end radial clearance inspection • set the crankshaft in a flywheel alignment jig or on v blocks, and place a dial gauge against the connecting rod big end. • push the connecting rod first towards the gauge and then in ...

Page 120

7-12 engine bottom end/transmission crankshaft, connecting rod crankshaft alignment inspection if the runout at either point exceeds the service limit, align the flywheels so that the runout falls within the service limit. • in the case of horizontal misalignment, which is the most common, strike th...

Page 121

Engine bottom end/transmission 7-13 transmission transmission shaft removal • split the crankcase (see crankcase splitting). • pull off the shift rods [a], and disengage the shift fork guide pins from the shift drum grooves. • remove the shift drum [b] • remove the shift forks [c] from the transmiss...

Page 122

7-14 engine bottom end/transmission transmission kx85-a1/b1, kx100-d1 kx85-a2 ∼ /b2 ∼ , kx100-d2 ∼ shift fork bending inspection • visually inspect the shift forks, and replace any fork that is bent. A bent fork could cause difficulty in shifting, or allow the transmission to jump out of gear when u...

Page 123

Engine bottom end/transmission 7-15 transmission shift fork/gear groove wear installation • measure the thickness of the shift fork ears [a], and mea- sure the width of the shift fork grooves [b] in the transmis- sion gears. If the thickness of a shift fork finger is less than the service limit, the...

Page 125: Wheels/tires

Wheels/tires 8-1 8 wheels/tires table of contents exploded view........................................................................................................................ 8-2 specifications ....................................................................................................

Page 126

8-2 wheels/tires exploded view t1: 79 n·m (8.1 kgf·m, 58 ft·lb) t2: 1.5 ∼ 3.0 n·m (0.15 ∼ 0.31 kgf·m, 13 ∼ 27 in·lb) g: apply grease. Wl: apply soap and water solution, or rubber lubricant..

Page 127

Wheels/tires 8-3 specifications item standard service limit wheels rim runout (with tire installed): axial/radial tir 1.0 mm (0.04 in.) or less tir 2 mm (0.08 in.) axle runout/100 mm (3.94 in.): tir 0.10 mm (0.004 in.) or less tir 0.2 mm (0.008 in.) tires air pressure front and rear 98 kpa (1.0 kgf/...

Page 128

8-4 wheels/tires specifications item standard service limit d1 ∼ d4 d5, d6f ∼ rim size: front 19 × 1.40 ← rear 16 × 1.85 ← (eu) europe model warning some replacement tires may adversely affect handling and cause an accident resulting in serious injury or death. To ensure proper handling and stabilit...

Page 129

Wheels/tires 8-5 wheels (rims) front wheel removal • remove the following. Cotter pin [a] axle nut [b] • using the jack [a] and a stand [b], raise the front wheel off the ground. Special tool - jack: 57001-1238 • pull out the axle to the right and drop the front wheel out of the forks. Notice do not...

Page 130

8-6 wheels/tires wheels (rims) rear wheel removal • remove the following axle nut cotter pin [a] rear axle nut [b] caliper mounting bolts [c] • using the jack [a] or a stand, raise the rear wheel off the ground. Special tool - jack: 57001-1238 • hang the caliper with a brake hose on the swingarm. • ...

Page 131

Wheels/tires 8-7 wheels (rims) • check the rear brake. Warning after servicing, it takes several applications of the brake pedal before the brake pads contact the disc, which could result in increased stopping distance and cause an accident resulting in injury or death. Do not attempt to ride the mo...

Page 132

8-8 wheels/tires wheels (rims) axle inspection • place the axle in v blocks that are 100 mm (3.94 in.) [a] apart, and set a dial gauge on the axle at a point halfway between the blocks. Turn the axle to measure the runout. The difference between the highest and lowest dial read- ings is the amount o...

Page 133

Wheels/tires 8-9 tires removal • remove the following. Wheel (see wheel removal) disc notice do not lay the wheel on the ground with the disc facing down. This can damage or warp the disc. Place blocks under the wheel so that the disc does not touch the ground. • to maintain wheel balance, mark [a] ...

Page 134

8-10 wheels/tires tires installation • inspect the rim and tire, and replace them if necessary. • install the tube. • apply a soap and water solution, or rubber lubricant to the rim flange and tire beads. • position the tire on the rim so that the valve [a] is at the tire balance mark [b] (the chalk...

Page 135

Wheels/tires 8-11 tires inspection as the tire tread wears down, the tire becomes more sus- ceptible the puncture and failure. • remove any imbedded stones or other foreign particles from the tread. • visually inspect the tire for cracks and cuts, replacing the tire in case of bad damage. Swelling o...

Page 136

8-12 wheels/tires hub bearing (wheel bearings) removal • remove the following. Wheel (see wheel removal) oil seals and circlips • use the bearing remover to remove the hub bearings [a]. Special tool - bearing remover shaft, 9: 57001-1265 [b] bearing remover head, 10 × 12: 57001 -1266 [c] inside circ...

Page 137: Final Drive

Final drive 9-1 9 final drive table of contents exploded view........................................................................................................................ 9-2 specifications ......................................................................................................

Page 138

9-2 final drive exploded view 1. Kx85-a1 ∼ a4/b1 ∼ b4, kx100-d1 ∼ d4 2. Chain adjuster locknuts t1: 79 n·m (8.0 kgf·m, 58 ft·lb) t2: 32 n·m (3.3 kgf·m, 24 ft·lb) t3: 9.8 n·m (1.0 kgf·m, 87 in·lb) g: apply grease ho: apply heavy oil. L: apply a non-permanent locking agent. R: replacement parts..

Page 139

Final drive 9-3 specifications item standard service limit drive chain make and type daido, did 420ds2, joint endless kx85a 120 links – – – kx85b, kx100 d 124 links – – – chain slack 54 ∼ 64 mm (2.13 ∼ 2.52 in.) – – – 20-link length 254.0 mm (10.0 in.) 259 mm (10.2 in.) sprockets rear sprocket warp ...

Page 140

9-4 final drive drive chain slack adjustment • set the motorcycle up on its side stand. • check to see that the notches [a] on the alignment indi- cators [b] on both sides are in the same relative position [c]. If they are not, adjust the chain slack and align them. Warning misalignment of the wheel...

Page 141

Final drive 9-5 drive chain note ○ in wet and muddy conditions, mud sticks to the chain and sprockets resulting in an overly tight chain, and the chain may break. • check the rear brake (see brakes chapter). Warning after servicing, it takes several applications of the brake pedal before the brake p...

Page 142

9-6 final drive drive chain if any measurements exceed the service limit, replace the chain. Also, replace the front and rear sprockets when the drive chain is replaced. Warning a chain that breaks or jumps off the sprockets could snag on the engine sprocket or lock the rear wheel, severely damaging...

Page 143

Final drive 9-7 sprockets engine sprocket removal • remove the following parts. Magneto cover drive chain [a] (free of engine sprocket) • remove the engine sprocket circlip [b], and pull off the engine sprocket [c]. Special tool - outside circlip pliers: 57001-144 engine sprocket installation • repl...

Page 144

9-8 final drive sprockets rear sprocket warp • using the jack or a stand, raise the rear wheel off the ground (see wheels/tires chapter). Special tool - jack: 57001-1238 • set a dial gauge [a] against the rear sprocket [b] near the teeth as shown. Turn [c] the rear wheel. The difference between the ...

Page 145: Brakes

Brakes 10-1 10 brakes table of contents exploded view........................................................................................................................ 10-2 specifications .............................................................................................................

Page 146

10-2 brakes exploded view 1. Kx85a9f ∼ /kx85b9f ∼ , kx100d9f t1: 5.9 n·m (0.60 kgf·m, 52 in·lb) t2: 1.5 n·m (0.15 kgf·m, 13 in·lb) t3: 7.8 n·m (0.80 kgf·m, 69 in·lb) t4: 8.8 n·m (0.90 kgf·m, 78 in·lb) t5: 9.8 n·m (1.0 kgf·m, 87 in·lb) t6: 25 n·m (2.5 kgf·m, 18 ft·lb) t7: 4.9 n·m (0.50 kgf·m, 43 in·l...

Page 147

Brakes 10-3 exploded view t1: 5.9 n·m (0.60 kgf·m, 52 in·lb) t2: 25 n·m (2.5 kgf·m, 18 ft·lb) t3: 18 n·m (1.8 kgf·m, 13 ft·lb) t4: 7.8 n·m (0.8 kgf·m, 69 in·lb) t5: 9.8 n·m (1.0 kgf·m, 87 in·lb) g: apply grease. L: apply a non-permanent locking agent. R: replacement parts si: apply silicone grease..

Page 148

10-4 brakes specifications item standard service limit brake adjustment brake lever free play adjustable (to suit rider) – – – brake pads pad lining thickness: front 4.0 mm (0.16 in.) 1 mm (0.04 in.) rear 4.0 mm (0.16 in.) 1 mm (0.04 in.) brake disc disc thickness: front 2.85 ∼ 3.15 mm (0.112 ∼ 0.12...

Page 149

Brakes 10-5 disc brake information warning when working with the disc brake, observe the pre- cautions listed below. 1. Never reuse old brake fluid. 2. Do not use fluid from a container that has been left unsealed or that has been open for a long time. 3. Do not mix two types and brands of fluid for...

Page 150

10-6 brakes brake lever and pedal brake lever play adjustment • adjust the front brake lever [a] to suit you. • loosen the adjuster locknut [c] and turn the adjuster [d] to either side. • after adjustment, tighten the locknut to the specified torque. Torque - brake lever adjuster locknut : 4.9 n·m (...

Page 151

Brakes 10-7 brake lever and pedal pedal removal • remove the following. Brake pedal return spring [a] cotter pin joint pin [b] • remove the brake pedal bolt [c] and remove the brake pedal [d]. Pedal installation notes • grease the brake pedal hole. • check the pedal o-ring for signs of damage. If ne...

Page 152

10-8 brakes calipers caliper removal • loosen the banjo bolt [a] so as not to spill brake fluid. • remove the caliper mounting bolts [b]. • remove the caliper [c]. • remove the banjo bolt and take off the brake hose from the caliper (see brake hose removal/installation). • if the caliper is to be di...

Page 153

Brakes 10-9 calipers warning the piston in the brake caliper can crush hands and fingers. Never place your hand or fingers in front of the piston. • remove the dust seal and fluid seal. • remove the bleed valve and rubber cap. Assembly notes • tighten the bleed valve to the specified torque. Torque ...

Page 154

10-10 brakes calipers caliper holder shaft wear inspection the caliper body must slide smoothly on the caliper holder shafts. If the body does not slide smoothly, one pad will wear more than the other, pad wear will increase, and con- stant drag on the disc will raise brake and brake fluid tem- pera...

Page 155

Brakes 10-11 brake pads removal • when removing the rear brake pads, take off the caliper guard and loosen the pad bolts [a]. • remove the caliper [b] with the hose installed (see caliper removal). • remove the pad bolt (rear caliper). • take the piston side pad from the caliper holder. • push the c...

Page 156

10-12 brakes brake pads brake pad wear inspection • check the lining thickness [a] of the pads in each caliper. If the lining thickness of either pad is less than the service limit [b], replace both pads in the caliper as a set. Pad lining thickness (front and rear) standard: 4.0 mm (0.16 in.) servi...

Page 157

Brakes 10-13 master cylinder front master cylinder removal • drain the front brake fluid (see brake fluid change). • remove the following. Brake hose banjo bolt [a] master cylinder clamp bolts • remove the front master cylinder [b] front master cylinder installation • position the master cylinder so...

Page 158

10-14 brakes master cylinder inspection and adjustment after installation • fill the brake line with the brake fluid (see brake fluid change). • check and adjust the following items after installation. Brake pedal position brake line air bleed brake drag braking power brake fluid leakage warning aft...

Page 159

Brakes 10-15 master cylinder rear master cylinder disassembly note ○ do not remove the push rod clevis for master cylinder disassembly since removal requires brake pedal posi- tion adjustment. • remove the following. Rear master cylinder (see rear master cylinder re- moval) dust cover on push rod re...

Page 160

10-16 brakes master cylinder inspection (visually) • disassemble the front and rear master cylinder. • check that there are no scratches, wear, rust or pitting on the following parts. Inside of the master cylinder outside of the piston primary cup secondary cup dust cover return spring relief and su...

Page 161

Brakes 10-17 brake disk brake disc removal • remove: front wheel (see wheels/tires chapter) rear wheel (see wheels/tires chapter) • remove the brake discs from the wheels. Brake disc installation • install the disc on the wheels so that the mark side of it faces out. • apply a non-permanent locking ...

Page 162

10-18 brakes brake fluid fluid level inspection in accordance with the periodic maintenance chart, in- spect the brake fluid level in the front [a] and rear [c] brake fluid reservoirs. • check the brake fluid level in the reservoir. Note ○ hold the reservoir horizontal when checking brake fluid leve...

Page 163

Brakes 10-19 brake fluid • level the brake fluid reservoir. • remove the reservoir cap and the rubber cap [b] on the bleed valve [a]. • attach a clear plastic hose [c] to the bleed valve on the caliper, and run the other end of the hose into a container. • change the brake fluid as follows: ○ repeat...

Page 164

10-20 brakes brake fluid note ○ the procedure to bleed the front brake line is as follows. Bleeding the rear brake line is the same as for the front brake. • bleed the air whenever brake parts are replaced or re- assembled. • remove the reservoir cap and fill the reservoir with fresh brake fluid. • ...

Page 165

Brakes 10-21 brake hose removal/installation • when removing the brake hose, take care not to spill the brake fluid on the painted or plastic parts. • when removing the brake hose, temporarily secure the end of the brake hose to some high place to keep fluid loss to a minimum. Notice brake fluid qui...

Page 167: Suspension

Suspension 11-1 11 suspension table of contents exploded view................................... 11-2 specifications .................................... 11-4 front fork .......................................... 11-5 air pressure adjustment .............. 11-5 compression damping adjustment ..........

Page 168

11-2 suspension exploded view 1: kx85-a1 ∼ a2/b1 ∼ b2, kx100-d1 ∼ d2 2: kx85-a3 ∼ /b3 ∼ , kx100-d3 ∼ t1: 27 n·m (2.8 kgf·m, 20 ft·lb) t2: 20 n·m (2.0 kgf·m, 15 ft·lb) t3: 54 n·m (5.5 kgf·m, 40 ft·lb) t4: 15 n·m (1.5 kgf·m, 11 ft·lb) l: apply a non-permanent locking agent. R: replacement parts..

Page 169

Suspension 11-3 exploded view t1: 83 n·m (8.5 kgf·m, 61 ft·lb) t2: 59 n·m (6.0 kgf·m, 44 ft·lb) t3: 39 n·m (4.0 kgf·m, 29 ft·lb) t4: 69 n·m (7.0 kgf·m, 51 ft·lb) g: apply grease. L: apply a non-permanent locking agent m: apply molybdenum disulfide grease. Z: the seal lips face outward..

Page 170

11-4 suspension specifications item standard service limit front fork air pressure atmospheric pressure – – – compression damping adjustment refer to 11-5 – – – oil type khl15-10 (kayaba01) or equivalent – – – oil capacity: kx85a 315 ±4 ml (10.7 ±0.14 us oz) – – – kx85b, kx100d 321 ±4 ml (10.9 ±0.14...

Page 171

Suspension 11-5 front fork air pressure adjustment ○ the air pressure in the fork legs is atmospheric pressure. The air pressure in the fork legs increases as the fork heats up, so the fork action will get stiffer as the vehicle operation progresses. • lift the front wheel off the ground using the j...

Page 172

11-6 suspension front fork • use wretches on the rod nut and the top plug [a] to loosen the rod nut. • remove the top plug from the push rod. • remove the fork spring holder (special tool). • lift the fork spring [b] and its top spring seat [c] out of the inner tube. • hold the fork tube [a] upside ...

Page 173

Suspension 11-7 front fork • screw the fork piston rod puller [a] onto the end of the rod. Special tool - fork piston rod puller, m10 × 1.0: 57001 -1298 • purge the air from the fork cylinder by gently moving the rod puller [a] up and down five times. • purge the air from between the inner and outer...

Page 174

11-8 suspension front fork fork clamp position adjustment fork clamp position greatly affects steering qualities. Fork tube height is the amount of the inner tube projecting above the steering stem head. When the fork tube height is smaller, the front end becomes lighter due to change in weight bias...

Page 175

Suspension 11-9 front fork ○ with the fork fully compressed, and held upright, measure the distance [d] from the top of the oil (see front oil level adjustment). Special tool - fork oil level gauge: 57001-1290 [a] if the oil is above or below the specified level, remove or add oil and recheck the oi...

Page 176

11-10 suspension front fork note ○ tighten the two clamp bolts alternately two times to en- sure even tightening torque. • check the front brake for good braking power, no brake drag, and no fluid leakage after installing the front fork. Disassembly (each fork leg) • loosen the fork top plug tempora...

Page 177

Suspension 11-11 front fork • separate the inner tube [a] from the outer tube [b] as follows: ○ slide up the spring band [c]. ○ slide up the dust seal [d]. ○ remove the retaining ring [b] from the outer tube [a]. ○ grasp the outer tube and stroke the inner tube up and down several times. The shock t...

Page 178

11-12 suspension front fork • install the following onto the inner tube. Washer [a] outer tube guide bush [b] inner tube guide bush [c] • when installing the outer tube guide bush [a] into the outer tube, put the washer on the outer tube guide bush, and tap the washer with the fork oil seal driver [...

Page 179

Suspension 11-13 front fork • screw the push rod nut until it touched the spring guide. • pour in the type and amount of fork oil specified and adjust the oil level (see fork oil level adjustment). • screw the fork push rod puller [a] onto the end of the push rod. Special tool - fork piston rod pull...

Page 180

11-14 suspension rear shock absorber to suit to various riding conditions, the spring preload of the shock absorber can be adjusted or the spring can be replaced with an optional one. Also the damping force can be adjusted easily so changing oil viscosity unnecessary. Compression damping force adjus...

Page 181

Suspension 11-15 rear shock absorber • using the steering stem nut wrenches [a], loosen the lock- nut [b] and turn the adjusting nut [c] as required. Special tool - steering stem nut wrench: 57001-1100 • turning the adjusting nut [a] downward makes the spring action harder and upward softer. • tight...

Page 182

11-16 suspension rear shock absorber notice when pulling out the mounting bolts, lift the swingarm slightly. Forcing or tapping on a bolt could damage the bolt, sleeve, and bearing • remove the rear shock absorber. Installation • installation is the reverse of removal. • torque: torque - rear shock ...

Page 183

Suspension 11-17 rear shock absorber oil draining the oil should be changed in the rear shock absorber at least once per racing season. The frequency for best per- formance must be based upon riding conditions and rider ability. • remove the following. Rear shock (see rear shock absorber removal) re...

Page 184

11-18 suspension rear shock absorber oil filling • check the o-ring on the air bleeder bolt, and replace it if necessary. • install the air bleeder bolt. • pour khv10-k2c (kayaba) (sae 5w or bel-ray se2 #40) oil into the rear shock body to 31 ∼ 35 mm (1.22 ∼ 1.38 in.) (from the shock body lower end....

Page 185

Suspension 11-19 rear shock absorber if oil comes out of the air bleeder bolt hole, let it overflow until it stops. If oil does not come out of the air bleeder bolt hole, add the specified oil into the air bleeder bolt hole until it overflows (that is, until all the remaining air is forced out). • i...

Page 186

11-20 suspension rear shock absorber • install a steel tire valve cap [a] on the gas reservoir valve, and pull the gas reservoir cap out of the gas reservoir using pliers. ○ the bladder [b] comes out with the gas reservoir cap. Assembly • check that the bladder [a] on the gas reservoir cap is not pa...

Page 187

Suspension 11-21 rear shock absorber • pull up the gas reservoir cap [a] against the circlip. The end [b] of the gas reservoir cap must be 1 mm (0.039 in.) lower than the end [c] of the gas reservoir. Warning pressurized nitrogen gas can explode out of the shock reservoir cap if the circlip is not p...

Page 188

11-22 suspension swingarm removal • squeeze the brake lever slowly and hold it with a band. • remove the following. Rear brake hose straps rear brake caliper (see brake chapter) tie rod rear bolt [a] (see tie-rod removal) swingarm pivot shaft nut [b] rear wheel (see wheels/tires chapter) • pull out ...

Page 189

Suspension 11-23 swingarm swingarm bearing installation • replace the needle bearings, dust seals and oil seals with new ones. • apply plenty of molibdenum disulfide grease to the dust seals, oil seals and needle bearings. Note ○ install the needle bearings so that the manufacturer’s marks face out....

Page 190

11-24 suspension tie-rod, rocker arm tie-rod removal • raise the rear wheel off the ground (see wheel/tires chapter). • squeeze the brake lever slowly and hold it with a band. • remove the following. Front and rear tie-rod bolts [a] notice when pulling out the tie-rod bolts, lift the swingarm or the...

Page 191

Suspension 11-25 tie-rod, rocker arm rocker arm/tie-rod bearing removal • remove the rocker arm for the rocker arm bearing re- moval (see rocker arm/tie-rod bearing removal). • remove the swingarm for the tie-rod bearing removal (see rocker arm/tie-rod bearing removal). • remove the grease seal [a]....

Page 193: Steering

Steering 12-1 12 steering table of contents exploded view........................................................................................................................ 12-2 specifications .........................................................................................................

Page 194

12-2 steering exploded view t1: 25 n·m (2.5 kgf·m, 18 ft·lb) t2: 64 n·m (6.5 kgf·m, 47 ft·lb) t3: 20 n·m (2.0 kgf·m, 15 ft·lb) t4: hand tight or 4.9 n·m (0.49 kgf·m, 43 in·lb) ad: apply adhesive. G: apply grease. O: apply oil..

Page 195

Steering 12-3 specifications special tools - bearing driver, 32: 57001-382 head pipe outer race press shaft: 57001-1075 steering stem bearing driver adapter: 57001-1092 steering stem nut wrench: 57001-1100 head pipe outer race driver, 46.5: 57001-1106 head pipe outer race remover id > 37 mm: 57001-1...

Page 196

12-4 steering handlebar installation • install the handlebar holders so that the arrow [a] on the holder points to the front. • align the punch mark [d] on the handlebar to the mating surface of each clamps of handlebar, front master cylin- der. • tighten the front holder bolts [b] first, and then t...

Page 197

Steering 12-5 steering adjustment • check the steering. ○ lift the front wheel off the ground using a stand and the jack. Special tool - jack: 57001-1238 ○ with the front wheel pointing straight ahead, alternately tap each end of the handlebar. The front wheel should swing fully left and right from ...

Page 198

12-6 steering steering stem removal • remove the following parts. Steering stem head nut [a] front fender front fork legs (see suspension chapter) handlebar stem head upper steering stem bearing [c] • push up on the steering stem [d], and remove the stem nut [b] using the stem nut wrench, then remov...

Page 199

Steering 12-7 steering stem steering stem warp inspection • whenever the steering stem is removed, or if the steering cannot be adjusted for smooth action, check the steering stem for straightness. If the steering stem shaft [a] is bent, replace the steering stem..

Page 200

12-8 steering steering stem bearing removal • remove the steering stem (see steering stem removal). • to remove the outer races pressed into the head pipe, install the outer race remover as shown below. Special tool - head pipe outer race remover id > 37 mm: 57001-1107 [a] • remove the lower tapered...

Page 201

Steering 12-9 steering stem bearing ○ check that there is no play and the steering stem turns smoothly without the rattle. If not, the steering stem bearing may be damaged. ○ again back out the stem nut a fraction of turn until it turns lightly. ○ turn the stem nut lightly clockwise until it just be...

Page 203: Frame

Frame 13-1 13 frame table of contents exploded view........................................................................................................................ 13-2 seat .........................................................................................................................

Page 204

13-2 frame exploded view 1. Rear frame pipe. 2. Front fender mounting bolts t1: 34 n·m (3.5 kgf·m, 25 ft·lb) t2: 5.9 n·m (0.60 kgf·m, 52 in·lb) o: apply oil..

Page 205

Frame 13-3 seat seat removal • remove the seat bolts [a]. • move back [b] and swing open the seat [c], and then remove it. Seat installation • slip the hooks [a] of the seat under the washer [b] on the fuel tank and the brace [c]. • tighten the seat bolts..

Page 206

13-4 frame side covers side cover removal • remove: seat bolts [a] side cover bolts [b] side covers.

Page 207: Electrical System

Electrical system 14-1 14 electrical system table of contents exploded view........................................................................................................................ 14-2 wiring diagram........................................................................................

Page 208

14-2 electrical system exploded view 1. Engine stop button 2. Cdi unit 3. Ignition coil 4. Spark plug 5. Magneto stator 6. Crankshaft sensor 7. Magneto flywheel 8. Kx85-a1 ∼ a5/b1 ∼ b5, kx100-d1 ∼ d5 t1: 9.8 n·m (1.0 kgf·m, 87 in·lb) t2: 29 n·m (3.0 kgf·m, 22 ft·lb) t3: 26 n·m (2.7 kgf·m, 20 ft·lb) ...

Page 209

Electrical system 14-3 wiring diagram kx85-a1 ∼ a5/b1 ∼ b5, kx100-d1 ∼ d5 kx85-a6f ∼ /b6f ∼ , kx100-d6f ∼.

Page 210

14-4 electrical system specifications item standard service limit magneto flywheel magneto output voltage 16 v or more – – – ignition system ignition timing 12° btdc @12 000 r/min (rpm) (kx85a1 ∼ a5/b1 ∼ b5) 12° btdc @12 040 r/min (rpm) (kx85a6f ∼ /b6f ∼ ) 15° btdc @12 500 r/min (rpm) (kx100d1 ∼ d5)...

Page 211

Electrical system 14-5 precautions and safety instructions there are numbers of important precautions that are musts when servicing electrical systems. Learn and ob- serve all the rules below. ○ the electrical parts should never be struck sharply, as with a hammer, or allowed to fall on a hard surfa...

Page 212

14-6 electrical system electrical wiring inspection • visually inspect the wiring for signs of burning, fraying, etc. If any wiring is poor, replace the damaged wiring. • pull each connector apart and inspect it for corrosion, dirt, and damage. If the connector is corroded or dirty, clean it careful...

Page 213

Electrical system 14-7 ignition timing adjustment • remove the magneto cover. • check to see if the middle mark [a] of the three-marks on the magneto stator is aligned with the mark [b] on the crankcase. If the marks are not aligned, loosen the magneto stator mounting screws [c] and turn the magneto...

Page 214

14-8 electrical system flywheel magneto removal • remove: magneto cover • hold the flywheel steady with the flywheel & pully holder [a] and remove the flywheel nut [b]. Special tool - flywheel & pully holder: 57001-1605 • remove the flywheel holder. • screw the flywheel puller [a] into the flywheel ...

Page 215

Electrical system 14-9 flywheel magneto • set the stator wiring grommet [a] securely in the notch in the left crankcase half, and route the wires [b] according to the cable, wire and hose routing section in the gen- eral information chapter. • fit the woodruff key securely in the slot in the cranksh...

Page 216

14-10 electrical system flywheel magneto magneto stator coil check • check the magneto stator coil resistance as follows. ○ disconnect the magneto lead connector [a]. ○ connect the hand tester [b] as shown in the diagram. Special tool - hand tester: 57001-1394 magneto stator coil resistance connecti...

Page 217

Electrical system 14-11 ignition system.

Page 218

14-12 electrical system ignition system warning the ignition system produces extremely high volt- age. Do not touch the spark plug, ignition coil or ig- nition coil lead while the engine is running, or you could receive a severe electrical shock. Crankshaft sensor installation • install the cranksha...

Page 219

Electrical system 14-13 ignition system crankshaft sensor peak voltage inspection • disconnect the magneto lead connector [c]. • set the hand tester [b] to the × 25 v dc range, and con- nect it the peak voltage adapter [a] as shown in the dia- gram. • connect the black lead of the adapter to white/g...

Page 220

14-14 electrical system ignition system kx85a6f ∼ /b6f ∼ , kx100d6f ∼ ignition coil arcing distance standard: 6 mm (0.24 in.) or more • to determine which part is defective, measure the arcing distance again with the spark plug cap removed from the ignition coil lead. If the arcing distance is subno...

Page 221

Electrical system 14-15 ignition system kx85a6f ∼ /b6f ∼ , kx100d6f ∼ [c] spark plug cleaning and inspection • remove the spark plug, and visually inspect it. • clean the spark plug, preferably in a sandblasting device, and then clean off any abrasive particles. The plug may also be cleaned using a ...

Page 222

14-16 electrical system ignition system • install the peak voltage adapter [a] into the hand tester [b]. • connect the adapter to the ignition coil primary lead ter- minal and the engine ground with the primary lead con- nected. Cdi unit [c] new spark plug [d] ignition coil [e] special tool - hand t...

Page 223

Electrical system 14-17 ignition system.

Page 225: Appendix

Appendix 15-1 15 appendix table of contents troubleshooting guide ........................................................................................................... 15-2 general lubrication ........................................................................................................

Page 226

15-2 appendix troubleshooting guide note ○ this is not an exhaustive list, giving every possible cause for each problem listed. It is meant simply as a rough guide to assist the troubleshooting for some of the more common difficulties. Engine doesn’t start, starting difficulty: engine won’t turn ove...

Page 227

Appendix 15-3 troubleshooting guide poor running or no power at high speed: firing incorrect: spark plug dirty, damaged, or maladjusted spark plug cap or high tension wiring dam- aged spark plug cap shorted or not in good con- tact spark plug incorrect c.D.I unit trouble crankshaft sensor broken or ...

Page 228

15-4 appendix troubleshooting guide clutch spring broken or weak clutch release mechanism trouble clutch hub or housing unevenly worn clutch not disengaging properly: clutch lever play excessive clutch plate warped or too rough clutch spring tension uneven transmission oil deteriorated transmission ...

Page 229

Appendix 15-5 troubleshooting guide fuel level too high handling and/or stability unsatisfactory: handlebar hard to turn: control cable routing incorrect wiring routing incorrect steering stem locknut too tight bearing ball damaged bearing race dented or worn steering stem bearing lubrication inade-...

Page 230

15-6 appendix general lubrication lubrication (periodic maintenance) • before lubricating each part, clean off any rusty spots with rust remover and wipe off any grease, oil, dirt, or grime. • lubricate the points listed below with indicated lubricant. Note ○ whenever the vehicle has been operated u...

Page 231

Appendix 15-7 bolt, nut, and fastener tightness bolt, nut, and fastener tightness tightness inspection • check the tightness of bolts and nuts listed here. Also, check to see that each cotter pin is in place and in good condition. Note ○ for the engine fasteners, check the tightness of them when the...

Page 232

15-8 appendix unit conversion table prefixes for units: prefix symbol power mega m × 1 000 000 kilo k × 1 000 centi c × 0.01 milli m × 0.001 micro µ × 0.000001 units of mass: kg × 2.205 = lb g × 0.03527 = oz units of volume: l × 0.2642 = gal (us) l × 0.2200 = gal (imp) l × 1.057 = qt (us) l × 0.8799...

Page 233

Model application year model beginning frame no. 2001 kx85-a1 jkbkxfac □ 1a000001 or jkbkx085aaa000001 2001 kx85-b1 jkvkxfbc □ 1a000001 or jkbkx085bba000001 2001 kx100-d1 jkakxtdc □ 1a000001 or jkakx100dda000001 2002 kx85-a2 jkbkxfac □ 2a007001 or jkbkx085aaa007001 2002 kx85-b2 jkbkxfbc □ 2a003001 o...