- DL manuals

- Kawasaki

- Robotics

- MPVDCONTV113E-3

- Troubleshooting And Component Replacement

Kawasaki MPVDCONTV113E-3 Troubleshooting And Component Replacement

Summary of MPVDCONTV113E-3

Page 1

D series controller troubleshooting and component replacement mpvdcontv113e-3 ka a a w s k kawasaki robotics (usa), inc. K a a a w s k.

Page 2

This publication contains proprietary information of kawasaki robotics (usa), inc. And is furnished solely for customer use only. No other uses are authorized or permitted without the express written permission of kawasaki robotics (usa), inc. The contents of this manual cannot be reproduced, nor tr...

Page 3: Ka A A

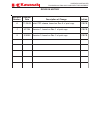

Revision history d series controller troubleshooting and component replacement ka a a w s k n o i s i v e r r e b m u n e s a e l e r e t a d e g n a h c f o n o i t p i r c s e d s l a i t i n i 0 - 3 0 / 0 2 / 1 1 y p o c t n i r p f o 0 - . V e r n o d e s a b , e s a e l e r f d p l a i t i n i ...

Page 4: Ka A A

Troubleshooting 1-1 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k 1.0 troubleshooting ................................................................................... 1-2 1.1 error recovery ..................................................................

Page 5: Ka A A

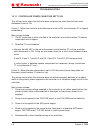

Troubleshooting d series controller troubleshooting and component replacement 1-2 august 9, 2005 ka a a w s k 1.0 troubleshooting this unit provides error recovery flowcharts, error code information, and error code troubleshooting flow charts. In addition, typical causes and remedies for the errors ...

Page 6: Ka A A

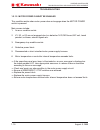

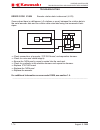

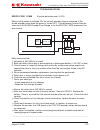

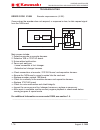

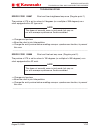

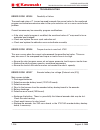

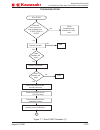

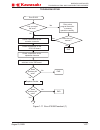

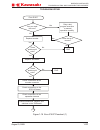

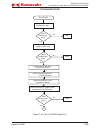

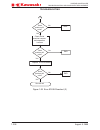

Troubleshooting 1-3 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-1 troubleshooting process source of error known locate error on the error table and determine the characteristics and possible causes of the error source of error unknown press the ...

Page 7: Ka A A

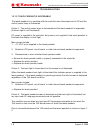

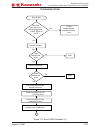

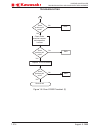

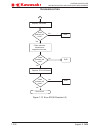

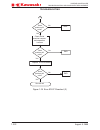

Troubleshooting d series controller troubleshooting and component replacement 1-4 august 9, 2005 ka a a w s k figure 1-2 troubleshooting process (continued) continued from previous pg error still present remove the 1ka board from the rack and allow ram memory to deplete reinstall 1ka board, initiali...

Page 8: Ka A A

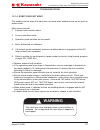

Troubleshooting 1-5 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k 1.2 preliminary troubleshooting prior to following error code troubleshooting procedures, ensure preliminary trouble- shooting steps are completed. 1. Ensure proper 460 vac three-phase power...

Page 9: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-6 august 9, 2005 ka a a w s k 1.2.1.1 controller power cannot be set to on this failure occurs when the controller does not power-up when the controller main disconnect is set to on. Failure 1: when the controller main d...

Page 10: Ka A A

Troubleshooting 1-7 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k ⇒ ensure primary power supply is within specifications. Ensure primary power supply cable is properly connected and is not damaged. ⇒ ensure connectors at the 1kq/1nr board are properly inst...

Page 11: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-8 august 9, 2005 ka a a w s k 1.2.1.2 teach pendant is inoperable the teach pendant is in operable with the controller main disconnect set to on and the control power lamp is illuminated. Failure 1: the control power lam...

Page 12: Ka A A

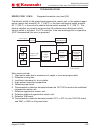

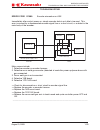

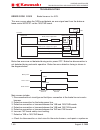

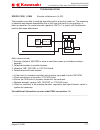

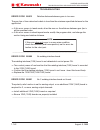

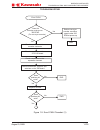

Troubleshooting 1-9 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k 1kx/1nx mother board 1ka main cpu board display device teach pendant input keys figure 1-3 1ka/teach pendant communication main causes include: 1. Interruption in data communication between ...

Page 13: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-10 august 9, 2005 ka a a w s k 1.2.1.3 motor power cannot be enabled this condition exists when motor power does not engage when the motor power switch is pressed. Main causes include: 1. An error condition exists. 2. K1...

Page 14: Ka A A

Troubleshooting 1-11 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k 1.2.1.4 robot does not move this condition exists when the robot does not move when conditions are set for teach or repeat mode. Main causes include: 1. External hold condition exists. 2. A...

Page 15: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-12 august 9, 2005 ka a a w s k 1.3 error codes this unit provides information about the error codes that are displayed on the teach pendant or other user interfaces that provide display screen information. The error code...

Page 16: Ka A A

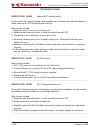

Troubleshooting 1-13 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k 1.3.1 error display error messages are displayed on the teach pendant lcd screen and/or a pc interfaced with the controller using krterm/kcwin32 terminal software. The teach pendant lcd scr...

Page 17: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-14 august 9, 2005 ka a a w s k 1.3.2.1 dxxxx fatal error codes error code d0001 cpu error. (pc=xx) the 1ka board cpu has stopped (detected by the as software). This error is caused by defective as or servo software, defe...

Page 18: Ka A A

Troubleshooting 1-15 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d0003 vme bus error. (pc=xx) this error occurs when the cpu does not receive a response from one of the i/o bus devices within a specific time. This error is caused by defective ...

Page 19: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-16 august 9, 2005 ka a a w s k error code d0005 [arm control board] cpu bus error. (pc=xx) on the 1kb board, a bus error occurs (in the vme bus line, detected by as software); data processing is not completed normally. T...

Page 20: Ka A A

Troubleshooting 1-17 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d0901 as flash memory sum check error. A check sum error occurrs in as software, in flash memory on the 1ka board, when the controller is powered-up. The check sum data is create...

Page 21: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-18 august 9, 2005 ka a a w s k error code d0904 memory is locked due to ac_fail. The memory is accessed during the controller shut down due to a power supply abnor- mality (acfail) (avr +5 v, +12 v, -12 v, +24 v). ⇒ cycl...

Page 22: Ka A A

Troubleshooting 1-19 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1002 init. Error of servo software. Servo software (armsc.Mb) initialization failure at controller power-up. Main causes include: 1. Servo software is not installed correctly or...

Page 23: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-20 august 9, 2005 ka a a w s k error code d1004 [arm ctrl board] watch dog error of servo control software. The watch dog circuit on the 1ka board or 1kb board has detected a software problem. This is caused by a defecti...

Page 24: Ka A A

Troubleshooting 1-21 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1006 amp power unit error. General servo system error. This error indicates that a servo system error has occurred. Refer to any other servo system errors which occurred at the ...

Page 25: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-22 august 9, 2005 ka a a w s k error code d1007 regenerative time over [xx]. This error occurs when current is sent to regenerative resistors for six or more consecu- tive seconds. When the robot decelerates, the motors ...

Page 26: Ka A A

Troubleshooting 1-23 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k ! Warning error code d1008 p-n low voltage [xx]. The voltage between p-n supplied to the power block is 60 vdc or less at servo on. Because motor power is not supplied, when low voltage occ...

Page 27: Ka A A

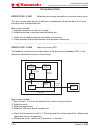

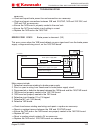

Troubleshooting d series controller troubleshooting and component replacement 1-24 august 9, 2005 ka a a w s k error code d1009 p-n- high voltage [xx]. The voltage between p-n supplied to the power block exceeded 410 vdc. 1kb board additional regenerative resistor (option) p-n power high voltage err...

Page 28: Ka A A

Troubleshooting 1-25 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1010 regenerative resistor over-heat [xx]. The thermal switch for the power block regenerative resistor unit, or the optional regen- erative resistor unit reached 140° c (284°f)...

Page 29: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-26 august 9, 2005 ka a a w s k ⇒ reteach program steps to eliminate sudden high speed direction changes (dynamic shock). ⇒ ensure cooling fans are in proper working condition. ⇒ reduce controller ambient temperature. ⇒ r...

Page 30: Ka A A

Troubleshooting 1-27 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1013 p-n capacitor is not discharged. This error occurs when motor power is off for a period of time and the p-n power voltage does not decrease to 60 vdc or less. 1kb board 1kp...

Page 31: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-28 august 9, 2005 ka a a w s k error code d1016 data applicable to the robot model not in servo servo data file. This error occurs when the installed robot model file is not found in the servo data file. ⇒ contact kri cu...

Page 32: Ka A A

Troubleshooting 1-29 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1500 encoder misread error jtxx. Immediately after control power on, steady encoder data is not able to be read. This error is caused by a disconnected encoder signal line or a ...

Page 33: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-30 august 9, 2005 ka a a w s k error code d1501 defective gun changer connection or encoder comm. Error. This error occurs when the servo weld gun is connected and encoder data is not read normally within the specified t...

Page 34: Ka A A

Troubleshooting 1-31 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1503 current detector type (xx) mismatch! When the control power supply is turned on, the id code data of the 1gm (1kv) board and the as software installed on the 1kb board do n...

Page 35: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-32 august 9, 2005 ka a a w s k error code d1504 abn. Curr. Feedback jt xx. (amp fail, pwr harness discon- nect). This error occurs if the current feedback value is near 0 from the time the servo is turned on until the br...

Page 36: Ka A A

Troubleshooting 1-33 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1505 motor harness disconnected or over heat. (xx) motor thermal circuit is open due to motor overheat or harness problem. Not all robot models utilize thermal switches in the m...

Page 37: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-34 august 9, 2005 ka a a w s k error code d1506 power module error jtxx. An error signal from the ipm module in the power block is detected by the 1kb board. 1kb board ipm error signal power block gate array servo cpu in...

Page 38: Ka A A

Troubleshooting 1-35 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1507 ac primary power off. This error occurs when there is an instantaneous decrease in the primary power to the avr for control power supply (130–145 vac or less for 20–30 msec...

Page 39: Ka A A

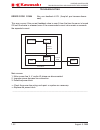

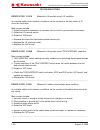

Troubleshooting d series controller troubleshooting and component replacement 1-36 august 9, 2005 ka a a w s k error code d1508 24vdc power source is too low. 24 vdc to the power sequence board has dropped to +21.6 vdc or less. Mother board 1kp board 1kb board 1kx board epld 24 vdc monitor avr for c...

Page 40: Ka A A

Troubleshooting 1-37 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1509 primary power source is too high. Voltage level of the avr for the control power supply is too high (267-277 vac or more for 1-2 sec.). Mother board 1kp board 1kx board epl...

Page 41: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-38 august 9, 2005 ka a a w s k error code d1510 primary power source is too low. Voltage level of the avr primary power supply is too low (150-158 vac or less for 1-2 sec.). Mother board 1kp board 1kb board 1kx board epl...

Page 42: Ka A A

Troubleshooting 1-39 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1511 +12vdc or -12vdc is abnormal. +/-12 vdc supplied to the 1ka board is out of specifications. +12 vdc: +10.75 vdc or less. -12 vdc: -10.4 vdc or more. Main causes include: 1....

Page 43: Ka A A

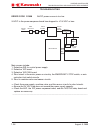

Troubleshooting d series controller troubleshooting and component replacement 1-40 august 9, 2005 ka a a w s k error code d1512 brake line error for jtxx. This error occurs when the 1kb board detects an error signal sent from the brake re- lease control mosfet on the 1kq/1nr board. Transformer circu...

Page 44: Ka A A

Troubleshooting 1-41 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k necessary. ⇒ check and repair brake power line and connections as necessary . ⇒ check and repair connections between 1kb and 1kq/1nr, 1kb and 1kx/1nx, and 1nr and 1nx as necessary. ⇒ ensure...

Page 45: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-42 august 9, 2005 ka a a w s k error code d1514 i/o 24v fuse is open. Fuse f2 on the 1kp board is open. Main causes include: 1. Solenoid valve or diode polarity reversed. 2. Current load on the 24 vdc i/o circuit exceeds...

Page 46: Ka A A

Troubleshooting 1-43 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1517 blown fuse on safety circuit emergency line. Fuse f1 on the 1kp board is open. Main causes include: 1. Incorrect wiring in the emergency line (wiring harness, emergency sto...

Page 47: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-44 august 9, 2005 ka a a w s k error code d1519 mismatch of the safety circuit ls condition. In a double safety circuit system, conditions set for contacts in the limit switch (ls) circuit do not match. Main causes inclu...

Page 48: Ka A A

Troubleshooting 1-45 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1522 mismatch in cond. Of safety circuit enabling device. In a double safety circuit system, conditions set for contacts at the trigger switch circuit do not match. If the trigg...

Page 49: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-46 august 9, 2005 ka a a w s k error code d1525 incorrect operation of mc (k1). Main causes include: 1. Defective controller harness. 2. Defective magnetic contactor k1. 3. Defective mc unit (1kq/1nq board). 4. Defective...

Page 50: Ka A A

Troubleshooting 1-47 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d1528 controller temperature is out of range. Temperature inside the controller exceeds specification. Main causes include: 1. Defective cooling fan(s). For d7x controller, defec...

Page 51: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-48 august 9, 2005 ka a a w s k error code d1531 heat sink on power block overheated. Main causes include: 1. Temperature inside the controller above specification because of air inlet or outlet blockage. 2. Defective coo...

Page 52: Ka A A

Troubleshooting 1-49 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d2002 no response from the arm id board. Main causes include. 1. Defective 1kb board. 2. Defective 1kp board. 3. Defective 1gv arm id board. 4. Defective harness. 5. Noise relate...

Page 53: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-50 august 9, 2005 ka a a w s k error code d2006 communication board to explosion-proof teach pendant watch-dog error. This error occurs when the cpu on the communication board (1gs board) for the explo- sion-proof teach ...

Page 54: Ka A A

Troubleshooting 1-51 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d2011 parameter download error between user i/f & arm ctrl boards. 1ka and 1kb boards parameter exchange cannot be downloaded. ⇒ replace the 1ka board. ⇒ replace the 1kb board. _...

Page 55: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-52 august 9, 2005 ka a a w s k error code d2016 no response from the arm control board. Request is sent to the 1kb board from the 1ka board and there is no response. ⇒ reset error and if error recurs, replace the 1ka/1kb...

Page 56: Ka A A

Troubleshooting 1-53 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d2020 [arm ctrl board] servo control software no response. 1kb board software stopped. Main causes include: 1. Servo software is not installed correctly or is corrupt. 2. Defecti...

Page 57: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-54 august 9, 2005 ka a a w s k error code d2024 [arm ctrl board] robot type setting failed. System software is not compatible with the robot model set in the as software. ⇒ ensure the correct model setting is used . ⇒ en...

Page 58: Ka A A

Troubleshooting 1-55 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d2028 (sscnet) initialization error. (code xx). The mitsubishi single axis amplifier failed to initialize at controller power-up. A 2 byte code follows the error message. The hig...

Page 59: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-56 august 9, 2005 ka a a w s k error code d2031 codes set in software and on add’l pwr block mismatch. (jt-a) software and hardware settings, for the axis assigned to channel 7 (seventh axis), do not match power block se...

Page 60: Ka A A

Troubleshooting 1-57 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code d2035 program execution error. Program failed to start when cycle start command was issued. ⇒ reset the error, and restart the program . ⇒ if the error recurs, contact kri custom...

Page 61: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-58 august 9, 2005 ka a a w s k error code d4502 field-bus-init) error reply. Xx at fieldbus start-up, a mismatch in length of i/o data with the node at the end of the connection is detected when a message is sent to the ...

Page 62: Ka A A

Troubleshooting 1-59 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k 1.3.2.2 exxxx non-fatal error codes error code e0001 unknown error. Unregistered error occurred. ⇒ contact kri customer service (include operating conditions/settings and operation log at t...

Page 63: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-60 august 9, 2005 ka a a w s k error code e0103 location data is not defined. Main causes include: 1. The location variable for the base, tool or point command is not specified. Example: “tool a” is specified and “a” is ...

Page 64: Ka A A

Troubleshooting 1-61 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e0108 divided by zero. Occurs when the system encounters a mathematical evaluation that involves division by “0”. Typically associated with the frame function and circular interp...

Page 65: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-62 august 9, 2005 ka a a w s k error code e0113 no expressions to evaluate. The type of data in an argument is incompatible with the operation being performed. ⇒ correct the program to evaluate compatible expressions. __...

Page 66: Ka A A

Troubleshooting 1-63 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e0118 too many subroutine calls. Occurs when more than 20 subroutines are nested with extcall or call instructions. ⇒ do not exceed 20 nested subroutines. _______________________...

Page 67: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-64 august 9, 2005 ka a a w s k error code e1001 adc input range error. This error occurs when an a/d converter input voltage is incorrect. The correct analog input voltage ranges are: 1. 0– +10 v 2. ±5 v 3. ±10 v ⇒ ensur...

Page 68: Ka A A

Troubleshooting 1-65 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1004 interbus board is not ready. At 1jf board start-up, the board did not achieve the ready state within the required time. ⇒ cycle controller power off and on . ⇒ ensure the 1...

Page 69: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-66 august 9, 2005 ka a a w s k error code e1008 no.2 power sequence board is not installed. The first address of the no.2 1kp power sequence board cannot be read at controller power-up. Main causes include: 1. The 1kp po...

Page 70: Ka A A

Troubleshooting 1-67 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1010 power sequence board detects error. An error signal, not classified through the error summary, is generated by the 1kp board and is sent to the 1kb board. This error occurs...

Page 71: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-68 august 9, 2005 ka a a w s k error code e1013 interbus board is not installed. The 1jf board is not installed. ⇒ ensure the 1jf board is properly installed . ⇒ replace the 1jf board. ___________________________________...

Page 72: Ka A A

Troubleshooting 1-69 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1021 arm id board error. (code xxx). E d o c n o i t p i r c s e d h a 4 t p u r r o c s i r o l a m r o n t o n s i a t a d d r a o b d i m r a h f 4 y r o m e m d r a o b d i ...

Page 73: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-70 august 9, 2005 ka a a w s k error code e1023 communication error in robot network. Main causes include: 1. Communication between robots is not normal during cooperative motion operation. 2. Power to one of the control...

Page 74: Ka A A

Troubleshooting 1-71 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1025 ext axis connecting error. (code xx) occurs when the gun axis connection is not normally completed. E d o c n o i t p i r c s e d 0 . E r a w t f o s o v r e s m o r f e s ...

Page 75: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-72 august 9, 2005 ka a a w s k error code e1027 safety circuit was cut off. The safety gate branch of the safety circuit is open due to a missing safety plug or defective circuit. ⇒ reinsert the safety plug. ⇒ repair ope...

Page 76: Ka A A

Troubleshooting 1-73 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k 6. Malfunction of the motor. 7. Servo spot weld gun: –clamping pressure and/or clamping time is excessive. –distance between weld points is short; the motor does not have time to cool suffi...

Page 77: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-74 august 9, 2005 ka a a w s k error code e1029 encoder rotation data is abnormal. (jt xx) occurs when there is a difference (+2 rotations or more) between the rotation data in the serial encoder data and the rotation da...

Page 78: Ka A A

Troubleshooting 1-75 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1030 encoder data abnormal. (jt xx) when control power is switched on, the current encoder value is compared to the stored encoder value when the power is turned off. If the dif...

Page 79: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-76 august 9, 2005 ka a a w s k error code e1031 miscount of encoder data (jt xx). The servo gun or tool changer harness is defective. ⇒ inspect the servo gun and tool changer harnesses; replace if necessary. ____________...

Page 80: Ka A A

Troubleshooting 1-77 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1034 encoder initialize error (jt xx). The encoder is not able to read the absolute position at control power on. The scanning of absolute data begins immediately after a shift ...

Page 81: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-78 august 9, 2005 ka a a w s k error code e1035 encoder response error (jt xx). Occurs when the encoder does not respond, or response is slow, to data request signal from the 1kb board. Power circuit battery encoder enco...

Page 82: Ka A A

Troubleshooting 1-79 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1036 encoder communication error. (jt xx) cyclic redundancy check (crc) fault or framing error is detected in communication with the encoder. Power circuit battery encoder encod...

Page 83: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-80 august 9, 2005 ka a a w s k error code e1037 encoder data conversion error. (jt xx). This error is caused by abnormal encoder absolute position data. Power circuit battery encoder encoder 1fg/1hg board robot controlle...

Page 84: Ka A A

Troubleshooting 1-81 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1038 encoder abs-track error. (jt xx) the absolute data and the incremental data in the encoder are different. Absalm=1 is output from the encoder when this error occurs. Power ...

Page 85: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-82 august 9, 2005 ka a a w s k error code e1039 encoder inc-pulse error. (jt xx) occurs when the encoder a and b incremental pulses are abnormal. The encoder inalm bit is sent with the serial data=1. Power circuit batter...

Page 86: Ka A A

Troubleshooting 1-83 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1041 limit switch (jt xx) is on. This error occurs when the robot moves beyond the set working range (restricted space) and activates the axis restriction limit switch. The mech...

Page 87: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-84 august 9, 2005 ka a a w s k error code e1042 limit switch signal line is disconnected. This error occurs when the axis restriction limit switch is activated and the robot did not move beyond the set working range (res...

Page 88: Ka A A

Troubleshooting 1-85 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1045 gun-clamp mismatch. (spot weld specifications type b) spot weld is not selected in aux 0605-1 when a servo spot weld gun is used. ⇒ ensure spot weld is selected in aux 0605...

Page 89: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-86 august 9, 2005 ka a a w s k error code e1050 encoder and brake power off signal not dedicated. A gun change is executed on a servo spot weld gun without setting [encoder and brake power (7)] dedicated signal in aux 06...

Page 90: Ka A A

Troubleshooting 1-87 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1054 cannot execute motion instruction. Main causes include: 1. A motion instruction is executed for the slave robot during cooperative motion. 2. A motion instruction is execut...

Page 91: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-88 august 9, 2005 ka a a w s k error code e1058 slave robot already exists. This error occurs when slave instructions are executed for both connected robots during cooperative motion in repeat mode. ⇒ do not execute slav...

Page 92: Ka A A

Troubleshooting 1-89 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1063 jt2 and jt3 interfere during motion to end pose. Movement from the current position to the end pose would cause jt2 and jt3 to move beyond their limits. ⇒ modify the positi...

Page 93: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-90 august 9, 2005 ka a a w s k error code e1067 illegal pattern type. Main causes include: 1. Program step does not comply with as language syntax. 2. Pattern type for work specified using block step instructions or the ...

Page 94: Ka A A

Troubleshooting 1-91 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1071 xmove signal is already input. An xmove instruction mode “/err” is specified and the signal condition to monitor is already attained when monitoring starts. ⇒ delete the “/...

Page 95: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-92 august 9, 2005 ka a a w s k error code e1076 cannot use negative time value. Displayed when a negative number is entered as part of a delay or timer command. ⇒ correct the time setting to a positive number. __________...

Page 96: Ka A A

Troubleshooting 1-93 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1081 cannot use negative value. Displayed when a negative number is used in conjunction with the pulse or accuracy commands/instructions. ⇒ use only positive numbers in the acce...

Page 97: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-94 august 9, 2005 ka a a w s k error code e1086 start point for jt xx beyond motion range. Robot pose at motion start is beyond the range set in aux 0507. Example: do home is executed at a point that is out of motion ran...

Page 98: Ka A A

Troubleshooting 1-95 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1090 external modulation data is not input. (option) external modulation data is not received. ⇒ check for abnormality in the external modulation data line and repair as necessa...

Page 99: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-96 august 9, 2005 ka a a w s k error code e1095 cannot execute motion instruction in pc program. A pc program cannot contain instructions that initiate robot motion. ⇒ correct the pc program by removing motion instructio...

Page 100: Ka A A

Troubleshooting 1-97 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1100 cannot execute in sealing specification. Occurs when a close(i), open(i), or relax(i) command is executed in a program and clamp specifications in aux 0605-1 are set for se...

Page 101: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-98 august 9, 2005 ka a a w s k error code e1106 cannot execute in this robot. This error occurs when a request is executed on a robot arm that does not support the function. ⇒ contact kri customer service to have the fun...

Page 102: Ka A A

Troubleshooting 1-99 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1113 work sensing signal is not detected. (sensing function) this error occurs when the x-linear step is executed and the workpiece is not detected before the robot axes reach c...

Page 103: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-100 august 9, 2005 ka a a w s k error code e1117 process time over. Lack of system processing time ⇒ contact kri customer service (include operating conditions/settings and operation log at the time the error occurred) ....

Page 104: Ka A A

Troubleshooting 1-101 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1119 commanded value for jt xx beyond motion range. Spot welding and material handling the commanded position for the joint identified exceeds the software limits. Condition is...

Page 105: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-102 august 9, 2005 ka a a w s k error code e1122 unexpected motor power off. Occurs when software turns motor power on (k1 or k2 contactors on) but there is no signal feedback (mcon) indicating motor power is on. Main ca...

Page 106: Ka A A

Troubleshooting 1-103 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1124 deviation error of jt xx. Spot welding and material handling the difference between the current value from the encoder and the command value in the as software exceeds the...

Page 107: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-104 august 9, 2005 ka a a w s k error code e1126 commanded speed error jt xx. This error occurs when the positional command value sent to the 1kb board from the 1ka board exceeds the value range. Main causes include: 1. ...

Page 108: Ka A A

Troubleshooting 1-105 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1128 uncoincidence error betw destination and current jt xx pos. This error occurs during program execution, if all joints do not reach total coincidence within the commanded a...

Page 109: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-106 august 9, 2005 ka a a w s k error code e1130 jt xx collision was detected. Motor current command value exceeds the threshold value set in aux 0510. ⇒ remove obstacles in the robot motion path area. ⇒ ensure tool sett...

Page 110: Ka A A

Troubleshooting 1-107 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1134 abnormal work transfer pitch. The signal for resetting the conveyor value is received before the conveyor reached the position specified by the work transfer pitch. ⇒ ensu...

Page 111: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-108 august 9, 2005 ka a a w s k error code e1138 aux. Terminal is not connected. External monitoring device is not connected. ⇒ ensure the external monitoring device is properly connected . ______________________________...

Page 112: Ka A A

Troubleshooting 1-109 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1143 conveyor axis number is not set. Conveyor axis number is not set at execution of conveyor synchronous motion. ⇒ set the conveyor axis number using the zcvaxis instruction ...

Page 113: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-110 august 9, 2005 ka a a w s k error code e1149 cannot open setting data, so cannot set to shipment state. When “2: setting to shipment state” is selected from the initialization screen, a data file in the setting file ...

Page 114: Ka A A

Troubleshooting 1-111 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1154 option sio port is not installed. Main causes include: 1. Optional communication port (1gs board) is not installed to the 1ka board. 2. Optional communication port (1gs bo...

Page 115: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-112 august 9, 2005 ka a a w s k error code e1157 arm id i/f board error. (code xxx) e d o c n o i t p i r c s e d h 1 c r o r r e m u s k c e h c n o i t a c i n u m m o c 1 h 5 c r o r r e l o c o t o r p n o i t a c i ...

Page 116: Ka A A

Troubleshooting 1-113 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e1162 buffer overflow occurred gravity comp. Value channel xx. Gravity compensation value overflow due to mismatch of load weight and the set value. ⇒ contact kri customer servi...

Page 117: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-114 august 9, 2005 ka a a w s k error code e1167 unable to download ext. Axis parameter. (jt-b) download failed due to channel 8 parameter is being downloaded by another process. ⇒ re-execute parameter download. ⇒ if thi...

Page 118: Ka A A

Troubleshooting 1-115 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e4000 data communication error. Main causes include: 1. When receiving data from vision sensor: –time out occurred, data is not received within the specified time. –robot is sto...

Page 119: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-116 august 9, 2005 ka a a w s k error code e4004 communication retry error. Communication retry error during host communication i. Main causes include: 1. No response after sending text. 2. After text is sent, nak (resen...

Page 120: Ka A A

Troubleshooting 1-117 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e4009 communication time out error. During host communication i or tcp/ip interface, data is not received within the al- lowed time after executing the receive instruction. ⇒ en...

Page 121: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-118 august 9, 2005 ka a a w s k error code e4014 telnet) recv error. Code=xx. During tcp/ip communication, data is not received due to a recv (receive) error. ⇒ check the communication line to the target end node and rep...

Page 122: Ka A A

Troubleshooting 1-119 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e4018 telnet) system error. Code=xx. Parameter settings entered using the netconf command does not comply with as language syntax. The code (code=xx) indicates a detailed sub er...

Page 123: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-120 august 9, 2005 ka a a w s k error code e4021 tcp/ip) communication error. Code=xx dst.Ip=xx.Xx.Xx.Xx. A communication error occurred during execution of the udp_sendto/ udp_recvfrom/tcp_send/tcp_recv instruction. May...

Page 124: Ka A A

Troubleshooting 1-121 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e4025 tcp/ip) connection aborted. Communication is disconnected during execution of the udp_sendto/ udp_recvfrom/tcp_connect/tcp_send/tcp_recv/tcp_accept instruc- tion. May be a...

Page 125: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-122 august 9, 2005 ka a a w s k error code e4029 ftp) data send error. (code=xx). Failure to transmit the teach data via memory → lan (manual save). May be a commu- nication cable connection problem. ⇒ ensure the communi...

Page 126: Ka A A

Troubleshooting 1-123 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e4034 ftp) failed to receive host os information. (code=xx) error occurred during receiving os information from the server. ⇒ ensure the communication cable is properly connecte...

Page 127: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-124 august 9, 2005 ka a a w s k error code e4052 [fdd/pc_card] failed to set verify function. Please set again. Failure to set condition for verify function for the 1kf board. ⇒ re-set condition for verify function in au...

Page 128: Ka A A

Troubleshooting 1-125 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e4056 tcp) this port is not in listen (sock). Main causes include: 1. Failure to open the socket when executing tcp_accept. 2. Failure to close the socket when executing tcp_end...

Page 129: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-126 august 9, 2005 ka a a w s k error code e4501 anybus) out/fb.Ctrl release timeout. Xx access to the input signal reading area is not released due to defective hardware. ⇒ check led indicator on the interface card, and...

Page 130: Ka A A

Troubleshooting 1-127 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e4521 abma-pdp) status offline. Xx an error occurred in the abma-pdp module, and the status of anybus profibus-dp master changed to offline. ⇒ use the sub-sub-code xx as a troub...

Page 131: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-128 august 9, 2005 ka a a w s k error code e4525 abma-pdp) timeout of sending message. Xx abma-pdp module overload, sending message cannot be processed within the allowed time. ⇒ check the fieldbus cable and connections,...

Page 132: Ka A A

Troubleshooting 1-129 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e4529 profibus) statistic counter-error response detected. Xx incorrect slave diagnosis command parameter is entered. ⇒ use the sub-code xx as a troubleshooting aid, clear the c...

Page 133: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-130 august 9, 2005 ka a a w s k error code e5003 illegal extend (retract) output signal. Occurs when the output signals for the extend and retract operation of a spot welding application are not properly set. ⇒ check the...

Page 134: Ka A A

Troubleshooting 1-131 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e5007 servo weld gun not connected or wrong gun connected. (servo spot weld gun only) main causes include: 1. The robot executes a step when a gun is not attached to the tool ch...

Page 135: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-132 august 9, 2005 ka a a w s k error code e5010 servo weld gun mechanical parameter is not set. (servo spot weld gun only) a new gun is connected and the mechanical parameters are not defined in aux 1021. ⇒ define the p...

Page 136: Ka A A

Troubleshooting 1-133 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e5015 gun status data disagrees with clamp condition. (servo spot weld gun only) incorrect program data is used. Main causes include: 1. Clamp on is taught in a step that includ...

Page 137: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-134 august 9, 2005 ka a a w s k error code e5018 weld completion signal has not been detected. Occurs when a weld complete signal is not received in the allowed time period. Main causes include: 1. Defective weld gun, we...

Page 138: Ka A A

Troubleshooting 1-135 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e5021 extend pos. Monitor error. Occurs when the input signal for the extend operation of a 2-stroke retractable gun is not received. Main causes include: 1. Defective weld gun,...

Page 139: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-136 august 9, 2005 ka a a w s k error code e5024 pressurization comp. Signal has not been detected. Pressurization completion signal is not received from the weld controller/timer. Main causes include: 1. Defective weld ...

Page 140: Ka A A

Troubleshooting 1-137 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e5027 robot stopped during weld. (spot weld specifications type c) (servo spot weld gun only) this error occurs when the robot is placed in a hold or an e-stop condition after t...

Page 141: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-138 august 9, 2005 ka a a w s k error code e5030 copper plate wear exceeds limit. Step=xx. (servo spot weld gun only) the copper backing plate wear exceeds the copper plate wear limit (aux 1029). The error is detected wh...

Page 142: Ka A A

Troubleshooting 1-139 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e5033 cannot weld because of abnormal thickness. (servo spot weld gun only) the thickness of the workpiece is out of tolerance. Main causes include: 1. Defective workpiece. 2. I...

Page 143: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-140 august 9, 2005 ka a a w s k error code e6002 signal condition already input. The signal condition is already met when an xdmove or xd(2)start move is ex- ecuted and the signal monitoring starts. ⇒ check input signal ...

Page 144: Ka A A

Troubleshooting 1-141 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6007 wrist can’t be straightened any more (singular point 1). The posture of jt5 is set too close to 0 degrees (or a multiple of 360 degrees) on a robot equipped with a 3s type...

Page 145: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-142 august 9, 2005 ka a a w s k error code e6012 relative distance between guns is too near. The gun tips of two networked robots is less than the minimum specified distance for the application. ⇒ if this error occurs in...

Page 146: Ka A A

Troubleshooting 1-143 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6502 arc failure. The signal (current detection: wcr) that indicates the robot is executing the weld was not returned from the weld controller/timer within 1 second, or less, a...

Page 147: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-144 august 9, 2005 ka a a w s k error code e6505 arc weld insulation defect. This error occurs when robot movement causes insulation failure. ⇒ ensure the welder, torch, and robot insulation are in good working condition...

Page 148: Ka A A

Troubleshooting 1-145 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6510 undefined sensing direction. (touch sensing) occurs when the step proceeding the work_detect instruction is not an air_cut point. ⇒ insert an air_cut point in the program ...

Page 149: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-146 august 9, 2005 ka a a w s k error code e6512 undefined mother or daughter work. (touch sensing) main causes include: 1. A previous work instruction is not completed before another work instruction is ex- ecuted. 2. P...

Page 150: Ka A A

Troubleshooting 1-147 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6514 work specification incorrect. (touch sensing) occurs when a previous work instruction is not completed before another work instruc- tion is executed. Example: 1. Ac joint ...

Page 151: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-148 august 9, 2005 ka a a w s k error code e6516 wire check failure. (touch sensing) main causes include: 1. The position of a taught point is recorded too far from the workpiece, and the wire tip did not touch the work ...

Page 152: Ka A A

Troubleshooting 1-149 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6519 weld condition data out of range. Ensure data is within range as shown below. Current: 0–999 amp voltage: 0–99.9 volt speed: 0–999 cm/min time: 0–9.9 second weaving width:...

Page 153: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-150 august 9, 2005 ka a a w s k error code e6522 laser sensor cannot detect welding joint. Main causes include: 1. The laser sensor unable to find a groove. 2. The laser sensor detects a groove that does not match the sp...

Page 154: Ka A A

Troubleshooting 1-151 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6526 no response from laser sensor controller. Main causes include: 1. Disconnected or defective laser sensor harness. 2. Incorrect laser sensor settings or defective laser sen...

Page 155: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-152 august 9, 2005 ka a a w s k error code e6529 finish point not found by laser sensor. Main causes include: 1. The laser sensor unable to find a groove. 2. Auto tracking function is enabled with no data present, and fi...

Page 156: Ka A A

Troubleshooting 1-153 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6533 no rtpm board. Main causes include: 1. The software for rtpm option is installed, but the hardware (1fh board) is not in- stalled properly. 2. Hardware for rtpm (1fh board...

Page 157: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-154 august 9, 2005 ka a a w s k error code e6536 rtpm current deviation error. Occurs when actual current exceeds commanded current (feedback current) for a time period exceeding the current deviation error time-out valu...

Page 158: Ka A A

Troubleshooting 1-155 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6538 beyond rtpm tracking ability. Occurs when the current tracking value exceeds the threshold value and the number of times value set for rtpm tracking ability errors. Exampl...

Page 159: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-156 august 9, 2005 ka a a w s k error code e6540 beyond avc tracking ability. Occurs when the current tracking value exceeds the threshold value and the number of times value set for rtpm tracking ability errors. Main ca...

Page 160: Ka A A

Troubleshooting 1-157 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code e6543 too many taught points for avc. Occurs when the number of taught points between the weld start point and the weld end point exceeds 127 points. ⇒ reteach program points, n...

Page 161: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-158 august 9, 2005 ka a a w s k error code e8200 not in cooperative mode. Cooperative motion instruction is taught before master/slave instruction or after alone instruction. ⇒ use cooperative motion instructions between...

Page 162: Ka A A

Troubleshooting 1-159 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k 1.3.2.3 pxxxx operation error codes error code p0100 illegal input data. As language command/instruction does not comply with as language syntax. ⇒ enter as language command/instruction in...

Page 163: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-160 august 9, 2005 ka a a w s k error code p0106 illegal priority. Priority level designation is out of the allowable range (1–127) . Example: lock 128 ⇒ ensure the correct priority level number is entered (1–127). Examp...

Page 164: Ka A A

Troubleshooting 1-161 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p0111 cannot use this command/instruction in current mode. The command/instruction entered could not be executed in the selected mode. Example: “edit” is entered in the program ...

Page 165: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-162 august 9, 2005 ka a a w s k error code p0117 invalid variable (or program) name. Displayed when illegal variable or program name is entered from the editor or monitor modes. Example: “jm ##a” too many precision point...

Page 166: Ka A A

Troubleshooting 1-163 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p0121 expected to be a binary operator. A non-binary operator has been entered where a command expected a binary operator. ⇒ enter a binary operator. ___________________________...

Page 167: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-164 august 9, 2005 ka a a w s k error code p0126 illegal switch name. Displayed when a system switch is incorrectly identified. Example: “switch light” there is no system switch named “light”. ⇒ use valid switch names. _...

Page 168: Ka A A

Troubleshooting 1-165 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p0131 no. Of dimension in array exceeds 3. Attempted to create an array variable with more than 3 dimensions. Example: “point[3,5,7,9]=1” returns an error. ⇒ use 3 or less dimen...

Page 169: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-166 august 9, 2005 ka a a w s k error code p0135 local variable expected. A global variable is used when defining a temporary argument for a subroutine. Example: “sub(a)” returns an error. ⇒ use a local variable when def...

Page 170: Ka A A

Troubleshooting 1-167 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p0139 illegal control structure. Main causes include: 1. In a control structure case is the last step, or value, end, or any are missing after case. 2. Destination step for stru...

Page 171: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-168 august 9, 2005 ka a a w s k error code p0144 step:xx preceding if missing. Displayed when control flow structure does not contain the correct structure for if…then… else…end commands. ⇒ use correct syntax and compone...

Page 172: Ka A A

Troubleshooting 1-169 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p0149 variable (or program) already exists. The name of a program, loaded from floppy disk or pc card using the load command, already exists in the system memory. This error is ...

Page 173: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-170 august 9, 2005 ka a a w s k error code p0153 illegal clock value. Time or date is entered in the wrong format. ⇒ re-enter the values correctly; time—military, date—yy/mm/dd. __________________________________________...

Page 174: Ka A A

Troubleshooting 1-171 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p0158 missing “by”. The argument is missing the necessary “by”. Example: “point y = shift (x 5,5,5) ⇒ ensure command/instruction complies with as language syntax and format. Exa...

Page 175: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-172 august 9, 2005 ka a a w s k error code p0162 cannot modify position data in this instruction. During modifying an as language program from the teach screen, pose data is modi- fied at a step with a non-positional com...

Page 176: Ka A A

Troubleshooting 1-173 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p1003 cannot execute a program because of ext.Hold input. An attempt to cycle start a program is made while external hold signal is on. ⇒ release the external hold and re-execut...

Page 177: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-174 august 9, 2005 ka a a w s k error code p1009 program is already running. Main causes include: 1. An attempt is made to edit or execute a program that is running. 2. Sysinit command is executed while a program is runn...

Page 178: Ka A A

Troubleshooting 1-175 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p1014 cannot execute because program already in use. An attempt to execute the same program using the execute and pcexecute is made. ⇒ allow the program to complete executing an...

Page 179: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-176 august 9, 2005 ka a a w s k error code p1019 pc program is running. Occurs when a pc program is running and instructions are entered that are not allowed. ⇒ allow the pc program to complete execution and re-enter the...

Page 180: Ka A A

Troubleshooting 1-177 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p1024 statement cannot be executed. Occurs when the as language instruction entered is not acceptable for the mode of operation. Example: do home is executed with teach lock on....

Page 181: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-178 august 9, 2005 ka a a w s k error code p1029 program name not specified. Displayed when no program is on the stack and the edit command is entered without specifying a program name. ⇒ specify the name of the program ...

Page 182: Ka A A

Troubleshooting 1-179 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p1034 this program is not editable. The auto load measurement program cannot be edited. ⇒ use a program name that does not include the auto load measurement program name. ______...

Page 183: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-180 august 9, 2005 ka a a w s k error code p1039 teach pendant is not connected . The “t” command is executed without the teach pendant connected. ⇒ install teach pendant and re-execute the “t” command. _________________...

Page 184: Ka A A

Troubleshooting 1-181 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p2000 turn off motor power. An attempt is made to execute an operation or command which is not permitted with motor power on. Example: zzero command. ⇒ turn motor power off and ...

Page 185: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-182 august 9, 2005 ka a a w s k error code p2006 option is off. Selected option is set off (disabled) or is not installed. ⇒ enable option or contact kri customer service to install option. ______________________________...

Page 186: Ka A A

Troubleshooting 1-183 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p2011 invalid disk format. Incorrect disk format. ⇒ ensure the disk format is: 2hd, 1.44 mb or 1.25 mb. _____________________________________________________________________ err...

Page 187: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-184 august 9, 2005 ka a a w s k error code p2016 cannot open the file. The file cannot be opened with the save or load commands. ⇒ ensure the floppy disk is properly inserted into the floppy disk drive. ⇒ ensure an exist...

Page 188: Ka A A

Troubleshooting 1-185 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p2022 cannot use double ox. When double type signals are used, if either output signal in the pair is set on, the other is set to off. An instruction (bits, pulse, dlysig, etc.)...

Page 189: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-186 august 9, 2005 ka a a w s k error code p2026 invalid coordinate value z. This error occurs when the work space output signal lower z value is greater than the upper value in aux 0403. ⇒ ensure upper and lower values ...

Page 190: Ka A A

Troubleshooting 1-187 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p2032 incorrect number input as where parameter. Occurs if a numeric value entered with the where command is not in the acceptable range. Example: where 100. ⇒ ensure that data ...

Page 191: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-188 august 9, 2005 ka a a w s k error code p2039 cannot start cycle from fn instruction. This error occurs when an fn instruction is the first step at cycle start. ⇒ do not execute cycle start at a step containing an fn ...

Page 192: Ka A A

Troubleshooting 1-189 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p2045 cannot format this card. An attempt is made to format a non-sram pc card. ⇒ use a pc to format a non-sram card . __________________________________________________________...

Page 193: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-190 august 9, 2005 ka a a w s k error code p2051 illegal sequence numbers for file i/o data. During data transfer between the 1ka and 1kf boards, the response from the 1kf board does not conform to the request from the 1...

Page 194: Ka A A

Troubleshooting 1-191 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p2055 [lseq] program is already running. During execution of the basic operation part of the sequence function of the klogic program, the program is executed again by the lsqexe...

Page 195: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-192 august 9, 2005 ka a a w s k error code p2059 [serialflash] data write error. The specified file cannot be written to the 1ka board. Main causes include: 1. The file is corrupt. 2. The serial flash memory on the 1ka b...

Page 196: Ka A A

Troubleshooting 1-193 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p2064 [fdd] no space available. Floppy disk has less than 12 kb of free space and the data cannot be saved. ⇒ insert a floppy disk with sufficient free space and re-execute. ⇒ d...

Page 197: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-194 august 9, 2005 ka a a w s k error code p2069 [fdd/pc_card] device already in use. Attempting to perform several processes at the same time to/from the floppy disk/pc card. The next task is commanded while the previou...

Page 198: Ka A A

Troubleshooting 1-195 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p2074 floppy disk is broken. This error occurs when ten or more defective sectors are detected on a floppy disk. ⇒ use a new or known good floppy disk. _________________________...

Page 199: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-196 august 9, 2005 ka a a w s k error code p4502 devnet) already in that mode. An attempt is made to change the operation mode setting, using the devnet com- mand, to the mode that is currently set. ⇒ ensure the correct ...

Page 200: Ka A A

Troubleshooting 1-197 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p5002 spot sequence is running. Step change, program change, or program execution attempted while the spot weld sequence is executing (after retract/extend input signal and weld...

Page 201: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-198 august 9, 2005 ka a a w s k error code p6500 cannot generate working line direction. This error occurs when weld start and end points are the same, and motion direction cannot be determined. ⇒ ensure the start and en...

Page 202: Ka A A

Troubleshooting 1-199 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code p7000 cannot program reset, because not at home position 1. The robot is not at the registered home 1 position, and the program reset signal is ignored. ⇒ ensure the robot is at...

Page 203: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-200 august 9, 2005 ka a a w s k 1.3.2.4 wxxxx mechanical/control warning error codes error code w1000 cannot move along straight line jtxx in this configuration. When operating manually in teach mode and in base or tool ...

Page 204: Ka A A

Troubleshooting 1-201 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code w1005 illegal center of gravity, default parameter is set. Load mass value is set to a value other than zero, but the center of gravity is set to all zeroes. ⇒ enter the correct...

Page 205: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-202 august 9, 2005 ka a a w s k error code w1010 ram battery low voltage. Main causes include: 1. Backup battery voltage below minimum value (3.3 vdc or less). 2. Defective battery harness. 3. Defective 1ka board. ⇒ back...

Page 206: Ka A A

Troubleshooting 1-203 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code w1013 encoder battery low voltage [servo (xx)]. Voltage of the encoder back up battery on the 1fg/1hg board decreased to 3.3 volts or less, or the encoder battery alarm signal (...

Page 207: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-204 august 9, 2005 ka a a w s k error code w1015 possibility of failure. The monitored value of i 2 (current squared) exceeds the normal value for the monitored program and indicates excessive wear in the cyclo reduction...

Page 208: Ka A A

Troubleshooting 1-205 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code w1018 network parameter is changed. Turn off & on the control power. When network setting data is changed, the controller power must be cycled off and on. ⇒ cycle controller pow...

Page 209: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-206 august 9, 2005 ka a a w s k error code w4501 field-bus) master port offline. Master port is offline due to communication line termination. ⇒ check the slave and communication line and repair as necessary . When repai...

Page 210: Ka A A

Troubleshooting 1-207 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code w5004 weld controller xx response error. During communication with the weld controller, data received from the weld controller does not conform to the specified protocol. ⇒ ensu...

Page 211: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-208 august 9, 2005 ka a a w s k error code w5007 (spot welding) weld fault xx. This error occurs when a weld complete signal is not received by the robot controller from the remote weld controller (rwc), or there is an e...

Page 212: Ka A A

Troubleshooting 1-209 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k error code w5010 (spot welding) main cable exchange alarm xx. The present value of the counter for the specified weld gun exceeds the set value for initiating an alarm to replace the main ...

Page 213: Ka A A

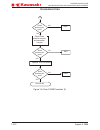

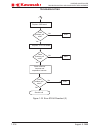

Troubleshooting d series controller troubleshooting and component replacement 1-210 august 9, 2005 ka a a w s k 1.4 troubleshooting flowcharts the following flowcharts are arranged by error code number. Refer also to the corre- sponding error code information in section 1.3.2.2 during troubleshootin...

Page 214: Ka A A

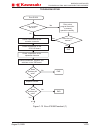

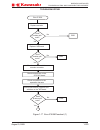

Troubleshooting 1-211 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-5 error e1029 flowchart (1) error e1029 end no check connections at the encoder connector check connections on the 1fg/1hg board check connections in the separation harness check ...

Page 215: Ka A A

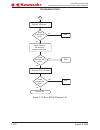

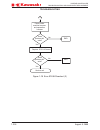

Troubleshooting d series controller troubleshooting and component replacement 1-212 august 9, 2005 ka a a w s k figure 1-6 error e1029 flowchart (2) service call a replace 1fg/1hg board does problem still exist? End no yes does problem still exist? End no yes does problem still exist? End no yes che...

Page 216: Ka A A

Troubleshooting 1-213 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-7 error e1032 flowchart (1) error e1032 no check connections at the encoder connector check connections on the 1fg/1hg board check connections in the separation harness check conn...

Page 217: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-214 august 9, 2005 ka a a w s k figure 1-8 error e1032 flowchart (2) service call a replace 1fg/1hg board does problem still exist? End no yes does problem still exist? End no yes does problem still exist? End no yes che...

Page 218: Ka A A

Troubleshooting 1-215 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-9 error e1034 flowchart (1) error e1034 does the encoder revolve over 300 rpm? (for conveyor encoder) check connections at the encoder connector does problem still exist? End redu...

Page 219: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-216 august 9, 2005 ka a a w s k figure 1-10 error e1034 flowchart (2) replace 1fg/1hg board service call a check machine harness and separation harness replace 1kb board does problem still exist? End no yes does problem ...

Page 220: Ka A A

Troubleshooting 1-217 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-11 error e1035 flowchart (1) error e1035 can y ou reset the error? Check connections at the encoder connector does problem still exist? End retr y robot program execution or manua...

Page 221: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-218 august 9, 2005 ka a a w s k figure 1-12 error e1035 flowchart (2) service call a replace 1kb board does problem still exist? End no yes does problem still exist? End no yes replace 1fg/1hg board does problem still ex...

Page 222: Ka A A

Troubleshooting 1-219 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-13 error e1036 flowchart (1) error e1036 can y ou reset the error? Check connections at the encoder connector does problem still exist? End retr y robot program execution or manua...

Page 223: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-220 august 9, 2005 ka a a w s k figure 1-14 error e1036 flowchart (2) service call a replace 1kb board does problem still exist? End no yes does problem still exist? End no yes replace 1fg/1hg board does problem still ex...

Page 224: Ka A A

Troubleshooting 1-221 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-15 error e1037 flowchart (1) error e1037 can y ou reset the error? Retr y robot program execution or manual operation carefull y end yes does the error reoccur? No no yes check co...

Page 225: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-222 august 9, 2005 ka a a w s k figure 1-16 error e1037 flowchart (2) service call a replace 1fg/1hg board does problem still exist? End no yes does problem still exist? End no yes does problem still exist? End no yes ch...

Page 226: Ka A A

Troubleshooting 1-223 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-17 error e1038 flowchart (1) error e1038 end check connections at the encoder connector check connections on the 1fg/1hg board check connections in the separation harness check co...

Page 227: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-224 august 9, 2005 ka a a w s k figure 1-18 error e1038 flowchart (2) service call a replace 1fg/1hg board does problem still exist? End no yes does problem still exist? End no yes check inside machine harness and separa...

Page 228: Ka A A

Troubleshooting 1-225 august 9, 2005 d series controller troubleshooting and component replacement ka a a w s k figure 1-19 error e1039 flowchart (1) error e1039 check connections at the encoder connector check connections on the 1fg/1hg board check connections in the separation harness check connec...

Page 229: Ka A A

Troubleshooting d series controller troubleshooting and component replacement 1-226 august 9, 2005 ka a a w s k figure 1-20 error e1039 flowchart (2) service call a replace 1fg/1hg board does problem still exist? End no yes does problem still exist? End no yes does problem still exist? End no yes ch...

Page 230: Ka A A

D series controller troubleshooting and component replacement 2-1 ka a a w s k 2.0 component replacement this chapter describes replacement procedure for parts inside the controller: printed boards, power blocks, hardware including avr, etc., and, units. 2.1 general safety precautions on replacement...

Page 231: Ka A A

D series controller troubleshooting and component replacement 2-2 ka a a w s k 2.1 general safety precautions on replacement this section describes the precautions to be taken when replacing parts due to trouble, etc. This information is presented here for use as general precautions. In addition to ...

Page 232: Ka A A

D series controller troubleshooting and component replacement 2-3 ka a a w s k 7. Use only kawasaki approved parts during replacement. 8. When replacing printed boards, do not fail to turn off control power. To replace power block, mc unit, or avr, wait at least seven minutes after control power off...

Page 233: Ka A A

D series controller troubleshooting and component replacement 2-4 ka a a w s k 18. Printed boards and power blocks are designed differently for each robot model. Be sure to replace the correct type. 19. When air or water is supplied, shut off the supply source and purge any remaining pressure from t...

Page 234: Ka A A

D series controller troubleshooting and component replacement 2-5 ka a a w s k 2.2.1 1ka board (user i/f board) 1. This is the user i/f board used for storing taught pose data, user program data, etc. In memory. Before replacing the board, be sure to save all data to storage media such as pccard, fd...

Page 235: Ka A A

D series controller troubleshooting and component replacement 2-6 ka a a w s k 2.2.2 1kb board (arm control board) 1. Turn off the control power. 2. Press the red button on the ejector of the 1kb board to release the lock, and pull out the 1kb from the card rack by extending the ejector up and down....

Page 236: Ka A A

D series controller troubleshooting and component replacement 2-7 ka a a w s k 2 .2.3 1kp board (power sequence board) 1. Turn off the control power. 2. Loosen the screws on top and bottom of the 1kp board, and pull out the 1kp from the card rack by holding the ejectors at both ends of the board. If...

Page 237: Ka A A

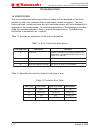

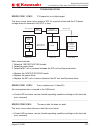

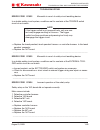

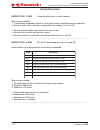

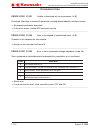

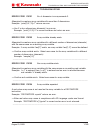

D series controller troubleshooting and component replacement 2-8 ka a a w s k 6. Confirm the voltage at each check pin on the 1ka and 1kp as shown below. 1ka board no. Color standard allowable range if the voltage is out of allowable range, tp2 yellow − 12.0 v − 11.95 v ∼ − 12.05 v adjust the volum...

Page 238: Ka A A

D series controller troubleshooting and component replacement 2-9 ka a a w s k 2 .2.5 1nr board (brake control board) 1. Turn off the control power. 2. Loosen the screws on top and bottom of the 1nr board, and pull out the 1nr from the card rack by holding the ejectors at both ends of the board. If ...

Page 239: Ka A A

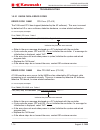

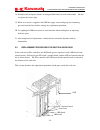

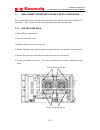

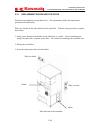

D series controller troubleshooting and component replacement 2-10 ka a a w s k 2.3 replacement procedure for power block unit this section describes the replacement procedure for the power block unit mounted in the controller. Four types of power block are available as described below. 1. 1kc: powe...

Page 240: Ka A A

D series controller troubleshooting and component replacement 2-11 ka a a w s k 1. Remove all connectors connected to the power block unit. 2. Loosen the four screws fixing the power block unit to the controller so that the power block unit can be removed from the controller. (these screws are not r...

Page 241: Ka A A