- DL manuals

- Kawasaki

- Motorcycle

- VN1600 MEAN STREAK - SERVICE

- Service Manual

Kawasaki VN1600 MEAN STREAK - SERVICE Service Manual

VULCAN 1600 MEAN STREAK

VN1600 MEAN STREAK

Motorcycle

Service Manual

2004 VULCAN 1600 MEAN STREAK, VN1600 MEAN STREAK

Motorcycle Service Manual

Part No. 99924-1321-01

KAWASAKI HEAVY INDUSTRIES, LTD.

Consumer Products & Machinery Company

Printed in Japan

Year

Model

Beginning Frame No.

□

: This digit in the frame number changes from one machine

to another.

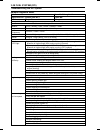

MODEL APPLICATION

2004

VN1600-B1

JKBVNKB1

□

4A000001 or

JKBVNT60BBA000001

Summary of VN1600 MEAN STREAK - SERVICE

Page 1

Vulcan 1600 mean streak vn1600 mean streak motorcycle service manual 2004 vulcan 1600 mean streak, vn1600 mean streak motorcycle service manual part no. 99924-1321-01 kawasaki heavy industries, ltd. Consumer products & machinery company printed in japan year model beginning frame no. □ : this digit ...

Page 3: Quick Reference Guide

Quick reference guide general information 1 j periodic maintenance 2 j fuel system (dfi) 3 j cooling system 4 j engine top end 5 j clutch 6 j engine lubrication system 7 j engine removal/installation 8 j crankshaft/transmission 9 j wheels/tires 10 j final drive 11 j brakes 12 j suspension 13 j steer...

Page 5: Vulcan 1600 Mean Streak

Vulcan 1600 mean streak vn1600 mean streak all rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of quality assura...

Page 6

List of abbreviations a ampere(s) lb pound(s) abdc after bottom dead center m meter(s) ac alternating current min minute(s) atdc after top dead center n newton(s) bbdc before bottom dead center pa pascal(s) bdc bottom dead center ps horsepower btdc before top dead center psi pound(s) per square inch...

Page 7

Emission control information to protect the environment in which we all live, kawasaki has incorporated crankcase emis- sion (1) and exhaust emission (2) control systems in compliance with applicable regulations of the united states environmental protection agency and california air resources board....

Page 8

We recommend that all dealers observe these provisions of federal law, the violation of which is punishable by civil penalties not exceeding $10,000 per violation. Tampering with noise control system prohibited federal law prohibits the following acts or the causing thereof: (1) the removal or rende...

Page 9: Foreword

Foreword this manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic in- formation to make it useful to the owner who de- sires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the prope...

Page 11: General Information

General information 1-1 1 general information table of contents before servicing ..................................................................................................................... 1-2 model identification................................................................................

Page 12

1-2 general information before servicing before starting to perform an inspection service or carry out a disassembly and reassembly opera- tion on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustra- tions, photographs, cautions, and detailed descriptions...

Page 13

General information 1-3 before servicing arrangement and cleaning of removed parts disassembled parts are easy to confuse. Arrange the parts according to the order the parts were disassembled and clean the parts in order prior to assembly. Storage of removed parts after all the parts including subas...

Page 14

1-4 general information before servicing tightening sequence bolts, nuts, or screws must be tightened according to the specified sequence to prevent case warpage or deformation which can lead to malfunction. If the specified tightening sequence is not indicated, tighten the fasteners alternating dia...

Page 15

General information 1-5 before servicing press for items such as bearings or oil seals that must be pressed into place, apply small amount of oil to the con- tact area. Be sure to maintain proper alignment and use smooth movements when installing. Ball bearing and needle bearing do not remove presse...

Page 16

1-6 general information before servicing direction of engine rotation when rotating the crankshaft by hand, the free play amount of rotating direction will affect the adjustment. Ro- tate the crankshaft to positive direction (clockwise viewed from output side). Electrical wires a two-color wire is i...

Page 17

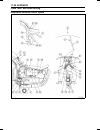

General information 1-7 model identification vn1600-b1 (us, and canada) left side view: vn1600-b1 (us, and canada) right side view:.

Page 18

1-8 general information model identification vn1600-b1 (europe) left side view: vn1600-b1 (europe) right side view:.

Page 19

General information 1-9 general specifications items vn1600–b1 dimensions: overall length 2 410 mm (94.9 in.) overall width 850 mm (33.5 in.) overall height 1 100 mm (43.3 in.) wheelbase 1 705 mm (67.1 in.) road clearance 125 mm (4.92 in.) seat height 700 mm (27.6 in.) dry mass 290 kg (639 lb) curb ...

Page 20

1-10 general information general specifications items vn1600–b1 capacity 3.5 l (3.7us qt, when engine is completely disassembled and dry) drive train: primary reduction system: type gear reduction ratio 1.517 (85/56) clutch type wet multi disc transmission: type 5-speed, constant mesh, return shift ...

Page 21

General information 1-11 general specifications items vn1600–b1 electrical equipment: battery capacity 12 v 18 ah headlight: type semi-sealed beam bulb 12 v 60/55 w (quartz-halogen) tail/brake light 12 v 5/21 w alternator: type three-phase ac rated output 23 a × 14 v @6 000 r/min (rpm) specification...

Page 22

1-12 general information unit conversion table prefixes for units: prefix symbol power mega m × 1 000 000 kilo k × 1 000 centi c × 0.01 milli m × 0.001 micro µ × 0.000001 units of mass: kg × 2.205 = lb g × 0.03527 = oz units of volume: l × 0.2642 = gal (us) l × 0.2200 = gal (imp) l × 1.057 = qt (us)...

Page 23: Periodic Maintenance

Periodic maintenance 2-1 2 periodic maintenance table of contents periodic maintenance chart .............. 2-2 torque and locking agent................. 2-4 specifications .................................... 2-10 special tools ..................................... 2-12 periodic maintenance procedu...

Page 24

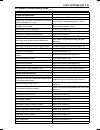

2-2 periodic maintenance periodic maintenance chart the scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running condition.The initial maintenance is vitally important and must not be neglected. Frequency whichever comes first * odometer reading km × 10...

Page 25

Periodic maintenance 2-3 periodic maintenance chart frequency whichever comes first * odometer reading km × 1000 (mile × 1000) 1 12 24 36 48 see change/replace item every (0.6) (7.5) (15) (24) (30) page spark plug (e) • • • 2–33 engine oil # year • • • • 2–22 oil filter year • • • • 2–24 coolant 3 y...

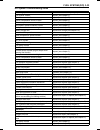

Page 26

2-4 periodic maintenance torque and locking agent the following tables list the tightening torque for the major fasteners requiring use of a non -permanent locking agent or liquid gasket. Letters used in the “remarks” column mean: g: apply grease to the threads. Eo: apply engine oil to the threads a...

Page 27

Periodic maintenance 2-5 torque and locking agent torque fastener n·m kgf·m ft·lb remarks radiator fan switch 18 1.8 13 radiator fan bolts 8.3 0.85 74 in·lb water temperature switch 7.8 0.80 69 in·lb ss water pump impeller bolt 8.8 0.90 78 in·lb lh water pump cover bolts 11 1.1 97 in·lb water pump a...

Page 28

2-6 periodic maintenance torque and locking agent torque fastener n·m kgf·m ft·lb remarks starter lockout switch screws 1.2 0.12 10 in·lb push rod guide bolts 11 1.1 95 in·lb l clutch cover bolts 11 1.1 95 in·lb clutch damper cover bolts 9.8 1.0 87 in·lb l clutch damper plate bolts 9.8 1.0 87 in·lb ...

Page 29

Periodic maintenance 2-7 torque and locking agent torque fastener n·m kgf·m ft·lb remarks oil hose banjo bolts 9.8 1.0 87 in·lb primary gear bolt 147 15 108 mo water pump chain guide spring hook bolt 2.9 0.30 26 in·lb water pump chain guide bolt 8.3 0.85 73 in·lb idle shaft holder bolts 8.3 0.85 73 ...

Page 30

2-8 periodic maintenance torque and locking agent torque fastener n·m kgf·m ft·lb remarks final gear case studs – – – l final gear case cover bolts: 8 mm 23 2.3 17 l 10 mm 34 3.5 25 l pinion gear nut (final gear) 127 13 93 mo, st bearing retainer bolt 6.9 0.70 61 in·lb l brakes: caliper bleed valves...

Page 31

Periodic maintenance 2-9 torque and locking agent torque fastener n·m kgf·m ft·lb remarks sidestand nut 44 4.5 32 electrical system: spark plugs 18 1.8 13 crankshaft sensor screws 2.9 0.30 26 in·lb stator lead holder screw 9.8 1.0 87 in·lb l crankshaft sensor lead holder bolt 2.9 0.30 26 in·lb l alt...

Page 32

2-10 periodic maintenance specifications item standard service limit fuel system (dfi): throttle grip free play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) – – – idle speed 950 ±50 r/min (rpm) – – – air cleaner element paper filter – – – cooling system: coolant: type (recommended) permanent type antifreeze – – – col...

Page 33

Periodic maintenance 2-11 specifications item standard service limit final drive: final gear case oil: grade api service classification: gl-5 – – – hypoid gear oil viscosity when above 5°c (41°f) sae90 – – – when below 5°c (41°f) sae80 oil level filler opening bottom – – – amount 200 ml (6.76 us oz)...

Page 34

2-12 periodic maintenance special tools steering stem nut wrench: 57001–1100 jack: 57001–1238 attachment jack: 57001–1398 driver-filler cap: 57001–1454.

Page 35

Periodic maintenance 2-13 periodic maintenance procedures fuel system (dfi) fuel hose and connection inspection ○ the fuel hoses are designed to be used throughout the motorcycle’s life without any maintenance, however, if the motorcycle is not properly handled, the high pressure in- side the fuel l...

Page 36

2-14 periodic maintenance periodic maintenance procedures idle speed inspection • start the engine and warm it up thoroughly. ○ at first the engine will run fast to decrease warm up time (fast idle). ○ gradually the fast idle will lower to a certain rpm auto- matically. This is the idle speed. • che...

Page 37

Periodic maintenance 2-15 periodic maintenance procedures • clean the element by tapping it lightly to loosen dust. • blow away the remaining dust by applying compressed air [a] from the inside to the outside (from the clean side to the dirty side). • visually check the element for no tears or no br...

Page 38

2-16 periodic maintenance periodic maintenance procedures cooling system radiator hose and connection inspection ○ the high pressure inside the radiator hose can cause coolant to leak [a] or the hose to burst if the line is not properly maintained. Visually inspect the hoses for signs of deteriorati...

Page 39

Periodic maintenance 2-17 periodic maintenance procedures • remove : right side cover (see frame chapter) reserve tank bolts • turn over the reserve tank [a], remove the cap [b], and pour the coolant into a suitable container. • install the reserve tank. • when filling the coolant, choose a suitable...

Page 40

2-18 periodic maintenance periodic maintenance procedures • fill the radiator up to the filler neck [a] with coolant. • install the radiator cap. • tighten the air bleeder bolt [b]. Torque - thermostat air bleeder bolt: 7.8 n·m (0.80 kgf·m, 69 in·lb) • fill the reserve tank up to the “f” (full) leve...

Page 41

Periodic maintenance 2-19 periodic maintenance procedures clutch clutch hose and connection inspection • the high pressure inside the clutch line can cause fluid to leak [a] or the hose to burst if the line is not properly maintained. Bend and twist the rubber hose while exam- ining it. Replace it i...

Page 42

2-20 periodic maintenance periodic maintenance procedures clutch fluid change • level the clutch fluid reservoir and remove the reservoir cap. • remove the alternator outer cover (see electrical system chapter.) and the rubber cap from the bleed valve on the clutch slave cylinder. • attach a clear p...

Page 43

Periodic maintenance 2-21 periodic maintenance procedures clutch master cylinder cup and dust seal replacement • remove the clutch master cylinder (see clutch chapter). • remove the reservoir cap [a] and diaphragm [b], and pour the clutch fluid into a container. • unscrew the locknut [c] and pivot b...

Page 44

2-22 periodic maintenance periodic maintenance procedures clutch slave cylinder piston seal replacement • remove the alternator outer cover (see electrical system chapter) • loosen the banjo bolt [a] at the clutch pipe lower end, and tighten it loosely. • unscrew the slave cylinder bolts [b] and det...

Page 45

Periodic maintenance 2-23 periodic maintenance procedures • remove: oil screen plug [a] • remove the oil screen [a], the spring [b], and the washer [c]. • clean the oil screen with a high-flash point solvent and remove any particles stuck to it. • clean the screen thoroughly whenever the engine oil ...

Page 46

2-24 periodic maintenance periodic maintenance procedures engine oil type: api se, sf or sg class api sh or sj class with jaso ma viscosity: sae 10w-40 amount: 2.9 l (3.1 us qt, when filter is not removed) 3.1 l (3.3 us qt, when filter is removed) 3.5 l (3.7 us qt, when engine is completely disassem...

Page 47

Periodic maintenance 2-25 periodic maintenance procedures • measure the tread depth at the center of the tread with a depth gauge [a]. Since the tire may wear unevenly, take measurement at several places. If any measurement is less than the service limit, replace the tire (see wheels/tires chapter)....

Page 48

2-26 periodic maintenance periodic maintenance procedures • the oil level [a] should come to the bottom of the filler opening. If it is low, first check the final gear case for oil leakage, remedy it if necessary, and add oil through the filler open- ing. Use the same type and brand of oil that is a...

Page 49

Periodic maintenance 2-27 periodic maintenance procedures brakes brake pad wear inspection • unscrew the bolts [a] and remove the pad spring [b] (front brake caliper) • unscrew the bolts [a] and remove the caliper [b] (rear brake caliper). • check the lining thickness [a] of the pads in each caliper...

Page 50

2-28 periodic maintenance periodic maintenance procedures brake fluid level inspection • check that the brake fluid level in the front brake reservoir [a] is above the lower [b] level line. Note ○ hold the reservoir horizontal by turning the handlebar when checking brake fluid level. If the fluid le...

Page 51

Periodic maintenance 2-29 periodic maintenance procedures brake fluid change note ○ the procedure to change the front brake fluid is as fol- lows. Changing the rear brake fluid is almost the same as for the front brake. • level the brake fluid reservoir. • remove the reservoir cap [a], plate [b] and...

Page 52

2-30 periodic maintenance periodic maintenance procedures • remove the clear plastic hose. • install the reservoir cap. • follow the procedure below to install the rear brake fluid reservoir cap correctly. ○ first, tighten the rear brake fluid reservoir cap [b] clock- wise [c] by hand until the resi...

Page 53

Periodic maintenance 2-31 periodic maintenance procedures if it does not, adjust the brake light switch. • while holding the switch body, turn the adjusting nut to adjust the switch. Switch body [a] adjusting nut [b] light sooner as the body rises [c] light later as the body lowers [d] caution to av...

Page 54

2-32 periodic maintenance periodic maintenance procedures steering stem bearing lubrication • remove the steering stem. (see steering chapter). • using a high-flash point solvent, wash the upper and lower tapered roller bearings [a] in the cages, and wipe the upper and lower outer races, which are p...

Page 55

Periodic maintenance 2-33 periodic maintenance procedures • remove the claw washer. • tighten the stem nut [a] firmly with the stem nut wrench [b], and loosen it. • tighten the stem nut again with the specified torque. Special tool - steering stem nut wrench: 57001-1100 torque - steering stem nut: 4...

Page 56

2-34 periodic maintenance periodic maintenance procedures points: lubricate with grease. Throttle inner cable upper ends [a] clutch lever pivot (apply silicone grease) brake lever pivot (apply silicone grease) brake pedal pivot sidestand cable: lubricate with cable lubricant. Choke cable throttle ca...

Page 57

Periodic maintenance 2-35 periodic maintenance procedures nut, bolt and fastener to be checked wheels: front axle front axle clamp bolts rear axle nut rear axle nut cotter pin final drive: final gear case mounting nuts brakes: front master cylinder clamp bolts caliper mounting bolts rear master cyli...

Page 59: Fuel System (Dfi)

Fuel system (dfi) 3-1 3 fuel system (dfi) table of contents exploded view................................... 3-4 dfi parts location............................. 3-8 dfi system........................................ 3-12 dfi wiring diagram ........................... 3-14 specifications ...............

Page 60

3-2 fuel system (dfi) resistance inspection.................. 3-86 fuel line............................................ 3-88 fuel pressure inspection ............. 3-88 pressure regulator removal....... 3-90 fuel flow rate inspection ........... 3-90 throttle grip and cables ................... 3-9...

Page 62

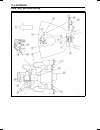

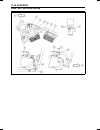

3-4 fuel system (dfi) exploded view.

Page 63

Fuel system (dfi) 3-5 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 water temperature sensor 18 1.8 13 ss 2 left air cleaner cover allen bolt 16 1.6 12 3 left air cleaner base bolts 11 1.1 97 in·lb 4 left air cleaner base screws 2.2 0.22 19 in·lb l 5 right air cleaner base screws 2.2 0...

Page 64

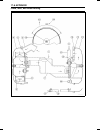

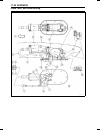

3-6 fuel system (dfi) exploded view.

Page 65

Fuel system (dfi) 3-7 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 fuel pump bolts 6.9 0.70 61 in·lb s, l 2 inlet air temperature sensor nut 7.8 0.80 69 in·lb 3 isc pipe bolts 11 1.1 97 in·lb 4 throttle body assy holder bolts 11 1.1 97 in·lb 5 spark plug lead holder bolts 11 1.1 97 in...

Page 66

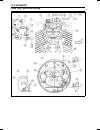

3-8 fuel system (dfi) dfi parts location.

Page 67

Fuel system (dfi) 3-9 dfi parts location dfi: dfi parts (this chapter) f: front 1. Atmospheric pressure sensor (dfi) 2. Water temperature sensor (dfi) 3. Ignition coils 4. Ignition switch 5. Starter motor 6. Water temperature switch 7. Regulator/rectifier 8. Crankshaft sensors 9. Alternator 10. Side...

Page 68

3-10 fuel system (dfi) dfi parts location.

Page 69

Fuel system (dfi) 3-11 dfi parts location dfi: dfi parts (this chapter) f: front 1. Atmospheric pressure sensor (dfi) 2. Water temperature sensor (dfi) 3. Ignition coils 4. Ignition switch 5. Starter motor 6. Water temperature switch 7. Regulator/rectifier 8. Crankshaft sensors 9. Alternator 10. Sid...

Page 70

3-12 fuel system (dfi) dfi system.

Page 71

Fuel system (dfi) 3-13 dfi system #1: for front cylinder #2: for rear cylinder 1. Ecu (electronic control unit) 2. Crankshaft sensor #1 3. Crankshaft sensor #2 4. Pressure regulator 5. Throttle sensor (front view) 6. Atmospheric pressure sensor 7. Inlet air pressure sensor 8. Water temperature senso...

Page 72

3-14 fuel system (dfi) dfi wiring diagram.

Page 73

Fuel system (dfi) 3-15 dfi wiring diagram dfi and electrical parts dfi: dfi parts a. Ecu: electronic control unit (dfi) b. Engine stop switch c. Starter button d. Ignition coils e. Crankshaft sensors f. Junction box g. Starter circuit relay h. Interlock diodes j. Diode: (for water temperature warnin...

Page 74

3-16 fuel system (dfi) dfi wiring diagram terminal numbers of ecu connectors terminal names #1: front cylinder, #2: rear cylinder 1. Starter lockout switch signal 2. Interlock circuit signal 3. Self-diagnosis signal (generated by grounding this terminal and shown by fi indicator led light) 4. Tachom...

Page 75

Fuel system (dfi) 3-17 specifications item standard throttle grip free play: 2 ∼ 3 mm (0.079 ∼ 0.118 in.) air cleaner element: paper filter dfi (digital fuel injection) system: make: mitsubishi electric idle speed: 950 ±50 r/min (rpm) throttle assy: type × bore two barrel type × 40 mm (1.57 in.) ecu...

Page 76

3-18 fuel system (dfi) specifications item standard water temperature sensor: resistance 2.162 ∼ 3.112 kΩ at 20° c (68° f) 0.785 ∼ 1.049 kΩ at 50° c (122° f) 0.207 ∼ 0.253 kΩ at 100° c (212° f) vehicle-down sensor: detection method magnetic flux detection method detection angle more than 45° ±5° for...

Page 77

Fuel system (dfi) 3-19 special tools and sealant oil pressure gauge, 5 kg/cm² : 57001–125 fork oil level gauge : 570101–1290 hand tester : 57001–1394 fuel pressure gauge adapter : 57001–1417 filler cap driver : 57001–1454 needle adapter set : 57001–1457 kawasaki bond (silicone sealant) : 56019–120

Page 78

3-20 fuel system (dfi) dfi servicing precautions there are a number of important precautions that should be followed servicing the dfi system. ○ to maintain the correct fuel-air mixture (f/a), there must be no inlet air leaks in the dfi system. Be sure to install the oil filler cap [a] after filling...

Page 79

Fuel system (dfi) 3-21 dfi servicing precautions ○ to prevent corrosion and deposits n the fuel system, do not add any fuel antifreeze chemicals to fuel. ○ when any fuel hose is disconnected, do not turn on the ignition sw. Otherwise, the fuel pump will operate and fuel will spout from the fuel hose...

Page 80

3-22 fuel system (dfi) dfi servicing precautions ○ fit the outlet hose joint #1 or #2 [a] onto the pipe until the joint clicks [b]. Front [c] ○ push and pull [a] the hose joint #1 or #2 [b] back and forth more than two times and make sure it is locked and doesn’t come off. When the hose joint is cor...

Page 81

Fuel system (dfi) 3-23 troubleshooting the dfi system outline when an abnormality in the system occurs, the fi indica- tor led light goes on to alert the rider on the meter panel. In addition, the condition of the problem is stored in the mem- ory of the ecu (electronic control unit). With the engin...

Page 82

3-24 fuel system (dfi) troubleshooting the dfi system ○ there are two ways to inspect the dfi system. One is voltage check method and the other is resistance check method. Voltage check method ○ this method is conducted by measuring the input voltage [b] to a sensor [a] first, and then the output vo...

Page 83

Fuel system (dfi) 3-25 troubleshooting the dfi system ○ after measurement, remove the needle adapters and ap- ply silicone sealant to the seals [a] of the connector [b] for waterproofing. Silicone sealant (kawasaki bond: 56019-120) - seals of connectors • always check battery condition before replac...

Page 84

3-26 fuel system (dfi) troubleshooting the dfi system if any wiring is deteriorated, replace the wiring. • pull each connector [a] apart and inspect it for corrosion, dirt, and damage. If the connector is corroded or dirty, clean it carefully. If it is damaged, replace it. Connect the connectors sec...

Page 85

Fuel system (dfi) 3-27 troubleshooting the dfi system dfi diagnosis flow chart inquiries to rider • refer to the next sample diagnosis chart. ○ each rider reacts to problems in different ways, so it is important to confirm what kind of symptoms the rider has encountered. ○ try to find out exactly wh...

Page 86

3-28 fuel system (dfi) troubleshooting the dfi system sample diagnosis sheet rider name: year of initial registration: registration no. (license plate no.): frame no.: model: engine no.: mileage: date problem occurred: environment when problem occurred. Weather □ fine, □ cloudy, □ rain, □ snow, □ al...

Page 87

Fuel system (dfi) 3-29 troubleshooting the dfi system poor running □ choke knob left pulled out fully (push it in fully). Or no power □ spark plug loose (tighten it). At high speed □ spark plug dirty, broken, or gap maladjusted (remedy it). □ spark plug incorrect (replace it). □ knocking (fuel poor ...

Page 88

3-30 fuel system (dfi) dfi system troubleshooting guide note ○ this is not an exhaustive list, giving every possible cause for each problem listed. It is meant simply as a rough guide to assist the troubleshooting for some of the more common difficulties. ○ the ecu may be involved in the dfi electri...

Page 89

Fuel system (dfi) 3-31 dfi system troubleshooting guide symptoms or possible causes actions (chapter) no spark or spark weak: ignition and engine stop switches not on turn both switches on. Clutch lever not pulled in and gear not in neutral whether sidestand up or not pull the lever in and shift the...

Page 90

3-32 fuel system (dfi) dfi system troubleshooting guide symptoms or possible causes actions (chapter) cylinder, piston worn inspect and replace (see chapter 5). Piston ring bad (worn, weak, broken or sticking) inspect and replace (see chapter 5). Piston ring/groove clearance excessive inspect and re...

Page 91

Fuel system (dfi) 3-33 dfi system troubleshooting guide symptoms or possible causes actions (chapter) fuel injector trouble inspect (see chapter 3). Throttle sensor trouble inspect (see chapter 3). Inlet air temperature sensor trouble inspect (see chapter 3). Water temperature sensor trouble inspect...

Page 92

3-34 fuel system (dfi) dfi system troubleshooting guide symptoms or possible causes actions (chapter) inlet air temperature sensor trouble inspect (see chapter 3). Throttle sensor malfunction inspect (see chapter 3). Water temperature sensor trouble inspect (see chapter 3). Atmospheric pressure sens...

Page 93

Fuel system (dfi) 3-35 dfi system troubleshooting guide symptoms or possible causes actions (chapter) throttle sensor malfunction inspect (see chapter 3). Inlet air temperature sensor trouble inspect (see chapter 3). Water temperature sensor trouble inspect (see chapter 3). Atmospheric pressure sens...

Page 94

3-36 fuel system (dfi) dfi system troubleshooting guide poor running or no power at high speed: symptoms or possible causes actions (detailed reference) firing incorrect: spark plug dirty, broken or maladjusted clean spark plug and adjust plug gap (see chapter 2). Spark plug cap or high tension wiri...

Page 95

Fuel system (dfi) 3-37 dfi system troubleshooting guide symptoms or possible causes actions (detailed reference) hla (hydraulic lash adjuster) damaged (worn, seizure or spring broken) inspect and replace (see chapter 5). Knocking: carbon buit up in combustion chamber repair (see chapter 5). Fuel poo...

Page 96

3-38 fuel system (dfi) dfi system troubleshooting guide symptoms or possible causes actions (detailed reference) air cleaner o-ring damaged replace (see chapter 3). Too low fuel pressure inspect (see chapter 3). Water temperature sensor trouble inspect and replace (see chapter 3). Inlet air temperat...

Page 97

Fuel system (dfi) 3-39 self-diagnosis self-diagnosis conducting ○ when a problem occurs with the dfi system, the dfi in- dicator led light [a] goes on. • remove the seat (see frame chapter). • with the ecu connector joined, the self-diagnosis mode by grounding the self-diagnosis check female connect...

Page 98

3-40 fuel system (dfi) self-diagnosis.

Page 99

Fuel system (dfi) 3-41 self-diagnosis service code reading ○ service codes are shown by a series of long and short blinks of the fi indicator led light as shown below. ○ read 10th digit and unit digit as the fi indicator led light blinks. ○ when there are a number of problems, all the service codes ...

Page 100

3-42 fuel system (dfi) self-diagnosis service code table service code fi indicator led light problems (1) 11 throttle sensor malfunction, wiring open or short 12 inlet air pressure sensor malfunction, wiring open or short 13 inlet air temperature sensor malfunction, wiring open or short 14 water tem...

Page 101

Fuel system (dfi) 3-43 self-diagnosis backups ○ the ecu takes the following measures to prevent engine damage when the dfi or the ignition system parts have troubles. Service codes parts output signal usable range or criteria backups by ecu 11 throttle sensor throttle valve opening angle α = – 4° ∼ ...

Page 102

3-44 fuel system (dfi) self-diagnosis service codes parts output signal usable range or criteria backups by ecu 51 ignition coil #1 the ignition coil primary winding must send signals (output voltage) continuously to the ecu. If the ignition primary winding #1 has failures (no signal, wiring short o...

Page 103

Fuel system (dfi) 3-45 throttle sensor (service code 11) throttle sensor removal/adjustment caution do not remove or adjust the throttle sensor [a] since it has been adjusted and set with precision at the factory. Never drop the sensor, especially on a hard surface. Such a shock to the sensor can da...

Page 104

3-46 fuel system (dfi) throttle sensor (service code 11) • remove the ecu (see this chapter). Do not disconnect the ecu connectors. • connect a digital meter [a] to the connector [b], using the needle adapters [c]. Special tool - needle adapter set: 57001–1457 caution insert the needle adapter strai...

Page 105

Fuel system (dfi) 3-47 throttle sensor (service code 11) a. Ecu c. Throttle sensor.

Page 106

3-48 fuel system (dfi) inlet air pressure sensor (service code 12) removal caution never drop the sensor, especially on a hard surface. Such a shock to the part can damage it. • remove the fuel tank (see fuel tank section in this chap- ter). • disconnect the inlet air pressure sensor connector [a]. ...

Page 107

Fuel system (dfi) 3-49 inlet air pressure sensor (service code 12) • turn the ignition sw on. Inlet air pressure sensor input voltage connections to ecu meter (+) → bl/w lead (terminal 35) meter (−) → br/bk lead (terminal 11) input voltage at ecu standard: 4.75 ∼ 5.25 v dc if the reading is less tha...

Page 108

3-50 fuel system (dfi) inlet air pressure sensor (service code 12) if the output voltage is normal, check the inlet air pressure sensor output voltage for vacuum other than 76 cmhg (abs) as follows. If the output voltage changes within the usable range as vacuum changes, the sensor is normal and the...

Page 109

Fuel system (dfi) 3-51 inlet air pressure sensor (service code 12) suppose: pg : vacuum (gauge) of throttle assy pl : local atmospheric pressure (absolute) measured by a barometer pv : vacuum (absolute) of throttle assy vv : sensor output voltage (v) then pv = pl – pg for example, suppose the follow...

Page 110

3-52 fuel system (dfi) inlet air pressure sensor (service code 12) pv = 55 ∼ 86 cm hg vv: inlet air pressure sensor output voltage (v) (digital meter reading) pv: throttle vacuum (absolute) ps: standard atmospheric pressure (absolute) id: idling to: throttle full open st: standard of sensor output v...

Page 111

Fuel system (dfi) 3-53 inlet air temperature sensor (service code 13) removal/installation caution never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. • remove the right air cleaner base (see right air cleaner housing removal in this chapter). • disconnect ...

Page 112

3-54 fuel system (dfi) inlet air temperature sensor (service code 13) sensor resistance inspection • remove the inlet air temperature sensor (see this sec- tion). • suspend the sensor [a] in a container of machine oil so that the heat-sensitive portion and threaded portion are submerged. • suspend a...

Page 113

Fuel system (dfi) 3-55 water temperature sensor (service code 14) removal/installation caution never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. • remove the thermostat housing [a] (see thermostat re- moval in the cooling system chapter). • disconnect the...

Page 114

3-56 fuel system (dfi) water temperature sensor (service code 14) sensor resistance inspection • remove the water temperature sensor (see this section). • suspend the sensor [a] in a container of machine oil so that the heat-sensitive portion and threaded portion are submerged. • suspend a thermomet...

Page 115

Fuel system (dfi) 3-57 atmospheric pressure sensor (service code 15) removal caution never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. • remove the fuel tank (see fuel tank section in this chap- ter). • disconnect the atmospheric pressure sensor connector...

Page 116

3-58 fuel system (dfi) atmospheric pressure sensor (service code 15) if the reading is within the standard range, check the wiring between the ecu and the atmospheric pressure sensor for continuity. If the wiring is good, check the output voltage. • remove the needle adapters. • apply silicone seala...

Page 117

Fuel system (dfi) 3-59 atmospheric pressure sensor (service code 15) a. Ecu b. Atmospheric pressure sensor if you need to check the atmospheric pressure sensor for various altitudes other than sea level, check the output voltage as follows: ○ determine the local altitude (elevation). If you know the...

Page 118

3-60 fuel system (dfi) atmospheric pressure sensor (service code 15) va: atmospheric pressure sensor output voltage (v) h: altitude (m or feet) sl: sea level (0 m) st: standard of sensor output voltage (v) ur: usable range of sensor output voltage (v).

Page 119

Fuel system (dfi) 3-61 crankshaft sensors (#1, #2: service code 21, 22) crankshaft sensor #1: for front cylinder (service code 21) crankshaft sensor #2: for rear cylinder (service code 22) crankshaft sensor removal/installation • see ignition system section in the electrical system chapter. Cranksha...

Page 120

3-62 fuel system (dfi) vehicle-down sensor (service code 31) removal caution never drop the down-sensor, especially on a hard surface. Such a shock to the sensor can damage it. • remove the seat (see frame chapter). • remove the bolt [a] and take out the vehicle-down sensor [b]. • raise the connecto...

Page 121

Fuel system (dfi) 3-63 vehicle-down sensor (service code 31) if the power source is normal, check the output voltage of the sensor. • connect a digital volt meter [a] to the connector (natural, 3p), using two needle adapters [b]. • turn the ignition sw on, and measure the output voltage with the con...

Page 122

3-64 fuel system (dfi) vehicle-down sensor (service code 31) a. Ecu n. Ignition switch q. Sealed battery d. Vehicle-down sensor o. Starter relay f. Ignition fuse 10 a f. Junction box p. Main fuse 30 a v. Dfi fuse 15a e. Dfi main relay.

Page 123

Fuel system (dfi) 3-65 fuel injectors (#1, #2: service code 41, 42) fuel injector #1: front fuel injector for front cylinder (service code 41) fuel injector #2: rear fuel injector for rear cylinder (service code 42) caution never drop the injector, especially on a hard sur- face. Such a shock to the...

Page 124

3-66 fuel system (dfi) fuel injectors (#1, #2: service code 41, 42) • if necessary, remove the screws [a] and the fuel hose [b], and then take off the pressure regulator [c]. ○ the screen [a] comes off from the pressure regulator [b]. Delivery joint [c] front [d] • clean the screen with a high-flash...

Page 125

Fuel system (dfi) 3-67 fuel injectors (#1, #2: service code 41, 42) • apply engine oil to the o-ring [a], and install each injector [b] into the delivery joint [c]. • check that there is no dirt or dust on the injector seating surface [a] of the inlet manifold [b]. • check that the two dowel pins ar...

Page 126

3-68 fuel system (dfi) fuel injectors (#1, #2: service code 41, 42) • check the injector fuel line for leakage as follows: ○ connect a commercially available vacuum/pressure pump [c] and a rubber hose [i] to the fuel hose [b] of the delivery joint [a] as shown. ○ plug the outlet of the pressure regu...

Page 127

Fuel system (dfi) 3-69 fuel injectors (#1, #2: service code 41, 42) • push and pull [a] the fuel hose joint #2 [b] back and forth more than two times and make sure it is locked and doesn’t come off. When the fuel hose joint #2 is correctly installed, it should slide on the delivery pipe about 5 mm (...

Page 128

3-70 fuel system (dfi) fuel injectors (#1, #2: service code 41, 42) if the power source voltage is incorrect, check the dfi power source (see dfi power source in this chapter). If the dfi power source is good, check the ecu for its ground and power supply. If the ground and power supply of the ecu a...

Page 129

Fuel system (dfi) 3-71 fuel injectors (#1, #2: service code 41, 42) injector signal test • prepare two test light sets with male terminals as shown. Rating of bulb [a]: 12 v × 3 ∼ 3.4 w terminal width [b]: 1.8 mm (0.07 in.) terminal thickness [c]: 0.8 mm (0.013 in.) caution do not use larger termina...

Page 130

3-72 fuel system (dfi) fuel injectors (#1, #2: service code 41, 42) injector unit test • use two wires [a] and the same test light set [b] as in “injector signal test”. Rating of bulb [c]: 12 v × (3 ∼ 3.4) w 12 v sealed battery [d] caution be sure to connect the bulb in series. The bulb works as a c...

Page 131

Fuel system (dfi) 3-73 fuel pump (service code 45) fuel pump removal caution never drop the fuel pump, especially on a hard sur- face. Such a shock to the pump can damage it. Warning gasoline is extremely flammable and can be explo- sive under certain conditions. Make sure the area is well-ventilate...

Page 132

3-74 fuel system (dfi) fuel pump (service code 45) fuel pump installation • clean the pump screen (see pump filter cleaning). • remove dirt or dust from the fuel pump by lightly applying compressed air. • replace the fuel pump gasket with a new one. • install a new pump gasket [a] with its tab [b] f...

Page 133

Fuel system (dfi) 3-75 fuel pump (service code 45) • secure the fuel pump leads [a] with the clamps [b]. • press the clamps flat by hands against the fuel tank bot- tom. • make sure that the end of each clamp is covered with a plastic cap [c] and touches the fuel tank bottom. • clamp the fuel pump l...

Page 134

3-76 fuel system (dfi) fuel pump (service code 45) if the reading is good, the power source voltage is normal. Inspect operating source voltage (see in this section). If the reading is incorrect, check the following: battery main fuse 30 a in starter relay (see electrical system chapter) dfi fuse 15...

Page 135

Fuel system (dfi) 3-77 fuel pump (service code 45) a. Ecu p. Main fuse 30 a v. Dfi fuse 15 a f. Junction box q. Sealed battery e. Dfi main relay n. Ignition switch u. Fuel pump f. Ignition fuse 10 a o. Starter relay.

Page 136

3-78 fuel system (dfi) ignition coils (#1, #2: service code 51, 52) ignition coil #1: ignition coil for front cylinder (service code 51) ignition coil #2: ignition coil for rear cylinder (service code 52) removal/installation caution never drop the ignition coils, especially on a hard surface. Such ...

Page 137

Fuel system (dfi) 3-79 fi indicator led light inspection flow chart.

Page 138

3-80 fuel system (dfi) fi indicator led light the fi indicator led light [a] goes on when the ignition sw is turned on and the led light goes off 2 seconds later. This is to ensure that the fi indicator led light has not burned out and the dfi system and the ignition system function properly. Led li...

Page 139

Fuel system (dfi) 3-81 ecu ecu identification ○ most countries have their own regulations, so each ecu has different characteristic of fuel injection according to each country. So, do not confuse ecu’s with each other and use only the ecu’s for your country. Otherwise, the motorcycle could not clear...

Page 140

3-82 fuel system (dfi) ecu ecu power supply inspection • visually inspect the terminals of the ecu connector. If the connector is clogged with mud or dust, blow it off with compressed air. Replace the main harness if the terminals [a] of the main harness connectors are cracked, bent, or otherwise da...

Page 141

Fuel system (dfi) 3-83 dfi power source dfi fuse removal • remove the seat (see frame chapter). • pull the lock [a] and open the lid [b]. • pull out the dfi fuse [c] from the case with needle nose pliers. Front [d] if a fuse fails during operation, inspect the dfi system to determine the cause, and ...

Page 142

3-84 fuel system (dfi) dfi power source dfi power source circuit a. Ecu q. Sealed battery w. Isc valve #2 f. Junction box r. Fuel injector #1 x. Isc valve #1 n. Ignition sw s. Fuel injector #2 e. Dfi main relay o. Starter relay u. Fuel pump f. Ignition fuse 10 a p. Main fuse 30 a v. Dfi fuse 15 a p....

Page 143

Fuel system (dfi) 3-85 isc valves removal/installation caution never drop the isc valves, especially on a hard sur- face. Such a shock to the valve can damage it. ○ the isc valves are removed during right air cleaner hous- ing removal (see this chapter). ○ the isc valve itself is the same for front ...

Page 144

3-86 fuel system (dfi) isc valves output voltage inspection • check the output voltage at the connectors [a] of the isc valves. • remove the right air cleaner cover (see this chapter). Special tool - hand tester [b] : 57001–1394 • measure the output voltage with the engine stopped, and with the conn...

Page 145

Fuel system (dfi) 3-87 isc valves a. Ecu v. Dfi fuse 15 a f. Junction box w. Isc valve #2 n. Ignition switch x. Isc valve #1 o. Starter relay e. Dfi main relay p. Main fuse 30 a f. Ignition fuse 10 a q. Sealed battery.

Page 146

3-88 fuel system (dfi) fuel line fuel pressure inspection note ○ this inspection can detect the faults of the dfi fuel line other than the dfi electronic system. ○ it is preferable to measure the fuel pressure while run- ning the motorcycle when the trouble has occurred in order to know symptom well...

Page 147

Fuel system (dfi) 3-89 fuel line • turn the ignition sw on. The fuel pump will turn for 3 seconds, and then stop. • measure the fuel pressure with the engine stopped. Fuel pressure right after ignition sw on, with pump running: standard: 310 kpa (3.2 kgf/cm², 46 psi) after 3 seconds from ignition sw...

Page 148

3-90 fuel system (dfi) fuel line • fit the fuel hose joint #2 [a] onto the pipe (for delivery joint) until the joint clicks [b]. ○ insert the hose joint straight along the pipe. Front [c] • push and pull [a] the fuel hose joint #2 [b] back and forth more than two times and make sure it is locked and...

Page 149

Fuel system (dfi) 3-91 fuel line • prepare a plastic hose of the inside diameter 7.5 mm × l about 400 mm and a measuring cylinder. • remove: seat (see frame chapter) indicator unit (see fuel tank removal in this chapter). Fuel tank bolts • raise the fuel tank. • stuff a clean shop towel around the f...

Page 150

3-92 fuel system (dfi) throttle grip and cables throttle grip free play inspection ○ refer to throttle control system check in the periodic maintenance chapter. Throttle grip free play adjustment • loosen the locknuts [a] and screw the adjusters [b] all the way in so as to give the throttle grip ple...

Page 151

Fuel system (dfi) 3-93 throttle body assy idle speed check ○ refer to idle speed check in the periodic maintenance chapter. Idle speed adjustment ○ refer to idle speed check in the periodic maintenance chapter. High altitude performance adjustment ○ any modification is not necessary in this model si...

Page 152

3-94 fuel system (dfi) throttle body assy • remove the following from the choke cable holder [a] (left -behind view). Screw [b] choke cable plate [c] • while pushing the choke lever [a] forward, remove the cable housing from the choke cable holder [b] and the inner cable out of the holder slit [c]. ...

Page 153

Fuel system (dfi) 3-95 throttle body assy • remove the decelerator cable end [a] from the throttle pulley [b]. • using needle nose pliers, move the accelerator inner ca- ble outside the engine, and remove the cable end [c] from the pulley. Front [d] • pinch the lock of the fuel hose joint #2 [a] wit...

Page 154

3-96 fuel system (dfi) throttle body assy • stuff a piece of lint-free, clean cloth into the throttle body assy, and the inlet ports of the cylinder heads to keep dirt out of the engine. Warning if dirt or dust is allowed to pass through into the throttle bore, the throttle may become stuck, possi- ...

Page 155

Fuel system (dfi) 3-97 throttle body assy • apply a thin coating of grease to the throttle cable upper ends. • install the upper ends of the throttle cables in the grip. • fit the projection [a] of the right switch housing into the hole [b] of the handlebar (front view). • turn the throttle grip and...

Page 156

3-98 fuel system (dfi) throttle body assy • remove the three throttle body flange bolts [a]. • split the throttle body assy into the throttle body [a] and the inlet manifold [b]. The gasket [c] comes off. • discard the gasket. ○ do not remove or adjust the following parts. These parts are set at the...

Page 157

Fuel system (dfi) 3-99 throttle body assy • remove the delivery joint and injectors (see injector sec- tion in this chapter). • open the butterfly valves [a], and wipe any carbon off the throttle bores [b] around the valves, using a piece of lint-free cloth penetrated with a high-flash point solvent...

Page 158

3-100 fuel system (dfi) air cleaner air cleaner element removal • remove: allen bolt and washer [a] left air cleaner cover [b] front [c] • remove the element [a]. • push a clean, lint-free towel into the lower air cleaner duct to keep dirt or other foreign material from entering. Warning if dirt or ...

Page 159

Fuel system (dfi) 3-101 air cleaner right air cleaner housing removal • remove: allen bolt and washer [a] right air cleaner cover [b] front [c] • remove: isc valve hoses [a] isc valve lead connectors [b] air cleaner allen bolts [c] and screws [d] air cleaner base bolt [e] • remove: air cleaner base ...

Page 160

3-102 fuel system (dfi) air cleaner if the air cleaner drain hose [a] has been removed with it attached to the right air cleaner base, pull the drain hose off the right air cleaner base. Remove the left air cleaner base and insert the drain hose under the lower air cleaner duct. • install the inlet ...

Page 161

Fuel system (dfi) 3-103 fuel tank fuel tank removal warning gasoline is extremely flammable and can be explo- sive under certain conditions. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. Do not smoke. Turn the ignit...

Page 162

3-104 fuel system (dfi) fuel tank • disconnect: indicator unit connector [a] ignition switch connector [b] • remove: ignition switch [c] and screws [d] bracket [e] and bolt [f] front [g] • remove the seat (see frame chapter). • disconnect the battery (−) terminal [a]. • open the fuel pump lead clamp...

Page 163

Fuel system (dfi) 3-105 fuel tank • prepare a 8 mm plug ( 7.8 ∼ 8.0 mm [a] × l 35 mm [b] with a rounded end [c]), and a 7.3 ∼ 7.5 mm inside diameter fuel hose [d] (e.G. Part no. 92191–1264). ○ the 8 mm plug can be made by cutting the threaded portion off a 8 mm bolt [f] (e.G. Part no. 92151–1444). ○...

Page 164

3-106 fuel system (dfi) fuel tank ○ be careful of fuel spillage from the fuel tank since fuel still remains in the fuel tank and fuel pump. Warning store the fuel tank in an area which is well -ventilated and free from any source of flame or sparks. Do not smoke in this area. Place the fuel tank on ...

Page 165

Fuel system (dfi) 3-107 fuel tank • fit the fuel return hose [a] onto the pipe fully and install the plate clamp [b] beyond the raised rib [c]. • secure the fuel pump leads [a] with the clamps [b]. • press the clamps flat by hands against the fuel tank bot- tom. • make sure that the end of each clam...

Page 166

3-108 fuel system (dfi) fuel tank fuel tank cleaning warning clean the tank in a well-ventilated area, and take care that there are no sparks or flame anywhere near the working area. Because of the danger of highly flammable liquids, do not use gasoline or low-flash point solvent to clean the tank. ...

Page 167

Fuel system (dfi) 3-109 evaporative emission control system the evaporative emission control system for california model routes fuel vapors from the fuel system into the run- ning engine or stores the vapors in a canister when the en- gine is stopped. Although no adjustments are required, a thorough...

Page 168

3-110 fuel system (dfi) evaporative emission control system hose inspection (periodic inspection) ○ refer to evaporative emission control system check in the periodic maintenance chapter. Separator operation test warning gasoline is extremely flammable and can be explo- sive under certain conditions...

Page 169: Cooling System

Cooling system 4-1 4 cooling system table of contents exploded view........................................................................................................................ 4-2 coolant flow chart.............................................................................................

Page 170

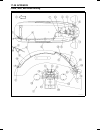

4-2 cooling system exploded view.

Page 171

Cooling system 4-3 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 water temperature sensor (dfi) 18 1.8 13 ss 2 water pipe bolts 11 1.1 97 in·lb 3 radiator fan bolts 8.3 0.85 74 in·lb 4 radiator drain bolt 2.2 0.22 19 in·lb 5 water temperature switch 7.8 0.80 69 in·lb ss 6 radiator fan ...

Page 172

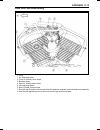

4-4 cooling system coolant flow chart permanent type antifreeze is used as a coolant to protect the cooling system from rust and corrosion. When the engine starts, the water pump turns and the coolant circulates. The thermostat is a wax pellet type which opens or closes as coolant temperature change...

Page 173

Cooling system 4-5 coolant flow chart 1. Water pump 2. Water jacket 3. Cylinder head 4. Water pipe 5. Water hose 6. Radiator cap 7. Thermostat 8. Reserve tank hose 9. Radiator 10. Radiator fan 11. Throttle body assy 12. Front 13. Cold coolant 14. Hot coolant 15. Reserve tank 16. Reserve tank overflo...

Page 174

4-6 cooling system specifications coolant provided when shipping: type (recommended) permanent type antifreeze (soft water and ethylene glycol plus corrosion and rust inhibitor chemicals for aluminum engines and radiators) color green mixed ratio soft water 50%, coolant 50% freezing point − 35°c (− ...

Page 175

Cooling system 4-7 special tools and sealant bearing driver set : 57001–1129 bearing remover shaft : 57001–1265 bearing remover head, φ 10 x φ 12 : 57001–1266 kawasaki bond (silicone sealant) : 56019–120

Page 176

4-8 cooling system coolant coolant deterioration inspection • remove the right side cover (see frame chapter). • visually inspect the coolant [a] in the reserve tank. If whitish cotton-like wafts are observed, aluminum parts in the cooling system are corroded. If the coolant is brown, iron or steel ...

Page 177

Cooling system 4-9 coolant pressure testing • remove the fuel tank (see fuel system chapter). • remove the radiator cap, and install a cooling system pressure tester [a] on the radiator filler neck [b]. Note ○ wet the cap sealing surfaces with water or coolant to prevent pressure leakage. • build up...

Page 178

4-10 cooling system water pump water pump removal • drain the coolant (see coolant change in the periodic maintenance chapter). • remove: water hose clamp [a] water hose [b] front [c] • remove: water pump cover bolts [a] water pump cover [b] • remove: impeller bolt [a] impeller [b] note ○ the impell...

Page 179

Cooling system 4-11 water pump • install the clamp [a] so that the clamp end is about 16 mm (0.63 in.) [b] apart from the pump inlet step. This prevents coolant leakage from the hose end. • tighten the hose clamp screw securely. Water pump inspection • check the water pump drainage outlet hose [a] a...

Page 180

4-12 cooling system water pump if the coolant still leaks through the drainage outlet hose, the seal and ball bearings is probably damaged. Replace the mechanical seal, ball bearings, and oil seal by splitting the crankcase. • split the crankcase (see crankshaft/transmission chap- ter). • remove the...

Page 181

Cooling system 4-13 water pump • clean both sliding surfaces of a new mechanical seal with a high-flash point solvent (e.G. Ethyl alcohol), and apply a little coolant to the sliding surface to give the mechanical seal initial lubrication. • apply coolant to the surface of the rubber seal [a] and sea...

Page 182

4-14 cooling system radiator warning the radiator fan is connected directly to the bat- tery. The radiator fan may start even if the ignition switch is off. Never touch the radiator fan until the radiator fan connector is dis- connected. Touching the fan before the connector is disconnected could ca...

Page 183

Cooling system 4-15 radiator • remove: radiator fan bolts [a] radiator fan [b] radiator installation • be sure to install the radiator fan ground lead terminal [a]. Torque - radiator fan bolts and fan ground lead terminal bolt: 8.3 n·m (0.85 kgf·m, 74 in·lb) • fit the radiator stoppers [a] into the ...

Page 184

4-16 cooling system radiator radiator cap inspection • check the condition of the top and bottom valve seals of the radiator cap. If any one of them shows visible damage, replace the cap. Bottom valve seal [a] top valve seal [b] valve spring [c] • install the cap [a] on a cooling system pressure tes...

Page 185

Cooling system 4-17 thermostat thermostat removal • remove: coolant : drain about 200 ml fuel tank (see fuel system chapter) four water hoses [a] bracket bolts [b] water temperature sensor connector [c] • remove the thermostat housing [d] along with the bracket. Front [e] • remove the screws [a], ta...

Page 186

4-18 cooling system hoses and pipes hose installation • install the hoses and pipes being careful to follow bend- ing direction. Avoid sharp bending, kinking, flattening, or twisting. • install the clamps [a] as near as possible to the hose end to clear the raised rib on the fitting. This will preve...

Page 187: Engine Top End

Engine top end 5-1 5 engine top end table of contents exploded view................................... 5-2 specifications .................................... 5-8 special tools and sealant ................. 5-11 clean air system............................... 5-14 air suction valve removal.............

Page 188

5-2 engine top end exploded view.

Page 189

Engine top end 5-3 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 rocker case cover bolts 8.8 0.90 78 in·lb s 2 air suction valve cover bolts 7.4 0.75 65 in·lb 3 rocker case nuts φ 12 mm 78 8.0 58 s, mo 4 rocker case nuts φ 8 mm 25 2.5 18 s 5 rocker case bolts φ 6 mm 8.8 0.90 78 in·lb s...

Page 190

5-4 engine top end exploded view.

Page 191

Engine top end 5-5 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 rocker shafts 25 2.5 18 2 exhaust pipe cover clamp screws 6.9 0.70 61 in·lb 3 premuffler chamber bolts 29 3.0 21 4 upper muffler bracket nut 29 3.0 21 5 muffler stay mounting bolts, φ 8 25 2.5 18 6 upper muffler mounting ...

Page 192

5-6 engine top end exploded view.

Page 193

Engine top end 5-7 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 cylinder head nuts 25 2.5 18 s 2 cylinder nuts 25 2.5 18 s 3 chain tensioner cap 20 2.0 15 s 4 chain tensioner lockbolt 4.9 0.50 43 in·lb s 5 chain tensioner mounting bolts 11 1.1 97 in·lb s 6 chain guide mounting bolts 1...

Page 194

5-8 engine top end specifications item standard service limit clean air system: air switching valve resistance: 18 ~ 22 Ω at 20° (68°f) – – – camshafts: cam height: exhaust 33.741 ~ 33.857 mm 33.64 mm (1.32839 ~ 1.33295 in.) (1.3244 in.) inlet 33.928 ~ 34.044 mm 33.83 mm (1.33575 ~ 1.34031 in.) (1.3...

Page 195

Engine top end 5-9 specifications item standard service limit valve stem diameter: exhaust 6.955 ~ 6.970 mm 6.94 mm (0.2732 in.) (0.27382 ~ 0.27441 in.) inlet 6.965 ~ 6.980 mm 6.95 mm (0.2736 in.) (0.27421 ~ 0.27480 in.) valve guide inside diameter: exhaust 7.000 ~ 7.015 mm 7.08 mm (0.2787 in.) (0.2...

Page 196

5-10 engine top end specifications item standard service limit valve seat surface: valve seat cutting angle 45°, 32°, 55° – – – outside diameter: exhaust 31.9 ~ 32.1 mm – – – (1.256 ~ 1.264 in.) inlet 36.4 ~ 36.6 mm – – – (1.433 ~ 1.441 in.) width: exhaust 0.8 ~ 1.2 mm – – – (0.031 ~ 0.047 in.) inle...

Page 197

Engine top end 5-11 special tools and sealant valve guide reamer, φ 7 : 57001–162 valve guide arbor, φ 7 : 57001–163 compression gauge : 57001–221 valve spring compressor assembly : 57001–241 valve spring compressor adapter, φ 28.2 : 57001–243 piston pin puller assembly : 57001–910 compression gauge...

Page 198

5-12 engine top end special tools and sealant valve seat cutter, 32° – φ 35 : 57001–1121 valve seat cutter, 32° – φ 38.5 : 57001–1122 valve seat cutter holder, φ 7 : 57001–1126 valve seat cutter holder bar : 57001–1128 hexagon wrench, hex 27 : 57001–1210 piston pin puller adapter : 57001–1211 valve ...

Page 199

Engine top end 5-13 special tools and sealant valve seat cutter 45° – φ 40 : 57001–1496 valve seat cutter 55° – φ 38.5 : 57001–1497 kawasaki bond (silicone sealant) : 56019–120 ○ compression gauge adapter: 57001-1183 can also be used. ○ valve seat cutter, 32° – φ 33: 57001-1199 can also be used inst...

Page 200

5-14 engine top end clean air system air suction valve removal • for rear air suction valve removal, remove the rear ex- haust pipe. • remove the hose [a]. • unscrew the mounting bolts [b] and remove the rear air suction valve cover [c]. • remove the rear air suction valve. • for front air suction v...

Page 201

Engine top end 5-15 clean air system air switching valve removal • remove: fuel tank (see fuel system chapter) • pull off the hoses [a] and air switching valve connector [b], and take out the air switching valve [c]. Air switching valve installation • install the air switching valve [a] so that the ...

Page 202

5-16 engine top end clean air system • connect the 12 v battery [a] to the air switching valve terminals as shown. • blow the air to the inlet air duct [a], and make sure does not flow the blown air from the outlet air ducts [b]. • disconnect the 12 v battery. • blow the air to the inlet air duct [a...

Page 203

Engine top end 5-17 camshaft chain tensioner camshaft chain tensioner removal caution this is a non-return type cam chain tensioner. The push rod does not return to its original position once it moves out to take up camshaft chain slack. Observe all the rules listed below: when removing the tensione...

Page 204

5-18 engine top end camshaft chain tensioner • install the larger spring [a], and then the ball bearing assy [b]. ○ fit the ball bearing assy into the body until it bottoms out, using a thin-bladed screwdriver. • screw in the lockbolt [a] finger-tight to hold the ball bear- ing assy temporarily. • i...

Page 205

Engine top end 5-19 rocker case cover rocker case cover removal • remove the engine (see engine removal/installation chapter). • remove the bolts [a] and take off the cover [b] from the rocker case. • take out the oil filter springs [a] and hla oil filters [b]. Rocker case cover installation • repla...

Page 206

5-20 engine top end rocker case cover rocker case cover assembly • apply adhesive to the rubber dampers [a] and install them on the rocker case cover as shown. ○ insert the projections [b] of the dampers to the holes [c] of the cover. Front cover [d] rear cover [e].

Page 207

Engine top end 5-21 rocker case rocker case removal • remove the engine (see engine removal/installation chapter). • remove the throttle body assy (see fuel system (dfi) chapter). • remove the rocker case covers (see rocker case cover removal). • remove the alternator outer cover (see electrical sys...

Page 208

5-22 engine top end rocker case • using the pry points [a], take the rocker case out of the cylinder head. • unscrew the rocker shafts [a], and take the rocker arms [b] out of the rocker case. • take out the oil filters if necessary. • remove the lash adjuster if necessary (see hla re- moval). Cauti...

Page 209

Engine top end 5-23 rocker case • apply molybdenum disulfide oil to the threads and seating surface of φ 12 mm nuts and both sides of washers. • tighten the rocker case nuts and bolts temporarily follow- ing the tightening sequence shown, and then tighten them to the specified torque. Torque - rocke...

Page 210

5-24 engine top end rocker case rocker arm assembly • prepare a flat-end bar [a] and a block [b] with a recess [c]. • press the oil chamber [d] for the hla into the rocker arm end [e] until the chamber end is even with the step [f] of the hole. ○ install the oil chamber as shown so that the air blee...

Page 211

Engine top end 5-25 rocker case hla installation • check that the hla plunger is not damaged. If the plunger does damage, replace the hla. Hla body [a] o-ring [b] plunger spring [c] pivot plunger [d] check valve [e] check valve spring [f] • air-bleed the hla (see hla air bleeding). • soak a rocker a...

Page 212

5-26 engine top end camshafts camshaft removal • remove the timing inspection cap [a] and rotor bolt cap [b]. Special tool - driver-filler cap: 57001–1454 [c] • turn the crankshaft counterclockwise [a] and align the “f” mark [b] (tdc mark for the front piston) with the middle of the notch [c]. • rem...

Page 213

Engine top end 5-27 camshafts • install the kacr on each camshaft. ○ the front kacr [a] and rear kacr [b] are different (inside view). Do not confuse these kacrs. • fit the pin [a] into the notch [b], and install the kacr [c] onto the camshaft [d]. • apply molybdenum disulfide oil to all cam parts, ...

Page 214

5-28 engine top end camshafts • align the “r” mark [a] (tdc mark for the rear piston) with the middle of the notch [b] (310° turn from the front piston tdc). • engage the rear camshaft sprocket with the camshaft chain as shown. Timing marks [a] and r mark [b] cylinder head upper surface [c] front [d...

Page 215

Engine top end 5-29 camshafts • apply molybdenum disulfide oil to the threads and seating surface of φ 12 mm nuts and both sides of washers. • tighten the rocker case nuts and bolts temporarily follow- ing the tightening sequence shown, and then tighten them to the specified torque. Torque - rocker ...

Page 216

5-30 engine top end camshafts • remove: alternator rotor (see electrical system chapter) lower chain guide bolts [a] lower chain guide [b] • take out the front camshaft chain [c]. Rear camshaft chain removal • remove: rear camshaft (see camshaft removal) spark plug (left side, see cylinder compressi...

Page 217

Engine top end 5-31 camshafts ○ the cylinder compression is released while the engine is running (abnormal): the pin [a] stays out the cam [b] and pushes up the exhaust rocker arm. • remove the spring [c] and move the weights [d] back and forth. If the weights do not move easily from the retracted p...

Page 218

5-32 engine top end cylinder head cylinder compression measurement note ○ be sure the battery is fully charged. • warm up the engine thoroughly. • stop the engine. • remove one spark plug and attach the compression gauge and adapter firmly into the spark plug hole. Do not remove the other spark plug...

Page 219

Engine top end 5-33 cylinder head the following table should be consulted if the obtainable compression reading is not within the us- able range. Problem diagnosis remedy (action) carbon buildup on piston and in combustion remove the carbon deposits chamber possibly due to damaged valve stem, and re...

Page 220

5-34 engine top end cylinder head • do not remove the coolant drain plug [a] yet. • remove the cylinder head nuts [b]. • take the cylinder head off the cylinder. Cylinder head installation ○ the front cylinder head [a] has an f mark while the rear cylinder head [b] has an r mark. Be careful not to m...

Page 221

Engine top end 5-35 cylinder head valve clearance adjustment note ○ since the hydraulic lash adjusters constantly maintain zero clearance, it is not necessary to inspect or adjust the valve clearance. Valve removal • remove the cylinder head (see cylinder head removal). • swing open the rocker arm. ...

Page 222

5-36 engine top end cylinder head valve guide installation • apply engine oil to the valve guide outer surface before installation. • heat the area around the valve guide hole to about 120 ~ 150°c (248 ~ 302°f) in the engine oil. • drive the valve guide in from the top of the head using the valve gu...

Page 223

Engine top end 5-37 cylinder head valve seat inspection • remove the valve (see valve removal). • check the valve seat surface [a] between the valve [b] and valve seat [c]. ○ measure the outside diameter [d] of the seating pattern on the valve seat with vernier calipers. If the outside diameter is t...

Page 224

5-38 engine top end cylinder head seat cutter operation care: 1. This valve seat cutter is developed to grind the valve for repair. Therefore the cutter must not be used for other purposes than seat repair. Do not drop or shock the valve seat cutter, or the diamond particles may fall off. Do not fai...

Page 225

Engine top end 5-39 cylinder head ○ to make the 32° grind, fit a 32° cutter into the holder, and slide it into the valve guide. ○ turn the holder one turn at a time while pressing down very lightly. Check the seat after each turn. Caution the 32° cutter removes material very quickly. Check the seat ...

Page 226

5-40 engine top end cylinder head.

Page 227

Engine top end 5-41 cylinders, piston cylinder removal • remove the cylinder head (see cylinder head removal). • remove the coolant drain plug [a] and drain the coolant from the cylinder. • pull out the front camshaft chain guide [b]. • remove the cylinder nuts [c]. • tap lightly up the cylinder wit...

Page 228

5-42 engine top end cylinders, piston • do not mix up the top ring and second ring. • install the top ring [a] so that the “r” mark [b] faces up. • install the second ring [c] so that the “rn” mark [d] faces up. • the piston ring openings must be positioned as shown in the figure. The openings of th...

Page 229

Engine top end 5-43 cylinders, piston note ○ if a new piston or cylinder is used, check piston to cylin- der clearance (see piston/cylinder clearance), and use new piston ring. • replace the cylinder base gasket [a] with a new one, and install the gaskets aligning the holes with the crankcase water ...

Page 230

5-44 engine top end cylinders, piston • install the front cylinder in the same way. ○ position the front piston at tdc. ○ tighten the cylinder nuts temporarily (these nuts are tightened to the specified torque after rocker case instal- lation). Cylinder wear • since there is a difference in cylinder...

Page 231

Engine top end 5-45 cylinders, piston cylinder boring and honing ○ there is an oversize piston available. The oversize piston requires oversize rings. Oversize piston and rings: 0.5 mm (0.02 in.) oversize • before boring a cylinder [a], first measure the exact di- ameter of the oversize piston, and ...

Page 232

5-46 engine top end cylinders, piston piston ring thickness • measure the thickness of the top [a] and second [b] rings. ○ use a micrometer to measure at several points around the ring. Piston ring thickness standard service limit top 1.17 ~ 1.19 mm 1.10 mm (0.04606 ~ 0.04685 in.) (0.0433 in.) secon...

Page 233

Engine top end 5-47 mufflers exhaust pipe removal warning to avoid a serious burn, do not remove the exhaust pipe or muffler when the engine is still hot. Wait until the muffler cools down. • loosen the upper muffler bracket bolt [a] for easy removal or installation of exhaust pipes. • loosen the cl...

Page 234

5-48 engine top end mufflers lower muffler removal • remove: front and rear exhaust pipe covers (see above) chamber flange nuts [a] muffler bracket bolts [b] • remove the lower muffler [c]. Note ○ if the chamber flange nuts are difficult to remove, spray a penetrating oil on the studs and nuts. Uppe...

Page 235

Engine top end 5-49 mufflers • tighten the front exhaust pipe cover clamp screw [a] with its head inclined at 50° or less to horizontal as shown. This prevents the screw from touching ground when bank- ing. Front exhaust pipe [b] torque - exhaust pipe cover clamp screws: 6.9 n·m (0.70 kgf·m, 61 in·l...

Page 236

5-50 engine top end mufflers chamber identification ○ the all models have a premuffler chamber (identification no. Khi m 092) with a honeycomb type catalytic con- verter and without any catalyst protection system. Do not mix up this chamber with the other type chamber (espe- cially with a non-cataly...

Page 237: Clutch

Clutch 6-1 6 clutch table of contents exploded view........................................................................................................................ 6-2 specifications ................................................................................................................

Page 238

6-2 clutch exploded view.

Page 239

Clutch 6-3 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 clutch reservoir cap screws 1.5 0.15 13 in·lb 2 clutch slave cylinder bleed valve 7.8 0.80 69 in·lb 3 clutch master cylinder clamp bolts 9.8 1.0 87 in·lb s 4 clutch hose banjo bolt 25 2.5 18 5 clutch slave cylinder bolts 6.9 0.70...

Page 240

6-4 clutch specifications item standard service limit clutch fluid grade dot4 (provided when shipping) – – – clutch lever position no. 1 (to suit rider) 5-way adjustable clutch lever free play non-adjustable – – – clutch clutch spring free height 4.3 mm (0.235 in.) 4 mm (0.16 in.) spring plate gap (...

Page 241

Clutch 6-5 special tools and sealant inside circlip pliers : 57001–143 clutch spring compressor : 57001–1162 gear holder: 57001–1557.

Page 242

6-6 clutch clutch fluid clutch fluid level check ○ refer to clutch fluid level check in the periodic mainte- nance chapter. Clutch fluid change ○ refer to clutch fluid change in the periodic maintenance chapter. Clutch line bleeding • remove: alternator outer cover (see electrical system chapter) • ...

Page 243

Clutch 6-7 clutch master cylinder clutch lever adjustment the adjuster has 5 positions so that the clutch lever posi- tion can be adjusted to suit the operator’s hand. • push the lever forward and turn the adjuster [a] to align the number with the arrow mark [b] on the lever holder (front view). ○ t...

Page 244

6-8 clutch clutch master cylinder clutch master cylinder disassembly/assembly ○ refer to clutch master cylinder cup and dust seal re- placement in the periodic maintenance chapter. Clutch master cylinder inspection • disassemble the clutch master cylinder. • check that there are no scratches, rust o...

Page 245

Clutch 6-9 clutch slave cylinder clutch slave cylinder removal • remove: alternator outer cover (see electrical system chapter) banjo bolt [a] clutch slave cylinder bolts [b] slave cylinder [c] caution immediately wash away any clutch fluid that spills. It may damage painted surfaces. • perform the ...

Page 246

6-10 clutch clutch slave cylinder • tighten the bolts [a]. Torque - clutch slave cylinder bolts: 6.9 n·m (0.70 kgf·m, 61 in·lb) ○ put the clamp [b] together the clutch slave cylinder bolt and bend along the slave cylinder with the end of the clamp straight to the engine side as shown in the figure. ...

Page 247

Clutch 6-11 clutch clutch cover removal • raise the rear wheel off the ground. Special tools - jack: 57001–1238 attachment jack: 57001–1398 • drain the engine oil (see periodic maintenance chapter). • support the engine with a suitable stand [a]. ○ put a plank [b] onto the stand. • remove: front exh...

Page 248

6-12 clutch clutch • unscrew the clutch hub nut [a] by using an air impact wrench. • take the clutch spring [b], and the clutch spring holder [c] out of the clutch hub. • take the back torque limiter springs [a], and the clutch spring plate out of the clutch housing. • take the friction/steel plate ...

Page 249

Clutch 6-13 clutch clutch installation when replacing any one of the following parts, check the spring plate gap (see spring plate gap measurement). Spring plate [a] friction plates [b] steel plates [c] • when installing the clutch housing, mesh the oil pump drive gear [a] with the oil pump gear [b]...

Page 250

6-14 clutch clutch • the spring plate pusher [a] into the clutch hub. Squeeze the clutch lever slowly and hold it with a band. ○ install the needle bearing [b] and the washer onto the pusher. • pushing [a] the operating plate [b] into the clutch hub, and insert the retaining ring [c] by hand. Inner ...

Page 251

Clutch 6-15 clutch • prepare sheet gum (chewing gum) or about 5 g clay [a]. • make an about 2.5 mm (0.098 in.) thick sheet [b] of gum or clay, using a press and two thickness gauges [c] which are overlapped to about 2.5 mm (0.098 in.). • cut the sheet with scissors into four strips [d] of gum or cla...

Page 252

6-16 clutch clutch spring plate gap adjustment if the plate gap is out of the usable range, change one of the steel plates [a] to a thicker or thinner one to get the correct gap. ○ use the standard steel plates (2.0 mm (0.079 in.) thick) × (6 ∼ 7) plates, and the adjustment steel plate (1.6 or 2.3 m...

Page 253

Clutch 6-17 clutch clutch spring height measurement • measure the height [b] of the clutch spring [a]. If the spring height is less than the service limit, it must be replaced. Clutch spring height standard: 4.3 mm (0.235 in.) service limit: 4 mm (0.16 in.) clutch housing finger inspection • visuall...

Page 255: Engine Lubrication System

Engine lubrication system 7-1 7 engine lubrication system table of contents engine oil flow chart............................................................................................................. 7-2 exploded view...............................................................................

Page 256

7-2 engine lubrication system engine oil flow chart.

Page 257

Engine lubrication system 7-3 engine oil flow chart →: oil flow (1 ∼ 30) --→: blowby gas 1. Oil screen 2. Oil pump 3. Relief valve 4. Oil filter 5. Bypass valve 6. Oil pressure switch 7. Inside oil pipe 8. Banjo bolts of right crankcase rear 9. Outside oil hoses 10. Hla oil filter 11. Rocker shafts ...

Page 258

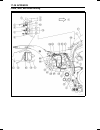

7-4 engine lubrication system exploded view.

Page 259

Engine lubrication system 7-5 exploded view torque no. Fastener n·m kgf·m ft·lb remarks 1 oil pipe holder bolts 11 1.1 97 in·lb l 2 oil pipe clamp bolts 11 1.1 97 in·lb l 3 oil hose flange bolts 9.8 1.0 87 in·lb 4 oil hose banjo bolt 9.8 1.0 87 in·lb 5 relief valve 15 1.5 11 l 6 oil pump mounting bo...

Page 260

7-6 engine lubrication system specifications item standard engine oil: type api service classification : se, sf or sg class api service classification : sh or sj class with jaso ma viscosity sae 10w-40 capacity 2.9 l (3.1 us qt, when filter is not removed) 3.1 l (3.3 us qt, when filter is removed) 3...

Page 261

Engine lubrication system 7-7 special tools and sealant oil pressure gauge, 5 kg/cm² : 57001–125 oil pressure gauge adapter, pt 1/8 : 57001–1033 oil filter wrench : 57001–1249 filler cap driver : 57001–1454 kawasaki bond (silicone sealant) : 56019–120

Page 262

7-8 engine lubrication system engine oil and oil filter warning motorcycle operation with insufficient, deteri- orated, or contaminated engine oil will cause accelerated wear and may result in engine or trans- mission seizure, accident, and injury. Oil level inspection • situate the motorcycle so th...

Page 263

Engine lubrication system 7-9 oil pump and oil line oil pump removal • remove the engine (see engine removal/installation chapter). • split the crankcase (see crankshaft/transmission chap- ter). • remove the oil pump mounting bolts [a], and take off the pump [b] out of the right crankcase. • unscrew...

Page 264

7-10 engine lubrication system oil pump and oil line oil hose installation • run the front oil hose over the rear oil hose as shown. ○ insert the rear oil hose [a] first. ○ next insert the front oil hose [b]. ○ run both oil hoses between the rocker case and the rocker case cover. Torque - oil hose f...

Page 265

Engine lubrication system 7-11 oil pump and oil line • remove the oil pipe clamp bolt [a], and oil return pipe [b]. • remove the separator [a]. • remove: oil pipe clamp bolt [a] oil pipe holder bolt [b] • remove the inside oil pipe [c] and the oil return pipe [d] from the left crankcase [e]. ○ pull ...

Page 266

7-12 engine lubrication system oil pump and oil line • install the inside oil pipe [a], separator [b] and the oil re- turn pipe [c] to left crankcase [d] as shown. ○ do not apply silicone sealant to the groove of the grommet and the mating surface of the grommet [e]. ○ apply silicone sealant to the ...

Page 267

Engine lubrication system 7-13 oil pump and oil line • install the inside oil pipe [a], separator [b], and the oil return pipe [c] to the right crankcase [d]. ○ do not apply silicone sealant to the groove of the grommet and the mating surface of the grommet [e]. ○ install the separator so that it’s ...

Page 268