Summary of W800 - 2011

Page 1

Viking installation guide freestanding gas self-clean ranges.

Page 2

Important: please read and follow • before beginning, please read these instructions completely and carefully. • do not remove permanently affixed labels, warnings, or plates from the product. This may void the warranty. • please observe all local and national codes and ordinances. • please ensure t...

Page 3

2 electrical grounding instructions this range must be electrically grounded in accordance with local codes, or in the absence of local codes, with the national electrical codes, ansi/nfpa 70-latest edition. This appliance is equipped with a three-prong plug for your protection against shock hazard ...

Page 4

Basic specifications description 30” w. Models 36” w. Models 48” w. Models overall width 29 7/8” (75.9 cm) 35 7/8” (91.1 cm) 47 7/8” (121.6 cm) overall height base height open top burners sealed top burners to top of: grate support - burner grate - min. 35 7/8 “ (91.1 cm) 37 3/8” (94.9 cm) max. 37 5...

Page 5

4 anti-tip stability device installation instructions 1. The anti-tip bracket is to be attached to the rear wall as shown. The dimension for the bracket location from the floor is to be determined after the range legs have been adjusted to the proper installation height shown in the installation ins...

Page 6

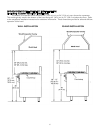

5 proximity to side cabinet installation 1. This range may be installed directly adjacent to existing 36” (91.4 cm) high base cabinets. Important: the top grate support must be 3/8” (.95 cm) above the adjacent base cabinet countertop. This may be accomplished by raising the unit using the adjustment...

Page 7

6 wood/composite overlay installation (including custom ventilator installation) the bottom of a standard hood should be 30” (76.2 cm) min. To 36” (91.4 cm) max. Above the countertop. This would typically result in the bottom of the hood being 66” (167.6 cm) to 72” (182.9 cm) above the floor. Refer ...

Page 8

7 important: leveling/adjustments/alignment careful leveling of the range is critical not only to performance, but also to allow the alignment of oven doors and drip tray. Closely follow the procedures below to ensure proper performance and appearance of the range. The range being even slightly out ...

Page 9

8 gas connection all gas connections must be made according to national and local codes. This gas supply (service) line must be the same size or greater than the inlet line of the appliance. This range uses an iso7 or iso128 inlet. The inlet depends on the end users national and local codes. 1. Manu...

Page 10

9 infrared broil burner 1. An electric ignitor is used to light the burner.. Do not attempt to insert any object into the openings of the protective shield surrounding the ignitor coil. Do not attempt to clean this area. 2. Universal models (nat. Or lp) are shipped from the factory orificed for natu...

Page 11

10 oven tubular gas burner adjustment (see illustration #1) check the gas supply, and set the regulator to proper supply of gas. A properly adjusted burner should be stable and quiet. The flame should have a sharp, well defined blue inner cone with no yellow tipping. The flame should also be stable ...

Page 12

11 surface burner adjustments (for open surface burners) (see illustration 2) to gain access to the surface burner adjustments: 1. Remove the grates, burner caps, bowls and grate supports. 2. Located the air shutter (a) and loosen the screw (b) that holds the air shutter in place. 3. Remove the drip...

Page 13

12 grill/griddle burner adjustment grill (illustration #) 1. The grill burner orifice and air shutter are located beneath the front end of the grill assembly. To gain access to the adjsutments, remove the grill grate, flavor generator plates, grate support, and the burner shield. 2. Remove the screw...

Page 14

13 dsi spark module specifications power requirements input voltage range (l1-n) 102 to 132 vac, 60/50 hz 135 ma current typical control outputs bake or broil burner coil pull-in pulse 54vdc + 10% @ 250ma coil hold-in 36 ma minimum life requirements 2000,000 cycles bake and broil spark: 16.5 kv @ 50...

Page 15

14 description of operation (con’t) lockout the control will lockout if any self-checks fail during normal operation. Also, the control will lockout if it failed to ignite gas after the selected number of ignition attempts or ignition recycles. In lockout the valve and ignition means are turned off....

Page 16

15 timing diagram: normal ignition cycle timing diagram: power up cycle - ignition, flame loss flame sense current measurement local sense: connect a dc micro-amp meter in series with the high voltage lead and the spark electode wire as shown. Push switch to read current after flame is established a...

Page 17

16 performance checklist the installer should carry out the following performance checks. Refer to instructions below. 1. Check open top burner ignition. 2. Check air shutter adjustment - sharp blue flame, no yellow tipping. (see “surface burner adjustment”) 3. Check low flame adjustment - surface b...

Page 18

17 specifications subject to change without notice.

Page 19

F1738r (ps050907j) viking range corporation 111 front street greenwood, mississippi 38930 usa (662) 455-1200 for more product information, call 1-888-viking1 (845-4641) or visit the viking web site at vikingrange.Com.

Page 20

Svgsc - basic specifications description 30” w. Models 36” w. Models overall width 29 7/8” (75.9 cm) 35 7/8” (91.1 cm) overall height to top of grate support - min. 35 7/8 “ (91.1 cm) to max. 37 5/8” (95.6 cm) legs adjust 1 3/4” (4.5 cm) additions to base height to top of spider grate - add 1 1/8” (...