- DL manuals

- Kaysun

- Air Conditioner

- KAM2-42 DN5

- Service Manual

Kaysun KAM2-42 DN5 Service Manual

Summary of KAM2-42 DN5

Page 1

Service manual airconditioner dc inverter multi type kam2-42 dn5 kam2-52 dn5 kam3-62 dn5 kam3-80 dn5 kam4-72 dn kam4-80 dn5 kam4-105 dn5 kam5-105 dn5 kam5-120 dn5 dc multi outdoor units.

Page 2: Contents

1 contents 1. General information of outdoor units ................................................. 2 2. Features ................................................................................................. 3 3. Dimensions ..........................................................................

Page 3

2 1. General information of outdoor units model name dimension (mm) compressor kam2-42 dn5 845x320x700 da130m1c-31fz kam2-52 dn5 845x320x700 da150s1c-20fz kam3-62 dn5 845x320x700 da150s1c-20fz kam3-80 dn5 900x315x860 da250s2c-30mt kam4-105 dn5 990x345x965 tnb306fpgmc-l kam5-105 dn5 990x345x965 tnb30...

Page 4

3 2. Features the hydrophilic fin can improve the heating efficiency at operation mode. It protects the valves and prevents water from dripping. 4 way valve control it is only operated in the heating operation mode except defrosting operation. Outdoor unit power relay control hydrophilic aluminum fi...

Page 5

4 3. Dimensions kam2-42 dn5, kam2-52 dn5 560 w1 h 6 d1 335 d2 360 845 w 313 d3 335 d1 r6 r5 a1 22 a2 50 b1 120 110 b2 700 w2 73 58 58 58 110 h1 h2 200.7 2 4 3 .6 l1 l2.

Page 6

5 kam3-62 dn5 560 w1 h 6 d1 335 d2 360 845 w 313 d3 335 d1 r6 r5 a1 22 a2 50 b1 120 110 b2 700 w2 73 58 58 58 58 58 110 h1 h2 200.7 2 4 3 .6 l1 l2.

Page 7

6 kam3-80 dn5 900 w 590 w1 860 h 12 d2 355 d1 333 302 d3 333 d1 50 97 90 b2 b1 8 a2 55 55 55 55 55 110 62 w2 h1 h2 r6 238.4 2 8 5 .7 l1 l2.

Page 8

7 kam4-80 dn5 900 w 590 w1 860 h 12 d2 355 d1 333 302 d3 333 d1 50 97 90 b2 b1 8 a2 55 55 55 55 55 55 55 110 62 w2 h1 h2 r6 238.4 2 8 5 .7 l1 l2.

Page 9

8 kam4-105 dn5 624 w1 990 w d2 397 d1 366 965 10 h 78 w2 340 366 d3 d1 125 145 b1 b2 60 22 a2 a1 55 140 h1 h2 r5 r6.

Page 10

9 kam5-105 dn5, kam5-120 dn5 990 w w2 81 624 w1 d2 397 d1 366 5 5 h 1 9 6 5 h 1 5 3 h 2 3 6 6 d 1 b 2 1 2 5 b1 145 d 3 3 4 5 60 22 a2 a1 r5 r6.

Page 11

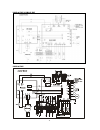

10 4. Wiring diagram kam2-42 dn5, kam2-52 dn5.

Page 12

11 kam3-80 dn5, kam3-62 dn5 kam4-80 dn5.

Page 13

12 kam4-105 dn5 kam5-105 dn5, kam5-120 dn5.

Page 14

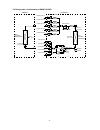

13 5. Refrigeration cycle diagram 5.1 refrigeration circuit drawing of inverter 1 drive 2 type liquid valve a gas valve a heat exchange (evaporator) heat exchange (condenser) compressor 4-way valve cooling heating t2 evaporator temp. Sensor middle t1 room temp. Sensor t3 condenser temp. Sensor t5 di...

Page 15

14 5.3 refrigeration circuit drawing of inverter 1 drive 4 type liquid valve a gas valve a heat exchange (evaporator) heat exchange (condenser) compressor 4-way valve cooling heating t2 evaporator temp. Sensor middle t1 room temp. Sensor t3 condenser temp. Sensor t5 discharge temp. Sensor t4 ambient...

Page 16

15 5.5 refrigeration circuit drawing of kam5-120 dn5 liquid valve a gas valve a heat exchange (evaporator) heat exchange (condenser) cooling heating t2 evaporator temp. Sensor t1 room temp. Sensor t3 condenser temp. Sensor t4 ambient temp. Sensor indoor outdoor exv a capiliary a check valve capiliar...

Page 17

16 6. Indoor units combination 6.1 indoor unit combination for kam2-42 dn5 one unit two unit 7 7+7 9+9 9 7+9 9+12 12 7+12 18 6.2 indoor unit combination for kam2-52 dn5 one unit two unit 7 7+7 9+9 9 7+9 9+12 12 7+12 9+18 18 7+18 12+12 6.3 indoor unit combination for kam3-62 dn5 one unit two unit thr...

Page 18

17 6.5 indoor unit combination for kam4-80 dn5 6.6 indoor unit combination for kam4-105 dn5 6.7 indoor unit combination for kam5-105 dn5 one unit two unit three unit 7 7+7 9+12 7+7+7 7+9+18 9+9+18 12+18+18 9 7+9 9+18 7+7+9 7+12+12 9+12+12 18+18+18 12 7+12 12+12 7+7+12 7+12+18 9+12+18 18 7+18 12+18 7...

Page 19

18 7+7+7+7+7 7+7+7+9+18 7+7+9+12+18 7+9+9+12+18 9+9+9+12+12 7+7+7+7+9 7+7+7+12+18 7+7+12+12+18 7+9+12+12+12 9+9+9+12+18 7+7+7+7+12 7+7+7+18+18 7+9+9+9+9 7+9+12+12+18 9+9+12+12+12 7+7+7+7+18 7+7+9+9+9 7+9+9+9+12 9+9+9+9+9 9+12+12+12+12 7+7+7+9+9 7+7+9+9+12 7+9+9+9+18 9+9+9+9+12 12+12+12+12+12 7+7+7+9...

Page 20

19 7. Installation details 7.1 wrench torque sheet for installation outside diameter torque additional tightening torque mm n.Cm n.Cm Ф6.35 1500(153kgf.Cm) 1600(163kgf.Cm) Ф9.52 2500(255kgf.Cm) 2600(265kgf.Cm) Ф12.7 3500(357kgf.Cm) 3600(367kgf.Cm) 7.2 connecting the cables the power cord of connect ...

Page 21

20 caution: ● refrigerant pipe diameter is different according to indoor unit to be connected. When using the extension pipe, refer to the tables below. ● when refrigerant pipe diameter is different from that of outdoor unit union (for 18k indoor unit), additional transfer connector needs to be used...

Page 22

21 1) completely tighten the flare nuts of the indoor and outdoor units, confirm that both the 2-way and 3-way valves are set to the closed position. 2) connect the charge hose with the push pin of handle lo to the 3-way valves gas service port.. 3) connect the charge hose of handle hi connection to...

Page 23

22 2. Air purging by refrigerant procedure: 1). Confirm that both the 2-way and 3-way valves are set to the closed position. 2). Connect the charge set and a charging cylinder to the service port of the 3-way valve. 3). Air purging. Open the valves on the charging cylinder and the charge set. Purge ...

Page 24

23 be sure to use a torque wrench to tighten the service port cap to a torque 18n · m. Be sure to check the gas leakage. 3. Adding the refrigerant if the pipe length >5m procedure: 1). Connect the charge hose to the charging cylinder, open the 2-way valve and the 3-way valve. Connect the charge hose...

Page 25

24 7.5 adding the refrigerant after running the system for many years procedure: 1). Connect the charge hose to the 3-way service port, open the 2-way valve and the 3-way valve. Connect the charge hose to the valve at the bottom of the cylinder. If the refrigerant is r410a, make the cylinder bottom ...

Page 26

25 procedure 1). Confirm that both the 2-way and 3-way valves are set to the opened position remove the valve stem caps and confirm that the valve stems are in the opened position. Be sure to use a hexagonal wrench to operate the valve stems. 2). Connect the charge hose with the push pin of handle l...

Page 27

26 procedure: 1). Confirm that both the 2-way and 3-way valves are set to the closed position. 2). Connect the charge set and a charging cylinder to the service port of the 3-way valve leave the valve on the charging cylinder closed. 3). Air purging. Open the valves on the charging cylinder and the ...

Page 28

27 be sure to use a torque wrench to tighten the service port cap to a torque 18n.M. Be sure to check the gas leakage. 7.7 re-installation while the outdoor unit need to be repaired 1. Evacuation for the whole system procedure: 1). Confirm that both the 2-way and 3-way valves are set to the opened p...

Page 29

28 2. Refrigerant charging procedure: 1). Connect the charge hose to the charging cylinder, open the 2-way valve and the 3-way valve connect the charge hose which you disconnected from the vacuum pump to the valve at the bottom of the cylinder. If the refrigerant is r410a, make the cylinder bottom u...

Page 30

8. Electronic control function 8.1 abbreviation t1: indoor ambient temperature t2: coil temperature of indoor heat exchanger middle. T2b: coil temperature of indoor heat exchanger outlet. T3: coil temperature of outdoor heat exchanger t4: outdoor ambient temperature t5: compressor discharge temperat...

Page 31

8.4 outdoor unit point check function there is a check switch in outdoor pcb. Press the switch n times it will display the content corresponding to no. N. After getting into the check function, it will display no. N with 1.5s, meanwhile the low bit decimal of digit display flashing, indicated to get...

Page 32

36 ad value of voltage for example ,the digital display tube show “cd”, it means ad value is 205. 37 exv open angle for a indoor unit actual data/4. If the value is higher than 99, the digital display tube will show single digit and tens digit. For example ,the digital display tube show “2.0”,it mea...

Page 33

Capacity area a b c d e f norm value (n) 3 2 1.5 1 0.5 0 heating mode t1 ts 4 0 a 3 1 -1 3 1 2 0 b c d e f 2 capacity area a b c d e f norm value (n) 3 2 1.5 1 0.5 0 8.4.4 number of indoor unit display number of indoor unit 1 1 2 2 3 3 4 4 5 5 8.4.5 opening degree of electronic expansion valve: actu...

Page 34

8.5 protection 8.5.1 three minutes delay at restart for compressor. 8.5.2 temperature protection of compressor discharge. When the compressor discharge temp. Is getting higher, the running frequency will be limited as below rules: ----if 102 ℃ ℃ , decrease the frequency to the lower level every 2 mi...

Page 35

Heat_f15 iheatlmt11 3 minutes. After that, the frequency will be adjusted according to the capacity demand and rise to the upper level every 3 minutes (when the frequency>heat_f4 via capacity demand). Heat_f14 iheatlmt10 heat_f13 iheatlmt9 heat_f12 iheatlmt8 heat_f11 iheatlmt7 heat_f10 iheatlmt6 hea...

Page 36

9. Troubleshooting 9.1 indoor unit error code explanation: spirit: display operation lamp flash times timer lamp failure e0 1 x indoor eeprom malfunction e1 2 x indoor / outdoor units communication error e3 4 x indoor fan speed has been out of control e4 5 x open or short circuit of t1 temperature s...

Page 37

For console no. Malfunction running lamp timer lamp defrosting lamp 1 open or short circuit of t1 temperature sensor ☆ x x 2 open or short circuit of t2 temperature sensor x x ☆ 3 communication malfunction between indoor and outdoor units. X ☆ x 4 outdoor fan speed has been out of control x ☆ o 5 in...

Page 38

9.2 outdoor unit error code explanation: display led status e0 outdoor eeprom malfunction e2 indoor / outdoor units communication error e3 communication malfunction between ipm board and outdoor main board e4 open or short circuit of outdoor unit temperature sensor e5 voltage protection e8 outdoor f...

Page 39

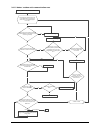

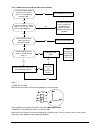

9.3 trouble shooting 9.3.1 for the indoor unit 9.3.1.1 indoor eeprom malfunction if the eeprom chip is welded on pcb, replace the pcb directly. Otherwise, check whether the eeprom chip plugged in pcb well? Yes no yes insert the eeprom well replace the indoor pcb. Shut off the power supply and turn i...

Page 40

9.3.1.2 indoor / outdoor units communication error indoor / outdoor units communication error start: power off , then power on the a/c by the breaker. (reconnect the power wire). Is it still displaying the error code? Yes no change outdoor unit pcb assembly(include wiring) totally check wiring on th...

Page 41

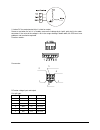

Pic 2: :ipm (for dual/tri-zone) self-check power, operating self-check operating els) pic 2: :ipm (for qua-zone) pic 1: check the voltage of n to s (vs), is it moving alternately between positive value and negative value?.

Page 42

. Pic3 :main board led when power on and unit standby. Pic 4: check point button, press 1 time for check how many indoor units are connected.

Page 43

9.3.1.3 indoor unit fan speed has been out of control shut off the power supply and turn it on 1 minute later. Is it still displaying the error code? Shut off the power supply, rotate the fan by hand. Does it rotate properly? The unit operates normally. Find out the cause and have it solved. For exa...

Page 44

For other models: no. Color 1 red 2 --- 3 black 4 white 5 yellow 6 blue for console: 5 4 6 3 2 1 no. Color 1 red 2 --- 3 white 4 blue 5 yellow 6 black index2: 1: indoor ac fan motor power on and set the unit running in fan mode at high fan speed. After running for 15 seconds, measure the voltage of ...

Page 45

2. Indoor dc fan motor(control chip is inside fan motor) power on and when the unit is in standby, measure the voltage of pin1-pin3, pin4-pin3 in fan motor connector. If the value of the voltage is not in the range showing in below table, the pcb must have problems and need to be replaced. For other...

Page 46

For a5 duct & four-way cassette (compact) no. Color signal voltage 1 red vs/vm 192v~380v 2 --- --- --- 3 black gnd 0v 4 white vcc 13.5-16.5v 5 yellow vsp 0~6.5v 6 blue fg 15v for console: 5 4 6 3 2 1 no. Color signal voltage 1 red v dc 310v 2 --- --- --- 3 white vcc 15v 4 blue fg 15v 5 yellow vsp 0-...

Page 47

9.3.1.4 open or short circuit of temperature sensor. Check the connections between temperature sensor and pcb. Are the connections good? Correct the connections. No yes yes replace indoor or outdoor pcb. Replace the sensor check the resistance value of the sensor via appendix 1 is it normal? No 9.3....

Page 48

9.3.2 for the outdoor unit 9.3.2 1 outdoor eeprom malfunction(odu e0) if the eeprom chip is welded on pcb, replace the pcb directly. Otherwise, check whether the eeprom chip plugged in pcb well? Yes no yes insert the eeprom well replace the outdoor main board outdoor eeprom malfunction.

Page 49

9.3.2.2 communication malfunction between ipm board and outdoor main board(odu e3) communication malfunction between ipm board and outdoor main board is there at least one led in the ipm board light? Check the signal wire between the ipm module and the main board, is it connected good? Reconnect and...

Page 50

9.3.2.3 voltage protection(odu e5) voltage protection check the voltage of outdoor unit power supply, whether the voltage between l(l1) and n (l2) is about 220~240vac check the power supply check whether the voltage of ipm board p and n is normal? Dc277-356v for 18-27kbtu/h; dc277-410v for 36-42kbtu...

Page 51

9.3.2.4 outdoor unit fan speed has been out of control (e8) shut off the power supply and turn it on 1 minute later. Is it still displaying the error code? Shut off the power supply, rotate the fan by hand. Does it rotate properly? The unit operates normally. Find out the cause and have it solved. F...

Page 52

No. Color 1 red 2 --- 3 black 4 white 5 yellow 6 blue index2: 1. Outdoor dc fan motor(control chip is inside fan motor) power on and when the unit is in standby, measure the voltage of pin1-pin3, pin4-pin3 in fan motor connector. If the value of the voltage is not in the range showing in below table...

Page 53

9.3.2.5 high pressure protection (odu p1) (for kam4-105 dn5, kam4-80 dn5, kam5-105 dn5, kam5-120 dn5) high pressure protection judge 1: whether the wiring between the high pressure switch and main control board is connected well or correctly method: short connect the high pressure protector socket, ...

Page 54

9.3.2.6 low pressure protection (odu p2) (for kam4-105 dn5, kam4-80 dn5, kam5-105 dn5, kam5-120 dn5) low pressure protection judge 1: whether the wiring between the low pressure protector and main control board is connected well or correctly method: short connect the low pressure protector socket, c...

Page 55

9.3.2.7 current protection of compressor(odu p3) current protection of compressor judge 1: check whether the input current of the power supply wire is higher than max protection current value yes replace the electric control box check whether the refrigerant system is ok judge 2: check whether the o...

Page 56

Temperature protection of compressor discharge check whether the compressor discharge temp. Is more than 115°c ? Check whether the wiring connection is right between compressor discharge temp. Sensor and pcb according to wiring diagrams? Method: check whether the resistance of compressor discharge t...

Page 57

9.3.2.9 high temperature protection of condenser(odu p5) when outdoor pipe temperature is more than 65°c, the unit will stop, and unit runs again when outdoor pipe temp. Less than 52°c. High temperature protection of condenser check whether the condenser temperature is more than 65°c yes judge 1: ch...

Page 58

9.3.2.10 ipm module protection(odu p6) ipm module protection check whether the voltage range of p-n on ipm module is normal? Dc277-356v for 18-27kbtu/h; dc277-410v for 36kbtu/h yes yes no yes check whether the input power supply is correct? 208-230v, 1n, 60hz no no regulate it to correct, then check...

Page 59

9.4 main parts check spec. Indoor unit model 7k 11m 9k 11m 12k 11m 18k 11m indoor fan motor wzdk20-38g wzdk20-38g wzdk20-38g wzdk58-38g model 9k 11p 12k 11p 18k 11p indoor fan motor wzdk20-38g wzdk20-38g wzdk20-38g model 7k 9a 9k 9a 12k 9a 18k(rc8) 9a 18k(rc4) 9a indoor fan motor wzdk20-38g rpg20d r...

Page 60

1. Temperature sensor checking disconnect the temperature sensor from pcb, measure the resistance value with a tester. Temperature sensors. Room temp.(t1) sensor, indoor coil temp.(t2) sensor, outdoor coil temp.(t3) sensor, outdoor ambient temp.(t4) sensor, compressor discharge temp.(t5) sensor. Mea...

Page 61

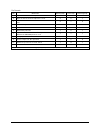

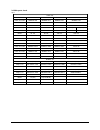

Appendix 1 temperature sensor resistance value table for t1,t2,t3,t4,t2b ( ℃ --k) ℃ k ohm ℃ k ohm ℃ k ohm ℃ k ohm -20 115.266 20 12.6431 60 2.35774 100 0.62973 -19 108.146 21 12.0561 61 2.27249 101 0.61148 -18 101.517 22 11.5000 62 2.19073 102 0.59386 -17 96.3423 23 10.9731 63 2.11241 103 0.57683 -1...

Page 62

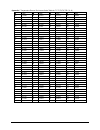

Appendix 2 temperature sensor resistance value table for t5 ( ℃ --k) ℃ k ohm ℃ k ohm ℃ k ohm ℃ k ohm -20 542.7 20 68.66 60 13.59 100 3.702 -19 511.9 21 65.62 61 13.11 101 3.595 -18 483 22 62.73 62 12.65 102 3.492 -17 455.9 23 59.98 63 12.21 103 3.392 -16 430.5 24 57.37 64 11.79 104 3.296 -15 406.7 2...

Page 63

2.Compressor checking measure the resistance value of each winding by using the tester. Position resistance value da130m1c-31fz da150s1c-20fz da250s2c-30mt tnb306fpgmc-l asn108d22uez mnb36faamc-l blue - red 1.77 Ω(20 ℃ ) 0.95Ω(20 ℃ ) 0.55 Ω(20 ℃ ) 0.53 Ω(20 ℃ ) 1.57 Ω(20 ℃ ) 0.44 Ω(20 ℃ ).

Page 64

3. Ipm continuity check turn off the power, let the large capacity electrolytic capacitors discharge completely, and dismount the ipm. Use a digital tester to measure the resistance between p and uvwn; uvw and n. Digital tester normal resistance value digital tester normal resistance value (+)red (-...