- DL manuals

- Keating Of Chicago

- Pasta Maker

- 240V

- Service Manual

Keating Of Chicago 240V Service Manual

Summary of 240V

Page 1

Keep this manual for training new personnel 1-800-keating www.Keatingofchicago.Com part # 000000 electric pasta 0107 09/07 custom pasta ™ system electric service manual.

Page 2: Post This Label In A

I this operating, installation, and service manual should be given to the user. The operator of the custom pasta ™ system should be familiar with the functions and operation of the cooker. This manual must be kept in a prominent, easily reachable location near the pasta system. Post this label in a ...

Page 3: Table of Contents

Section i specifications . . . . . . . . . . . . . . 1 section ii installation shipment and transit . . . . . . . . . . . . . . . . . . . . . . . .1 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 a. Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 b...

Page 4: I Introduction

2 i introduction general keating electric custom pasta ™ systems are designed to give maximum production efficiency, delivering high quality food products. The following design features are incorporated in keating pasta electric systems. Standard features • highly polished stainless steel vessel • h...

Page 5: II Installation

• keating custom pasta ™ systems are intended for other than household use. • always instruct new employees on proper pasta system operation. • a custom pasta system ™ should be operated only by properly trained personnel. • always turn pasta system off each night. • always turn pasta system off at ...

Page 6

4 positioning the pasta cooker must be no closer than 6" from any combustible material. When placed under an exhaust hood with a fire retardant system it must comply with ansi/ul 507-(latest edition) and ansi/nfpa 96- (latest edition). No frame or restriction can be constructed around the lower part...

Page 7: III Operation

5 in most cases the health department will not allow a direct connection between the cooker drain and the floor receptical. Contact your local health department for specific information in your area. Iii operation filling note: before filling the pasta system make certain the vessel is sanitized, dr...

Page 8

6 procedures below for your model. Note: use of sodium chloride during the cooking process will have a detrimental effect on the cooker tank and will void the warranty. Operation of this pasta system should be limited to personnel who have been thoroughly trained in operating procedures. Use only ke...

Page 9

7 3. Drain water from pasta system. 4. Fill pasta system vessel with water. See page 7 – filling. Under no circumstances should the pasta system be left unattended during boil-out. Trained personnel must be present during the procedure to prevent boil over or to turn off the power if water drops bel...

Page 10: IV Maintenance

8 contacts will open, the display will flash, and the audible alarm will sound. To cancel the audible alarm, press any button. C. Pause feature to pause a cycle in progress, press any button. The relay output contacts will open, the display will flash, and the countdown will pause. To resume the cou...

Page 11

9 b. The water auto-fill and low water safety shut- off systems the water supply connection, located at the bottom rear of the pasta system and marked water, is a standard 3 / 8 ” female pipe connection. The water pressure should be between 20-60 psi. If the pressure exceeds 60 psi, a pressure regul...

Page 12: V Service And Parts

10 v service and parts information the cooker must be disconnected from its power source or shut down at the breaker prior to service. Auto-fill system the auto-fill system allows the automatic addition of water to the pasta cooker during cooking or idle function. The system is controlled by the on/...

Page 13: VI Service Diagnosis

11 common problems solutions (follow in sequence) water always filling 1. Clean sensors thoroughly with brush and vinegar. 2. Adjust the sensitivity of the b board (for the top sensor) fully clockwise. 3. If filling persists, ground out the top sensor (if filling stops, replace sensor – part #010212...

Page 14

Problem probable cause solution pasta cooker has poor recovery or runs cold. A.Over-filling baskets. B.Thermostat out of calibration. C. Element is faulty. D.Thermostat is faulty. E.Contactor is faulty. A.Don’t overfill baskets. B.Calibrate thermostat. See page 4 - calibration. C. Replace element. D...

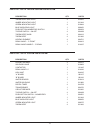

Page 15: Vii Parts List

Vii parts list custom pasta system electric control panel assembly 13 item # description qty part # 1 indicating light, amber, power on 1 031624 2 toggle switch– main on-off 2 004499 3 indicating light, green, thermostat heating 2 010682 4 indicating light, water filling 1 009256 5 manual water fill...

Page 16

14 parts list for custom pasta system ™ item description models part # 14 18 20 24 1 heating element 220v 6500w 14" only 018668 3 1 heating element 18" & 20" only 004353 2 2 2 drain valve – 1" front 14" only 026813 1 2 drain valve handle – 1" front 14" only 016387 1 2 drain valve – 1 1 /4" front 18"...

Page 17

15 parts list for 14" drop-in custom pasta system description qty part# thermostat dial plate 2 034975 amber indicating light 1 031624 green indicating light 2 010682 blue indicating light 1 009256 push button momentary switch 1 004304 toggle switch – on-off 2 004499 thermostat knob 2 004163 thermos...

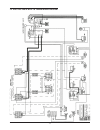

Page 18: Viii Wiring Diagrams

16 viii wiring diagrams 14" electric pasta 2-thermostat wiring diagram (without timers).

Page 19

17 14" electric pasta with 138 timers wiring diagram.

Page 20

18 18" & 20" electric pasta with 138 timers wiring diagram.

Page 21

19 18" electric pasta 2-thermostat wiring diagram (without timers).

Page 22: Arranty

L imited w arranty keating of chicago, inc. ("keating”) warrants to the original purchaser . ("customer"), all new keating fryers, filter systems, griddles, keep krisp ® , custom pasta systems, t op-side™ cookers, computer t imers, fryer & pasta v essels, and keating replacement parts ("pro ducts") ...

Page 23

Keating limited warranty card please complete and mail at once–warranty is not in effect until card is returned warranty registration is also available online for your convenience company: __________________________________________________________________________________________________________ addr...