- DL manuals

- Keating Of Chicago

- Pasta Maker

- Gas Custom Pasta System

- Service Manual

Keating Of Chicago Gas Custom Pasta System Service Manual

Summary of Gas Custom Pasta System

Page 1

Custom pasta ™ system gas service manual keep this manual for training new personnel 1-800-keating www.Keatingofchicago.Com gas pasta 0107 9/07.

Page 2: Post This Label In A

I this operating, installation, and service manual should be given to the user. The operator of the pasta system should be familiar with the functions and operation of the cooker. This manual must be kept in a prominent, easily reachable location near the pasta system. Post this label in a prominent...

Page 3: Table of Contents

Table of contents section i introduction general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 standard features . . . . . . . . . . . . . . . . . . . . . . . . . .1 model variations . . . . . . . . . . . . . . . . . . . . . . . . . . .1 safety precautions . . . . . . . . . . ...

Page 4: I Introduction

I introduction general keating pasta gas systems are designed to give maximum production efficiency, delivering high quality food products. The following design features are incorporated in keating pasta gas systems. Standard features highly polished stainless steel vessel highly polished stainless ...

Page 5: Warning

You must maintain this appliance free and clear from combustibles. You must maintain the following minimum clearances from combustible and noncombustible construction: adequate clearance for servicing and proper operation must be maintained. Your pasta system is designed to be serviced from the fron...

Page 6: II Installation

If not installed, operated and maintained in accordance with the manufacturer’s instructions, this product could expose you to substances in fuel or in fuel combustion which can cause death or serious illness and which are known to the state of california to cause cancer, birth defects or other repr...

Page 7: Warning

4 figure 2-1 restraining devices on pasta system installations with casters, casters and jam nuts must be completely tightened. Adequate means must also be provided to limit the movement of the appliance without depending on the connector, the quick-disconnect device or its associated piping to limi...

Page 8: Warning

5 a 3 / 4 " ips manual gas valve is shipped with each single pasta system for field installation. Batteries have a factory installed manual gas valve for each pasta system. The required gas pressure for proper operation of each pasta system is 4" water column (wc) for natural gas and 10” water colum...

Page 9: III Operating

6 constructional changes to the area where the pasta system is installed shall not affect the air supply to the pasta system. The installation, start-up and changes required when changing from one gas type to another can be performed only by a certified professional. The pasta system is intended onl...

Page 10: Warning

2. Turn “on” main power on/off switch (located between the amber and green indicating lights). 3. Light the constant pilot (located next to left burner as you face it). If your pasta system has an optional spark ignitor, omit this step. 4. Activate pilot light momentary switch (let top corner) and h...

Page 11: Warning

1. Turn off pasta system and open the door. Figure 3-3 drain, drain valve and overflow tubing 2. Slowly turn handle. The drain valve will be completely open after 1 / 4 turn. Cleaning when cleaning and boiling out your pasta system, use white vinegar and keating klenzer to keep your pasta system in ...

Page 12: IV Maintenance

B. How to program the “keating” electronic timer the keating electronic timer is programmable to four different timer ranges with two different alarm modes for each time range. The timers are shipped from the factory preset to program 5: minutes : seconds (00:01 to 59:59) with continuous alarm to pr...

Page 13: Caution

10 (at 1-800-keating) before calling a local service company preventive maintenance preventive maintenance should be done in daily, weekly, monthly and yearly intervals as necessary. Following preventive maintenance procedures will help keep your pasta system working efficiently. Proper care and ser...

Page 14: Warning

Auto-fill system. The water level is controlled by two circuit boards and two sensors. The sensors are located in the tube on the right side of the overflow deck. The upper sensor controls the water level and the lower sensor controls the low water safety shut-off system. Once the water on/off switc...

Page 15

12 problem probable cause solution constant pilot won’t light. A.Gas isn't turned on. B.Clogged constant pilot tubing. C. Constant pilot valve isn't turned on. A.Turn manual gas valve on. If using flexible connector with quick disconnect, make sure quick disconnect is completely engaged. B.Turn cust...

Page 16

13 problem probable cause solution flames come out front. A.Burners misaligned. B.Exhaust problems. C. Radiants have slipped forward. D.Flue blockage. A.Adjust position of burners. B.Install deflector to block down draft. Install or adjust flue restrictors. If problem persists, contact your hvac rep...

Page 17

14 problem solutions (follow sequentially) water always filling. A.Clean sensors thoroughly with brush and vinegar. B.Adjust the sensitivity of the b board (for the top sensor) fully clockwise. C. If filling persists, ground out the top sensor (if filling stops, replace sensor – part #010212). D.If ...

Page 18

15 replacement of a and b boards 1. Locate the wiring diagram. It will help later with connecting wires to the board. 2. Disconnect wires from the board. 3. Unscrew mounting screws. There are three of them per board. 4. Replace the board. 5. Reconnect the wires. 6. Adjust sensitivity. 7. Close the b...

Page 19: V Service Diagnosis

16 custom pasta ™ system control panel with digital timers v service diagnosis the burners when on will produce clear blue flames directed at the inside walls of the heat transfer tubes. The radiant’s fins, located towards the rear of each transfer tube, will glow bright red, helping to ensure optim...

Page 20

17 item description quantity part number 1 toggle switch - pilot on 1 004507 2 indicating light, amber - pilot on 1 031624 3 toggle switch – main on-off 1 004501 4 indicating light, green - secondary burner on 1 009375 5 unused 3 ------ 6 digital timer(s) 2 056921 7 thermostat 2 031466 8 dial plate ...

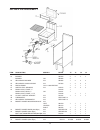

Page 21

18 gas pasta system assembly i item description models part# 14 18 20 24 1 gas valve, 120v all natural gas 004269 1 1 1 1 lp 008123 1 1 1 1 2 runner pilot tube see below 1 1 1 1 3 constant pilot assembly all (1.8"x28") 004259 1 1 1 1 4 constant pilot valve all 004266 1 1 1 1 5 runner pilot gas cock ...

Page 22

19 item description models part# 14 18 20 24 22 radiant, 2 - fins all 000041 3 4 4 5 23 burner 008264 2 2 2 3 burner cm 004088 2 24 secondary burner all 004088 1 2 2 2 25 secondary gas solenoid all 037033 1 2 2 2 26 pasta vessel call 1-800-keating 1 1 1 1 27 water level sensors all 010212 2 2 2 2 28...

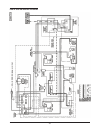

Page 23

20 pasta system wiring diagram.

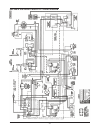

Page 24

21 gas pasta system with basket-lift wiring diagram.

Page 25: Arranty

L imited w arranty keating of chicago, inc. ("keating”) warrants to the original purchaser . ("customer"), all new keating fryers, filter systems, griddles, keep krisp ® , custom pasta systems, t op-side™ cookers, computer t imers, fryer & pasta v essels, and keating replacement parts ("pro ducts") ...

Page 26

Keating limited warranty card please complete and mail at once–warranty is not in effect until card is returned company: ____________________________________________________________________________________________________ address: _____________________________________________________________________...