- DL manuals

- KEB

- Servo Drives

- COMBIVERT F6

- Instruction manual

KEB COMBIVERT F6 Instruction manual

Summary of COMBIVERT F6

Page 1

Combivert original manual mat.No. Rev. 00f50eb-ku00 2k instruction manual housing u 55…90 kw 230 v 75…200 kw 400 v.

Page 3

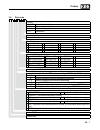

Gb - 3 table of content 1. Preface ..............................................................................................................5 1.1 general ................................................................................................................................. 5 1.2 valid...

Page 4

Gb - 4 table of content annex a .....................................................................................................................37 a.1 overload characteristic ..................................................................................................... 37 a.2 overload pr...

Page 5

Gb - 5 preface 1. Preface 1.1 general the described hard- and software are developments of the keb automation kg. The en- closed documents correspond to conditions valid at printing. Misprint, mistakes and technical changes reserved. The instruction manual must be made available to the user. Before ...

Page 6

Gb - 6 preface 1.3 copyright the customer may use the instruction manual as well as further documents or parts from it for internal purposes. Copyrights are with keb and remain valid in its entirety. All rights reserved.Keb®, combivert®, combicontrol® and combivis® are regis- tered trademarks of keb...

Page 7

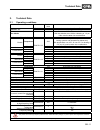

Gb - 7 preface 1.6 part code 27.F5. A b u-9 0 0 a cooling 0, 5, a, f heat sink (standard) 1, b, g flat rear 2, c, h water-cooling system 3, d, i convection encoder interface 0:none switching frequency; short time current limit; overcurrent limit 0 2 khz; 125 %; 150 % 5 4 khz; 150 %; 180 % a 8 khz; 1...

Page 8

Gb - 8 general 1.7 transport instructions transportofheatsinkswithanedgelengthof≥75cm: transportbyfork-lifttruckcanleadtoadeflectionoftheheatsink.Thiscanhavetheagingor destruction of internal components as a result. Attention transport instructions must be observed. To avoid damage, the inverter may...

Page 9

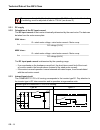

Gb - 9 general 1.8.2 control cabinet installation mounting distances dimen- sion distance in mm distance in inch c a b d d a 150 6 b 100 4 c 30 1.2 d 30 1.2 x 1) 50 2 1) distance to preceding elements in the cabinet door. Direction of the cooling fins front and side view of the coolant inlet coolant...

Page 10

Gb - 10 safety instructions 1. General in operation, drive converter depending on their degree of protection, may have live, uninsulated and possibly also moving or rotating parts, as well as hot surfaces. In case of inadmissible removal of the required covers, of improper use, wrong installation or...

Page 11

Gb - 11 technical data 2. Technical data 2.1 operating conditions standard standard/ class instructions definitionacc. En 61800-2 inverter product standard: ratedspecifications en 61800-5-1 inverter product standard: general safety site altitude max. 2000 m above sea level with site altitudes over 1...

Page 12

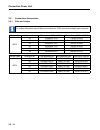

Gb - 12 technical data of the 230 v class 2.2 technical data of the 230v class unit size 22 23 24 housing size u phases 3 output rated power [kva] 87 115 143 max. Rated motor power [kw] 55 75 90 output rated current [a] 220 290 360 max. Short time current 1) [a] 330 362 450 oc-tripping current [a] 3...

Page 13

Gb - 13 technical data of the 400 v class 2.3 technical data of the 400 v class unit size 23 24 25 26 27 28 housing size u phases 3 output rated power [kva] 104 125 145 173 208 256 max. Rated motor power [kw] 75 90 110 132 160 200 output rated current [a] 150 180 210 250 300 370 max. Short time curr...

Page 14

Gb - 14 technical data of the 400 v class the response threshold of the braking transistsor (pn.69) for all controls without safe- ty technology must be adjusted at least to 770 vdc (see annex d). 2.3.1 dc supply 2.3.2 calculation of the dc input current the dc input current of the inverter is basic...

Page 15

Gb - 15 technical data - dimensions and weights 2.4 dimensions and weights 2.4.1 mounted version with sub construction (default) housing type a b c f g h weight air-cooling 800 340 357 300 775 Ø11 75 kg water cooling 2-plate heat sink (special version) 800 340 275.5 300 775 Ø11 – water cooling extru...

Page 16

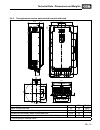

Gb - 16 technical data - dimensions and weights 2.4.2 through-mount version heat sink with fan (size 24…27) 130 345 130 370 390 201,5 153.

Page 17

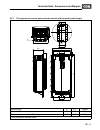

Gb - 17 technical data - dimensions and weights 2.4.3 mounted version water-cooled heat sink 340 g 1/2" din iso 228-1 201,5 74 4x ø25 u2.F5.T40-f019 300 13,5 800 774 300 11 857 4x m10

Page 18

Gb - 18 technical data - dimensions and weights 2.4.4 through-mount version water-cooled heat sink 120 360 600 840 m10 20 x 7 370 130 203,5 2 26 230 305 340 820 120 360 600 840 130 350 370 b housing type a b c weight water-cooled heat sink 862 390 46 58 kg water-cooled heat sink with braking resisto...

Page 19

Gb - 19 technical data - dimensions and weights 2.4.5 through-mount version water-cooled heat sink with stud 2 230 305 340 203,5 a 26 130 370 390 120 360 600 840 862 20x Ø7 m10 820 350 370 130 840 600 360 120 b housing type a b *) weight water-cooled heat sink 46 55 58 kg water-cooled heat sink with...

Page 20

Gb - 20 technical data - dimensions and weights 2.4.6 through-mount version water-cooled heat sink with stud (small design) 340 g 1/2 " din iso 228-1 u2.F4.Tk4-k0we u2.F4.T40-a019 m10 u2.F4.T05-0008 2xm8 318 120 a b 355 330 110 805 360 600 840 230 305 26 110 330 355 20 x 9 120 840 600 360 377 862 20...

Page 21

Gb - 21 technical data - dimensions and weights 2.4.7 through-mount version water-cooled heat sink without stud (small design) 2x g 1/2 din iso 228-1 862 120 120 120 120 120 120 120 11 11 r7,5 20x ø9 3x m8 m8 330 305 305 230 110 355 120 120 120 120 120 120 120 805 110 318 330 110 330 350 377 110 110...

Page 22

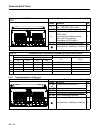

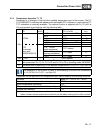

Gb - 22 terminals 400 v class 2.5 terminal strips of the power circuit 2.5.1 terminal strips for 400v units all terminal strips following the requirements of the en 60947-7-1 (iec 60947-7-1) unit size 23…25 default with gtr7 terminal in accordance with table 2.5 l1 l3 l2 u v w +pa - pb k1k2 t2 t1 na...

Page 23

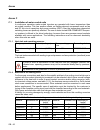

Gb - 23 terminals 400 v class unit size 26…27 28 default with gtr7 terminal in accordance with table 2.5 l1 l2 l3 pa pb u v w name function no. L1, l2, l3 3-phase mains connection 5 u, v, w motor connection pa, pb connection for braking resistor 1 t1, t2 connection for temperature sensor 3 k1, k2 gt...

Page 24

Gb - 24 terminals 400 v class unit size 26, 27 advanced special version terminal in accordance with table 2.5 l1 l3 l2 u v w +pa - pb k1k2 t2 t1 name function no. L1, l2, l3 3-phase mains connection 1 u, v, w motor connection pa, pb connection for braking resistor 4 +pa, – dc link voltage 420…746 v ...

Page 25

Gb - 25 terminals 400 v class housing size 23…27 dc versionspecial ver- sion without gtr terminal in accordance with table 2.5 ++ - - u v w + - t2 t1 name function no. ++, -- dc voltage input 420…746 v dc (400v class) 1 u, v, w motor connection +, - dc link voltage 420…746 v dc (400v class) connecti...

Page 26

Gb - 26 terminals 400 v class housing size 23…27 dc version without gtr7 terminal in accordance with table 2.5 ++ + - - - u v w t1t2 name function no. ++, -- dc voltage input 420…746 v dc (400v class) 5 u, v, w motor connection +, - dc link voltage 420…746 v dc (400v class) connection for braking mo...

Page 27

Gb - 27 terminals 230 v class unit size 22…24 default without gtr7 terminal in acc. With table 2.6 l1 l2 l3 + - u v w t1 t2 name function no. L1, l2, l3 3-phase mains connection 5 u, v, w motor connection +, - dc link voltage 250…370 v dc (200v class) connection for braking module, filterordclinkcou...

Page 28

Gb - 28 connection power unit 2.6 connection accessories 2.6.1 filter and chokes for further information about filters and chokes for 230v units are available upon request. Voltage class inverter size mains choke 50 hz / 4 % uk motor choke 100 hz / 4 % uk 400 v 23 23drb18-1741 23drc18-8231 24 24drb1...

Page 29

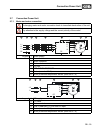

Gb - 29 connection power unit 2.7 connection power unit 2.7.1 mains and motor connection exchanging mains and motor connection leads to immediate destruction of the unit. Pay attention to the supply voltage and the correct polarity of the motor ! L1 l2 l3 pe l1 7 8 l2 l3 u v w pe u v w pe pe t1 t2 l...

Page 30

Gb - 30 connection power unit 2.7.2 selection of the motor cable correct selection and wiring of the motor cable is very important: • lower abrasion of the motor bearings by leakage currents • improved emc characteristics • lower symmetrical operating capacities • less losses by transient currents p...

Page 31

Gb - 31 connection power unit 2.7.4 temperature detection t1, t2 parameter in.17 displays in high byte the installed temperature input of the inverter. The f5/ f6 combivert is delivered as standard with switchable ptc evaluation. A switchable kty/ ptc evaluation is optionally available. The desired ...

Page 32

Gb - 32 connection power unit • do not lay kty or ptc cable of the motor (also shielded) together with control cable ! • kty or ptc cable only permissible with double shielding within the motor cable ! The error message e.Doh should never be disabled, otherwise the load shunt is no longer evaluated....

Page 33

Gb - 33 connection power unit wiring example in ptc mode mixed sensor chain t1 t2 the function can be switched off with pn.12 = “7“ (cp.28) if no evaluation of the input is desired (standard in operating mode general). Alternatively a bridge can be installed be- tween t1 and t2. 2.7.5 connection of ...

Page 34

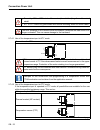

Gb - 34 connection power unit 2.7.5.1 braking resistor without temperature monitoring intrinsically safe braking resistor without temperature monitoring +pa pb r b g1 only "intrinsically safe" braking resistors are permissible for operation without tem- perature monitoring. 2.7.5.2 braking resistor ...

Page 35

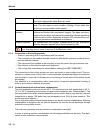

Gb - 35 connection power unit braking resistor with over-heat protection and gtr7 monitoring t1 t2 l1 l2 l3 k3 2 u v w l1 l2 k1 k2 l3 1 4 3 6 5 12 11 g1 r1 +pa pb oh1 oh2 i1 oh1 oh2 pe dr1 hf1 f r2 +24v s2 k1 i1 k2 gtr7-error g1 k3 gnd s1 k3 11 12 h1 0v r1 oh2 oh1 dr1 oh2 oh1 k3 line contactor with ...

Page 36

Gb - 36 connection power unit braking resistor with over-heat protection without gtr7 monitoring t1 t2 l1 l2 l3 k3 2 u v w l1 l2 l3 1 4 3 6 5 12 11 14 13 g1 r1 +pa pb oh1 oh2 i1 0v oh1 oh2 pe dr1 hf1 f r2 +24v s2 i1 g1 k3 gnd s1 k3 11 12 h1 0v r1 dr1 oh1 oh2 oh1 oh2 k3 13 14 k3 line contactor with a...

Page 37

Gb - 37 annex annex a a.1 overload characteristic 30 60 90 120 150 180 210 240 270 300 0 105 110 115 120 125 130 135 140 145 150 160 170 180 190 200 210 220 time [s] load [%] time [s] load [%] 30 60 90 120 150 180 210 240 270 300 0 105 110 115 120 125 130 135 140 145 150 characteristic 1 characteris...

Page 38

Gb - 38 annex a.3 calculation of the motor voltage the motor voltage for dimensioning of the drive is depending on the used components. The mains voltage reduces according to the following table: mains choke uk 4 % example: inverter open loop 4 % closed loop inverter with mains- and motor choke at n...

Page 39

Gb - 39 annex storage period • start-up without special measures storage period 1…2 years • operate frequency inverter one hour without modulation storage period 2…3 years • remove all cables from the power circuit; especially of braking resistor or module • open control release • connect variable t...

Page 40

Gb - 40 annex annex b b.1 certification b.1.1 ce marking ce marked drive converters and servo drives were developed and manufactured to comply with the regulations of the low-voltage directive 2006/95/ec. The inverter or servo drive must not be started until it is determined that the installation co...

Page 41

Gb - 41 annex short circuit rating and branch circuit protection: following marking shall be provided: 23.F5/f6 240v models: „suitable for use on a circuit capable of delivering not more than 100 ka rms symmetrical amperes, 240 volts maximum when protected by class ___ fuses, rated ____ amperes as s...

Page 42

Gb - 42 annex annex c c.1 installation of water-cooled units in continuous operation water-cooled inverters are operated with lower temperature than air-cooled inverters. This has positive effects on lifetime-relevant components such as fan and dc link circuit capacitors and power modules (igbt). Al...

Page 43

Gb - 43 annex table 1.5.2 electro-chemical voltage series / standard potentials against hydrogen material generated ion standard po- tential material generated ion standard po- tential aluminium al 3+ -1.67 v copper cu 2+ 0.34 v manganese mn 2+ -1.05 v carbon c 2+ 0.74 v zinc zn 2+ -0.76 v silver ag...

Page 44

Gb - 44 annex impurities mechanical impurities in half-open cooling systems can be counter- actedwhenappropriatewaterfiltersareused. Salt concentration the salt content can increase through evaporation at half-open sys- tems. Thus the water is more corrosive. Adding of fresh water and removing of pr...

Page 45

Gb - 45 annex supply of temper coolant this is possible by using heatings in the cooling circuit for the control of the coolant temper- ature. The following dew point table is available for this: coolant inlet temperature [°c] is depending on ambient temperature and air humidity air humidity [%] sur...

Page 46

Gb - 46 annex c.1.6 coolantheatingdependingonpowerlossandflowratewithwater 0 1 2 3 4 5 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 pv [kw] Δt [k] 100 l/min 50 l/min 40 l/min 30 l/min 20 l/min 10 l/min 5 l/min c.1.7 typicallyfallofpressuredependingontherateofflow bar 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9...

Page 47

Gb - 47 annex annex d d.1 changing the response threshold of the braking transistor to avoid a premature switching of the brake transistor at an input rated voltage of 480 vac, the response threshold must be controlled or adjusted according to the following graphic. Stop enter f/r enter f/r func. Sp...

Page 48

Keb antriebstechnik austria gmbh ritzstraße8•4614marchtrenk fon:+43724353586-0•fax:+43724353586-21 net: www.Keb.At •mail: info@keb.At keb antriebstechnik herenveld2•9500geraadsbergen fon:+3254437860•fax:+3254437898 mail: vb.Belgien@keb.De keb power transmission technology (shanghai) co.,ltd. No. 435...