- DL manuals

- KEB

- Power Supply

- Combivert R6

- Instruction Manual

KEB Combivert R6 Instruction Manual

Summary of Combivert R6

Page 1

1/2017 00.R6.Nub-k000 rev .1g c o m b i v e r t us instruction manual power supply and regeneration unit type r6-n size 15/19 version 1.0 r c us.

Page 2

Us - 2 1. Introduction ......................................................................................................................4 1.1 preface ............................................................................................................................................... 4...

Page 3

Us - 3 table of contents 6.1 status display: status and error messages................................................................................ 35 6.1.1 status messages ...............................................................................................................................

Page 4

Us - 4 preface 1. Introduction 1.1 preface first we would like to welcome you as a customer of keb and congratulate you on the purchase of this product. You have decided on a product of the highest technical innovation. The enclosed documents as well as the specifi ed hardware and software are devel...

Page 5

Us - 5 preface 1.3 specifi ed application the r6-n serves exclusively for the supply of frequency inverters with dc input and/or regeneration of excess energy into the line supply system. The operation of other electrical loads is prohibited and can lead to malfunctions or destruction of the unit. 1...

Page 6

Us - 6 safety instructions 2. Safety instructions 2.1 general instructions caution - risk of electrical shock the r6 power supply and recovery unit contains dangerous voltages which can cause death or serious injury. The r6 can be adjusted such that energy is returned to the line supply system even ...

Page 7

Us - 7 safety instructions 2.3 electrical connection note capacitor discharge time before any installation and connection work, the system must be switched off and secured. After switch off, the intermediate circuit capacitors are still charged with high voltage for a short period of time. The unit ...

Page 8

Us - 8 safety instructions different ground potentials when using components without isolated inputs / outputs, it is necessary that equal potential bonding exist between the components to be connected (e.G. Through the equalizer). Disregard can cause destruction of the components by the equalizing ...

Page 9

Us - 9 safety instructions conditionally short-circuit proof (regen) the r6 is conditionally short-circuit proof (en 61800-5-1 / vde 0160). After resetting the internal protection devices, the function as directed is guaranteed. Exception: • a ground fault or short-circuit frequently occurring at th...

Page 10

Us - 10 emc instructions 2.4 emc instructions the r6-n represents electrical equipment designed for use in industrial and commercial installations. In accordance with the emc directive 89/336/eec, it is not mandatory to mark these devices as they represent components to be further handled by the res...

Page 11

Us-11 storage 2.6 storage of the unit the dc bus of the keb r6 is equipped with electrolytic capacitors. If the electrolytic capacitors are stored de-energized, the oxide fi lm working as dielectric fl uid reacts with the acidic electrolyte and destroys itself slowly. This affects the dielectric str...

Page 12

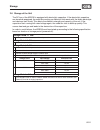

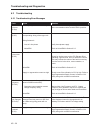

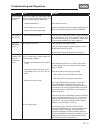

Us - 12 technical data 3. Technical data 3.1 power data unit size 15 19 housing size e phases 3 rated voltage *) [v] 208/240/480 supply voltage 1) [v] 180…528 ±0 % line frequency [hz] 50 / 60 ±2 regenerative operation output rated power *) [kva] 18 (10.5) 45 (26) rated active power *) [kw] 17 (10) 4...

Page 13

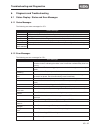

Us - 13 technical data 3.2 operating environment specifi cations standard classifi cation specifi cations defi nition according to en 61800-2 inverter product standard: measurement specs. En 61800-5-1 inverter product standard: general safety operating altitude 2000m above sea level with 1% power de...

Page 14

Us - 14 technical data 3.3 accessories unit size 15 19 rated voltage 480 v (can also be used at 230v) regen choke 14.Z1.B04-1000 15.Z1.B04-1000 16.Z1.B04-1000 17.Z1.B04-1000 18.Z1.B04-1000 19.Z1.B04-1000 20.Z1.B04-1000 synchronization cable* 00.F5.0c3-4010 * synchronization cables are only required ...

Page 15

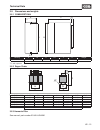

Us - 15 technical data 3.5 dimensions and weights 3.5.1 combivert r6-n h c b a Ø f c1 housing a b c c1* f h weight e 5.12 11.4 8.19 0.55 0.27 10.8 12.4 lb values are in inches * c1 with operator 3.5.2 regen choke Ø f b h g c a part number a b c f g h weight 14.Z1.B04-1000 3.03 5.71 5.83 0.32 2.28 5....

Page 16

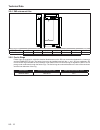

Us - 16 technical data 3.5.4 emi sub-mount fi lter c a g b h Øf part number a b c f g h weight 15.E4.T60-1000 1.97 13.9 5.14 0.28 3.94 13.0 4.4 lb 19.R6.T60-1001 2.56 16.6 7.80 0.28 5.91 15.6 16.8 lb values are in inches 3.5.5 ferrite rings ferrite rings are required to minimize electrical disturban...

Page 17

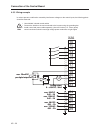

Us - 17 installation 4. Installation 4.1 emc-compatible control cabinet installation 1 line fuse 150 mm 30 mm 150 mm 1 2 6 8 7 10b 9 10c 10a 11 11a 12 4 + 5 3 2 line contactor 3 harmonic fi lter 4 r6 5 hf sub-mounting fi lter 6 choke 7 frequency inverter 8 if necessary, external dc fuses 9 motor cab...

Page 18

Us - 18 connection terminals 4.3 connection of the r6 4.3.1 connection terminals of the power circuit pay attention to the input voltage, since both 230 v and 480 v are possible ! Housing size e name tightening torque [nm] - - ++ l12 ++ l32 l22 - - permissible line cross section [awg] size 15 2 to 4...

Page 19

Us - 19 connection power unit 4.4 connection power circuit r6-n with internal fuses 4.4.1 points for general consideration always use ul listed and csa approved wire. Use 60/75°c copper conductors only. Use minimum 300v rated wire with 230v systems and minimum 600v rated wire with 480v systems. Suit...

Page 20

Us - 20 connection power unit 4.4.3 wiring scheme 'a' with parallel regen units and commutation chokes 4 3 8 l1.2 l2.2 l2.1 l3.2 l1.1 l3.1 7 l2 l1 l3 1 2 pe l1.2 l2.2 l2.1 l3.2 l1.1 l3.1 ++ ++ - - - - l1.2 l2.2 l3.2 x2d ++ ++ - - - - l1.2 l2.2 l3.2 x2d 9 6 $ppð d e ++/+pa - - / - w v u pe l2 l1 l3 ...

Page 21

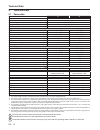

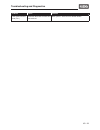

Us - 21 connection power unit 4.4.4 sizing for wiring scheme a below is regen system sizing for wiring scheme a (sections 4.4.2.1, 4.4.2.2, and 4.4.3) by horsepower according to line voltage, motor type, and whether a regen choke or harmonic fi lter is used in conjunction with the r6 unit. Keb r6 re...

Page 22

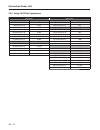

Us - 22 connection power unit 4.4.5 sizing f5 dc bus capacitances 230 v units 480 v units size dc bus capacity (uf) size dc bus capacity (uf) 13f5a1e-plx2, b 3,280 13f5a1e-rlx2, b 705 14f5a1e-plx2, b 4,100 14f5a1e-rlx2, b 820 14f5a1g-plx2, b 3,280 15f5a1g-plx2, b 4,000 15f5a1e-rlx2, b 1,230 15f5a1g-...

Page 23

Us - 23 connection power unit 4.4.6 wiring scheme 'b' with single regen unit not yet available. 4.4.7 wiring scheme 'b' with parallel regen units not yet available. 4.4.8 sizing for wiring scheme 'b' not yet available..

Page 24: Harmonic

Us - 24 connection power unit 4.4.9 manual motor starter (mms) for capacitor assembly with harmonic filter when using a harmonic fi lter, the mms must be turned on to bring the capacitor assembly into the circuit. If the mms is turned off, it may cause operational issues. A fi gure showing the mms i...

Page 25

Us - 25 connection of the control board 4.5 control connections 4.5.1 assignment of the control terminal strip x2a x2a tightening torque 0.5 nm pin function name description specifi cations 10 24…30 v input vin external supply of the control board 11 common com reference potential 12 enable st enabl...

Page 26

Us - 26 connection of the control board 4.5.3 wiring example in order to prevent a malfunction caused by interference voltages on the control inputs, the following points should be observed: emc • use shielded / twisted control cables • connect the shield on the end connected to the inverter using t...

Page 27

Us - 27 installation and connection 4.6 operator as an accessory a keypad operator can be installed. A digital operator (00.F5.060-k000) is provided with every regen unit. To prevent malfunctions, the combivert must be brought into nop status before connecting or disconnecting the operator (de-activ...

Page 28

Us - 28 operation of the unit 5. Operation of the unit 5.1 keyboard when switching on the keb combivert r6-n the value of parameter cp.1 appears. The enter key changes between the parameter name (cp.1) and parameter value or switches the parameter value into edit mode. Enter the escape key (esc) exi...

Page 29

Us - 29 operation of the unit 5.3 turn-on and operation procedure the combivert r6-n is initialized after connection of the main line supply. The power circuit identifi cation is checked fi rst. If an invalid power circuit is recognized, "error pow. Unit code inv." is triggered and displayed in the ...

Page 30

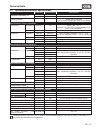

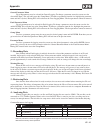

Us - 30 operation of the unit 5.4 parameter summary the cp parameters serve as the base level parameters to adjust and monitor operation of the combivert r6 unit. Display parameter setting range resolution factory setting cp.0 password input 0…9999 1 – cp.1 status display – – read only cp.2 main lin...

Page 31

Us - 31 operation of the unit 5.5 parameter description the following parameters the allow the user to monitor the functionality during operation. Cp.01 status display the status display shows the actual operating mode of the combivert r6. Refer to section 6.0 for additional descriptions and trouble...

Page 32

Us - 32 operation of the unit cp.11 power module temperature display of the actual heat sink temperature in °c. First a pre-warning can be given via digital output if the heat sink temperature is too high, so a controlled deceleration of the unit is possible. The modulation is shut off and the unit ...

Page 33

Us - 33 operation of the unit cp.29 software version this parameter displays the software version. Example: version 1.02 = 1.02 cp.30 software date code this parameter displays the software compile date in the format ddmm.Y. Example: 2012.3 cp.31 power part id code this parameter displays the identi...

Page 34

Us - 34 operation of the unit cp.36 harmonic filter integral gain integral current gain in regen mode when using harmonic fi lter. Does not apply when using commutation choke. The default value of 8 should be suffi cient, particularly with high impedance line (eg. Isolation transformer). Contact keb...

Page 35

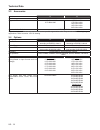

Us - 35 troubleshooting and diagnostics 6. Diagnosis and troubleshooting 6.1 status display: status and error messages 6.1.1 status messages the following are status messages for cp.1: status messages regen active regen active (regeneration operation) base block base-block time, unit is blocked from...

Page 36

Us - 36 troubleshooting and diagnostics 6.2 troubleshooting 6.2.1 troubleshooting error messages fault cause solution synchronizat- ion error (e.Syn) line frequency calculated incorrectly if the value in cp.02 is negative, swap l1.1 and l2.1 at the commutation choke so that cp.02 is positive. Error ...

Page 37

Us - 37 troubleshooting and diagnostics fault cause solution error dc bus charge fault (e.Lsf) if the error does not reset itself after power up and the fault remains, then the following causes may be applicable: load-shunt defective input voltage wrong or too low high losses in the supply cable uni...

Page 38

Us - 38 troubleshooting and diagnostics 6.2.2 troubleshooting operational problems problem cause solution high regenerative or supply current high nominal motor current high peak motor current during acceleration/deceleration low input voltage/excessive line sag overutilization check the current on ...

Page 39

Us - 39 troubleshooting and diagnostics problem cause solution fault reset level rea- ched (frlr) automatic fault reset counter limit was reached. Must cycle st. See cp.20 for further details..

Page 40

Us - 40 appendix a.1 data logging the keb lcd regen keypad has internal data logging capabilities built in. The function can be activated from the 'data logging' menu under the main menu of the keypad. Once enabled, up to 10 trending parameters can be logged at a variable sample rate, as well as up ...

Page 41

Us - 41 appendix generic parameter menu up to 10 parameters may be selected for general logging. To change a parameter, move the cursor over the slot and hit 'enter'. This will take you to the 'group menu'. To remove a parameter from the list, highlight the parameter name and hit f3 (delete). Hittin...

Page 42

Us - 42 appendix a.2 ups wiring example 4 5 3 7 l1.2 l2.2 l2.1 l3.2 l1.1 l3.1 l2 l1 l3 l1’ l2’ l3’ ++ ++ - - - - l1.2 l2.2 l3.2 6 ++/+pa - - / - w v u pe l3 l2 l1 l1l2 l3 1 2 pb control connections x2a drive enable 9 external fault 8 1 ups power supply 5 combivert r6-n 9 r6-n control connections x2a...

Page 43

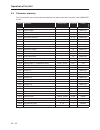

Display parameter display parameter cp.0 password input cp.21 last error cp.1 status display cp.22 last error 1 cp.2 main line frequency cp.23 last error 2 cp.3 ac-phase current l1 cp.24 last error 3 cp.4 ac-phase current l2 cp.25 last error 4 cp.5 ac-phase current l3 cp.26 last error 5 cp.6 actual ...

Page 44

© keb 00.R6.Nub-k000 re v.1g 1/2017 karl e. Brinkmann gmbh försterweg 36-38 • d-32683 barntrup ph: +49 5263 401-0 • fax: +49 5263 401-116 net: www.Keb.De • mail: info@keb.De keb antriebstechnik gmbh & co. Kg wildbacher str. 5 • d–08289 schneeberg ph: +49 3772 67-0 • fax: +49 3772 67-281 mail: info@k...