- DL manuals

- Keen Pump

- Water Pump

- K(H)GS2

- Installation And Service Instructions Manual

Keen Pump K(H)GS2 Installation And Service Instructions Manual

1

Effective June 2016 -

471 US Hwy 250 East, Ashland, Ohio 44805

PH: 419-207-9400 FX: 419-207-8031

INSTALLATION AND SERVICE INSTRUCTIONS AND

REPAIR PARTS LIST FOR 2HP “SEMI-OPEN”

K(H)GS2 CENTRIFUGAL SUBMERSIBLE

GRINDER SEWAGE PUMPS

__________________________________________________________________________________

P/N O&M-K(H)GS2

Summary of K(H)GS2

Page 1

1 effective june 2016 - 471 us hwy 250 east, ashland, ohio 44805 ph: 419-207-9400 fx: 419-207-8031 installation and service instructions and repair parts list for 2hp “semi-open” k(h)gs2 centrifugal submersible grinder sewage pumps ____________________________________________________________________...

Page 2: Models

2 effective june 2016 - models standard flow w/ radial cutters catalog no. Hp ph volts cord disch kgs2-2001 2 1 208 10-5 1.25 kgs2-2401 2 1 240 10-5 1.25 kgs2-2003 2 3 208 14-7 1.25 kgs2-2303 2 3 230 14-7 1.25 kgs2-4603 2 3 460 14-7 1.25 high head w/ radial cutters catalog no. Hp ph volts cord disch...

Page 3

3 effective june 2016 - standard flow & high head w/ axial slicers internal capacitors catalog no. Hp ph volts cord disch kgsl2-2001c 2 1 208 10-3 1.25 kgsl2-2401c 2 1 240 10-3 1.25 khgsl2-2001c 2 1 208 10-3 1.25 khgsl2-2401c 2 1 240 10-3 1.25 read all instructions in this manual before operating pu...

Page 4: Specifications

4 effective june 2016 - keen pump is not responsible for losses, injury or death resulting from a failure to observe these safety precautions, misuse, abuse or misapplication of pumps or equipment. Pump specifications: specifications warning! The pump must be wired by a qualified electrician, using ...

Page 5: Wiring Diagrams

5 effective june 2016 - wiring diagrams (internal capacitors) single phase, 208/240v, 10/3 cable wires ohm 208v ohm 240v white (1) black (3) 1.0 1.6.

Page 6

6 effective june 2016 - single phase, 208/240v, 10/5 cable wires ohm 208v ohm 240v white (1) black (3) 1.0 1.6 white (1) red (2) 6.2 6.8 black (3) red (2) 5.2 5.2.

Page 7

7 effective june 2016 - 3-phase, 208/230/460v, 14/7 cable wires 230 volt ohm white black white red black red wires 460 volt white black white red black red.

Page 8: Pump Specifications

8 effective june 2016 - pump specifications discharge…………………………. 1-1/4” npt or 2-bolt flange, vertical liquid temperature…………… 120 degrees f (continuous) 140 degrees f. (intermittent) motor housing………………….. Cast iron, astm a-48, class 30 cord cap…………………………… cast iron, astm a-48, class 30 volute……………...

Page 9

9 effective june 2016 - start capacitor run capacitor 208 & 240 volt models.................... 216-259 mfd, 250 vac 50 mfd, 370 vac motor (three phase)…………. 2 hp, 3450 rpm, 60 hz tri-voltage, 208 / 230 / 460 volts on-winding temperature sensor, requires temperature sensor circuitry in control panel...

Page 10: Installation

10 effective june 2016 - installation usage: the 2 hp grinder pumps are for pumping domestic sewage. One pump can handle the sewage from a maximum of 2 homes. These pumps are not to be used for pumping commercial or industrial sewage from factories, schools, motels, apartments, etc.. This pump is in...

Page 11: Troubleshooting

11 effective june 2016 - troubleshooting the troubles listed below are potential problems involving the pump. Other troubles can occur from faulty control box operation. Consult control box instructions for troubleshooting list involving the control box. Problem probable cause pump will not run. Tri...

Page 12: Shredding Ring

12 effective june 2016 - replacing grinder impeller and shredding ring “radial cutters” note: this is the only disassembly operation permitted in the field. All other repairs must be performed at an authorized service center or the factory. Standard tools required: standard socket wrench set. Standa...

Page 13: “Axial Slicers”

13 effective june 2016 - 8. Make sure allen head cap screw in bottom of pump shaft is tight. Make sure the impeller turns freely by hand after reassembly. Some drag will be present due to the shaft seals. There should not be any binding or tight spots when turning the grinder impeller. Replacing imp...

Page 14

14 effective june 2016 - disassembly or replacing of slicer plate and slicer impeller 1. Remove slicer retainer (3 bolts). 2. Use a ball-peen hammer to tap onto (3 blade) rotary slicer impeller. Tap in a counterclockwise direction (thread is right hand). 3. Remove “disk-shaped” slicer plate. May hav...

Page 15

15 effective june 2016 -.

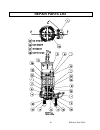

Page 16: Repair Parts List

16 effective june 2016 - repair parts list.

Page 17

17 effective june 2016 -.

Page 18

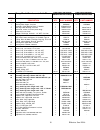

18 effective june 2016 - pump model numbers w/ axial slicers kgsl2-2001/2301/2401(c) khgsl2-2001/2301/2401(c) kgsl2-2003/2303/4603 khgsl2-2003/2303/4603 ref. # description qty. Part number qty. Part number castings 1 bearing plate, upper, cast iron 1 kgx2004 1 kgx2004 1 assembly, upper bearing plate...

Page 19

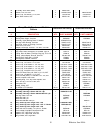

19 effective june 2016 - 38 assembly, start switch (230v) 1 k0653-5-01 - - 40 washer, lock, 3/8” sst 2 lwash3/8ss 2 lwash3/8ss 41 screw, cap, 3/8- 16unc x 1” lg, sst 2 cs3/8x1ss 2 cs3/8x1ss 42 plate, slicer retainer, sst 1 k0453-1-01 1 k0453-1-01 pump model numbers w/ radial cutters kgs2-2001/2301/2...

Page 20

20 effective june 2016 - 31 ring, grinder, sst, high head 1 kg2072-2-01 1 kg2072-2-01 32 impeller, grinding, sst 1 kg2150-2-01 1 kg2150-2-01 33 plug, 1/4" npt pipe, sst 3 plug1/4 3 plug1/4 34 assy, wire, moisture detector w/ resistor 1 k0138-1-01 1 k0138-1-01 35 resistor, 330k ohm 1 k0381-1-01 1 k03...

Page 21: Limited Warranty

21 effective june 2016 - 471 us hwy 250 east, ashland, ohio 44805 ph: 419-207-9400 fx: 419-207-8031 limited warranty during the time periods and subject to the conditions hereinafter set forth, keen pump will repair or replace to the original user or consumer, any portion of your new keen product wh...