- DL manuals

- KEEWAY

- Scooter

- 50cc Series

- Service Manual

KEEWAY 50cc Series Service Manual

Summary of 50cc Series

Page 1

Scooter service manual keeway 50cc models © keeway america, llc spring 2008.

Page 2: Keeway America, Llc

2 if problems cannot be resolved or further assistance is needed, please feel free to contact us. Keeway america, llc 2912 skyway circle n. Irving, tx 75038 214-441-9661 phone 214-441-9641 fax service@keeway-america.Com our support staff will assist in any way possible..

Page 3: Pre-Delivery Inspection

3 pre-delivery inspection in order for keeway america to maintain its high standards of quality, it is necessary for each dealer to thoroughly inspect each unit before their customer takes delivery. Initial: wash entire vehicle with warm water and wipe dry with a soft cloth. Do not use soap or terry...

Page 4

4 test drive: verify proper front and rear suspension for correct damping and travel. Ensure proper operation and settings of gauge cluster. Verify wheel alignment, and adjust accordingly. Check for fluid leaks, and adjust levels accordingly. Verify proper operation and adjustment of all vehicle lig...

Page 5: Maintenance Chart

5 maintenance chart.

Page 6

6 table of contents__________________________ predelivery inspection maintenance chart preface keeway service guidelines electrical precautions safety guidelines specialty tools required general information terminology the 2-stroke engine cycle vehicle information general specifications powertrain s...

Page 7

7 engine component fit/tolerance cylinder head/valve cylinder jug/piston system fundamentals kick start chain reaction fuel delivery system brake system fundamentals fundamental front absorber theory troubleshooting and procedures common issues electric starter doesn’t engage or rotate only clicking...

Page 8

8 powertrain components carburetor removal/installation engine and components removal/installation cowling assembly cylinder head assembly camshaft/rocker arm assembly piston assembly lh crankcase cover rh crankcase cover, magneto, and associated parts rh crankcase internals lh crankcase cover and a...

Page 9

9 preface______________________________________ this service manual serves as keeway america’s promise of quality service and technical support for its entire line of vehicles. This manual is intended to provide most of the necessary information for the proper service and maintenance of all 50cc sco...

Page 10: Keeway Service Guidelines

10 keeway service guidelines 1. Use only genuine keeway parts, and use proper lubricants where specified. 2. Use only the proper tools for the task at hand. 3. Please be sure to replace all washers, seals, o-rings, cotter pins, etc. 4. Please note that all fasteners are metric. 5. When reassembling ...

Page 11: Safety Guidelines

11 safety guidelines warnings: use only the appropriate, well-maintained tool for the task at hand. Gasoline is a highly volatile chemical, and should be treated with care. Never handle near open flame or heat source. Keep floor clean and free of debris. Avoid fluid spills to minimize the risk of ac...

Page 12: Specialty Tools Required

12 specialty tools required t01 t-driver and socket set (8, 10, 12, 13mm, and screwdriver bits needed) t02 flywheel removal tool t03 valve spring compressor t04 spanner socket t05 cylinder compression tester t06 piston pin removal tool.

Page 13

13 t07 13/16 spark plug socket (2 styles shown) t08 impact wrench t9 impact sockets (17 & 18mm needed) t10 clutch clamp tool t11 torque wrench (and appropriate sockets) recommend both lbs-ft and lbs-in.

Page 14

14 general information_________________________ terminology the two absolute maximums of linear piston travel in the internal combustion engine are referred to as top dead center (tdc) and bottom dead center (bdc). Note that tdc is at the point farthest from the rotation center of the crankshaft, an...

Page 15

15 the 2-stroke engine cycle the 2-stroke engine differs slightly from the 4-stroke, in that it combines its phases, or strokes. Upon initial inspection, the most noticeable difference in overall 2-stroke architecture is the location of the intake port. It provides a direct feed into the crankcase, ...

Page 16

16 now the piston is reaching tdc, completely compressing the air/fuel mix in the combustion chamber. Note: the exhaust and transfer ports are still blocked by the piston skirt; the intake port is still open, but the crankcase has now filled to capacity. The spark plug now fires, igniting the compre...

Page 17

17 this is the final, and perhaps most complicated step in the 2-stroke process. As the piston travels downward, the exhaust port opens. This allows the combusted gasses to exit the engine. As the piston continues downward, the transfer port is now exposed. This allows for the compressed mix in the ...

Page 18

18 vehicle information engine number the engine number is stamped into the rear of the crankcase, as shown in the illustration. Fuel be sure to only use unleaded fuel, 90 octane or better. Engine oil for keeway’s oil injection system, high-quality engine oil is necessary. Keeway america recommends f...

Page 19

19 general specifications chassis front shock absorber spring, oil damped rear shock absorber spring, oil damped turn angle 48° (to left/to right) brakes f/r disk/drum engine type 2-stroke, forced-air-cooling intake piston-reed valve cylinder single bore 40.0mm stroke 39.6mm displacement 49.8ml comp...

Page 20

20 powertrain specifications________________ fastener torque self-tapping screws for fan cover assembly 1-3nm (9-26 lbs-in) locknuts for fan cover assembly 10-12nm (8-9lbs-ft) self-tapping screws for air cover 1-3 nm (9-26 lbs-in) lock nut for air cover 10-12nm (8-9lbs-ft) self-tapping screw and nut...

Page 21

21 locknut for fixed drive assembly 40-60nm (29-43lbs-ft) kick starter locknut 10-12nm (8-9lbs-ft) transmission case cover locknut 10-12nm (8-9lbs-ft) transmission case drain nut 22-25nm (16-18lbs-ft) lh crankcase drain nut 22-25nm (16-18lbs-ft) lh crank position shaft nut 18-22nm (13-16lbs-ft).

Page 22

22 engine component fit/tolerance___________ reed valve/ cylinder head reed valve seat clearance (a): mm overlap (b): 1mm cylinder head surface clearance mm cylinder/piston compression 155±5psi cylinder inner diameter 40.005-40.020mm piston diameter 39.94-39.955mm piston/cylinder tolerance 0.06-0.07...

Page 23

23 piston pin piston pin guide 12.01mm piston pin 12.00mm pin/guide tolerance 0.01mm piston ring ring/groove tolerance first: 0.04-0.06mm second: 0.02-0.04mm acceptable ring end-gap 0.75-3.6mm (uniform) system fundamentals________________________ kick start chain reaction kick-start lever (9) starti...

Page 24

24 fuel delivery system the vehicle’s fuel flows by gravity feed into the petcock valve, where its flow rate is boosted through vacuum assistance, allowing for a steady and potentially constant feed into the carburetor. From the petcock to the carburetor, the fuel undergoes a double-filtration proce...

Page 25

At idle, the fuel is sprayed in a fine mist into the carburetor throat by the idle jet. Since the throttle body is completely closed, air passes through the idle passage and into the throat as well, blending with the fuel mist. This blending process can be adjusted through the idle air screw. As the...

Page 26

Under a high-speed condition, the throttle body is opened up all the way, allowing maximum airflow. This creates the greatest vacuum pressure possible, resulting in maximum fuel spray from the main jet. The air/fuel mixture becomes richer to facilitate the faster, hotter combustion necessary to supp...

Page 27

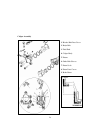

27 disk brake system fundamentals hydraulic theory: liquid cannot be compressed, only displaced. Therefore, force can be amplified and carried through fluids by application of force to surface in a sealed system. 1 cap 8 plunger 2 gasket 9 tension spring 3 fluid journal 10 fluid outlet 4 dust boot 1...

Page 28

28 caliper assembly 1 bleeder bolt dust cover 2 banjo bolt 3 fluid path 4 caliper body 5 pistons 6 guide bolt sleeves 7 piston seals 8 piston dust covers 9 brake rotor.

Page 29

29 fundamental front absorber theory this illustration depicts the front fork assembly of this vehicle. The triple clamp connects the fork assembly to the vehicle’s frame and handlebars. An inner shaft is supported by a spring within the outer shaft, which is submerged in fluid. The spring acts as a...

Page 30: Common Issues

30 troubleshooting and procedures________ important note: before attempting any troubleshooting or repairs, please ensure that scooter is placed on the main stand. Common issues the following compilation describes the most common symptoms and potential solutions in the form of a flow chart. Further ...

Page 31

31 upon completion of properly tuning the carburetor, replace the vehicle spark plug. If condition continues, verify adequate oil flow and ensure proper spark, then verify proper engine timing (refer to guide for proper procedure and specifications) if necessary. If out of range, the magneto assembl...

Page 32

Vehicle should now start. If hard-start/poor idle condition is now present, refer to appropriate section (above). If no-start condition remains and spark plug is gas-fouled, the carburetor’s enrichment valve needs replacing. From this point, if no-start condition remains, perform an engine compressi...

Page 33

33 if proper tire pressure ensure airflow is free of blockage/restriction. Verify proper tuning of carburetor (refer to technical guide for 50cc carburetors for proper procedure/specifications) and replace spark plug. If tire pressure is low inflate to recommended pressure. Check for leaks or improp...

Page 34

34 the magneto assembly most likely has damaged components, and needs replacement (refer to guide for removal/installation). Recommend replacement of cdi as well. Poor/difficult handling/instability if turning is difficult inspect fork bearings and lubricate/replace as needed. Ensure proper torque i...

Page 35

35 soft brakes or too much lever travel ensure proper brake fluid level. Inspect both pads and shoes for proper travel and excessive wear. Ensure absence of air in brake lines. Inspect system for leaks. Inspect caliper piston seal for signs of aging/damage. Verify that wear on brake pads and rotor i...

Page 36

36 the battery in order to troubleshoot the battery, the cornerstone of the vehicle’s electrical system, all vehicle systems must be off. Turn voltmeter to dc volts. With the alarm disarmed, connect the test leads from the digital multimeter to the battery posts, red to positive and black to negativ...

Page 37

37 power circuitry and parasitic draw test guidelines the parasitic draw test is a procedure used to pinpoint the source of severe voltage draws in electrical systems due to a short in the circuitry. Specific tool required: digital multimeter parasitic draw test procedure: before beginning, ensure t...

Page 38

38 important note: in vehicles with theft-deterrent/remote-start systems, unplugging the alarm box will result in an amperage drop. This does not necessarily denote a faulty alarm system. The entire vehicle is powered through the alarm box..

Page 39

39 magneto assembly structure the magneto is composed of the stator assembly (star-pattern of copper-wound spools), the charging coil, and the magnetic pickup coil. This assembly is located inside the rh crankcase cover, behind the cooling fan and flywheel. Function the stator acts as the primary ch...

Page 40

40 engine compression test procedure note: perform initially on cold engine, then bring engine to operating temperature and repeat. Compare results. Disable ignition (via the vehicle kill switch), remove the spark plug, and connect compression tester. Requires special tool t05 disconnect vacuum line...

Page 41

41 if engine compression is below specifications, repeat test procedure, placing several drops of oil into combustion chamber just before connecting compression gauge. If the compression rises to within range, there is excessive wear or damage to the cylinder, piston, rings, or cylinder head/gasket....

Page 42

42 ignition timing test procedure remove inspection cap from fan cover. Connect timing light according to manufacturer-specific directions start engine and aim timing light at the timing reference. At idle: i and f marks should line up. This denotes ignition timing of 13º btdc. Idle speed should be ...

Page 43

43 note: as part of the initial preparation procedure, it is necessary to bring the unit to operating temperature, and with a voltmeter connected to the battery, proceed to adjust the idle speed until you get a reading of 12.5-12.8 volts at the battery. Technical guide for keeway 50cc carburetors ke...

Page 44

44 the 50cc carb also has an “automatic enrichment valve” mounted on the right side. This valve feeds both fuel and air to the engine side of carb slide. It is designed to maintain stochiometric metering, admitting both fuel and air. This valve is an electronic solenoid that moves in or out based on...

Page 45

45 important note: when adjusting the idle air mixture screw to baseline settings do not tighten screw after it “seats”. If the air mixture screw is over tightened one of two things will occur; the tapered needle will mushroom and not function, or the needle will break off in the carb body, ruining ...

Page 46

46 powertrain components___________________ carburetor removal/installation removal remove seat/helmet box assembly. Remove fuel inlet line loosen the clamp between carburetor and air box and remove intake duct. Remove plug from fuel overflow/discharge hose and drain any remaining fuel into a safe c...

Page 47: Installation

47 engine components removal and installation cylinder/head assembly removal (remove cowling prior) spark plug and cylinder head nuts (3 & 7) cylinder head and assoc. Gasket (1 & 2) cylinder jug and assoc. Gasket (4 & 5) installation procedure is opposite of removal..

Page 48

48 piston assembly ring end gap: 0.25mm (0.010in) minimum service limit: 0.75mm (0.030in) ring/groove tolerance first: 0.04-0.06mm (0.0015- 0.002in) second: 0.02-0.04mm (0.001- 0.0015in) removal (remove cowling, cylinder head assembly and cylinder jug prior) first and second rings (1 & 2) pin clips ...

Page 49

49 lh crankcase cover removal cable clip and fender bracket (1 & 2) lh crankcase cover (3) dowel and gasket (4 & 5) installation procedure is opposite removal. Note: after ensuring proper alignment, installation may be facilitated by gently tapping cover into position with a rubber mallet. Upon star...

Page 50

50 lh crankcase cover and associated parts removal nut, star washer, and fixed face (6, 7, & 8) drive belt, nut, and washer (16, 15, & 14) spacer and variator assembly (4 & 5) clutch hub and drive assembly (12 & 13) spring retainer and kick-start gear (10 & 11) crankshaft starter and transition gear...

Page 51

51 reference aligned with contact point at transition gear. A brake spring tool is recommended for applying tension to kick start spring; use caution. Immediately install retaining plate and lock bolt. Install drive belt before installing fixed face. Crankcase assembly removal (remove cylinder head,...

Page 52

52 notes: when installing crankshaft assembly, coat lh crankcase bearing with oil, then vertically press oil seal into bearing recess; place crankshaft gear into camshaft timing chain; ensure free movement of crankshaft and connecting rod assembly. A rubber mallet may be needed to gently tap the cra...

Page 53

53 notes: position each bearing with number facing outward, and ensure free movement. Lightly coat oil seal with oil when installing, and ensure proper direction and fit. Ensure proper fit and free movement of all gears and pinions. Torque bolts in modified star pattern to 8lbs-ft. Drive wheel clutc...

Page 54

54 rear seat (6) installation procedure is opposite of removal. Notes: when assembling clutch shoe assembly, be sure to use new limiters and pins, to ensure proper fit and function. When installing bearings, coat with assembly lube to ensure free rotation, and ensure proper positioning of the clip. ...

Page 55

55 notes: coat bushings and shaft ends with grease to ensure proper installation, and ensure proper spring pin installation. Transition gear assembly removal transition gear assembly pin (6) washer (4) transition gear (3) with bracket (5) intact tension spring (2) transition gear shaft (1) bracket (...

Page 56

56 notes: install bracket in proper groove before installing transition gear. Ensure proper movement of transition gear..

Page 57

57 variator/cvt assembly removal fixed face (1) spacer (2) retaining face (8) dampers (7) rollers (6) bushing (3) thrust washer (4) movable face (5) installation procedure is reverse of removal. Notes: before installing retaining face, install dampers. Ensure free movement of the spacer..

Page 58

58 starter clutch assembly removal clutch gear (1) needle bearing (2) m6 screws (3) clutch hub (4) pin (5) rollers, spring and bushing (6, 7, & 8) clutch cover (9) spring retainer (10) clutch body (11) installation procedure is reverse of removal. Notes: there should be no play in clutch assembly. E...

Page 59

59 chassis_______________________________________ torque specifications front wheel/fork axle nut (1) 41-44lbs-ft fork legs to triple clamp (4) 27-32lbs-ft brake assembly mount (2) 16-21lbs-ft handlebar handlebar to triple clamp (1) 27-32lbs-ft frame engine bracket mount (1) 28-32lbs-ft rear shock t...

Page 60

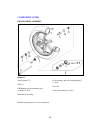

60 component guide front wheel assembly removal axle locknut (17) axle (3) lh bushing and speedometer gear assembly (4 & 8) front wheel assembly seal, bearings, and axle shaft bushing (5, 6, & 18) tire (16) valve stem and cap (2 & 20) installation procedure is reverse of removal..

Page 61

61 rear wheel assembly removal locknut rear wheel assembly tire (8) valve stem and cap (11 & 12) rear wheel (7) brake shoes and springs (1 & 2) tension spring and bushing (3 & 4) m6x35 bolt (9) brake rocker arm (5) brake cam (6) installation procedure is reverse of removal..

Page 62

62 exhaust assembly removal bolts and flange gasket (8 & 9) expansion chamber stabilizer bolts, washers, and grommets (11, 12, & 13) exhaust assembly (1) muffler strap, insulator, and associated bolt (4, 6, & 10) muffler mounting nuts and gasket (5 & 15) installation procedure is reverse of removal ...

Page 63

63 front fork assembly removal m10x1.25x40 bolts (17) lh and rh shock absorbers (12 & 13) stem locknut and seal (1 & 2) external nut and dust seal (3 & 4) upper steel balls, race, and cap (5, 6, and 16.1). Slide triple clamp (14) down. Do not remove. Bring washer and spacer (9 & 10) down onto triple...

Page 64

64 installation triple clamp, washer, and spacer (9, 10, & 14) assemble lower bearing assembly (parts 7, 8, & 16; recommend heavy coat of grease and constant pressure to maintain proper fit.), and position above spacer (9) on triple clamp stem. Ensure assembly remains together. Slide triple clamp as...