- DL manuals

- KEEWAY

- Offroad Vehicle

- ATV250

- Service And Maintenance Manual

KEEWAY ATV250 Service And Maintenance Manual

Summary of ATV250

Page 1

1 atv service and maintenance manual model: atv250 c o p y r i g h t : k e e way i n t e r n at i o n a l d e v e l o p m e n t c o . , lt d . Feb.2006.

Page 2

2 if you have any problems can not fnd the solution in this manual, please fell free to contact with: keeway international development co.,ltd 2000 szentendre u.8 kozuzo. Hungary tel:0036-26-500005 fax:0036-26-312034 emai: info@keewaymotor.Com our engineer are very glad to give you the necessary ass...

Page 3: C O N T E N T

3 c o n t e n t a. General information 1. Basic terminology- engine 2. Engine types-4 stroke engine work cycle/illustrations 3. Workshop safety service rules electricals safety b product 1. Technical specifications 2. Special service tools 3. Engine and transmission a) specified torque value b) smal...

Page 4

4 a) magneto(a.C.G) b) wiring diagram c) ignition circuit test d) the relational matters of the battery e) the process of debugging of battery f) signal system circuit g) battery charging system circuit h) power flowing chart of electric start i) removal and replacement of various bulbs j) testing p...

Page 5: General Information

5 a general information.

Page 6

2 b a s i c t e r m i n o l o g y - e n g i n e a. .. . Dead center either of the two limits in the cylinder at which the piston changes its moving direction. Tdc ------- top dead center(the upper limit of the piston movement) bdc------- bottom dead center(the lower limit of the piston movement) b. ...

Page 7: Engine Work Cycle

3 engine work cycle each 4-stroke petrol engine has the following 4 processes the completion of these 4 processes is termed as one cycle of the engine work. 1、 suction: air and fuel mixture is sucked inside the cylinder 2、 compression: air and fuel mixture is being compressed in cylinder 3、 power : ...

Page 8

4 c: : : :power stroke 1. Spark plug lights the compressed air- fuel mixture. 2. The combustion of air-fuel mixture causes the the temperature and the pressure increase in the firebox, the air expands, the power forces the piston to push the protuberance down. 3. The power forced on the plug transfe...

Page 9

5 w o r k s h o p s a f e t y warning never use worn-out tools which may slip and cause injury to you. Warning do not smoke or allow flames or spark near petrol which is highly explosive as well as inflammable.Work in a well ventilated area. Warning do not spill oil on the workshop floor as one may ...

Page 10: Electricals Safety

6 electricals safety 1. A loose wire harness can be a safety hazard.After clamping,check each wire to be sure it is secure. 2. Don’t curve clamps towards welds. 3. Secure wire bands to the frame at the designated locations.Tighten the wire bands (strap) so that the insulated surfaces can contact the...

Page 11: Product

7 b product.

Page 12

8 te c h n i c a l s p e c i f i c a t i o n s item parameter total length 1950mm total width 1100mm total height 1110mm seat height 840mm wheelbase 1290mm front wheel 860mm tread rear wheel 830mm min process from the ground 150mm atv250 net weight 238kg e n g i n e type disposal of cylinder cylinde...

Page 13

9 carburetor manufacturer/type of carburetor identify no. Diameter of throat pipe size of main muzzle size of idle speed muzzle clip position of oil needle idle speed air adjusting screw hight of floater keeway-wenling-china,vacuum chaff type pd31 31mm #294 #34 the third case from the top exit1 2 1 ...

Page 14

10 to o l s l i s t i n g item parameter specs electric ignition system timing ignition ‘f’ mark ‘Ⅱ’full advance alternator(magnetic electrode) spark plug clearance of spark plug fuse battery tci 1500rpm before tdc 10 0 ±2 0 3500rpm before tdc 32 0 ±2 0 310w@4000rpm d7rtc 0.6~0.7mm 15a 12n9-4b-1 lig...

Page 15

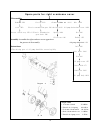

11 the tools are indispensable to install or dischange the engine down blow: no. Code of tools use 1 2 3 4 5 6 7 8 9 10 11 12 t01 t02 t03 t04 t05 t06 t07 t08 t09 t10 t11 t12 “t”shape sleeve sleeve (7、8、10、12、13) assembly and disassembly tools of stator assembly and disassembly tools of air valve spr...

Page 16

12 ① ② ③ ④ ⑤ ⑥.

Page 17

13 ⑦ ⑧ ⑨ ⑩ ○ 11 ○ 12.

Page 18

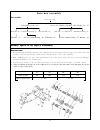

14 s p e c i f i e d t o r q u e v a l u e no. Name qun torque( ( ( (n.M) ) ) ) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 lock bolt of chain tension pole lock bolt of chain tensioner lock bolt of cylinder head spark plug dtud bolt of cylinder head intake valve dtud b...

Page 19

15 s m a l l b u t v i t a l c o m p o n e n t dowel pin-16nos. S.No. Size (mm) qty. Description location 1 φ10×15.5 2 cylinder head and body engine 2 φ10×14 2 crankcase and cylinder body engine 3 φ10×14 2 right and left crankcase engine 4 φ10×14 2 left crankcase speed gear box cover engine 5 φ10×14...

Page 20

16 bearing s.No. Code qty. Description location 1 6303 1 transition shaft-speed gear box cover engine 2 hk15×28×15 1 idle shaft-speed gear box cover engine 3 6205 1 intake shaft- speed gear box cover engine 4 62/22 1 transition shaft-left crankcase engine 5 hk15×28×15 1 idle shaft-left crankcase eng...

Page 21

17 washer-6 nos s.No. Gasket type qty. Location 1 cylinder head steel 1 engine 2 cylinder body oil-proof asbestos rubber 1 engine 3 crankcase oil-proof asbestos rubber 1 engine 4 right cover of crankcase oil-proof asbestos rubber 1 engine 5 left cover of crankcase oil-proof asbestos rubber 1 engine ...

Page 22

18 i n f o r m a t i o n o f c h a i n g e a r c h a i n n o n d i r e c t i v e f i t m e n t – p a r t s o f e n g i n e read the instructions down blow carefully and make sure that the spare parts refered are assembled in suitable positions. Or it will effects the capability of the engine serious...

Page 23

19 e n g i n e r e m o v a l / i n s t a l l a t i o n st e p s o f di s a s s e m b l y : front and rear luggage comp seat、front fender、rear fender、footrest ttub off switch of tank,disassemble the clip、oil pipe disassemble the tank(with the switch and oil pipe) disassemble the throttle oil cable an...

Page 24

20 e n g i n e a s s e m b l y instructions: : : : 1、 the spare parts must be clean before the assembly of engine , lubricate the parts when assemble them ,lock the screw according to the value of torque. 2、 the sole directional fixed elements should be paid more attention on them when assemble the ...

Page 25

21 r a d i a t o r a s s e m b l y d i s a s s e m b l y d i s a s s e m b l y d i s a s s e m b l y d i s a s s e m b l y : : : : circlip(9) intake pipe of water pump(11)/outtake pipe of water pump(10) radiator comp(14) assembly assembly assembly assembly: : : : opposite of the steps of disassembly...

Page 26

22 c a r b u r e t o r i n t a k e p i p e a s s e m b l y disassembly disassembly disassembly disassembly: : : : nut(5) o ring(2) carburetor comp(6) bolt(3) bakelite washer(4)/o ring(2) assembly assembly assembly assembly: : : : opposite of the steps of disassembly..

Page 27

23 g e a r c a s e / r e v e r s e g e a r disassembly disassembly disassembly disassembly outtake chain wheel(b29) rocker (a23) bearing(a26)/display of gear (a5)/feeler of gear (a29) bolt(a19) gear case cover(a6)/washer(a14) reverse gearing drive gear(b6)/needle bearing (b10) outtake bearing comp(b...

Page 28

24 c y l i n d e r h e a d a s s e m b l y disassembly : timing tensioner(a-15)/chain wheel cover(b-7)/ valve cap(b-10、11) snap to the“t”mark of the magneto (in the cylinder head comp, at the tdc of the compress jotubey) breather hose(b-23)/circlip(b-24) chain wheel cover(b-11)/timing driven chain w...

Page 29

25 istructions istructions istructions istructions: : : : 1.The valve should be rubbed evenly before assembly,the rubbing lines of the valve and valve seat should be even after rubbing. 2.When assembling the valve, check the vale pole and adda little fixing oil on it,the ploe should roll agilely wit...

Page 30

26 p i s t o n a s s e m b l y disassembly: the first ring the second ring washer of oil ring (1) washer of oil ring(2) gasket of oil ring piston assembly: : : : opposite to the steps of disassembly instructions: : : : 1、 the first one is white,the second is black. 2、the surfaces whit letters of the...

Page 31

27 l e f t c r a n k c a s e c o v e r a s s e m b l y disassembly: : : : front cover of the engine(6) real cover of the engine(9) left crankcase cover(1) dowel pin(2)/washer(3) assembly assembly assembly assembly: : : : opposite of the steps of disassembl instructions: : : : 1、use wooden or rubber ...

Page 32

28 w a t e r p u m p a s s e m b l y disessembly disessembly disessembly disessembly: : : : bolt(13) outtake of pipe(15)/o ring(16) bolt(5)/bolt(14)/washer(11) water pump cover(3)/water pump seal(4) impeller (2)/whishtring comp(8) water pump body(7)/pump bearing(10)/o ring(12) assembly assembly asse...

Page 33

29 r i g h t c r a n k c a s e c o v e r a s s e m b l y disassembly: : : : blot ( 12 ) oil lever(1) sensor ( 13 ) seal ring(2) bolt ( 10 ) right crankcase cover(6) magneto stator ( 11 ) washer(5) assembly:assemble the right crankcase cover opposite to the process of disassembly..

Page 34

30 s p a r e p a r t s f o r r i g h t c r a n k c a s e c o v e r disassembly: : : : lock nut(b9) circlip(b4) cover of oil filter net (a11) bolt(a20) rotor(b2) electic transmission gear(b1)o ring(a12) oil pump chain wheel cover(a19) starter clutch assy(b5、6)electic transmission spring(a10) nut(a6) ...

Page 35

31 c l u t c h a s s e m b l y disassembly disassembly disassembly disassembly: : : : big gear comp of starting clutch(1) inside ring of starting clutch(2)/outside ring of starting clutch(3)/starting clutch block(4) outside ring of starting clutch(5) assembly assembly assembly assembly : : : : oppos...

Page 36

32 d r i v e g e a r c o m p a s s e m b l y disassembly: disassembly: disassembly: disassembly: nut(2) /washer(14) impeller(6) collar(2)/belt(15) right grive plate comp screw(10)/cover(9) /o ring(8) movable drive plate (6)/damper(7)/kickstand(11) roller(5)/oil seal(4) right drive plate(1) assembly:...

Page 37

33 dr i v e n g e a r c l u t c h c o m p a s s e m b l y disassembly: : : : disassembly of the dirve plate comp of clutch: : : : driven wheel comp cover of spring(6) circlip(16) clutch plate(1) fixing shaft(12)/slip bearing(11) side cover of clutch(17) nut(2) seal(7)/driven automatic gear plate(8) ...

Page 38: A S S E M B L Y

34 c r a n k c a s e a s s e m b l y disassembly: : : : circlip(11)/piston pin(12)/piston comp(26) bolt 15/bolt 16/gear 5 right crankcase comp(3)/left crankcase comp(12)/dowel pin(13) crankcase comp(4)/chain(27) damper ( 1 ) /stud bolt damper(1)/stud bolt /oil seal(16)/damper(17) right crankcase(3) ...

Page 39: A S S E M B L Y

35 g e a r b o x a s s e m b l y disassembly: : : : gear box comp left crankcase comp(24) screw(19)/gear box cap cmop(20)/washer(21、23) idle shaft comp(1)transmition bearing(6) rear axle shaft(12) rear axle(13) idle shaft(4 )transmition bearing(5) idle shaft (4) oil seal of intake bearing(11)和 beari...

Page 40: Power Flow Chart

36 from the engine: : : : piston(1) connecting rod(2) crankshaft(3) primary driven disk(12) pressure disk(7) clutch(8) intake shaft of gear box(4) idle shaft of gear box(5) transation shaft of gear box(6) idler pulley rear axle shaft power flow chart x-outmatic speed-down rate y-junior speed-down ra...

Page 41

37 l u b r i c a t i o n s y s t e m.

Page 42

38 t h e s e t u p o f v a l v e i n t e r v a l launch it under the cold state 1、take down a rubber cover on the worm wheel body 2、let the mark “t” on the flywheel be in the same level with the mark on the right cover. 3、make sure that the timing carved line of cam chain snap to the critical surfac...

Page 43

39 e n g i n e c y l i n d e r c o m p r e s s i o n t e s t the first step: 1.Start the engine ,so that the temperature reaches to the temperature of going normally ; 2.Take down the spark plug, and connect the manometer; 3.Check following switches: (a) fuel switch be in th position of “off”; (b) i...

Page 44

40 some important dimensions –engine cylinder head /valve project standard the pressure of the cylinder 12±1kg/cm 2 intake 0.03~0.05mm the valve interval outtake 0.05~0.06mm intake 36.63 the height of cam of the camshaft outtake 31.6 intake 5975~5990 mm valve poles outtake 5955~5.970 mm intake 6.000...

Page 45: Air Filter Assy

41 air filter assy the way of cleaning the core of air cleaner 1、 dismantle the cover of air cleaner. 2、 clean the core in the clean washing oil ,and then make the core dry. 3、 drop the core into the clean oil of the gear to be soaking enough,and then push out the surplus oil 4、 reinstallate all the...

Page 46

42 m i x e d a i r ( a i r b u r n i n g ) s y s t e m the flowing process of mixtual gas : : : : the fuel oil flow out from the fuel tank depends on its gravity through the entering oil switch,at last flow into the carburetor. The fuel oil had been filtered for three times in the above process(firs...

Page 47

43 1、 、 、 、 the process of oil entering the fuel oil flows into the float room of carburetor from fuel tank depend on one's own gravity.The float room communicates with the atmosphere by balance pipe of carburetor ,in order to guarantee that the pressure in the float room is the same as pressure of ...

Page 48

44 3、 、 、 、 idle speed after starting the engine, the channels of oil concentrating will close and concentration of mixed gas become less, then the fuel oil was absorbed into throat pipe through idle speed hole and transit hole. The other parts of fuel oil was absorbed into throat pipe through mixed...

Page 49

45 6、 、 、 、 high speed when the engine have sped up to raise lever plug completely, the high speed of engine make the air in throat pipe speed up, and it produce big negative pressure around the main jet so that it can absorb more mixed gas ..

Page 50

46 disassembly and assembly of the carburetor disassembly 1) take apart the seat of atv and front or rear fender 2) keep the control switch of oil “off” 3) pull out the oil pipe ,in with pliers 4) loosen clip ring between carburetor and air cleaner 5) pull out the plug at the end of oil pipe, out. P...

Page 51

47 4) turning mail hole tightly 5) put needle valve and floater into seat of needle valve together, hook of needle valve is put on the tongue of floater 6) put the pin into seat of floater, floater pin go through the floater and floater in order 7) check the high in the range 13+_1mm,please adjust t...

Page 52

48 s p e c i f i e d t o r q u e v a l u e no. Subject total value of fixed torque front wheel/front shock absorber 1 redirector and front wheel nut 2 70~83n.M 2 front wheel and bolt of front hub 8 37~44n.M 3 front shock absorber, frame and bolt of rocker 4 37~44n.M redirector 1 up and down rockers ...

Page 53

49 f r o n t w h e e l a s s y assembly: the fixing bolt of front wheel, front hub inside bearing(61905-2rz) special tools spacer center outside bearing(6203-2rs) special tools front brake disc、the bolt of brake disc oil seal comp (25×42×8)、inside spacer 、 dustproof seal 、outside front hub comp、the ...

Page 54

50 f r o n t d i s c b r a k e a s s y working rule of caliper. Disc brake:: : : : liquid can not be compressed easily, so the power can be transfer through it. Master cylinder when the brake handle is compressed, the lever plug of master cylinder will move in the compressed direction, when rubber b...

Page 55

51 图 7 diagram 7 diagram 9 1. Dustproof seal of airproof muzzle 2. Oil intake bolt 3. Brake oil channel 4. Brake tub 5. Oil plug 6. Long shaft 7. Seal ring of oil plug 8. Dustproof ring of oil plug 9. Brake plate 10. Brake shoe brake tub comp brake tub comp brake tub comp brake tub comp diagram 8 di...

Page 56

52 checking of disc brake notice 1) don not touch the liquid with bare hands for a long time 2) please clean with water and ask for doctors once the liquid of disc brake spatter into eyes 3) do not let liquid of disc brake spatter onto paint part, which will cause the painting to drop down, please c...

Page 57

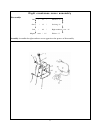

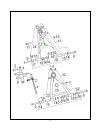

53 r e d i r e c t o r , , , , u p p e r a n d l o w e r s w i n g a r m a s s y disassembly: front wheel assy、front disc brake comp ttubing pole(1) 、gimbal comp(2) pin(3) 、nut(4)、fixing bolt (5) right redirector jointing comp(6) screw(7) 、nut(8、10)、bolt(9、11) right upper rocker comp(12)、right lower...

Page 58

54.

Page 59

55 s t e e r i n g s y s t e m disassenbly: protecting sleeve comp(1) 、bolt(2) fixing plate(3)pilot lamp comp(4)up handle cover (5) stay up line(6) 、throttle cable(7) handle bar comp(8) seat、front fender 、rear fender bolt(9)steering wheel cover and seat(10) 、seal ring (11) ttubing pole(12) 、gimbal c...

Page 60

56.

Page 61

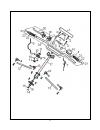

57 r e a r w h e e l , t r a n s m i s s i o n s y s t e m a s s y steps of disassembly: stay up line、pump of rear disc brake comp. Dust seal(1) 、pin(2)、nut(3)、washer(4) rear wheel comp(with seat of rear wheel) (5) round nut(6) 、relaxproof washer(7)、washer(8) seat of disc plate comp(9) 、chain(10)tra...

Page 62

58.

Page 63

59 r e a r h y d r a u l i c b r a k e a s s y rear disc brakeer( ( ( (disc) ) ) ) principle of disc breacker:liquid can’t be compressed,so power can be past by a go-between of liquid。 oil punp body: : : : when brakeer is stepped down,the press passes by the shaft,the piston in the oil pumpbody move...

Page 64

60 digram 7 diargram 8 dirgram 9 dirgram 10

Page 65

61 overhaul of rear hydraulic brake instrutions: 1.don’t touch the brake liqucd directly. 2.once brake liqucd splashescnto eyes, wash them by cold water and see the doctor. 3.don’t let brake liqucd splashes on the part painted , otherwise it will cause the drop of paint.Use wet cloth clean it as soo...

Page 66

62 r e a r s w i n g a r m a s s y steps of disassembly: stay up line、pump of rear disc brakeer comp、transmission comp nut、bolt、rear absorber comp nut(1) 、bolt of rear swinging arm(2)、cushion(3) rear swinging arm(4) spacer i(5) 、spacer ii(6) oil seal of bearing(7) 、inner bush(8)、 bearing(gb943/20) (...

Page 67

63 i m p o r t a n t t i p s o n v e h i c l e a s s e m b l y 1. the seal side of the wheel bearing should be outside 2. the running direction’s mark on the tyre should keep the same as the running direction of the wheel. 3. the smaller ends of the front and rear absorber should be adown. 4. the op...

Page 68

64 i m p o r t a n t d i m e n s i o n s o f v e h i c l e front wheel/absorber rear wheel content standerd driver 58kpa(8psi) air pressure of tyre free length of front absorber’s spring oil cubage of front absorber oil level of front absorber producer of front absorber’s oil content standerd driver...

Page 69

65 m a g n e t o ( ( ( ( a c g ) ) ) ) configuration: : : : atv’s magneto is made up by stator and rotor. Type of stator’s loop: star model. Assembly of stator : : : : stator with 12loops: 12 loops are for lighting and electrification. Spring loop and stator are formed to the cover of right crankcas...

Page 70

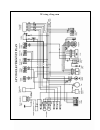

66 w i r i n g d i a g r a m.

Page 71

67 i g n i t i o n c i r c u i t t e s t for any corn of c.D.I we can always check each b.The resistance between the gihg voltage lead part step by step according the processed down and sub loop should be -7.5±1kΩ, including the below. 5k of disturb proof implement’s cap in series . 1.Spark plug: : ...

Page 72

68 test of timming ignition 1.Remove the cap of ignition inspection. 2.Join the stroboscope according to the instruction of the manufacturer. 3.Start the engine and aim the stroboscope to the ignition mark on the flywheel of the magneto. •course of slow down: “f”ignition mark snaps the “v” mark on t...

Page 73

69 t h e r e l a t i o n a l o f m a t t e r s o f t h e b a t t e r y proportion full accumulation:1.220-1.240. Term of electrification:<1.220. Use densimeter to check the battery. Warning disassemble the cathode perior to the anode. Replace it if the protuberance is cankered by sulfate; replace it...

Page 74

70 t h e p r o c e s s o f d e b u g g i n g o f b a t t e r y disassemble the battery from the body tie anode and cathode of battery to the red(+) 、 black(-) leads of the debugger. Measure the voltage of the battery, it may be 12~14.5v normally. Press the button of the acbugger and get the reading ...

Page 75

71 s i g n a l s y s t e m c i r c u i t.

Page 76

72 b a t t e r y c h a r g i n g s y s t e m c i r c u i t.

Page 77

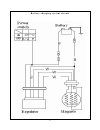

73 p o w e r f l o w c h a r t o f e l e c t r i c s t a r t flow of electric current battery fuse the power switch the brake switch the starting switch starter relay starting motor grounding magneto.

Page 78

74 r e m o v a l a n d r e p l a c e m e n t o f v a r i o u s l i g h t s ( ( ( (front light) ) ) ) disassembly steps of front light: : : : front cover / shield(with front light comp) screw、cushion headlight comp tapping screw、cover disassembly the front light 12v 18/18w×2 (impact the bulb and cont...

Page 79

75 te s t i n g p r o c e d u r e o f e l e c t r i c a l c o m p o n e n t s inspect the continuum of the electic seitch hereinafter with multimeter.

Page 80

76 i m p o t a n t s p e c i f i c a t i o n s - e l e c t r i c a l battery charging system ignition system item specification clearance 0.6~0.7mm “ ”igniting ahead of due time Ⅱ 32 0 ±2 0 btdc 以 4000rpm primary coil resistance 0.3~0.4Ω ignition coil comp. Secondary coil resistance 7~10kΩ spring co...

Page 81: Others

77 c others.

Page 82

78 p r e - d e l i v e r y i n s p e c t i o n ( ( ( ( p. D . I ) ) ) ) / c h e c k p o i n t s it is very important to do thoroughly inspection before delivery. Please perform the procedure and feedback the information to dealer。 1. Clear of the outer of vehicle with med scour and soft brush, and t...

Page 83

79 c h e c k p i o n t s check the function of the ignition switch check the fuction of the combinatorial switch check the fasten moment of front wheel axle check the fasten moment of the engine bolt check the chains degree of droop 5-20mm check the pressure of real tyre check the light of the front...

Page 84

80 p e r i o d i c a l m a i n t e n a n c e the table show the schedule of the regular maintenance according to the process. At the end of the dtep,check test,lubricate, maintain. I: check, clean, adjust, lubricate in demand and replace c: clean l: lubricate * should be check by the seller: ** all ...

Page 85

81 d o ’s a n d d o n ’ t ’s allowed 1、 disassemble and install by professional tools 2、 install oil seal by professional tools 3、 keep the free clearance of the brake arm and control bar of oil value 4、 keep chain’s sucitable degree of loop and lubricate it in demand 5、 use lube commended to lubric...

Page 86

82 s a f e t y r i d e the posture of drive what kind of driving posture can be regarded as the good driving posture? 1. Helpful to the driver to gather information necessary for the driving accurately. 2 .Driver and motor are the one. 3. Allow driver to be finished various kinds of movement freely ...

Page 87

83 6. After stopping you put your feet on the ground. The front shock absorber restores to the original state after the vehicle stops. Tr o u b l e s h o o t i n g ·engine can not start or hard to start (check whether ignition switch is in the position of opening) reasons possible 1. Loosen the bolt...

Page 88

84 not adjusted the engine can not start -jam of carburetion appropriately -ignition in advance or lag -mixed air is too sparse or dense 4.Disassemble and check spark plug spark plug is wet -airproof valve of carburetion is too tight -seep of carburetion -mixed air is too dense spark plug is dry -ai...

Page 89

85 the ground by hard -brake resistance -abration or ruin of wheel bearing the wheel runs freely -the wheel bearing need be lubricated -drive chain is too tight 2.Check the pressure of the pressure is too low tire -seep of tire -malfunction of tire’s air valve pressure is normal 3.Check whether the ...

Page 90

86 oil character not enough -oil level is too low -pollution of oil in good condition 7.Check the time of ignition incorrect -malfunction of c.D.I -malfunction spring loop correct -spring loop is fixed in wrong way 8.Check whether the the clutch is slided clutch is skided -loosen of clutch’s spring ...

Page 91

87 10. Check the pressure of the cylinder the pressure - air valve seat tooth’s incorrectly is low -clearance of air valve is narrow the pressure is normal -abration of cylinder and piston ring -ruin of cylinder head washer -incorrect of air intake phase 11. Unstill the cylinder head and check bad l...

Page 92

88 5. Check if the carburetion blocked -block in oil duct of carburetion is blocked -block of carburetion muzzle expedite ·badness in high speed badness in high speed badness in high speed badness in high speed reasons possible reasons possible reasons possible reasons possible 1. Check ignition inc...

Page 93

89 -rocker or bracket bends -front or real absorber looses or l malfunction checking •fuel system •c cc cylinder head ylinder head ylinder head ylinder head engine can’t start –malfunctions of cylinder head or assembly –carburetion without oil valve will effect the capability of the engine. –tank wi...

Page 94

90 –jam of tank assembly hole –pressure of cylinder is low –jam of oil tube –intake leaks capability of driving is weak, waste oil capability of driving is weak, waste oil capability of driving is weak, waste oil capability of driving is weak, waste oil –jam of fuel supply system –jam of fuel system...

Page 95

91 –malfunction of tyre –wheel slopes excessive –wheel is screwed wrongly.

Page 96

92 check the malfunctions • light light light light/ // /electrification system of battery electrification system of battery electrification system of battery electrification system of battery • electric start system electric start system electric start system electric start system battery is empty ...

Page 97

93 –malfunction of light or battery electrification and the clutch is detached, press down the start loop button, and start motor works. Front light is dark –grounding weakly –malfunction of rectifier –malfunction of light or battery electrification loop.