- DL manuals

- KEEWAY

- Offroad Vehicle

- ATV300

- User Manual

KEEWAY ATV300 User Manual

1

CONTENTS

GENERAL INFORMATION

1.Information

…

…

…

……………………………………..…….…2

2

2

2

2.Maintenance………………………………………...…..6

3.EngineRemoval&Installation…

…

…

…

………………...…..13

ENGINE

4.LubricationSystem………...…………………………15

5.FuelSystem…………………………………………….19

6.CylinderHEAD&CylinderValve………...……….…..30

7.Cylinder&Piston……………………………………..46

8.V-Beltdrivingsystem…………………………………54

9.ACG&Startonewayclutch……………...…………..67

10.CoolingSystem……………...……………………..76

CHASSIS

11.SteeringSuspension…………..………................84

12.FrontWheel&BrakeSystem……………...……….90

13.RearWheel&BrakeSystem…………………….….95

14.ElectricalSystem…………………………………..97

15.TroubleShooting…………………………………..107

Summary of ATV300

Page 1

1 contents general information 1.Information … … … ……………………………………..…….…2 2 2 2 2.Maintenance………………………………………...…..6 3.Engineremoval&installation… … … … ………………...…..13 engine 4.Lubricationsystem………...…………………………15 5.Fuelsystem…………………………………………….19 6.Cylinderhead&cylindervalve………...……….…..30 7.Cylinder&p...

Page 2: 1. Information

2 1. Information 1.1 safty 1.2 notes 1.3 specification 1.4 serial number 1.5 torque value 1.1 safety gasoline gasoline is extremely flammable and is explosive under certain condition. Do not smoke or allow sparks or flames in your work area. ● carbon monoxide never run the engine in a closed area. T...

Page 3

3 suspension front double a-arm & adjustable shocks rear double a-arm & adjustable shocks brakes front hydraulic disc*2 rear hydraulic disc*2 tires front 25x8-12 rear 25x10-12 pressure 【 psi ( kgf/cm 2 ) 】 front 8(0.58) rear 9(0.65) coloring specifications subject to change without notice. Compressi...

Page 4

4 1.4 serial number vehicle identification number (vin) and engine no. Are used for registration. When you order parts or need special service, these numbers can help you receive the best service from our authorized dealers. We recommend copying your vehicle identification date in your operation and...

Page 5

5 1.5 torque values frame ● handlebar upper holder bolt 24 n.M (17.7 lbf.Ft) ● throttle housing cover screw 4 n.M (2.9 lbf.Ft) ● steering shaft nut 50 n.M (36.9 lbf.Ft) ● steering shaft holder bolt 33 n.M (24 lbf.Ft) ● wheel rim bolt 18 n.M (13.3 lbf.Ft) ● tie rod lock nut 35 n.M (25.8 lbf.Ft) ● kin...

Page 6

6 2. Maintenance 2.1 maintenance data 2.8 idle speed 2.2 maintenance schedule 2.3 fuel tuble 2.9 brake system 2.4 throttle operation 2.10 wheels and tires 2.5 throttle cable ajustment 2.11 steering system 2.6 air cleaner 2.12 toe-in 2.7 spark plug 2.1 maintenance data specification spark plug spark ...

Page 7

7 2.2 maintenance schedule to keep the performance good, the motorcycle should be checked and maintained at certain interval. The meanings of capital in following table are: i: inspection, including check, clean, lubricate, refuel, repair or replacing if necessary. A: adjusting c: cleaning r: replac...

Page 8

8 2.3 fuel tube inspect the fuel lines for deterioration, damaging or leakage and replace if necessary. 2.4 throttle operation inspect for smooth throttle lever full opening and automatic full closing in all steering positions. Inspect if there is no deterioration, damage or kink in the throttle cab...

Page 9

9 2.7 spark plug this spark plug is located at the front of the engine. Disconnect the spark plug cap and unscrew the spark plug. Check the condition of spark plug electrodes wear. Change a new spark plug if the electrodes and insulator tip appear unusually fouled or burned. Discard the spark plug i...

Page 10

10 inspect the rear brake lever and cable for excessive play or other damage. Replace or repair if necessary. Measure the free play of the rear brake lever at the end of the lever. The standard is 5-15 mm. The second method to adjust brake level is under the driver seat and rear brake component. Bec...

Page 11

11 steering shaft holder bushing remove the front fender first. Remove the steering shaft holder and check the steering shaft bushing for wears or damage. If the bushing is worn or damaged, please change a new one. Grease the steering shaft bushing and install the parts in the reverse order of remov...

Page 12

12 if the toe-in is out of standard, adjust it by changing the length of the tie-rods equally by turning the tie-rod while holding the ball joint. Tighten the lock nuts. Torque: 35-43 n.M.

Page 13

13 3. Engine remove and installation 3.1 repair condition 3.3 engine installation 3.2 engine removal 3.1 engine shall be removed in the conditions of necessary repairment or adjustment to the transmission and combustion system only 3.2 engine removal before removing engine, you need to remove all of...

Page 14

14 3.3 engine installation the engine installation is essentially in the reverse order of removal. The torque of engine hanger bolt is 30 n.M route the wires and cable in reverse order properly..

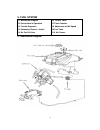

Page 15: 4. Lubrication System

15 4. Lubrication system 4-1 mechanism diagram 4-2 precautions in operation 4-3 troubleshooting 4-4 engine oil 4-5 engine oil strainer clean 4-6 gear oil 4-1 mechanism diagram.

Page 16

16 4-2 precautions in operation general information: this chapter contains maintenance operation for the engine oil pump and gear oil replacement. Specifications engine oil quantity disassembly: 1200 c.C. Change: 1000c.C. Oil viscosity sae 10w-40 (recommended king serial oils) 單位 單位 單位 單位 :mm gear o...

Page 17

17 4-4 engine oil turn off engine, and park the atv in flat surface with main stand. Check oil level with oil dipstick. So not screw the dipstick into engine as checking. If oil level is nearly low level, fill out recommended oil to upper level. Oil change caution drain oil as engine warmed up so th...

Page 18

18 4-6 gear oil gear oil change remove oil join bolt. Remove drain bolt and drain gear oil out. Install the drain bolt after drained. Torque value: 1.0~1.5kgf-m make sure that the drain bolt washer can be re-used. Add oil to specified quantity from the join hole. Gear oil quantity: 650c.C. When repl...

Page 19: 5. Fuel System

19 5. Fuel system 5-1 mechanism diagram 5-2 precautions in operation 5-3 trouble diagnosis 5-4 carburetor remove / install 5-5 air cut-off valve 5-6 throttle valve 5-7 float chamber 5-8 adjustment of idle speed 5-9 fuel tank 5-10 air cleaner 5-1 mechanism diagram.

Page 20

20 5-2 precautions in operation general information warning gasoline is a low ignition point and explosive materials, so always work in a well-ventilated place and strictly prohibit flame when working with gasoline. Cautions ● ● ● ●do not bend off throttle cable. Damaged throttle cable will make uns...

Page 21

21 5-3 trouble diagnosis poor engine start no fuel in fuel tank clogged fuel tube too much fuel in cylinder no spark from spark plug(malfunction of ignition system ) clogged air cleaner malfunction of carburetor chock malfunction of throttle operation stall after started malfunction of carburetor ch...

Page 22

22 5-4 carburetor remove / install removal drain out fuel in the float chamber. Disconnect the fuel hose. Release the clamp strip of air cleaner. Remove the carburetor upper parts from the carburetor. Release the 2 nuts of carburetor insulator, and then remove the carburetor. Installation install in...

Page 23

23 5-5 air cut-off valve disassembly 1-真空活塞阀盖 2-弹簧 3-柱赛组件 4-电加浓阀座 5-密封圈 6-截气阀盖 7-弹簧 8-截气阀 9-下壳体 10-密封圈 11-浮子 12-浮子销 13-针阀芯 14-怠速量孔 15-主量孔 16-主泡沫管 17-油门拉线固定板 18-怠速调节螺钉、怠速调节螺钉弹簧及垫片 19-混合比螺钉、混合比螺钉弹簧及垫片 assembly install in reverse order of removal procedures..

Page 24

24 5-6 throttle valve disassembly remove carburetor upper parts, and then remove throttle valve and throttle cable. Disconnect the throttle cable from the throttle valve and remove the valve spring. Remove the fuel needle clamp and fuel needle assembly place the fuel needle onto the throttle valve a...

Page 25

25 5-7 float chamber disassembly remove 4 mounting screws and remove float chamber cover. Remove the fuel level plate, float pin, float and float valve. Inspection check float valve and valve seat for damage, blocking. Check float valve for wearing, and check valve seat face for wear, dirt. Caution ...

Page 26

26 remove main jet, needle jet holder, needle jet, slow jet and air adjustment screw. Caution clean jets with cleaning fluid. Then use compressed air to blow the dirt off. Blow carburetor body passages with compressed air. Assembly install main jet, needle jet holder, needle jet, slow jet and air ad...

Page 27

27 5-8 adjustment of idle speed caution ˙ ˙ ˙ ˙air screw was set at factory, so no adjustment is needed. Note the number of turns it takes to screw it all the way in for ease of installation. ˙ ˙ ˙ ˙the parking brake must be used to stop the atv to perform the adjustments. Use a tachometer when adju...

Page 28

28 5-9 fuel tank fuel unit removal open the seat. Remove the front cover and fuel tank. Remove the side covers and lower side covers. Remove the front fender. (covers remove please refer chapter 13) disconnect fuel unit coupler. Remove fuel unit (4 bolts). Caution ˙ ˙ ˙ ˙do not bend the float arm of...

Page 29

29 5-10 air cleaner removal loosen the clamp strip of air cleaner and carburetor,and then remove the vapor hose. Loosen the clamp strip of air cleaner, and then remove the air cleaner vapor hose. Remove the air cleaner (2 bolts). Installation install the tank in the reverse order of removal. Cleanin...

Page 30

30 6. Cylinder head/valve 6-1 mechanism diagram 6-2 precautions in operation 6-3 troubleshooting 6-4 cylinder head removal 6-5 cylinder head inspection 6-6 valve stem replacement 6-7 valve seat inspection and service 6-8 cylinder head reassembly 6-9 cylinder head installation 6-10 valve clearance ad...

Page 31

31 6-2 precautions in operation general information this chapter is contained maintenance and service for cylinder head, valve, and camshaft as well as rocker arm. Cylinder head service can be carried out when engine is in frame specification item standard limit compression pressure 12+/2 kg/cm2 ---...

Page 32

32 6-3 troubleshooting engine performance will be affected by troubles on engine top parts. The trouble usually can be determined or by performing cylinder compression test and judging the abnormal noise generated. Low compression pressure 1. Valve ˙ ˙ ˙ ˙improper valve adjustment ˙ ˙ ˙ ˙burnt or be...

Page 33

33 6-4 cylinder head removal remove engine. (refer to chapter 5) remove the inlet pipe (2 nuts). Remove 1 bolt of thermostat and then remove the thermostat. Remove hole bolt and spring for the cam chain tensioner. Loosen 2 bolts, and then remove tensioner. Remove thermostat (2 bolts). Remove the sid...

Page 34

34 timing mark remove left crankcase cover, and turn the turn the drive face, and align the timing mark on the sprocket with that of cylinder head, piston is at tdc position. Remove cam sprocket bolts and then remove the sprocket by prying chain out. Remove cam shaft setting plate (1 bolt). Remove r...

Page 35

35 remove the 2 cylinder head mounting bolts from cylinder head right side, and then remove 4 nuts and washers from cylinder head upper side. Remove the cylinder head. Remove cylinder head gasket and 2 dowel pins. Remove chain guide. Clean up residues from the matching surfaces of cylinder and cylin...

Page 36

36 remove valve stem seals clean carbon deposits in combustion chamber. Clean residues and foreign materials on cylinder head matching surface. Caution 6-5 cylinder head inspection check if spark plug and valve holes are cracked. Measure cylinder head warp with a straightedge and thickness gauge. Se...

Page 37

37 rocker arm measure the cam rocker arm i.D., and wear or damage, oil hole clogged? Service limit: replace when it is less than 12.10 mm. Rocker arm shaft measure the active o.D. Of the cam rocker arm shaft and cam rocker arm. Service limit: replace when it is less than 11.91 mm. Calculate the clea...

Page 38

38 valve guide caution tool: 5.0 mm valve guide reamer measure and record each valve guide inner diameters. Service limit: 5.03 mm the difference that the inner diameter of valve guide deducts the outer diameter of valve stem is the clearance between the valve stem and valve guide. Service limit: in...

Page 39

39 6-6 valve stem replacement heat up cylinder head to 100~150 ℃ ℃ ℃ ℃ with heated plate or toaster. Caution hold the cylinder head, and then press out old valve guide from combustion chamber side. Tool: valve guide driver: 5.0 mm caution adjust the valve guide driver and let valve guide height is i...

Page 40

40 6-7 valve seat inspection and service clean up all carbon deposits onto intake and exhaust valves. Apply with emery slightly onto valve contact face. Grind valve seat with a rubber hose or other manual grinding tool. Caution remove the valve and check its contact face caution valve seat inspectio...

Page 41

41 use 60° cutter to cut a quarter lower parts out. Remove the cutter and check new valve seat. Use 45° cutter to grind the valve seat to specified width caution grind valve seat again if necessary. Coat the valve seat surface with red paint. Install the valve through valve guide until the valve con...

Page 42

42 after the valve seat ground, coat valve seat surface with emery and then slightly press the ground surface. Clean up all emery coated onto cylinder and valve after ground 48 6-8 cylinder head reassembly lubricate valve stem with engine oil, and then insert the valve into valve guide. Install new ...

Page 43

43 6-9 cylinder head installation clean up all residues and foreign materials onto the matching surfaces of both cylinder and cylinder head. Install chain guide, dowel pins and a new cylinder head gasket onto the cylinder. Caution do not damage the matching surfaces of cylinder and cylinder head. Av...

Page 44

44 install cam chain on to sprocket and align the timing mark on the sprocket with that of cylinder head. Align sprocket bolt hole with camshaft bolt hole. Tighten the sprocket mounting bolts 50 caution install cylinder head side cover (3 bolts). Install thermostat (2 bolts). Loosen auto tensioner a...

Page 45

45 6-10 valve clearance adjustment remove cylinder head cover remove the cylinder head side cover. Remove left crankcase cover, and turn the drive face, and align the timing mark on the cam sprocket with that of cylinder head, piston is at tdc position. Loosen valve clearance adjustment nuts and bol...

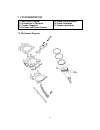

Page 46: 7. Cylinder/piston

46 7. Cylinder/piston 7-1 mechanism diagram 7-2 precautions in operation 7-3 trouble diagnosis 7-4 cylinder and piston removal 7-5 piston ring installation 7-6 piston installation 7-7 cylinder installation 7-1 mechanism diagram.

Page 47

47 7-2 precautions in operation general information both cylinder and piston service cannot be carried out when engine mounted on frame specification unit :mm item standard limit cylinder id bend piston/ piston ring clearance between piston rings top ring 2 nd ring ring-end gap top ring 2 nd ring oi...

Page 48

48 7-4 cylinder and piston removal remove cylinder head (refer to chapter 6). Remove coolant hose from cylinder. Remove cylinder. Cover the holes of crankcase and cam chain with a piece of cloth. Remove piston pin clip, and then remove piston pin and piston remove cylinder gasket and dowel pin. Clea...

Page 49

49 check cylinder if warp. Service limit: 0.05 mm measure clearance between piston rings and grooves. Service limit: top ring: 0.09 mm 2 nd ring: 0.09 mm remove piston rings check if the piston rings are damaged or its grooves are worn caution place piston rings respective into cylinder below 20 mm ...

Page 50

50 measure the outer diameter of piston pin. Service limit: 17.00 mm measure the inner diameter of connecting rod small end. Service limit: 17.02 mm measure the inner diameter of piston pin hole. Service limit: 17.02 mm calculate clearance between piston pin and its hole. Service limit: 0.02 mm meas...

Page 51

51 7-5 piston ring installation clean up piston top, ring groove, and piston surface. Install the piston ring onto piston carefully. Place the openings of piston ring as diagram shown caution do not damage piston and piston rings as installation. All marks on the piston rings must be forwarded to up...

Page 52

52 clean up all residues and foreign materials on the matching surface of crankcase. Pay attention to not let these residues and foreign materials fall into crankcase. Caution 7-6 piston installation install piston and piston pin, and place the in marks on the piston top side forward to inlet valve....

Page 53

53 7-7 cylinder installation install dowel pins and new gasket coat some engine oil to inside of cylinder, piston and piston rings. Care to be taken when installing piston into cylinder. Press piston rings in one by one as installation. Caution install coolant hose onto cylinder. Install cylinder he...

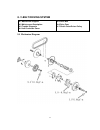

Page 54: 8. V-Belt Driving System

54 8. V-belt driving system 8-1 mechanism diagram 8-2 maintenance description 8-3 trouble diagnosis 8-4 left crankcase cover 8-5 drive belt 8-6 drive face 8-7 clutch outer/driven pulley 8-1 mechanism diagram.

Page 55

55 8-2 maintenance description precautions in operation general information drive face, clutch outer, and driven pulley can be serviced on the motorcycle. Drive belt and drive pulley must be free of grease. Specification unit :mm item standard value (mm) limit (mm) drive belt width id of drive face ...

Page 56

56 8-4 left crankcase cover left crankcase cover removal release the 2 clamp strips of left crankcase cover ducts, and then remove the ducts. Remove left crankcase cover. (10 bolts) remove 2 dowel pin and gasket. Left crankcase cover install install left crankcase cover in the reverse procedures of ...

Page 57

57 8-5 drive belt removal remove left crankcase cover. Hold drive face with universal holder, and remove nut and drive face. Special tool :universal holder hold clutch outer with universal holder, and remove nut, bearing stay collar and clutch outer caution push the drive belt into belt groove as di...

Page 58

58 installation caution install drive belt onto driven pulley. Install the driven pulley that has installed the belt onto drive shaft. On the drive belt another end to the movable drive face install the clutch outer and bearing stay collar. Hold the clutch outer whit universal holder, and then tight...

Page 59

59 8-6 drive face removal remove left crankcase cover. Hold drive face with universal holder, and then remove drive face nut. Remove drive face and drive belt. Remove movable drive face comp and drive face boss from crankshaft. Remove ramp plate. Remove weight rollers from movable drive face. Univer...

Page 60

60 inspection the weight rollers are to press movable drive face by means of centrifuge force. Thus, if weight rollers are worn out or damaged, the centrifuge force will be affected. Check if rollers are worn or damaged. Replace it if necessary. Measure each roller’s outer diameter. Replace it if ex...

Page 61

61 install ramp plate. With 4~5g grease spreads wipes drives in the movable drive face axis hole. Install drive face boss. Caution install movable drive face comp. Onto crankshaft driven pulley installation press drive belt into pulley groove, and then pull the belt onto drive shaft install drive fa...

Page 62

62 8-7 clutch outer/driven pulley disassembly remove drive belt, clutch outer and driven pulley. Install clutch spring compressor onto the pulley assembly, and operate the compressor to let the wrench be installed more easily. Caution hold the clutch spring compressor onto bench vise, and then remov...

Page 63

63 clutch lining measure each clutch weight thickness. Replace it if exceeds service limit. Service limit: 2.0 mm driven pulley spring measure the length of driven pulley spring. Replace it if exceeds service limit. Service limit: 83.2 mm driven pulley check following items: · · · ·if both surfaces ...

Page 64

64 clutch weight replacement remove snap ring and washer, and then remove clutch weight and spring from driving plate caution check if spring is damage or insufficient elasticity. Check if shock absorption rubber is damage or deformation. Replace it if necessary. Apply with grease onto setting pins ...

Page 65

65 install snap ring and mounting plate onto setting pin. Replacement of driven pulley bearing remove inner bearing. Caution remove snap ring and then push bearing forward to other side of inner bearing. Place new bearing onto proper position and its sealing end should be forwarded to outside. Apply...

Page 66

66 installation of clutch outer/driven pulley assembly install new oil seal and o-ring onto movable driven face. Apply with specified grease to lubricate the inside of movable driven face. Install the movable driven face onto driven face. Install the guide pin and guide pin roller. Install the colla...

Page 67

67 9. Alternator/starting clutch 9-1 mechanism diagram 9-2 precautions in operation 9-3 right crankcase cover removal 9-4 a.C.G. Set removal 9-5 right cover bearing 9-6 flywheel removal 9-7 starting clutch 9-8 flywheel installation 9-9 a.C.G. Set installation 9-10 right crankcase cover installation ...

Page 68

68 9-2 precautions in operation general information refer to chapter 17: the troubleshooting and inspection of alternator refer to chapter 17: the service procedures and precaution items of starter motor specification item standard value (mm) limit (mm) id of starting clutch gear 25.026~25.045 25.10...

Page 69

69 9-3 right crankcase cover removal remove left footrest. Drain out the engine oil and coolant, and then remove coolant hoses. Remove water pump cover (4 bolts). Remove 11 bolts from the right crankcase cover. Remove the right crankcase cover. Remove dowel pin and gasket. 9-4 a.C.G. Set removal rem...

Page 70

70 check the oil seal for wear or damage. Replace it if necessary. 89 install a new one bearing (6201lu) by bearing driver. Special tool: bearing driver 9-6 flywheel removal remove right crankcase cover. Remove left crankcase cover. Hold the flywheel by drive face with universal holder. Remove flywh...

Page 71

71 remove starter reduction gear and shaft. Pull out flywheel with a.C.G. Flywheel puller. Special tool: a.C.G. Flywheel puller remove flywheel and starting driven gear. 9-7 starting clutch starting clutch inspection remove starting clutch driven gear. Check the gear for wear or damage. Measure the ...

Page 72

72 install starting clutch driven gear onto one way clutch. Hold flywheel and rotate starting clutch gear. The starting clutch gear should be rotated in c.C.W direction freely, but not c.W direction. (view as shown in this figure.) one way clutch removal remove starting driven gear. Remove 3 socket ...

Page 73

73 one way clutch installation install the components in the reverse procedures of removal. Caution torque value: 1.0~1.4kgf-m install starting driven gear. 9-8 flywheel installation align the key on crankshaft with the flywheel groove, and then install the flywheel hold the flywheel by drive face w...

Page 74

74 install reduction gear shaft and reduction gear 9-9 a.C.G. Set installation install the a.C.G. Coil set onto right crankcase cover (3 screws). Install pulse generator (2 screws). Tie the wire harness securely onto the indent of crankcase. Caution 9-10 right crankcase cover installation install do...

Page 75

75 install right crankcase cover (11 screws). Install the dowel pin, new gasket and water pump cover onto crankcase cover. Connect water hoses to the right crankcase cover and water pump cover.

Page 76: 10. Cooling System

76 10. Cooling system 10-1 mechanism diagram 10-2 general information 10-3 trouble diagnosis 10-4 trouble diagnosis for cooling system 10-5 system test 10-6 radiator 10-1 mechanism diagram.

Page 77

77 10-2 general information general warning: · · · · refill the radiator with distilled water or specified additives. Add coolant to the reservoir. The cooling system can be serviced on the atv. Never spill the coolant to the painted surface. Test the cooling system for any leakage after the repair....

Page 78

78 10-3 trouble diagnosis the engine temperature is too high the water thermometer and the temperature sensor do not work properly. The thermostat is stuck to close. Insufficient coolant. The water hose and jacket are clogged. Fan motor malfunction. The filler cap of the radiator malfunction. The en...

Page 79

79 10-4 trouble diagnosis for cooling system.

Page 80

80

Page 81

81 10-5 system test test on the filler cap hermetically seal the filler cap, apply water and pressure to the filler cap. Replace it with new one if found failing to maintain the specified pressure within a given time limit, or the opening pressure is too high or too low. The specified pressure shall...

Page 82

82 air bubble in the radiator coolant, also the coolant liquid level is stable. · · · ·stop the engine. Add coolant to proper level if necessary. · · · ·screw and tighten up the radiator filler cap caution coolant recommended: sym bramax radiator agent. Oncentration: 50% check reserve tank · · · · r...

Page 83

83 loosen the radiator 4 bolts. Remove coolant upper side pipes. Remove coolant outlet pipe. Disconnect the couplers for the thermo switch and fan motor, and then remove radiator and cooling fan. Disassembly loosen the 3 bolts from the fan duct, and then remove the fan duct. Loosen 3 screws from the...

Page 84

84 11. Steering and suspension 11.1 parts drawing 11.2 troubleshooting 11.3 handlenar 11.4 throttle housing 11.5 steering system 11.1 parts drawing.

Page 85

85 11.2 troubleshooting hard steering ★ faulty tire ★ steering shaft holder too tight ★ insufficient tire pressure ★ faulty steering shaft bushing ★ damaged steering shaft bushing front wheel wobbling ★ faulty tire ★ worn front brake drum bearing ★ bent rim ★ axle nut not tightened properly steers t...

Page 86

86 remove the handle bar switch on the left handle bar. Remove rear brake lever bracket assembly. Remove the handle cover and instrument panel by four screws at right and left side as shown in picture remove the bolts attaching the handlebar upper holder. Remove the handlebar. Screws bolts screws.

Page 87

87 installation put the handlebar on the lower holders. Make sure the handlebar punch marks match with the top end of the handlebar of lower holders. Install the handlebar upper holders with the l or r marks facing forward. Tighten the forward bolts first, and then tighten the rear bolts. Install th...

Page 88

88 11.4 throttle housing disassembly · · · ·loosen the screws on the throttle housing cover. · · · ·remove throttle housing cover and gasket. · · · ·disconnect throttle cable from the throttle arm and remove from the throttle housing. Note: assembly is in the reverse order of disassembly 11.5 steeri...

Page 89

89 steering shaft removal remove the handle bar cover and handle bar. Remove the front fender. Remove handlebar lower holder. Loosen the steering shaft holder bolt and remove steering shaft holder. Take off the cotter pin below steering shaft. Loosen the steering shaft fixed out below shaft. Pull st...

Page 90

90 12. Front wheel and brake system 12.1 parts drawing 12.2 troubleshooting 12.3 front wheel 12.4 hydraulic brake 12.5 suspension system 12 .1 parts drawing front wheel brake.

Page 91

91 12.2 troubleshooting hard steering ★ faulty tire ★ insufficient tire pressure front wheel wobbling ★ faulty tire ★ worn front brake drum bearing ★ bent rim ★ axle nut not tightened properly brake drag ★ ★ ★ ★ incorrect brake adjustment ★ sticking brake cable steers to one side ★ bent tie rods ★ w...

Page 92

92 12 .4 hydraulic brake this type of brakes are applying in front of two wheels of ra1 removal raise the front wheels off the ground by placing a jack or other support under the frame. Remove the front wheel nuts, washer and wheels. Please follow the next three steps of right pictures. Loosen fours...

Page 93

93 then using the power tools to take the screw out from brake stopping plate. You can take the brake disc off. When change brake shoe wear, you must push the master piston to rearward. After removal the front brake assembly, you must fabricate in reverse sequence. Add brake oil the brake oil tank i...

Page 94

94 12 .5 suspension system suspension system in this type of avt can be adjustable. There are two ways to adjust suspension: 1. You can raise the all atv body up by using a repair platform. The four wheel are in the free position, you can easy to adjust the suspension. 2. If you do not have any repa...

Page 95

95 13. Rear wheel and brake system 13.1 parts drawing rear wheel fr./rr. Axle 13.1 parts drawing 13.2 troubleshooting 13.3 suspension adjustment.

Page 96

96 13.2 troubleshooting bad brake performance ★ brake shoes are worn ★ bad brake adjustment ★ brake linings are oily, greasy or dirty ★ brake drums are worn ★ brake arm setting is improperly engage vibration or wobble ★ axle is not tightened well ★ bent rim ★ axle bearings are worn ★ faulty tires ★ ...

Page 97: 14. Electrical System

97 14. Electrical system 14.1 troubleshooting 14.2 ignition coil 14.3 ignition timing 14.4 battery information 14.5 electric starter 14.6 light bulbs replacement 14.7 instrument panel 14.8 wiring diagram 14.9 electrical starter switch 14.1 troubleshooting engine starts but stops ★ improper ignition ...

Page 98

98 14.2 ignition coil remove the spark plug cap from the spark plug. Disconnect the ignition coil primary wire. Measure the primary coil resistance. Standard: 0.1 - 0.3 Ω(20℃) measure the secondary coil resistance with the spark plug cap in place standard : 3 – 12 k Ω(20℃) 14.3 ignition timing the i...

Page 99

99 battery installation install the battery in the reverse order of removal. After installing the battery, coat the terminals with clean grease. Charging firstly, connect the charged positive cable to the battery positive terminal. Secondly, connect the charged negative cable to the battery negative...

Page 100

100 after loosen these three screws, users can find a connector. Please disjoin the connector in order to replace an electrical bulb conveniently and safely. The steps show on pictures. Installation is in the reverse order of disassembly. Front direction lights remove to replace the direction lights...

Page 101

101 front position light removes there are two screws inside the cap. Please disassemble first then push the cap upward. You could replace the electrical bulb turn around the cap, you could see the connector. Turn the seat to replace the electrical bulb . Taillight the taillight combines a position ...

Page 102

102 rear direction lights remove the same disassembling procedure like front direction light. Please use the pliers to remove the seat. Then the bubble could be see and replaced 14.7 instrument panel the instrument panel includes fuel gauge, speed meter, water temperature gauge, right and left turn ...

Page 103

103.

Page 104

104 14.9 electrical starter switch with main switch ‘on’, press electrical starter switch “ ” , the engine will start. Warning: release the button after the engine has started. To avoid engine damage, do not engage starter with engine running. Turn signal switch turn signal lights are used when turn...

Page 105

105 indicator and warning lights . 1 2 3 4 5 6 7 8 9 10 11 12 1. Speed indicator in mph. 2. Left turning indicator 3. High light indicator 4. Low light indicator 5. Right turning indicator 6. Temperature indicator 7. Fuel indicator 8. Four wheel drive 、 、 、 、 two wheel drive indicator. 9. Mileage od...

Page 106

106 fuse 1 2 3 4 5 6 1 、 、 、 、 ignition system fuse (10 a) 2 、 、 、 、 fan system fuse(10a) 3 、 、 、 、 light system fuse (15 a) 4 、 、 、 、 charging system fuse(15a) 5 、 、 、 、 auxiliary dc jack fuse (10 a) 6 、 、 、 、 auxiliary dc jack fuse (15 a).

Page 107: 15.Troubleshooting

107 15.Troubleshooting 15.1 engine can not work 15.2 poor performance at low and idle speeds 15.3 poor performance at high speed 15.4 loss power 15.5 poor handling 15.1 engine can not work.

Page 108

108 15.2 poor performance at low and idle speeds 15.3 poor performance at high speed.

Page 109

109 15.4 loss power.

Page 110

110 15.5 poor handling.