- DL manuals

- KEEWAY

- Motorcycle

- FACT 50 4T

- Maintenance Manual

KEEWAY FACT 50 4T Maintenance Manual

Summary of FACT 50 4T

Page 1

1 fact 50 4s maintenance manual contents.

Page 2

2 contents .................................................................................. 2 preface ................................................................................... 5 preparing documents ................................................................... 5 inspection/adjustmen...

Page 3

3 7.2 failure diagnosis ................................................................ 99 7.3 front wheel ...................................................................... 99 7.4 steering handle ................................................................. 102 7.5 front fork ................

Page 4

4 14.5 clutch/driven wheel ............................................................ 149 14.6 breakdown of clutch and driven wheel............................................ 150 14.7 installation ................................................................... 153 14.8 kickstart mechanism ......

Page 5: Preface

5 preface this maintenance manual is used for operating and maintaining motorcycle fact 50 4t. Preparing documents include all necessary instructions and statements. Please carefully read this manual before operation. Inspection & adjustment states how to check and adjust your motorcycle. All safety...

Page 6: Maintenance Rules

6 start up engine in an open place. The exhaust cleaning system shall be adopted if engine is started up in a closed area. Petrol ventilation is required for working places. Fire is strictly forbidden in any working place or where petroleum is stored. Battery battery emits explosive gas. Therefore, ...

Page 7

7 套:boot when loosening assembly parts, please start from outside to inside. Small assembly parts shall be loosened first. Complex assembly parts, such as gearbox, shall be stored in proper order for facilitating installation in the future. Please specially note important connections before disassem...

Page 8

8 when installing a hose (fuel, vacuum or cooling agent), insert its end into the bottom of the connector so that the hose clip can properly fix the connector. Rubber or plastic dirt-proof boot shall be mounted at the original design position. 槽:groove 夹子:clip 接头:connector during dismantling ball be...

Page 9

9 loose cables threaten electrical safety. Check each cable after it is clamped to another for electrical safety; wire clamps are not allowed to bend towards welding point; bind cables at the designated place; do not deploy cables at the end of frame or at sharp point; do not deploy cables at the en...

Page 10: Identification

10 identification 1.the identification number of motorcycle frame is marked at : *lbbtebaa????????? . The 10 th digital and 11 th digital respectively indicate year code and factory code. “*” shall be added before and after the frame number. The frame sign is nailed at . See fig. 1-1. Fig. 1-1 2.the...

Page 11: Special Tools

11 special tools special tools refer to tools which are specially designed for assembling or disassembling some motorcycle parts on special positions. Applicable special tools are necessary for precise adjustment and installation. With them, parts and accessories can be mounted safely, reliably and ...

Page 12

12 fig.1-7 fig.1-8 fig.1-9 fig.1-10 handle fig.1-11 fig.1-12 pliers piston fig.1-13 fig.1-14.

Page 13

13 fig.1-15 fig.1-16 2.tools for repairing the chassis table and drawing (1-17, 1-18) of ordinary tools and special tools for disassembling/assembling chassis parts are as follows: table 1-17 name remark torque spanner inner hexagon spanner socket spanner micrometer magnetic rack, v-block dial indic...

Page 14

14 fig. 1-21 fig. 1-22 fig. 1-23 fig. 1-24 fig. 1-25 fig. 1-26 fig. 1-27 fig. 1-28 (2) special tools for repairing the chassis: tool for hammering seal of front fork fig. 1-29 (3) steering nut spanner.

Page 15

15 fig. 1-30 3.tools for electric parts table and drawings (1-31, 1-32) of special tools for testing electric parts are as follows: table 1-31 name remark multimeter ignition tester fig. 1-33 fig. 1-34 table 1-32 (continued) fig. 1-33 fig. 1-34 specification (fact 50 4t25km) model fact 50 4t engine ...

Page 16

16 total 92 front outer tire 120/70-12 lubrication splash lubrication front rim 3.50×12 rear outer tire 130/70-12 air filter e9qjaf-b70 tire size rear rim 3.50×12 capacity of gasoline tank 6.0±0.2l clutch dry centrifugal clutch carburetor type pd19jb variable speed gear stepless idle speed - rpm 180...

Page 17

17 backshaft 55 cooling air cooling (curb weight) total 92 front outer tire 120/70-12 lubrication splash lubrication front rim 3.50×12 rear outer tire 130/70-12 air filter e9qjaf-b70 tire size rear rim 3.50×12 capacity of gasoline tank 6.0±0.2l clutch dry centrifugal clutch carburetor type pd19jb va...

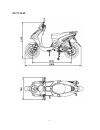

Page 18: Fact 50 4T

18 fact 50 4t.

Page 19: Failure Diagnosis

19 n y n y y n y n failure diagnosis diagnosis on failure or difficulty in starting engine failure or difficulty in starting engine check ignition system remove the spark plug and check whether there is carbon fouling between electrode. Sparkover test for spark plug eliminate carbon fouling weak spa...

Page 20

20 y n moist electrode of spark plug dry electrode of spark plug check whether there is oil spillover in the carburetor drop a little gasoline into the cylinder for trial startup 1. Check whether the float needle valve and the valve seat are firmly combined 2. Check whether the conical surface of fl...

Page 21

21 y n y n y n n y y n diagnosis on engine overheating engine overheating check whether operation is correct 1. Check whether gasoline grade is improper or gasoline is stored for a long time 2. Check whether the engine works at high speed for a long time or with overload during driving check cooling...

Page 22

22 remove the spark plug; check the colors of spark plug insulators and judge the proportion of mixed combustible gas based on abnormity the spark plug insulators are black; the exhaust muffler emits black smoke or causes backfire if the engine works at low speed; bad acceleration property; instable...

Page 23

23 y n diagnosis on power shortage of engine power shortage of engine raise the main kickstand and suspend wheels; rotate wheels with hands flexible rotating of wheels inflexible rotating of wheels check tire pressure 1. Check whether there is braking drag. 2. Check whether wheel bearing is excessiv...

Page 24

24 y n y n n y y n y n diagnosis on abnormal idle speed of engine abnormal idle speed of engine high idle speed no idle speed unstable idle speed check compression pressure of cylinder check whether the carburetor throttle is completely closed with your hand. Check whether ignition is timely conduct...

Page 25

25 y n y n y n y n diagnosis on excessive fuel consumption of engine excessive fuel consumption of engine check whether operation is correct raise the main kickstand and rotate wheels with hands 1. Check whether the motorcycle runs with overload or not at economical speed or at low gear. 2. Check wh...

Page 26

26 y n y n y n n y y n diagnosis on dense bluish white smoke from the exhaust muffler of the two-stroke engine diagnosis on difficulty in transmission shift the exhaust muffler of the two-stroke engine emits dense bluish white smoke. Check whether the fuel level in the crankcase exceeds the upper li...

Page 27

27 n y n y n y y n y n n y diagnosis on transmission gear skip shift diagnosis on clutch slipping clutch slipping automatic shoe-type centrifugal & dry clutch is slipping. Check whether the shoe- type friction plate is excessively abraded. Replace the whole set of clutch shoes clean and remove oil s...

Page 28

28 n y y n n y diagnosis on malfunction of hydraulic disc brake diagnosis on malfunction of drum brake malfunction of hydraulic disc brake check the level of brake fluid inside the brake fluid reservoir. The level of brake fluid is below the lower limit of the reservoir. The level of brake fluid is ...

Page 29

29 y n diagnosis on battery charging failure battery charging failure resistance value lower than standard value. Short circuit of charging coil infinite resistance value. Resistance value in accordance with standard value. Open circuit of charging coil or output conductor. Set the multimeter to dc ...

Page 30

30 y n y n diagnosis on insufficient battery charging insufficient battery charging check whether the brake lamp is always light. Adjust or replace the brake lamp switch. Leakage current smaller than the required. Leakage current larger than the required (normally it shall be no more than 1ma). Chec...

Page 31

31 riding-style motorcycle motorcycle scooter y n diagnosis on starter motor failure in rotation the electric horn does not make sound or makes weak sound; the steering lamp emits weak light. Battery power shortage or bad contact of conductor joint starter motor failure in rotation turn the ignition...

Page 32

32 y n n y y n diagnosis on starter motor running weak repair or replace starting button open circuit or short circuit inside the electric starting control system starter motor running weak turn the ignition switch; press the horn or turn the steering lamp switch. The electric horn does not make sou...

Page 33

33 y n y n diagnosis on motorcycle lamp failure in illumination motorcycle lamp failure in illumination ac power supply system for illumination dc power supply system for illumination remove the connector between the conductor bundle of electromagnetic motor and the cable assembly; check whether the...

Page 34

34 n y diagnosis on burnt-out bulbs burnt-out bulbs turn the ignition switch; press the horn or turn the steering lamp switch. The horn works abnormally or does not make sound; the steering lamp emits weak light. The horn makes loud sound and the steering lamp emits bright light. 1. Check whether th...

Page 35

35 y n y n y n y n diagnosis on weak light from lamps weak light from lamps ac power supply system for illumination dc power supply system for illumination remove the connector between the conductor bundle of electromagnetic motor and the cable assembly; check whether the resistance between the outp...

Page 36

36 y n y n y n n y diagnosis on steering lamp failure in illumination . Steering lamp failure in illumination steering lamps at one side are partly not light. Steering lamps at one side are wholly not light. All the steering lamps are not light. Remove the lamp covers and check whether the bulbs are...

Page 37

37 diagnosis on electric horn failure in making sound the test lamp is light. The test lamp is not light. Open circuit or short circuit of power cord of steering lamp. Open circuit or short circuit between the ignition switch and the flasher or between the flasher and the steering lamp switch. Elect...

Page 38

38 y n y n diagnosis on brake lamp failure in illumination diagnosis on power shortage of battery brake lamp failure in illumination disassemble the cover of brake lamp and check whether the circuit board is burnt. Replace the circuit board of brake lamp use a lead wire to short-circuit two terminal...

Page 39

39 y n check whether short circuit occurs to the charging coil of electromagnetic motor. Short circuit between the rectifier or the rectifier regulator or the battery and the ignition switch. Replace charging coil 1. Check whether the electrolyte inside the battery is sufficient. 2. Check whether th...

Page 40: Inspection/adjustment

40 inspection/adjustment preparing information cylinder pressure periodic maintenance & inspection table gear oil engine oil/ oil filter replacement of gear oil fixing steering stem bearing & handlebar driving belt inspection & adjustment of throttle cable free stroke of front/rear brake air filter ...

Page 41

41 specification engine idle speed 1800±100rpm/min spark plug gap 0.6-0.7mm spec. Of spark plug ngk cr6sha frame free stroke of front brake lever 10-20mm free stroke of rear brake lever 10-20mm specification tire pressure front outer tire 120/70-12 front rim 3.50×12 145-170kpa rear outer typre 130/7...

Page 42

42 periodic maintenance & inspection table per 300 km per 1000 km per 3000 km per 6000 km per 12000 km per 14500 km service cycle and time inspection item new one month three months six months twelve months fifteen months tools * air filter i c c r c ordinary tools * petrol filter i i r ordinary too...

Page 43: Engine Oil/filter

43 anticipated inspection 1 ignition system—obviously continuous ignition abnormality, engine fire or overheating, which requires inspection and maintenance. 2 carbon fouling elimination—obviously insufficient horsepower, which requires carbon fouling removal from cylinder head, piston head and exha...

Page 44: Throttle Cable

44 check oil leakage when the engine operates at its idle speed for minutes. Check the oil level again. (放油螺栓:drain bolt) throttle cable inspection/adjustment check whether the throttle cable works smoothly. Check the free stroke of the throttle cable. Free stroke: 5-10mm it is mainly adjusted at th...

Page 45: Spark Plug

45 the filter. Spark plug remove the spark plug. Check whether the spark plug is damaged or stained or has carbon fouling. If yes, please clean it with spark plug cleaner or steel brush. Check spark plug gap. Gap: 0.6-0.8mm (火花塞间隙:spark plug gap) * note for the installation of spark plug, it shall b...

Page 46

46 warning! To prevent short circuit, connect the positive wire first and then the negative wire. Do not remove the battery during commissioning. Otherwise, it may cause damage to inner parts of the vehicle. Check the charging condition (closed circuit voltage) open the battery box cover. Remove the...

Page 47: Carburetor

47 quick: 30 minutes charging completed: open circuit voltage: above 12.8v carburetor idle speed adjustment * note idle speed adjustment is carried out when the engines warms up. It is carried out when the engines warms up. Operate the engine and connect the engine rotary meter. Adjust the adjusting...

Page 48: Gear Oil

48 remove the spark plug. Install the cylinder pressure gauge. At full throttle, measure the cylinder pressure by starting the engine. Following items shall be checked in case of extra-low pressure: —whether the spacer of cylinder cover is damaged; —whether piston ring is damaged; —whether piston ri...

Page 49: Drive Belt

49 add gear oil. Check whether there is oil leakage in any part. Install the dipstick. (放油螺栓:drain bolt) drive belt remove the cover of left crankcase. Check whether the drive belt is ruptured or abraded. Periodically maintenance shall be guaranteed, and replace the drive belt if necessary. (驱动皮带:dr...

Page 50: Headlamp

50 brake to the maximum and check the oil level through the oil sight glass. In case the brake fluid level is at or below the arrow in the picture, certain brake fluid shall be added until it reaches the upper limit. Note: the fuel pump assembly shall be parallel with the ground during inspection. H...

Page 51: Bolt/nut/fastener

51 whether any component is damaged or loosened. (上下压缩:compress upwards or downwards) rear compress the rear absorber upwards or downwards for check. Check whether each part of the rear absorber is damaged or loosened. Suspend the rear wheel and check shimmy. Check whether the suspension bushing of ...

Page 52: Tire Specification

52 tire specification front outer tire 120/70-12 front rim 3.50×12 rear outer tire 130/70-12 fact 50 4t rear rim 3.50×12 check whether the locking nut of the front wheel spindle is loose. Check whether the fixing nut of the rear wheel is loose. Tighten it to the required torque value if it is loose....

Page 53

53 inspection and maintenance of electrical system table of torque force of electrical system fasteners name of fastening parts and fasteners tightening torque(n·m) clutch cover bolt of the startup motor clutch fixing nut of the startup motor rectifier bolt high-voltage coil fixing bolt flywheel fix...

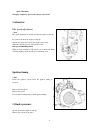

Page 54: Charging System

54 charging system 1. Battery 12v,4ah 2. Seat lock assembly 3. Horn 4. Rectifier 5. Power lock assembly 6. Cdi igniter 7. Relay 8. Release resistance.

Page 55: 1. Battery/charging System

55 1. Battery/charging system preparing documents -------------1.1 failure diagnosis -------------1.2 battery ---------------1.3 charging system -------------1.4 voltage/current regulator -------1.5 charging coil of magnetor---1.6 disassembly of magnetor-----1.7 1.1 preparing documents work instruct...

Page 56

56 preparing principles item specifications capacity/type 12v-4ah/ dry-charged fully charged 13.1v voltage (20 ) necessary charging 12.3v(not working for 1h) charging current standard: 0.4a,quick: 4a battery charging time standard: 10-15 hours,quick: 30 mins capacity 90w/8000rpm impedance of lightin...

Page 57

57 1.3 battery 1.3.1 battery disassembly remove fixing screws of the battery box cover. Remove the battery box cover. Remove the negative wire and then the positive wire. Remove the battery. Warning! When the positive wire is disassembled, do not make the tool contact with the frame. Otherwise, it m...

Page 58

58 • except emergencies, you should not use emergency charging. • measure voltage in 30 minutes after the battery is charged. Charging current: standard: 0.4a quick: 4.0a charging time: standard: 10-15 hours quick: 30 minutes charging completed: open circuit voltage: above 12.8v 1.4 charging system ...

Page 59

59 1.5 voltage/current regulator 1.5.1 main wiring check remove 4p plug of the voltage/current regulator. Check conductivity between main wiring terminals. Item (wire color) judgment between battery(red) and gnd of the body with battery voltage between gnd wire (black) and gnd of the body with lead ...

Page 60

60 check remove the 6p connector of the magnetor. Measure impedance between the white coil of the magnetor and the body with multimeter. Standard: 1.5-2Ω(20 ) replace the magnetor coil when the measured value exceeds the standard value. 1.7 magnetor lighting coil * note check the magnetor lighting c...

Page 61

61 1.7.3 installation 飞轮:flywheel 冷却风扇:cooling fan 风扇盖:fan cover install the stator on the body of the engine. Connect the magnetor joint. Clean up the crankshaft and the taper part of the flywheel. Install the solid key into the groove above the upper crankshaft key and confirm it. Aim the groove i...

Page 62: Ignition System

62 ignition system 1. Storage battery 12v,4ah 2. Fbt assembly 3. Rectifier 4. Power lock assembly 5. Cdi igniter 6. Relay 7. Seat lock assembly 8. Horn 点火系统:ignition system.

Page 63: 2. Ignition System

63 2. Ignition system preparing documents--------------2.1 cdi group ----------------2.4 failure diagnosis --------------2.2 ignition coil --------------2.5 ignition system check----------2.3 trigger --------------------2.6 2.1 preparing documents work instructions 1. Check the ignition system follo...

Page 64: 2.2 Failure Diagnosis

64 2.2 failure diagnosis non-sparking of spark plug abnormality cause (confirm it sequentially as follows) ignition coil too low high-voltage the inner resistance is too small and it should be tested by required tester. Low speed of the crankshaft. Interfered tester (it is normal that voltage is alw...

Page 65: 2.3 Ignition System Check

65 2.3 ignition system check * note • when there is no spark, check whether there is loose wiring or poor contact, and make sure all voltage values are normal. • there are kinds of multimeters with different impedances and different test values. Connect a high-pressure shunt or an ammeter with an in...

Page 66

66 connection: positive pole to black/red; negative pole to black. Minimum voltage: above 95v * note never touch any metal part of the test rod with your finger to avoid electric shock. When the maximum voltage measured at the terminal of cdi group is abnormal, dismantle the body guard and the magne...

Page 67: 2.4 Cdi Group

67 2.4 cdi group 2.4.1 system check check the system. Remove the cdi group, and check components of the ignition system at the terminal. (黑:black 红:red 白:white 绿:green 蓝:blue 墨绿: blackish green 2.4.2 check remove cdi group and check whether the terminal is loose or corrosive item test terminal stand...

Page 68: 2.6 Trigger

68 2.5.3 secondary coil attached with spark plug. Measure the impedance between the wiring side of the spark plug cap and the terminals. Standard: 5-11kΩ(20 ) it shows good if the impedance is within the range of standard values. The impedance ∞ indicates that the coil breaks. Remove the spark plug ...

Page 69: Startup System

69 startup system 1. Storage battery 12v,4ah 2. Seat lock assembly 3. Horn 4. Rectifier 5. Power lock assembly 6. Cdi igniter 7. Relay 8. Release resistance (启动示意图:startup schematic diagram).

Page 70: 3. Startup System

70 3. Startup system preparing documents---------------3.1 failure diagnosis -------------------3.2 startup motor------------------------3.3 starter relay--------------------------3.4 3.1 preparing documents work instructions disassemble the startup motor on the engine. For the disassembly of the st...

Page 71: 3.2 Failure Diagnosis

71 3.2 failure diagnosis startup failure weak in rotation no rotation of re rotary engine of the startup motor of the startup motor • fuse blow • low battery • poor startup clutch • low battery • poor wiring contact • reversal rotation of the startup motor • poor main switch • gear seized • low batt...

Page 72

72 attached to it. Check conduction between the surfaces of other components. Ensure non-conduction between armature shafts of the commutator. Check the conduction of the shell of the startup motor. Ensure non-conduction between the conduction terminal and the startup motor shell. Check conduction b...

Page 73: 3.4 Starter Relay

73 3.4 starter relay 3.4.1 check remove the body guard. When the main switch is “on”, check there is “click” sound at the time of pressing the startup motor. With click sound, it is normal. Without click sound: • check voltage of the starter relay; • check the gnd loop of the starter relay; • check ...

Page 74: Bulbs/switches/meters

74 bulbs/switches/meters 1. Left rearview mirror assembly 2. Right rearview mirror assembly 3. Front left steering lamp assembly 4. Front right steering lamp assembly 5. Meter 6. Power lock assembly 7. Headlamp (twin lamps) 8. Tail lamp 9. Rear left steering lamp assembly 10. Rear right steering lam...

Page 75: 4. Bulbs/switches/meters

75 4. Bulbs/switches/meters preparing documents ---------------------4.1 meters -------------------------4.6 failure diagnosis--------------------------4.2 main switch ------------------4.7 replacement of headlamp bulbs --------4.3 horn ---------------------------4.8 replacement of front steering la...

Page 76: Bulbs

76 4.3.2 installation install the bulb in reverse order. 4.4 replacement of rear steering lamp bulbs 4.4.1 disassembly remove the foot guard and pedal assembly. Remove the front shield, and disconnect the steering lamp connecting wire. Loosen the fixing nuts (4) of the steering lamp. Remove the bulb...

Page 77: 4.6 Meter

77 4.6 meter remove the left and right rearview mirror. Remove fixing screws of the handlebar cover. Remove the decorating cover of the upper handlebar shade. Remove the odometer assembly to dismantle the odometer. Install the speedometer in reverse order. 4.7 main switch 4.7.1 check remove the fron...

Page 78: 4.9 Handlebar Switch

78 4.9 handlebar switch remove the left/right rearview mirror assembly. Remove the fixing screws of the left/right combined switch. Loosen the left/right combined switch. Remove the right grip assembly and the left steering grip. Remove the left/right combined switch. 逻辑图: logic diagram.

Page 79

79 inspection and maintenance of the chassis torque force table of chassis fasteners name of fastening parts and fasteners tightening torque(n·m) fuel pump assembly fixing bolt mounting bolt of front brake cylinder assembly brake handle fixing bolt fixing screw of muffler decorating shade fixing bol...

Page 80: Front Disc Brake

80 front disc brake 1. Fuel pump assembly 2. Brake assembly 3. Oil cup pad 4. Fuel pump gasket 5. Oil cup cap 6. Screw m4×10 7. Fixing cover 8. Bolt m6×23 9. Fuel pump body 10. Connecting bolt 11. Gasket 12. Brake hose assembly 13. Nut m6 14. Spring gasket 6 15. Handle fixing bolt 16. Handle return ...

Page 81: Rear Drum Brake

81 rear drum brake 1. Rear absorber assembly 2. Bolt m10Χ1.25Χ40 3. Cotter pin 4. Bolt m8Χ35 5. Nut m14Χ1.5 6. Brake shoe assembly 7. Brake shoe spring 8. Rear indicator 9. Rear brake camshaft 10. Rear brake return spring 11. Rear brake swing arm assembly 12. Rear swing arm mounting bolt 13. O-ring ...

Page 82: 5. Brake

82 5. Brake maintenance instruction ------------------------5.1 failure diagnosis --------------------------------5.2 front disc brake ---------------------------------5.3 rear drum brake --------------------------------5.4 5.1 maintenance instruction work instructions * note *check brake before rid...

Page 83: 5.3 Front Disc Brake

83 3. Improper installation of brake shoe 3. Improper installation of brake shoe or friction disc assembly or friction disc assembly 4. Stained brake shoe or friction disc assembly abnormal noise 1. Abraded brake shoe or friction disc assembly 2. Stained brake shoe or friction disc assembly of the f...

Page 84: 5.4 Rear Drum Brake

84 * note • measurement with micrometer. Measure the thickness of the friction disc assembly. If the thickness of the front brake disc or the friction disc assembly is below the required value for maintenance or it is stained with grease, please replace it. Limit for use: friction disc 5.0mm front b...

Page 85

85 remove the muffler. Remove the fixing nuts of the rear wheel. Remove the rear wheel. Remove the brake shoe assembly. * note • replace the brake shoe assembly. • if the brake shoe will be used again, mark it before disassembly so as to reinstall it at the original place. Remove following assemblie...

Page 86

86 5.4.3 installation install the brake shoe assembly. Install the rear wheel. Install the muffler. * note any grease on brake shoes will reduce the brake performance and even lead to failure. Tighten bolts and nuts to the required torque force. Torque force: fixing nuts for rear wheel: 100-113 n·m ...

Page 87: Body

87 body 1seat assembly 2rear rack 3 tapping screw st3×10 4 tapping screw st5×16 5 battery box cover 6 helmet box front cover 7odometer shade 8 handlebar cover 1 9 handlebar cover 2 10 right guard 11left guard 12 connecting bracket of the left/right guard i 13 screw m6×14 14 decorating panel of the f...

Page 88: 6. Body

88 6. Body dismantle the body in following order: left/right rearview cover→ odometer shade→ handlebar cover 1→ handlebar cover 2→ front inner fender→ helmet ↓ hook → frame number cover→ foot protection board → front shield→ headlamp → set assembly→ helmet ↓ front cover→ connecting bracket of the le...

Page 89: Front Wheel

89 front wheel 1 front wheel spindle m12Χ1.25Χ224 2 left spindle sleeve of front wheel 3 oil seal 22×35×7 4 bearing 6201-2rs 5 middle spindle sleeve assembly 6 front rim 3.50×12 7 tire 120/70-12 8 gear housing assembly 9 nut m12Χ1.25 10 valve cap 11 valve 12 front brake disc 13 installation nut of f...

Page 90: Front Suspension

90 front suspension 1 front right absorber assembly 2 front left absorber assembly 3 weld assembly of lower connecting bracket 4 odometer cable clamp 5 brake cable clamp 6 gland nut 7 dust cover 8 one-piece cup 9 steel ball φ5 10 upper cup of the lower bearing 11 lower cup of the lower bearing 12 bo...

Page 91: Handlebar

91 handlebar 1 handlebar weld assembly 2 bolt m10×1.25×45 3 nut m10×1.25 4 left grip 5 throttle lever assembly 6 left handle 7 right combined switch 8 right combined switch fitting seat 9 screw m5×20 10 screw m5×25 11 left combined switch assembly 12 left combined switch assembly fitting seat 13 spr...

Page 92: 7.1 Preparing Documents

92 7. Front wheel / front suspension preparing documents-------------------------7.1 failure diagnosis -----------------------------7.2 front wheel -----------------------------------7.3 handlebar -------------------------------------7.4 front fork assembly -------------------------7.5 7.1 preparing...

Page 93: 7.3 Front Wheel

93 7.2.2 unsteady steering damaged steering handle bearing. Low tire pressure. Bending of the front fork or the front wheel spindle. Deformed or unbalanced front tire. 7.2.3 front tire shimmy deformed rim. Loose front wheel bearing. Poor tire. 7.2.4 difficulty in wheel rolling failure of wheel beari...

Page 94

94 7.3.2 check 7.3.2.1 check the bending of the wheel spindle place the wheel spindle on the v-base and measure the eccentricity ratio with a dial indicator. Limit for use: replacement when beyond 0.2mm 7.3.2.2 check the rim shimmy place the rim on a precision bracket and check the rim shimmy. Rotat...

Page 95: 7.4 Steering Handle

95 • bearings must be pressed in horizontally. 7.3.4 installation install it in reverse order. Instructions: lubricate the front wheel spindle, gear housing assembly, oil seal (opening), spindle sleeve, bearing 6201-2rs and middle spindle sleeve assembly. Albany grease is suggested. Install the fron...

Page 96: 7.5 Front Fork

96 install it in reverse order. Fixing bolt of handlebar weld assembly torque force: 40-60 n·m 7.5 front fork 7.5.1 disassembly remove the front wheel. Remove the body guard. Remove the brake hose and the odometer cable. Remove the handlebar. Remove the gland nut (6) and the dust cover (7). Remove t...

Page 97

97 install the handlebar. Install the body guard. Install the front wheel. * note: for the disassembly and assembly of the front fork , please see p89..

Page 98: Rear Wheel/rear Suspension

98 rear wheel/rear suspension 1 outer tire 130/70-12 2 rim 3.50×12 3 cotter pin 4 bolt m8×31 5 nut m16×1.5 6 brake shoe assembly 7 brake shoe spring 8 rear indicator 9 rear brake camshaft 10 rear brake return spring 11 rear brake swing arm 12 rear swing arm mounting bolt 13 o-ring 14 bolt m10×1.25×4...

Page 99: Rear Wheel

99 rear wheel 1 outer tire 130/70-12 2 rim 3.50×12 3 valve cap 4 valve 5 nut m16Χ1.5 6 brake shoe assembly 7 brake shoe spring 8 rear indicator 9 rear brake camshaft 10 rear brake return spring 11 rear brake swing arm assembly 12 rear swing arm mounting bolt 13 o-ring a tire size: 130/70-12 b rim si...

Page 100: 8.1 Preparing Documents

100 8. Rear wheel/rear suspension preparing documents -----------------8.1 failure diagnosis ----------------------8.2 rear wheel -----------------------------8.3 rear absorber --------------------------8.4 8.1 preparing documents work instructions the surface of the brake drum and brake shoes shall...

Page 101: 8.3 Rear Wheel

101 8.3 rear wheel 8.3.1 disassembly remove the muffler assembly. Remove the rear inner fender. Remove fixing nuts of the rear wheel spindle. Remove the rear wheel. 8.3.2 check 8.3.2.1 check rim shimmy rotate the wheel by manual and measure the eccentricity ratio with a dial indicator. Limit for use...

Page 102: 8.4 Rear Absorber

102 8.4 rear absorber 8.4.1 disassembly remove the seat and the rear left/right guard. Remove the rear storage box, rear rack assembly and rear fender. Remove fixing bolts of the rear absorber. Remove the rear absorber. 8.4.2 installation installation of the rear absorber: torque force: upper fixing...

Page 103: Fuel Tank/seat

103 fuel tank/seat 1 seat assembly 2 fuel tank assembly 3 right cover sheet 4 left cover sheet 5 front cover of helmet box 6 rear storage box rack 7 seat steel rope 8 rear storage box rack holder 9 bolt m6×16 10 bolt m6×12 a note: for the disassembly of the fuel tank, turn the fuel switch to “off”. ...

Page 104: Fuel Tank

104 fuel tank 1 tank assembly 2 bolt m6×16 3 fuel tank switch assembly 4 fuel tube 1 φ4.5xφ8.5x80mm 5 thermal- isolating spring 6 clampφ8 7 vacuum tube φ4xφ8x360mm 8 clamp φ7 9 fuel tube 2 φ4.5xφ8.5x250mm 10 filter assembly 11 oil level sensor 12 bolt m5×16 13 oil level sensor gasket 14 sealing rubb...

Page 105: Seat

105 seat 1 seat assembly 2 seat hinge assembly 3 o ring 84.4×3.1 4 boss bolt m6×14 5 helmet box 6 assembling bolt m6×20 a torque for bolt 4: 5- 9n·m b torque for bolt 6: 5- 9n·m.

Page 106: 9.Fuel Tank/seat

106 9.Fuel tank/seat preparing documents -----------9.1 failure diagnosis ---------------9.2 fuel tank/seat -------------------9.3 9.1 preparing documents work instructions it shall be dismantled far from fire sources. Turn the fuel switch to “off” when the fuel tank is dismantled. Tighten all the b...

Page 107

107 9.3 fuel tank/seat 9.3.1 disassembly open the seat. Remove (four) fixing bolts of the seat. Remove the machine oil pot guard. Remove the machine oil pot. Remove the seat and the helmet box (1). Remove the rear storage box rack. Remove the rear left/right guard assembly. Remove the rear rack and ...

Page 108

108 disassembly and installation of engine 1 engine stationary axis m12×1.25×280 2 bolt m10×1.25×40 3 seat steel rope 4 bolt m8×31 5 rear shock absorber assembly 6 engine assembly 7 rear wheel assembly 8 rear brake rocker arm assembly a torque force of engine stationary axis 1: 55- 62n·m b torque fo...

Page 109

109 10. Disassembly/installation of engine preparing documents -----------10.1 failure diagnosis ---------------10.2 engine ----------------------------10.3 engine suspension standing clamp------10.3 10.1 preparing documents work instructions make motorcycle not tilt in removing motor. Remove motor ...

Page 110

110 10.3 disassembly of engine 10.3.1 disassembly remove bolt and left crankcase ventilated tube. Disassembly procedures: -remove frame cover. -remove gas filter. -remove primary cable of ignition coil. -remove starter motor cable. -remove fuel tube and vacuum tube. -remove starter valve 2p connecto...

Page 111

111 connect carburetor fuel tube and vacuum tube. Connect the engine suspension assembly to engine assembly. Install bolt and nut of engine suspension temporarily. 10.3.3 installation install according to reversed procedures of “disassembly”. Note: for details, see p106. Torsion value of installatio...

Page 112

112 inspection and maintenance of engine table of torque force of engine fasteners name of fastening parts and fasteners tightening torque(n·m) fan cowl locking bolt cylinder cover locking nut spark plug air intake pipe locking bolt cooling fan blade locking screw flywheel locking bolt locking screw...

Page 113: Lubricating System

113 lubricating system 摇臂---rocker arm 凸轮---camshaft 曲轴活塞连杆组件---crankshaft piston connecting rod assembly 机油泵组件---fuel pump assembly 机油滤芯组件--- fuel filter element assembly note: worm gears and worm wheels shall rotate flexibly without being seized or imbalanced tightening. A little axial movement sh...

Page 114: 10. Lubricating System

114 10. Lubricating system preparing documents -----------10.1 failure diagnosis ----------------10.2 fuel pump ------------------------10.3 10.1 preparing documents work instructions worm gears and worm wheels shall rotate flexibly without being seized or imbalanced tightening. A little axial movem...

Page 115

115 10.3 fuel pump 10.3.1 disassembly loosen the bolt and remove the fan cowl assembly. Loosen fan screws and remove the fan. Remove the right cover. Remove the worm wheel from the crank and also the fuel pump assembly. 导风罩 fan screw 磁电机定、转 子、支架 right cover fuel pump.

Page 116

116 remove screw, take down the fuel pump base, and disassemble the fuel pump. Check the radial clearance between inner and outer rotors. Limit for use: 0.19mm。 check the clearance between outer rotor and fuel pump base. Limit for use: 0.21mm。 screw fuel pump gauge gauge.

Page 117

117 check the end clearance of rotors. Limit for use: 0.11mm. Assembly of fuel pump as shown below 1. Cross recessed small pan head screws2. Locating pin 3. O ring 4. Fuel pump base 5. Inner rotor 6. Outer rotor 7. Fuel pump body 8. Hexagon flange bolt 9. Round pin 10. Fuel pump gear assembly 11. Fu...

Page 118: Carburetor

118 measure the outer diameter of the plunder. Limit for use: 2.61mm。 carburetor 1. Screw 2. Float chamber 3. Needle valve assembly 4. Float 5. Float pin 6. Main metering jet 7. Idling jet 8. Main foam pipe 9. Idle adjusting screw note: gasoline is very dangerous. Fire is strictly forbidden in workp...

Page 119: 11.Carburetor

119 11.Carburetor preparing documents --------------11.1 failure diagnosis -------------------11.2 carburetor disassembly -----------11.3 carburetor installation ------------11.4 carburetor adjustment ------------11.5 11.1 preparing documents work instructions ·gasoline is very dangerous. Fire is st...

Page 120

120 11.2 failure diagnosis abnormal startup difficulty in startup, flameout after startup, unstable idle speed no fuel in the carburetor blocked carburetor blocked oil filter too dense or dilute mixed gas blocked oil pipe secondary air suction into the air intake system adhesive needle valve idle sp...

Page 121

121 11.3.2 carburetor breakdown loose screws of the electric enrichment valve and remove the electric enrichment valve assembly. Check abrasion of electric enrichment valve and oil needle. If it is severe, replace the electric enrichment valve assembly. Loose screw and remove upper cover. Remove spr...

Page 122

122 11.3.3 check check whether the needle valve assembly, needle valve seat and float assembly are abrasive or damaged. Replace any abrasive or damaged needle valve core. Replace the carburetor body if the needle valve seat is abrasive. Replace any abrasive float tongue. Check whether the carburetor...

Page 123

123 (retreat the screw by 2 circles to the maximum); readjust the idle adjusting screw to lower the engine speed to 1800±100rpm; pull the throttle to speed up for several times and check whether the idle speed is steady; test exhaust and compare it with standard..

Page 124: Cylinder Cover

124 cylinder cover 1 cylinder cover assembly 2 cylinder cover gasket 3 intake valve 4 spark plug 5 exhaust valve 6 locating pin(Ф10×14)7 valve spring gasket 8 valve spring 9 exhaust double end stud 10 valve oil seal assembly 11 o ring(40×2.65) 12 valve cover 13 gasket 14 acorn nut 15 valve rocker 16...

Page 125: 12. Cylinder Cover

125 12. Cylinder cover preparing documents -----------------12.1 failure diagnosis ----------------------12.2 cylinder cover -------------------------12.3 cylinder cover check -----------------12.4 installation of cylinder cover --------12.5 12.1 preparing documents work instructions the cylinder co...

Page 126: Cylinder Block and Piston

126 loosen fixing nuts and spark plug, remove the cylinder cover. 12.4 cylinder cover check check whether cylinder cover is broken. Check flarness of cylinder cover bottom surface. Limit for use: 0.04mm。 12.5 installation of cylinder cover install it in reverse order. Cylinder block and piston fixin...

Page 127

127 1. Piston 2. Piston pin 3. Cylinder block 4. Cylinder gasket 5. Cylinder cover 6. Nut 注意:所有零件在检查测 定前应清洗,并用高压空 气吹干净。 note: all parts shall be cleaned and blown by high pressure air before check..

Page 128

128 13.Cylinder block and piston preparing documents-----------------13.1 piston---------------------------13.4 failure diagnosis --------------------13.2 piston installation-------------13.5 cylinder block-----------------------13.3 13.1 preparing documents work instructions all parts shall be clea...

Page 129

129 13.2 failure diagnosis low compression pressure white smoke from the exhaust pipe abrasive, burnt or ruptured piston abrasive or damaged piston ring abrasive or damaged cylinder or piston abrasive or damaged cylinder or piston damaged spacer or crankcase leakage over-high compression pressure ab...

Page 130

130 13.4 piston 13.4.1 disassembly remove the retainer ring of the piston. Note: during assembly, do not make the retainer ring fall into the crankcase. Remove the piston pin and the piston. Check the piston, piston pin and piston ring. Remove the piston ring. Note: do not rupture or damage the pist...

Page 131

131 measure the outer diameter of the piston pin. Limit for use: 9.94mm。 clearance between the piston pin holr an the piston pin limit for use: 0.014mm。 measure the outer diameter of the piston. Note: the measuring point shall be at 90°with the piston pin, and at 11.5mm below the piston skirt. Limit...

Page 132

132 measure the inner diameter of the smaller end of the connecting rod. Limit for use: 10.018mm。 13.4.2 piston installation install the locating pin. Apply fuel to each piston ring and pistion. Install the piston ring with inclined side upward. Note: do not scratch the piston or break the piston ri...

Page 133

133 drive face/clutch/driven wheel 1 gasket 2 spring 3 friction plate 4 check ring note: during operation, the surface of the triangle belt can not be stained with any grease which must be removed. It helps avoid slipping between the triangle belt and the belt pulley as much as possible..

Page 134: Kickstart Mechanism

134 kickstart mechanism 1. Snap spring 2. Start claw 3. Idle gear 4. Idler shaft 5. Start shaft assembly 6. Kickstart shaft spring note: during operation, the surface of the triangle belt can not be stained with any grease which must be removed. It helps avoid slipping between the triangle belt and ...

Page 135

135 14. Drive face/clutch/driven wheel/kickstart mechanism preparing documents -------------------14.1 clutch/driven wheel ---------14.5 failure diagnosis --------14.2 breakdown of clutch and driven wheel -----14.6 left crankcase cover ----------------14.3 installation --------------------14.7 drive...

Page 136

136 ruptured clutch spring stained surface of the driving pulley 14.3 left crankcase cover disassembly remove fixing bolts, spacer and locating pin. Note: fixing bolts should be removed in staggered sequence. Remove the locating pin. 14.4 drive face 14.4.1 disassembly remove fixing nuts for drive fa...

Page 137

137 remove the right half drive wheel assembly 14.4.2 breakdown of right half drive wheel assembly check abrasion of the ball. Measure the outer diameter of the ball. Limit for use: 15.8mm right half drive wheel assembly.

Page 138

138 measure the inner diameter of the right half drive wheel. Limit for use: 20.05mm。 measure the outer diameter of the sliding sleeve. Limit for use: 19.94mm。 14.5 clutch/driven wheel 14.5.1 disassembly install the clutch sleeve with the fixer and remove fixing nuts. Remove the clutch sleeve, clutc...

Page 139

139 check abrasion of the clutch sleeve. Measure the outer diameter of the clutch sleeve. Limit for use: 107.2mm。 check abrasion of the clutch facing. Measure the thickness of the clutch facing. Limit for use: 3.5mm 14.6 breakdown of clutch and driven wheel clutch spring compressor must be used for ...

Page 140

140 remove the guide pin. Remove the weldment on the left half driven wheel. Remove the oil seal on the left half driven wheel. Check the free length of the clutch spring. Limit for use: 93mm。 (自由长度:free length) check abrasion of the driven wheel. Measure the outer diameter of the bushing on the rig...

Page 141

141 apply grease evenly to the outer rolling bearing and then place it into the sleeve. Note: place the outer rolling bearing into the sleeve with its marked side outwards. Then fill the sleeve with 8-9g grease. Install the elastic retainer ring. Install the needle bearing. Press the needle bearing ...

Page 142

142 install the spring guard. Eliminateleaked grease. (弹簧护套:spring guard) install the clutch spring and the clutch on the driven wheel. Compress the set with the clutch spring. Install locking nuts after compression. Note: properly compress the spring to avoid damage to the spring 扳手(锁紧螺母):spanner (...

Page 143

143 decelerator 1 gearbox cover gasket 2 input shaft 3 hex flange bolt 4 output shaft assembly 5 input shaft gear 6 intermediate shaft assembly 7 hex flange nut 8 rolling bearing 9 gasket 10 output shaft seal ring 11rolling bearing 12 gearbox cover 13 hex flange lock nut 14 o-ring 15 anchor pin func...

Page 144: 15. Decelerator

144 15. Decelerator preparing documents -----------------15.1 failure diagnosis ----------------------15.2 gearbox --------------------------------15.3 assembly-----------------------------15.4 15.1 preparing documents function: transfer torque and decide final output torque and rotational speed. 15...

Page 145

145 remove the spacer and the locating pin. Remove the clutch spindle and gear of output shaft. Remove the middle shaft and the middle gear. 15.3.2 check the output gearbox cover check abrasion and damage of the clutch spindle, gear and bearing. Exchange gearbox cover bearings. Press the clutch spin...

Page 146

146 crankcase 1 double-end stud(b) 2 pin bush 3 double-end stud (a) 4 left box assembly 5 forward-bouncing joint 6 tube union 7distance sleeve 8 crankshaft seal ring 9starter bearing 10drain belt 11gasket 12 oil seal 17×30×5 13 shock absorbing bushing 14 hex flange bolt 15gasket 16 locating pin10×20...

Page 147: 16 Crankcase

147 16 crankcase preparing documents -----------------16.1 failure diagnosis ----------------------16.2 crankcase ------------------------------16.3 assembly ------------------------------16.4 16.1 preparing documents work instructions the crankcase is thin-section casting thus shall not suffer impa...

Page 148

148 16.2 failure diagnosis noise in crankcase loose or broken parts inside the crankcase loose crankshaft bearing loose crankpin bearing seized clutch 16.3 crankcase 16.3.1 crankcase disassembly loosen the bolts and remove the fan, flywheel and coil. Remove right cover and fixing bolts of the crankc...

Page 149

149 remove the oil seal from the left crankcase. 16.3.2 check measure the left-right clearance of the larger end of the connecting rod. Limit for use: 0.3mm. (连杆大端测量位置:measuring point at the larger end of the connecting rod) measure the clearance of the larger end of the connecting rod (x-y directio...

Page 150

150 note: removed oil seal cannot be used any more. Remove the oil seal with a special tool 16.4 assembly install the crankcase in reverse order. Note: install the oil seal with special tools to avoid any damage to it..

Page 151: Muffler

151 inspection and maintenance of exhaust emission system muffler 1 muffler assembly 2 muffler tube assembly 3 bolt m6×20 4 gasket 6mm 5 sealing gasket 6 tube assembly 7 bolt m8×20 8 bolt m6×16 9 exhaust pipe gasket assembly 10 heat-insulating rubber 11 muffler hoop 12 nut m6 13 exhaust pipe assembl...

Page 152

152 18. Exhaust emission & control system warranty on the exhaust emission & control system ---------------------------18.1 instructions on the periodic maintenance/ compliance with standards-------18.2 mechanical function of the exhaust control system ----------------------------18.3 catalytic conv...

Page 153

153 3〉please comply with periodic maintenance requirements. The exhaust control system of this motorcycle is in accordance with the national regulation. For replacement of any component, please use our original parts and have our designated distributor or service center carry out such replacement. 4...

Page 154

154 18.4.2 instruction: 1. The function of convertible catalyst is to converse exhaust gas hc, co and no x after complete combustion to harmless gas such as h 2 o, co 2、 and 、 n 2 before emission. 2. Convertible catalyst contains rare metal such as platinum and rhodium. Only lead-free gasoline can b...

Page 155: 18.5

155 satisfactory 18.5 measures when the idle speed emission value exceeds the standard (four-stroke) note 1: measure it with the idle speed measurement program. Note 2: adjust the engine speed with stop screws to live up to requirements and measure co/hc at the idle speed. Periodic inspection (maint...

Page 156

156 green black flasher b o r/w r/w n b08 electricity principle diagram bl blue white red black color symbol left turn light 10w b r w instrument light 5w head light 35/35w green white green yellow dark green light blue brown purple yellow orange green brake seitch g/b horn switch light switch o g y...