- DL manuals

- KEEWAY

- Motorcycle

- RKV125

- Instruction And Maintenance Manual

KEEWAY RKV125 Instruction And Maintenance Manual

Summary of RKV125

Page 1

Two-wheel motorcycle rkv125 instruction and maintenance manual keeway motorcycle co., ltd..

Page 2

Contents contents. ......................................................................................................................................................................... 2 preface ........................................................................................................

Page 3

Vii front wheel/front suspension ........................................................................................................................... 98 7.1 preparatory data ..........................................................................................................................

Page 4

14.4 disassemble main shaft and countershaft ................................................................................................. 148 xv reduction gear ..........................................................................................................................................

Page 5: Preface

Preface the instruction and maintenance manual contains an introductory description of maintenance means on rkv125 motorcycle. Preparatory data include attentions that shall be paid on all the maintenance operations in the instruction and maintenance manual. Please read the manual carefully before o...

Page 6: Preparatory Data

Preparatory data general safety maintenance rules specification table fault diagnosis general safety carbon monoxide (co) when it is necessary to start the engine, please make sure the operation area is well ventilated. Never run the engine in an enclosed place. Attention gas exhausted from the moto...

Page 7: Maintenance Rules

Maintenance rules while repairing and servicing, use tools of metric system as possible. Incorrect tools may damage the motorcycle. Before taking down or opening protecting plate for repair work, please clean the dirt on the external surfaces of components or combination parts and prevent the dirt f...

Page 8

Length of bolts and screws are different for assembly components and protecting plates. They shall be installed at correct positions. If confused, just put the bolt in the hole and see if it matches. Fill lubricating grease into the groove during oil seal installation. Check if the oil seal is smoot...

Page 9

Slack cable implies potential safety hazard on electrics. Check the next cable when the cable is clamped to ensure electric safety; cable clamp shall not be bent towards solder joint; tie the cable at appointed position; do not lay the cable at the end of frame or at the closed angle; do not lay the...

Page 10

Identification of motorcycle 1. Frame number ① labeled as: *lbbk6910?????????*, as shown in figure 1-1. Figure 1-1 2. Frame nameplate is riveted at frame position ②, as shown in figure 1-1. Words on the nameplate are as described in figure 1-2. Figure 1-2 3. Serial number of engine ① is marked on th...

Page 11: Special Tools

Special tools special tools are known as specially designed tools used at particular places for assembly or disassembly of certain components on a motorcycle. Suitable special tools are essential for complete and accurate adjusting and assembling work. Use of special tools can realize safe, reliable...

Page 12

Figure 1-5 figure 1-6 figure 1-7 figure 1-8 figure 1-9 figure 1-10 ① handle figure 1-11 figure 1-12 ① pliers ② piston.

Page 13

Figure 1-13 figure 1-14 figure 1-15 figure 1-16 figure 1-17 figure 1-18 figure 1-19 figure 1-20 figure 1-21 figure 1-22.

Page 14

Figure 1-23 figure 1-24 2. Tools used for chassis overhaul common and special tools, as well as their pictures for chassis component assembly and disassembly are listed in table 1-25 and table 1-26. Table 1-25 name remarks torque wrench allen wrench socket wrench micrometer magnetic stand, v-block d...

Page 15

Figure 1-31 figure 1-32 figure 1-33 figure 1-34 figure 1-35 figure 1-36 (2)special tools for chassis overhaul: front fork seal driver figure 1-37 (3)steering nut wrench figure 1-38.

Page 16

3. Tools used for electrical components special tools and their pictures for electrical component test are listed in table1-39 and 1-40. Table 1-39 name remarks multimeter ignition tester figure 1-41 figure 1-42 continued table 1-40 figure 1-41 figure 1-42.

Page 17: Specifications (Rkv125)

Specifications (rkv125) model rkv125 e ngi ne engine type kw157fmi-2b overall length 2090mm fuel 90# or higher unleaded gasoline overall width 830mm number of cylinders 1 overall height 1,060mm bore*stroke 57.0×48.8 wheelbase 1,330mm displacement 125cc weight (kg) (dry weight) front axle 56 starting...

Page 18: Rkv125

Rkv125.

Page 19: Fault Diagnosis

Fault diagnosis symptom: engine will not start or is hard to start diagnosis procedures perform spark-over test clean deposited carbon spark is weak between electrodes or no spark at all. Strong blue or violet spark leaps between electrodes engine will not start or is hard to start check ignition sy...

Page 20

Electrodes of spark plug are wet. Electrodes of spark plug are dry. Check overflow of carburetor drop a little gasoline into the cylinder for a trial start. 1. Check if there is foreign substance between needle valve and valve seat of carburetor float and it cannot be closed; 2. Check if the conical...

Page 21

Symptom: engine overheats diagnosis procedures 1. Check cdi igniter. 2. Check if magneto flywheel or trigger coil looses. Check if clutch slips. Engine overheats check improper operation method 1. Check if gasoline brand being used is too low or the gasoline has been stored for a too long time; 2. C...

Page 22

Clutch slips handle it according to item 1.7. Remove the spark plug and check color of skirt section of insulating part and other abnormalities to judge mixture ratio of air/fuel. Skirt section of insulating part is black and when the engine runs at middle or low speed, exhaust muffler gives off bla...

Page 23

Symptom: engine lacks power diagnosis procedures yes no use an ignition timing lamp to check ignition timing of engine lift it with main stand to have the wheels off the ground. Rotate wheels by hands. 1. Check braking drag; 2. Check if bearing of wheels are over worn or injured; 3. Check if the mid...

Page 24

Symptom: poor idle speed of engine diagnosis procedures n y no yes yes poor idle speed higher idle speed engine has no idle speed. Unsteady idle speed check compression pressure in cylinder pull throttle valve of carburetor by hand and see if it is completely closed. Use an ignition timing lamp to c...

Page 25

Symptom: too much fuel consumption by the engine diagnosis procedures too much fuel consumption check operation method lift it by main stand, rotate wheels by hands 1. Check if motorcycle is driven over speed or not at economical speed or driven at low gear; 2. Check if gasoline grade being used is ...

Page 26

Symptom: clutch slips diagnosis procedures clutch slips manually controlled wet multi-plate clutch slips automatic centrifugal dry type shoe clutch slips check if clearance of clutch handle bar is within 10mm~20mm. Check if braking shoe of shoe-type clutch is contaminated by oil re-adjust check if t...

Page 27

Symptom: 4-stroke engine exhaust muffler gives off blue-white smoke diagnosis procedures symptom: incomplete separation of clutch diagnosis procedures no yes incomplete separation of clutch check if clearance of clutch handle bar is within 10mm-20mm. Re-adjust check if adjusting screw for clutch pus...

Page 28

No yes symptom: difficult gearshift on transmission diagnosis procedures symptom: drum-type brake fails diagnosis procedures yes yes yes yes no no no no difficult gearshift on transmission start engine and check if idle is too high. Re-adjust check if the operation is harmonious at gearshift. Check ...

Page 29

No yes yes no symptom: transmission jumps of gear diagnosis procedures symptom: hydraulic disc brake fails diagnosis procedures transmission jumps of gear yes yes yes no no no 1. Check if fork hole and fork shaft are over worn; 2. Check if matching clearance between fork pin and cam groove of shift ...

Page 30

Symptom: battery does not charge diagnosis procedures yes no wire from connector to battery is broken. Set multimeter on 0v~20v dc voltage, measure the voltage between connector to the battery wire terminal (usually a red or red/white wire) and the ground. Wire from magneto to rectifier or wires amo...

Page 31

Symptom: battery runs down quickly diagnosis procedures yes no yes no check if braking lamp is always on. Adjust or replace braking lamp switch. Set ignition switch to “off” position, disconnect negative wire from battery, and then put negative probe of ammeter onto the negative pole terminal and po...

Page 32

Symptom: starting motor does not run diagnosis procedures electric horn does not sound or sound weakly. Turn signal lamp is dim. Electric horn sounds loudly. Turn signal lamp is bright. Battery is low or the wire terminal connected with battery is poorly contacted. Grasp brake handle bar (autoscoote...

Page 33

Coil in starter coil is broken or shorted. Striding motorcycle autoscooter yes yes no no check wiring in electrical starter control system contact of starting relay is burnt or injured. Disassemble starter motor and make the following inspections: 1. Check if the carbon brush is over worn; 2. Check ...

Page 34

Symptom: starting motor runs weakly diagnosis procedures starter motor runs weakly. Check if the lead wire connector from starter relay to starter motor is poorly contacted. Remove the starter motor lead wire and battery connecting wire from starter relay, press starter button; when starter relay gi...

Page 35

Symptom: all the lights are not on diagnosis procedures test lamp is not lit test lamp is lit. All the lights are not on ac power supplied lighting system dc power supplied lighting system separate conductors of lead wire bundle of magneto from the cables of the whole vehicle. Check if there is powe...

Page 36

Replace headlamp bulb and check other bulbs one by one. Check if there is power output from power input wire of light switch by lamp test use a piece of wire to short circuit power line and output line of lighting switch. Wiring from magneto or ignition switch to lighting switch is broken or shorted...

Page 37

Symptom: light bulb is burnt frequently diagnosis procedures light bulb is burnt frequently turn on ignition switch; press horn button or slide turn signal lamp switch. Electric horn does not sound or sound hoarse. Turn signal lamp is dim. Electric horn sounds loudly. Turn signal lamp is bright. 1. ...

Page 38

Symptom: headlamp is dim. Diagnosis procedures headlamp is dim separate conductors of lead wire bundle of magnet from cables of the whole vehicle. Measure and check with an ohmmeter if resistance between lead wire section output from magneto lighting coil is smaller than the standard. Turn on igniti...

Page 39

No yes yes no check if power of bulb in the lighting system is up to the requirement. Replace the bulb. 1. Check if headlamp switch and side-lamp switch is poorly contacted; 2. Check if connectors and earth wire are poorly contacted. Replace bulb..

Page 40

Symptom: turn signal lamp is off. Diagnosis procedures electric horn does not sound or sounds hoarse. Separate connectors of turn signal lamp, measure and check with an ohmmeter if turn signal lamp switch works on faulty side. Yes no battery is low. All the turn signal lamps on one side are not on. ...

Page 41

Separate connectors of turn signal lamp switch and use a piece of wire to short circuit respectively power input line of the switch and power lines output to left and right turn signal lamps. Scintillator is damaged. Inner contact of turn signal lamp is poor contacted. Check if there is power output...

Page 42

Symptom: electric horn mutes. Diagnosis procedures electric horn mutes. Turn on ignition switch; slide turn signal lamp switch and check. Turn signal lamp is not lit or dim. Turn signal lamp shines brightly. Battery is low or the wire from battery to ignition switch is broken or shorted. Power suppl...

Page 43

Symptom: brake lamp does not work. Diagnosis procedures brake lamp does not work. Take down cover of brake lamp and check if bulb is burnt. Replace bulb use a piece of wire to short circuit two terminals of brake lamp switch or plugs of two hatching lines. Lamp is not lit after short circuit. Brake ...

Page 44: Inspection/adjustment

Inspection/adjustment preparatory standard compression pressure of cylinder periodic maintenance schedule chart engine oil engine oil/filter replacement of engine oil steering stem bearing and handle fixation drive chain slackness throttle cable adjustment front/rear brake clearance air cleaner head...

Page 45

Specifications engine idle speed 1400±100rpm/min spark plug clearance 0.6-0.7mm spark plug type ngk dr8ea combustion chamber ball type ignition time btdc15°±1° 1400±100rpm frame clearance of front brake handle 10-20mm clearance of rear brake pedal 20-30mm pneumatic pressure unit of tyre: kpa specifi...

Page 46

Periodic maintenance schedule mileage and interval items every 300 km every 1000 km every 3000 km every 6000 km every 12000 km every 14500 km tools new vehicle one month three months six months twelve months fifteen months * air cleaner i c c r c common tool * gasoline filter i i r common tool * eng...

Page 47: Engine Oil/filter

Expected inspection 1 ignition system -- perform maintenance inspection on obvious and continuous ignition malfunctions, engine on fire, overheated back burning and others. 2 carbon deposit removal -- obvious underpowered, get rid of carbon deposit at cylinder head, piston head and air exhaust syste...

Page 48: Throttle Cable Adjustment

When the engine oil is completely drained, put back cleaned drain plug and sealing ring. Refill engine oil to specified level. Check if there is engine oil leakage. Start the engine and run the engine on idle for a few minutes. Check engine oil level again. Throttle cable adjustment *attention adjus...

Page 49: Spark Plug

Replacing time if driving under dusty condition or in rainy days frequently, replace the air cleaner earlier. * attention while removing filter element of air cleaner, please do not run the engine, in case unfiltered air comes into the engine, which may result in fast wear of some components or dama...

Page 50: Battery

Battery removal remove the seat and take down the right protecting plate. Remove the battery from the battery case (1). Disconnect the battery negative (-) lead wire first and then the positive (+) lead wire. Remove the battery. Warning! During positive lead wire disconnection, be sure to prevent th...

Page 51: Carburetor

• battery shall be away from fire. • shut off charger switch first before or after charging in case sparks may be generated at connection parts, which may result in explosion. • during charging, please take the current time labeled on the battery as basic time. * attention • battery quick recharging...

Page 52: Engine Oil

Compression pressure of cylinder warm up engine. Insert the pressure gauge. Turn choke valve to its full open position. Set throttle handle to its full open position and kick start the engine. Compression pressure of cylinder: 1-1.2 mpa * attention start the engine till reading of pressure gauge doe...

Page 53: Engine Oil Replacement

* attention check if sealing ring is damaged. Install the engine oil ruler. Engine oil replacement warm up engine. Place an oil pan below the engine and drain engine oil by removing drain plug and oil ruler. Kick start engine several times to drain thoroughly the engine oil. After drainage, inspect ...

Page 54: Headlamp

* attention do not install new drive chains onto worn sprockets or install worn drive chains onto the new sprockets. Keep both sprocket and drive chain in good conditions, or newly replaced chain or sprocket will be worn soon. Clearance of front/rear brake front brake clearance measure the clearance...

Page 55: Clutch

Install a new headlamp bulb (3). Screw tightly the new bulb into the adapter. Avoid touching bulb glass with your bare hands during installation and staining it with oil, which may affect transparency, service life and luminous flux of bulb. If oil is adhered to the bulb, clean it with a cloth moist...

Page 56: Bolt/nut/fastening Part

Front/rear suspension system front suspension grasp the front brake handle and compress upward and downward the front shock absorber to check its actuator. Check if the front shock absorber leaks oil and if the components are loosened. Rear suspension compress upward and downward the rear shock abso...

Page 57: Wheel Rim/tyre

Wheel rim/tyre check if there is crack, nails and similar sharp objects, and other injuries on the tyres. Inspect pneumatic pressure of tyres. * attention measure cold inflation tyre pressure specified air pressure unit: kpa tyre specifications rkv125 front tubeless tyre 100/70-17 rear tubeless tyre...

Page 58

Inspection and maintenance of electric system table of tightening torque for fastening parts used in electric system fastening position and fastening part name tightening torque (n·m) starting motor clutch cover bolt starting motor clutch locknut rectifier bolt high-voltage coil pinch bolt flywheel ...

Page 59: Charging System

Charging system 1. Starting relay 2. Scintillator 3. Battery 4. Electric igniter 5 high-voltage ignition coil 6. Power lock assembly.

Page 60: I Battery/charging System

I battery/charging system preparatory data---------------1.1 fault diagnosis--------------1.2 battery--------------------------1.3 charging system-------------1.4 voltage/current adjuster------1.5 magneto charging coil------- 1.6 removal of magneto--------- 1.7 1.1 preparatory data precautions on op...

Page 61

Preparatory standard item specification battery capacity/type 12v dry-charged type voltage (20℃) fully recharged 13.1v must be recharged 12.3v (not work for one hour) recharging current standard: 0.9a, quick: 9a recharging time standard: 10-15hours; quick: 30minutes magneto max. Capacity 120w coilin...

Page 62

1.3 storage battery 1.3.1 battery removal take down the right protecting plate (1). Disconnect the battery negative (-) lead wire first and then the positive (+) lead wire. Remove the battery breather. Remove battery mounting bracket (2). Remove the battery (3). Warning! During positive lead wire di...

Page 63

Recharging current: standard: 0.3a quick charging: 3.0a recharging time: standard: 10-15hours quick recharging: 30minutes recharging completed: open circuit voltage: over 12.8v 1.4 charging system 1.4.1 short circuit test disconnect the grounding wire from the battery and use a voltmeter to connect ...

Page 64

Check continuity between main wiring terminals in the following way: item (wire color) judgment battery (red) and ground of vehicle block it is battery voltage. Ground wire (black) and ground of vehicle block there is a lead wire. Charging coil (white) and ground of vehicle block no power flowing be...

Page 65

1.7 magneto removal * attention inspection of magneto lighting coil can be performed on the engine. 1.7.1 inspection disconnect the 4p connector on the magneto. Use a multimeter to measure impedance value between yellow coil of magneto and ground wire of vehicle block. Standard value:0.4-0.6Ω (20℃) ...

Page 66

* attention there is magnetism on the inner surface of flywheel, ensure there is no bolt on it. Fix the flywheel using a universal non-adjustable spanner and then tighten the locknut. Torque value: 9.0 n·m install protecting plate on the left side..

Page 67: Ignition System

Ignition system 1 relay 2 scintillator 3 battery 4 igniter 5 high-voltage ignition coil 6. Power lock assembly 7 voltage regulator.

Page 68

Ii ignition system preparatory data-------------------2.1 cdi assembly--------------2.4 fault diagnosis--------------------2.2 ignition coil----------------2.5 ignition system inspection-------2.3 trigger----------------------2.6 2.1 preparatory data precautions on operation 1. Ignition system inspe...

Page 69: 2.2 Fault Diagnosis

2.2 fault diagnosis spark plug not sparking ignition coil symptom possible causes (determine the cause from 1 in sequence) when the high voltage power is too low. ① inner impedance is too small. Use appointed tester to test. ②crankshaft rpm is too low. ③ tester is disturbed (it is normal when more t...

Page 70

2.3 ignition system inspection * attention • when the spark plug is not sparking, check if components of wiring are loosened or badly contacted and make sure if all the voltage values are normal. • there are many brands of multimeters with different interior impedance. The values they measured are n...

Page 71: 2.4 Cdi Assembly

Green/white. Min. Voltage: higher than 1.7v. * attention please do not touch the metal parts of testing probe with your fingers while measuring the voltage, or you will be shocked. Please take care. When the peak voltage measured at connector of cdi assembly is abnormal, take down the protecting pla...

Page 72: 2.5 Ignition Coil

2.5 ignition coil 2.5.1 removal remove protecting plate of vehicle block. Remove spark plug cap. Remove primary lead wire of ignition coil. Remove locknut of ignition coil and take out the ignition coil. Install it in the reverse order of removal. *attention the primary coil is installed with black/...

Page 73: 2.6 Trigger

2.6 trigger * attention trigger inspection can be performed on the engine. Inspection remove protecting plate of vehicle block. Remove lead-wire connector of trigger. Measure the impedance between blue/white terminal of lead wire at engine side and grounding vehicle block. Standard value: 100-200Ω (...

Page 74: Starting System

Starting system 1 starting relay 2 scintillator 3 battery 4 electronic igniter 5 high-voltage ignition coil 6 power lock assembly 7 rectifier 8 electric horn.

Page 75: III

Iii starting system preparatory data-------- 3.1 fault diagnosis----------3.2 starting motor-----------3.3 starting relay------------3.4 3.1 preparatory data precautions on operation starting motor removal can be performed on the engine. Starting clutch removal refers to removal instruction. Basic d...

Page 76: 3.2 Fault Diagnosis

3.2 fault diagnosis starting motor will not run starting motor runs weakly starting motor runs but the engine does not •broken fuse •low battery •defective starting clutch •low battery •poor connecting wire contact •starting motor counter-rotate •defective ignition switch •starting motor gear stuck ...

Page 77

Inspect continuity between conducting terminal and brush. Replace it with a new one if abnormality exits. Inspect carbon brush holder for continuity. If there is continuity, replace it. Measure carbon brush length service limit: replace it when it is shorter than 8.5mm check rotation smoothness of t...

Page 78: 3.4 Starting Relay

3.4 starting relay 3.4.1 actuation inspection take down the protecting plate of vehicle block. When the ignition switch is set at “on” position, press starting motor and a “click” sound can be heard. “click” sound indicates normal. No sound: • check starting relay voltage. • check starting relay gro...

Page 79: Bulbs/switches/instruments

Bulbs/switches/instruments 1 headlamp 2 instruments 3 electric horn 4 left rear turn signal lamp 5 tail lamp.

Page 80: Bulbs/switches/instruments

Iv bulbs/switches/instruments preparatory data---------------------------------------------------4.1 fault diagnosis----------------------------------------------------4.2 headlamp bulb replacement------------------------------------4.3 front turn signal lamp bulb replacement---------------------4.4...

Page 81

4.3 headlamp bulb replacement 4.3.1 removal screw off with a wrench locknut (1) of headlamp and take down the headlamp. Pull out socket of headlamp adapter and remove the rear cover. Release circlip and take out of the lamp adapter. * attention when the bulb is lit, keep you hands and inflammable ma...

Page 82: 4.6 Instrument

4.5 tail lamp bulb replacement 4.5.1 removal screw off the two bolts (1). Remove the tail lamp hood. Disconnect wire connector to the tail lamp. While pressing down the tail lamp, rotate it counterclockwise remove the tail lamp. 4.5.2 installation install the tail lamp in the reverse order of remova...

Page 83: 4.8 Electric Horn

4.7 ignition switch and steering lock 4.7.1 inspection remove the headlamp from the cover. Remove ignition switch-wire connector. Inspect continuity of connector terminal. This kind of power lock has electromagnetic anti-theft function. When the switch under the power lock is moved to “open” positio...

Page 84: 4.9 Handle Switch

4.9 handle switch remove protecting plate of steering handle. Screw off mounting bolt on the brake lever and take down the bracket. Remove bracket for the rear brake lever. Remove throttle handle and bolts. Take down throttle handle from the handle and remove the throttle cable. Remove locknut on th...

Page 85

Chassis inspection and maintenance tightening torque of fastening part on chassis fastening position and part name tightening torque (n·m) oil pump block assembly mounting bolt front brake cylinder assembly mounting bolt rear brake rocker arm mounting bolt rear shaft locknut upper bracket assembly m...

Page 86

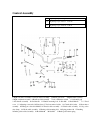

Front hydraulic brake a front brake disc diameter:260mm b front brake disc thickness:4.0mm service limit:3.0 c brake shoe thickness:4 mm service limit:3mm d mounting torque for bolt 7 in the diagram: 22-29 n·m 1 oil pump block assembly 2 hydraulic brake handle 3 handle mounting bolt 4 nut m6 5 fixin...

Page 87

Rear hydraulic brake a rear brake disc diameter:240mm b rear brake disc thickness:5.0mm service limit:4.0 c brake shoe thickness:5mm service limit:4mm d mounting torque for bolt 7 in the diagram:22-29 n·m 1 rear hydraulic brake assembly 2 bushing Ⅱ 3 bracket 4 friction disc assembly 5 brake cylinder...

Page 88: V Braking System

V braking system maintenance instruction--------------------5.1 fault diagnosis-------------------------------5.2 front hydraulic disc brake----------------- 5.3 rear drum brake-----------------------------5.4 5.1 maintenance instruction precautions on operation * attention • plea se do not contamin...

Page 89: 5.2 Fault Diagnosis

5.2 fault diagnosis braking system poor braking performance brake drags or tight handle 1. Improper brake adjustment 1. Improper brake adjustment 2. Worn braking shoe assembly and brake disc 2. Worn braking shoe assembly and brake disc 3. Braking shoe assembly improperly installed 3. Braking shoe as...

Page 90

Screw off braking cylinder assembly mounting bolt. Remove the braking cylinder assembly from front shock absorber. Remove front shaft. Remove front wheel. Remove brake disc from the front wheel. 5.3.2 inspection check if braking shoe assembly and brake disc are worn. Replace them if necessary. Measu...

Page 91: 5.4 Rear Hydraulic Brake

A contaminated braking shoe will reduce braking performance. * attention • please do not contaminate braking shoe assembly with oil while assembly or disassembly • please use specified detergent to clean the braking assembly, or it may reduce braking performance. 5.4 rear hydraulic brake 5.4.1 remov...

Page 92

5.4.3 installation install braking shoe assembly install rear wheel. Install muffler assembly (24). Install brake pedal assembly (21). * attention a contaminated braking shoe will reduce braking performance and result in braking failure. Tighten bolt and nut to their specified torque value. Torque v...

Page 93: Exterior Parts

Exterior parts attention do not damage exterior parts during disassembly and assembly. Do not damage the pawls on the exterior parts of the vehicle during assembly or disassembly. Align built-in panel and cover plate to their grooves respectively. Correctly install jaw of each part during combinatio...

Page 94: Motorcycle Exterior

Vi motorcycle exterior disassemble the exterior parts in the following sequence: seat cushion assembly → left and right protecting plate assemblies → left and right tail covers → left and right hanger → left and right hanger → ↓ left and right pedals → front mudguard brace panel → front mudguard → r...

Page 95

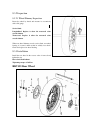

Front wheel / front suspension 1 front shaft 2 gear seat assembly 3 gear seat oil seal 4 drive plate 5 bearing 6301 6 front wheel middle shaft sleeve 7 front brake disc 8 front brake disc mounting bolt 9 front wheel oil seal assembly 10 front wheel left shaft sleeve 11 tubeless tyre 12 front wheel r...

Page 96: Control Assembly

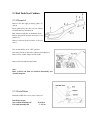

Control assembly a tightening torque of hexagon socket bolt 2:37-44 n·m b tightening torque of nut 19:5-9 n·m c tightening torque of bolt 20:5-9 n·m 1 right rear mirror assembly 2 left rear mirror assembly 3 handle gear block 4 right handle assembly 5 right combination switch 6 handle welded assembl...

Page 97: Front Fork Assembly

Front fork assembly 1 steering lever nut 2 dust cover 3 upper steel bowl of upper bearing 4 steel ball 3/16 inch 5 lower steel bowl of upper bearing 6 upper steel bowl of lower bearing 7 steel ball 1/4 inch 8 lower steel bowl of lower bearing 9 lower bracket of headlamp 10 main cable clamp 11 hexago...

Page 98: 7.1 Preparatory Data

Assembly 40 front mudguard right bracket i assembly vii front wheel/front suspension preparatory data-----------------7.1 fault diagnosis------------------7.2 front wheel----------------------7.3 control assembly---------------7.4 front fork assembly------------7.5 7.1 preparatory data precautions o...

Page 99: 7.2 Fault Diagnosis

7.2 fault diagnosis 7.2.1 heavy steering handle handle bearing damaged too low tyre pressure tyre leakage 7.2.2 wobbly direction handle damaged handle bearing not enough tyre pressure. Front fork bent, front wheel shaft bent. Distorted and crooked front wheel tyre. 7.2.3 wobbly front wheel distorted...

Page 100

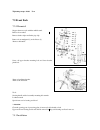

* note: refer to page 95 of the manual for detailed kw125 motorcycle front wheel disassembly and assembly diagram. 7.3.2 inspection 7.3.2.1 shaft bow inspection place the shaft onto a v block and measure its eccentricity with a dial gauge. Service limit: when the measured value exceeds 0.2mm, replac...

Page 101: 7.4 Steering Handle

Install the bearing in the reverse order of removal. Attentions: lubricate front shaft, gear seat assembly, oil seal (lip), shaft sleeve, bearing 6301-2rs, and middle sleeve. Recommended lubricant is calcium base grease. Install front shaft (3), front wheel, gear seat assembly (5) and nut m12Χ1.25 (...

Page 102: 7.5 Front Fork

Tightening torque: 40-60 n·m 7.5 front fork 7.5.1 removal support the motorcycle with the middle stand. Remove front wheel. Remove brake caliper and brake pipe clip. Remove front mudguard (1) and reflector (2). Remove the handle. Screw off upper bracket mounting bolt and lower bracket pinch bolt. Re...

Page 103

Apply lubricating grease onto the bottom bearing steel bowl and confirm the number of steel balls (23balls). Steering handle shall not be rotated in case of steel ball falling off; then install steering rod. Support the steering handle and apply lubricating grease on to the top bearing steel bowl an...

Page 104: Rear Wheel/rear Suspension

Rear wheel/rear suspension 1 rear shock absorber assembly 2 rear brake rocker arm 3 rear shaft 4 nut m8 5 sprocket stopper 6 sprocket 43 teeth 7 oil seal 8 rolling bearing 6204-2rs 9 chain drive sleeve 10 sprocket hub 11 sprocket mounting bolt 12 rear wheel left sleeve assembly 13 rear wheel buffer ...

Page 105: Rear Swing Arm

Rear swing arm a side clearance (opening swing arm end) limit value:1.0mm b tightening torque of nut 3 in the diagram is:70-83 n·m 1 locking nut m14x1.5 2 rear swing arm mounting washer 3 oil seal 4 rear swing arm shaft 5 chain protector 6 rear swing arm welded assembly 7 chain adjuster 8 screw m5x1...

Page 106: Chain Drive Assembly

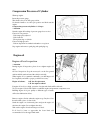

Chain drive assembly 1 sprocket mounting bolt 2 sprocket hub 3 chain drive sleeve 4 rolling bearing 6204-2rs 5 oil seal 6 sprocket 43 teeth 7 sprocket stopper 8 nut m8 9 chain 428hg-1×126 10 chain guard 11 boss bolt 1 a tightening torque of bolt 1 in the diagram is:22-29 n·m b drive chain specificat...

Page 107: 8.1 Preparatory Data

Viii rear wheel/rear suspension preparatory data----------------------------------- 8.1 fault diagnosis-------------------------------------8.2 rear wheel------------------------------------------8.3 rear shock absorber/rear swing arm----------- 8.4 chain drive assembly-----------------------------8...

Page 108: 8.3 Rear Wheel

Worn or injured swing arm pivot bush improper adjustment of drive chain adjuster bent frame or swing arm 8.2.2 inflexible wheel rotation incorrect brake adjustment worn rear bearing too tight drive chain 8.2.3 poor braking performance incorrect brake adjustment worn braking shoe worn brake drum inco...

Page 109: Rkv125 Rear Wheel

8.3.2 inspection 8.3.2.1 wheel shimmy inspection rotate the wheel by hands and measure its eccentricity with a dial gauge. Service limit: longitudinal: replace it when the measured value exceeds 2.0mm. Transversal: replace it when the measured value exceeds 2.0mm. When rear wheel shimmy exceeds serv...

Page 110

8.4 rear shock absorber/rear swing arm 8.4.1 remove rear shock absorber remove left and right protecting plates, seat cushion assembly and hood. Screw off mounting bolt and cap nut (1) from rear shock absorber. Remove rear shock absorber. 8.4.2 rear shock absorber inspection check rear shock absorbe...

Page 111

Check rear swing arm installation shaft. Rotate the shaft on a flat surface or measure it with a dial gauge. If it is bent, replace it. * attention don’t attempt to straighten bent shaft. Wash in solvent the components for rear swing arm installation shaft. Check sleeve assembly (7) and intermediate...

Page 112

8.5.2.inspection measure length of 10 chain links. If they cannot meet the specified value, replace the drive chain. Length limit of 10 chain links is 127mm. * attention: • stretch the chain by hands and then measure it. • the measuring range is from chain link roller ① to inner side of roller ○ 11 ...

Page 113

Check rear wheel buffer, replace it with a new one if it is worn or damaged. Check wheel bearing. If there is bearing clearance in the wheel hub or rotation of the wheel is unbalanced, replace it with a new one. Check oil seal. If it is worn or broken, replace it with a new one. 8.5.4.installation i...

Page 114: Seat Cushion

Seat cushion a note: fuel switch shall be at “off” position while removing fuel tank. B tightening torque for bolt 10 in the diagram:5-9 n·m c tightening torque for bolt 12 in the diagram:5-9 n·m 1 seat cushion assembly 2 bolt m8×20 3 rear luggage carrier screw i 4 right rear rail 5 rear luggage car...

Page 115: Fuel Tank Assembly

Fuel tank assembly 1 fuel tank assembly 2 sensor rubber gasket 3 screw m5×22 4 screw m5×10 5 damper 6 bolt m6×35 7 washer 8 fuel tank installation shaft sleeve 9 fuel tank installation gasket 1 10 fuel tank installation gasket 2 11 oil hose 4.5×8.5 1 clip Ф8 13 oil hose 5×9×600 14 fuel tank switch a...

Page 116: Fuel Tank/seat Cushion

Ix fuel tank/seat cushion preparatory data-------------------9.1 fault diagnosis--------------------9.2 fuel tank/seat cushion-----------9.3 9.1 preparatory data precautions on operation working site for removal shall be away from fire source. Fuel switch shall be set at “off” position while removin...

Page 117

9.3 fuel tank/seat cushion 9.3.1 removal remove left and right protecting plates (3) and (4). Insert ignition key into the seat lock. Rotate clockwise the key and unlock it. Pull downward and take out the helmet hook. Release the pawl from frame and remove seat cushion (1) . Remove connector from le...

Page 118: Engine

Engine inspection and maintenance table of tightening torque for fastening parts used in engine fastening position and part name tightening torque(n·m) cylinder cap nut m8 cylinder cap nut m6 cylinder cap bolt cylinder block connecting bend bolt cylinder block connecting nut flywheel locknut valve c...

Page 119: Lubricating System

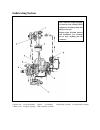

Lubricating system 1 rocker arm 2 cam mechanism 3 piston 4 crankshaft 5 main shaft assembly 6 countershaft assembly 7 filter screen 8 engine oil pump 9 filter element assembly 1 2 note: when the engine oil pump is removed, clean carefully all the components and purge them with high-pressure gas. Dur...

Page 120: X Lubricating System

X lubricating system preparatory data--------10.1 fault diagnosis---------10.2 oil engine pump-------10.3 10.1 preparatory data precautions on operation when the engine oil pump is removed, clean carefully all the components and purge them with high-pressure gas. During engine oil pump removal and i...

Page 121

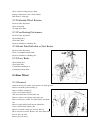

10.3 oil pump 10.3.1 removal remove right cover. Take down the engine oil filter and release oil pump mounting screw. Take down oil pump block, drive gear and pump shaft. Screw off the screw take down pump seat. Remove the screw and take down pump cover. Disassemble oil pump. Check radial clearance ...

Page 122

Check clearance between external rotor and oil pump seat. Allowable limit: 0.2mm. Check clearance between rotor end faces. Allowable limit: 0.15mm. 测试规 testing gauge flat board.

Page 123

10.3.2 assemble engine oil pump as shown in the following figure: * attention: after assembly, inner and external rotors shall rotate smoothly and be out of nimbleness. 10.3.2 installation install the oil pump in the reverse order of removal. 外转子 内转子 机油泵盖 螺钉 定位销 机油泵体 柱塞 柱塞弹簧 齿轮.

Page 124: Carburetor

Carburetor 1- upper cover 2- upper cover seal ring 3- plunger spring 4- plunger assembly 5- lower housing connecting screw 6- lower housing assembly 7- seal ring 8- float assembly 9- float pin 10- needle valve core 11- idle jet 12- main jet 13- main nozzle 14- main foam pipe 15-mixture screw 16- mix...

Page 125: Carburetor

Xi carburetor preparatory data--------------11.1 fault diagnosis--------------- 11.2 carburetor removal---------- 11.3 carburetor installation-------11.4 11.1 preparatory data precautions on operation ·gasoline is very dangerous. Fire and smoking are forbidden in working site. ·pay specially attenti...

Page 126

Clogged oil filter too high or too low mixed gas concentration clogged oil pipe secondary air sucked by the intake system sticky needle value improper idle adjustment improper oil level adjustment improper oil level adjustment clogged idle system or enrich valve too much fuel in engine too low mixed...

Page 127

11.3.3 inspection check if needle valve assembly, needle valve seat and float assembly are worn or broken. If needle valve core is worn or broken, replace it with a new one. If needle valve seat is worn, the main carburetor body shall be replaced. If the tongue plate of float is worn, replace it. Ch...

Page 128: Cylinder Head/valve

Cylinder head/valve 1 limit screw 2 washer 3 cylinder cover hood bolt 4 valve cover 5 o ring 6 cylinder cover hood bolt 7 plug 8 o ring 9 rocker arm shaft 10 wave spring washer 11 rocker arm 12 rocker arm return spring 13 cylinder cover hood 14 spark plug assembly 15 cover nut 16 washer 17 c-type ga...

Page 129: Xii Cylinder Head/valve

Xii cylinder head/valve preparatory data-----------------12.1 valve guide replacement-------------12.5 fault diagnosis------------------12.2 valve race fixing and adjustment---12.6 cylinder head--------------------12.3 cylinder head installation------------12.7 valve inspection---------------- 12.4 ...

Page 130

Valve clearance intake 0.03-0.05 _ 12.2 fault diagnosis low compression pressure noisy cylinder head improperly adjusted valve clearance improperly-adjusted valve clearance valve burnt or bent valve spring hurt poorly sealed valve race too high compression pressure air leakage at cylinder head too m...

Page 131

Measure rocker arm shaft od. Allowable limit: 11.95mm. Measure rocker arm hole id. Allowable limit: 12.05mm. Clearance between rocker arm and rocker arm shaft allowable limit: 0.08mm. Screw off the two locknuts and remove the lock washer, cam shaft and c-type gasket. Screw off the three cap nuts and...

Page 132

Compress valve spring with a valve spring compressor, and remove the valve collet, remove in sequence spring disc, external and inner valve springs, external valve spring washer and valve. 12.3.2 disassemble valve 12.4 valve inspection clean carbon deposition on the cylinder cover. Measure flatness ...

Page 133

Measure the free length of valve inner /external spring. Allowable limit: inner spring: 30mm. External spring: 37.8mm. Measure od of valve stem allowable limit: 4.9mm. Check valve guide. Please eliminate the carbon deposition in the valve guide with a reamer before inspection. Attention: rotate the ...

Page 134

12.5 valve guide replacement * attention: when the clearance between valve and valve guide exceeds service limit value, please replace the valve guide. When a valve guide is replaced, surface of valve seat retainer shall be fixed and adjusted. Put the valve guide into the freezing chamber of refrige...

Page 135

12.6 valve race fixing and adjustment remove hackly and ragged parts on the valve race with a 45° angled milling cutter. Note: apply a layer of transparent or prussian blue film onto the valve race so that it can be observed clearly. Remove 1/4 of external edge of valve race with a 32° angle milling...

Page 136

If contacted place is the higher part of valve, please use a 32°angle plain milling cutter to lower the valve race. If contacted place is the lower part of valve, please use a 60°angle internal milling cutter to raise the valve race. Grind and cut valve race with a 45°angle precise milling cutter ti...

Page 137: Cylinder Block And Piston

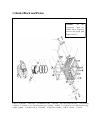

Cylinder block and piston 1 piston 2 retainer 3 piston pin 4 combined oil ring 5 top ring 6 second compressing ring 7 location pin 8 washer 9 cylinder cover connecting bent pipe assembly 10 bolt 11 cylinder cover connecting bent pipe washer assembly 12 cylinder block 13 washer 14 tensioner assembly ...

Page 138

Xiii cylinder block and piston preparatory data------------ 13.1 piston---------------------- 13.4 fault diagnosis--------------13.2 cylinder installation----- 13.5 cylinder block-------------- 13.3 13.1 service data precautions on operation all the components shall be cleaned before inspection and ...

Page 139

13.2 fault diagnosis low compression pressure white smoke from exhaust pipe worn, burnt or broken piston worn or damaged piston ring work or damaged cylinder and piston worn or damaged cylinder and piston broken washer, air leakage between crankcase and gas higher compression pressure noisy piston t...

Page 140

13.4 piston 13.4.1 removal remove piston pin retainer. * attention: please do not drop the retainer into crankcase during removal. Take out piston pin and remove piston. Remove piston ring. Inspect piston, piston pin and piston ring. * attention: please do not break or hurt piston ring. Remove depos...

Page 141

Measure piston pin hole id. Allowable limit: 14.04mm. Measure piston pin od. Allowable limit: 13.96mm. Measure the clearance between piston pin hole and piston pin. Allowable limit: 0.05mm. Measure piston od * attention: measuring position forms a 90° angle with piston pin, about 11mm below piston s...

Page 142

Measure the roundness of cylinder inner wall. (internal diameter difference between x direction and y direction). Allowable limit: 0.05mm. Measure the cylindricity of inner wall of cylinder. (internal diameter difference of three positions (upper, intermediate and lower) along x direction or y direc...

Page 143

Scrape the washer attached to the crankcase. * attention: no foreign matters can be dropped into the crankcase. Install piston, piston pin and piston pin retainer. * attention: install with the “in” mark at the top of piston facing the intake valve. 13.5 install cylinder install washer and location ...

Page 144: Clutch

Clutch 1 nut 2 cross recessed adjusting screw 3 thrust washer 4 plane needle bearing 5 locknut 6 bearing seat 7 lock washer 8 bolt combination assembly 9 pressure plate 10 clutch spring 11 friction disc assembly 12 driven friction plate 13 center bracket 14 sleeve 15 thrust washer 16 housing assembl...

Page 145: Xiv Clutch

Xiv clutch preparatory data-----------------------------------------------14.1 fault diagnosis------------------------------------------------ 14.2 clutch-----------------------------------------------------------14.3 kick start mechanism---------------------------------------- 14.4 disassembly of m...

Page 146

Bent or injured gearshift plate abnormal engine oil and oil level 14.3 clutch 14.3.1 removal screw off the four bolts for separating plate in criss-cross mode. Remove release lever, sleeve, bearing, separating plate and clutch spring. Removed components refer to exploded view. Use a special tool to ...

Page 147

14.3.2 disassemble clutch 14.3.3 inspection check if there are burs or broken parts on the housing groove of clutch. If there are, fix and adjust with a file. If there is a lot for fix and adjustment, replace it. Check if teeth of pressure plate and center bracket are injured. If they are, replace t...

Page 148

Measure the thickness of friction plate with a vernier caliper. Allowable limit: replace it when it is below 2.6mm. 14.4 disassemble main shaft and countershaft inspection check respectively wear of tooth surface and drive pawls. If they are seriously worn or damaged, replace them. Remove bearing an...

Page 149

* attention: hammered-out bearing cannot be reused. Replace it with a new one. Remove bearing and oil seal with special tools. Remove bearing on right crankcase. Check if bearing is injured. Replace if necessary. * attention: hammered-out bearing cannot be reused. Replace it with a new one. Remove b...

Page 150: Reduction Gear

Reduction gear 1 gearshift drum 2 shift fork 3 shift fork shaft 4 main shaft assembly 5 countershaft assembly xv reduction gear preparatory data----------------15.1 fault diagnosis-----------------15.2 gearshift mechanism----------15.3 installation----------------------15.4 function: transfer torque...

Page 151

15.1 service data function: transfer torque and determinate the final output torque and rotary speed. Basic data unit: mm gearshift mechanism shift fork shaft od 9.98-9.995 9.96 15.2 fault diagnosis hard to engage gear difficult gearshift worn or distorted gearshift fork clutch is not completely sep...

Page 152

15.3.2 exploded view 15.3.3 inspection before disassembly, gearshift plate shall work flexibly and smoothly. Check if gearshift plate and gearshift shaft assembly are worn. If they are seriously worn, replace them. Check if gearshift locking plate is worn. If it is seriously worn, replace it. Check ...

Page 153

Allowable limit: 9.96mm. Measure shift fork hole id. Allowable limit: 10.05mm. Measure shift fork thickness. Allowable limit: 4.6mm. Measure od of gearshift drum allowable limit: 39.75mm. Measure the width of gearshift drum lock groove. Allowable limit: 6.35mm. Micrometer tester vernier caliper lock...

Page 154: Crankcase

Remove balance shaft gear 15.4 installation install it in the reverse order of removal. Crankcase 1 right crankcase 2 left crankcase 3 crankshaft connecting rod assembly 4 piston pin 5 bolt 6 piston 注意:曲轴箱为薄壁铸件, 作业中要避免冲击,以免 产生变形或断裂。 所有零件在检查测定 前应清洗,并用高压空气 吹干净。 作业前,应将曲轴箱 内的润滑油放出。 balance shaft gear.

Page 155: Xvi Crankcase

Xvi crankcase preparatory data------------ 16.1 fault diagnosis--------------16.2 crankcase--------------------16.3 16.1 preparatory data precautions on operation attention: crankcase is a thin-wall casting part. Avoid impact on it during operation in case it may be distorted or broken. Clean carefu...

Page 156

16.2 fault diagnosis noise in the crankcase engine stops automatically spare pars falling off or broken in the crankcase stuck clutch 16.3 crankcase 16.3.1 crankcase removal screw off starting motor mounting bolts,and remove starting motor. Release starting motor gear chamber cover mounting bolt and...

Page 157

Use an electric or pneumatic tool to screw off flywheel locknut. Pull out flywheel assembly (including the star wheel). Remove gear display. Remove cam shaft limit plate and take down cam assembly. Remove bearing locating device. 16.3.2 exploded view of cam assembly measure cam bush id. Allowable li...

Page 158

Remove screws, engine oil filter roller cover and its cover washer. Remove washer and location pin. Use an electric or pneumatic tool to screw off locknut. Remove oil filter roller and take down the drive gear. Screw off engine oil pump screws and remove oil pump assembly. 16.4 crankshaft connecting...

Page 159

Inspection measure the connecting rod big end left-to-right clearance. Allowable limit: 0.55mm. Measure the connecting rod big end clearance along x-y direction. Allowable limit: 0.05mm. Crankshaft shimmy measurement allowable limit: 0.01mm. Check if there is abnormal noise and looseness when the cr...

Page 160: Muffler Assembly

Exhaust system inspection and maintenance muffler assembly a tightening torque of mounting bolt 5 for muffler connector in the diagram:5-9 n·m b dual catalysts are added into the muffler welding assembly in the diagram. C tightening torque of combined screw 6 for muffler protecting plate in the diag...

Page 161: Xvii

Xvii emission control system emission control system guarantee-----------------------------------------17.1 periodical maintenance instructions/ensure emission standard---------------17.2 emission control system mechanical function----------------------------17.3 solutions to idle exhaust exceeding ...

Page 162

Your motorcycle in the specified time intervals. ·if you have any other individual problem, please contact or call your local dealer or service center of keeway motorcycle co., ltd. · relevant emission specifications: emission specifications co hc no x emission standard ≤ 2.0g/km ≤ 0.3g/km 0.5 g/km ...

Page 163

Perform regular inspection (repair and maintenance plan) measure idle exhaust (note 1) adjust carburetor (note 2) disassemble and clean the carburetor (sj, mj, saj, maj, etc.) replace carburetor disassemble and repair engine. • valve (leak) • piston (worn) • combustion chamber (clean) for delivery; ...

Page 164

Rkv125 schematic circuit diagram.