- DL manuals

- KEF

- Grinder

- BO 50/5

- Instruction Manual

KEF BO 50/5 Instruction Manual

Summary of BO 50/5

Page 1

Industrivej 3-9 dk 9460 brovst tel. +45 9823 6266 fax. +45 9823 6144 25.04.12 kef-motor a/s instruction manual psd 5 – bo 50/5 – pod 5 - poda 5 industrial grinders.

Page 2: Kef-Motor A/s

1 introduction you can connect your dual grinder in many ways. This manual includes the following options for use of your dual grinder: psd 5 for grinding, bo 50/5 for grinding and belt grinding pod 5 for polishing poda 5 for polishing and deburring eu declaration of conformity hereby declares that ...

Page 3: Table Of Contents

2 table of contents 1 transport & handling 3 1.1 t ransport 3 1.2 h andling 3 1.3 p lacing 3 2 directions for use 4 2.1 o peration 4 2.2 s afety rules for stationary power tools . 4 2.3 m aintenance 6 3 belt arm 7 3.1 a ssembly and mounting of belt arm 7 3.2 c hanging of grinding belt 8 3.3 m ainten...

Page 4: 1 Transport & Handling

3 1 transport & handling 1.1 transport psd 5 industrial belt grinder and others are delivered on a pallet packed in protective wrapping. 1.2 handling the machines can easily be transported on the pallet on which they are delivered. If the machine is delivered on a pedestal you must insure that the p...

Page 5: 2 Directions For Use

4 2 directions for use 2.1 operation after adjustment and connection the machine is ready for use. The grinding kan take place by the contact wheel (e) or on the surface grinding table by opening the cover (h). When you start grinding please start by letting the material touch the grinding wheel lig...

Page 6

5 8. Make workshop kidproof with padlocks, master switches, or by removing starter keys. 9. Don’t force tool. It will do the job better and be safer at the rate for which it was designed. . 10. Use right tool. Don’t force tool or attachment to do a job it was not designed for. 11. Wear proper appare...

Page 7

6 2.3 maintenance keep the machine in a dry place so the grinding wheels or belts will not risk getting any damp or rain. The grinding wheel will often get uneven because of use and therefore we recommend that you level the grinding wheel off frequently. When the grinding wheel is worn more than 25%...

Page 8: 3 Belt Arm

7 3 belt arm 3.1 assembly and mounting of belt arm if the grinding machine is mounted with a grinder cover or a deburrer cover these must be removed completely before mounting the belt arm. Mount the telescopearm (a) to the cover (b) by using the fitting for the telescope arm (c) and mounting the co...

Page 9

8 3.2 changing of grinding belt when the grinding belt is worn out it must be replaced which is done the following way: the top plate (a) (se fig.: 3.2) on the cover is opened and the handle (b) is pulled down. This way the pressure on the grinding belt will be lowered (c), so that it can be dismoun...

Page 10

9 3.3 maintenance of belt arm empty the spark arrester (a) (see fig.: 3.3) to avoid hot sparks damaging or deforming grinding belt and contact wheel. If the machine is equipped with vfcb- exhaust unit you must control if the suction channels need cleaning. The dust bag must be emptied when necessary...

Page 11

10 4 vfcb-complete exhaust unit 4.1 assembling and mounting of vfcb – complete exhaust unit the following description of assembling and mounting of vfcb-exhaust unit is valid both if it is a vfcb-220 or if it is a vfcb-121. The mounting order is exactly the same for both models. The guard (a) (see f...

Page 12: 5 Deburrer

11 5 deburrer 5.1 assembling and mounting of deburrer the deburrer cover is to be assembled in the order shown in fig.: 5.1. The four screws in the end cover (a) must be unscrewed and the mounting plate (b) is to be placed on the end cover (a), the four countersinked machine screws m6x20 (c) are ret...

Page 13

12 5.3 maintenance of deburrer/steel brush nothing on the deburrer/steel brush needs maintenance except that it is necessary to adjust the grinding system as the steel brush is worn. The eye shield and other accessories must be replaced immediately if they are damaged. 5.4 use of deburrer when the d...

Page 14: 6 Polishing Machine

13 6 polishing machine 6.1 adjustment the polishing machine. Placing of the machine must take place on a firm and level surface. Now secure the polishing machine to the work table or the floor by using the four holes in the base used for mounting the machine to the pallet. Please wire the machine ac...

Page 15: 7 Spare Parts

14 7 spare parts in this chapter there are split drawings and matching spare parts lists. 7.1 machine line up of psd 5 fig.: 7.1 (a) motorpart, (b) grinding cover, (c) belt arm, (d) vfcb-exhaust unit..

Page 16

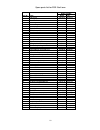

15 7.2 psd 5 basic model fig.:7.2 drawing of psd 5 basic model spare parts list for psd 5 basic model pos.Nr. Type ident. Nr. 1 collar bushing e 308 0995681 2 screw m6x20 ch z 4345678 4 bearing end shield v 0187860 5 o-ring 50x45x3 mm 1385259 6 wave spring 50x44x0.6 0100331 7 bearing 6205 2z/c3 0104...

Page 17

16 7.3 psd 5 cover fig.: 7.3 split drawing of psd 5 cover spare parts list for psd 5 cover pos.Nr. Type cover l cover r 1 eye shield for psd 5 1311948 1311948 2 cross handle Ø32 m6 din 6335 0922021 0922021 3 disc 6.4x1.6 0737631 0737631 4 carriage bolt 6x50 0932043 0932043 5 nut m10 z 5438761 543876...

Page 18

17 7.4 psd 5 belt arm fig.: 7.4 split drawing of psd 5 belt arm.

Page 19

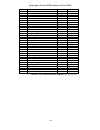

18 spare parts list for psd 5 belt arm order number pos. Nr. Type right left 1 top screw 2078212 2078212 2 sliding pipe for belt stand 9480687 9480687 3 machine screw m4x4 z 0737618 0737618 4 lock ring dim 42, din 472 7655123 7655123 5 ball bearings 6302 2z 1462846 1462846 6 distance pipe ø22/15x10 ...

Page 20

19 7.5 vfcb-exhaust system for psd 5 fig.: 7.5 split drawing of vfcb-exhaust system for psd 5.

Page 21

20 spare parts list for vfcb-exhaust unit for psd 5 pos.Nr. Type vfcb-220 vfcb-121 1 fan housing l. Outer 0781266 0781266 2 screw m5x16 ch z 0120626 0120626 3 washer dim 5 z 0102555 0102555 4 disc Ø5.5x26,5x2.5 0233030 0233030 5 fan wheel vfcb alu. 0995703 0995703 6 screw m6x16 z 0300604 0300604 7 w...

Page 22

21 7.6 deburring cover for poda 5 fig 7.6 drawing of parts in deburrer spare parts list for deburrer for poda 5 pos.Nr. Type cover r cover l 1 disc 6.4x1.6 0737631 0737631 2 cross handle ø32 m6 din 6335 0922021 0922021 3 bolt for wood 6x50 0932043 0932043 4 eye protective guard psd 5 1311948 1311948...

Page 23

22 7.7 pod 5 w/flange fig 7.7 split drawing of pod 5 w/flange spare parts list for pod 5 w/flange pos.Nr. Type left right 1 polishing guard left 0921432 0921434 2 disk 6mm 0737631 0737631 3 skrew m6x10 0110089 0110089 4 distance ring ø20x30x6 1551176 1551176 5 spindle 1532367 1532375 6 polishing mop...

Page 24

23 7.8 pod 5 w/spindle fig 7.8 split drawing of pod 5 w/spindle spare parts list for pod 5 w/spindle pos.Nr. Type left right 1 polishing guard left 0921432 0921434 2 disk 6mm 0737631 0737631 3 skrew m6x10 0110089 0110089 4 flange inner 0921572 0921572 5 polishing mop ø200x20xø6 1531506 1531506 6 fla...

Page 25: 8 Technical Data

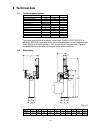

24 8 technical data 8.1 technical specifications model psd 5 bo 50/5 pod 5 grinding belt - 50x1600 - motor effect in watt 1100 1100 1100 rpm. 2800 2800 2800 contact wheel - 200x50xø20 - grinding wheel 200x38xø20 - - polishing mop to spindle - - 200x20xø6 polishing mop to flange - - 200x20xø20 ip cla...

Page 26

25 8.3 wiring diagrams psd 5, bo 50/5 and pod 5 industrial grinding machines can be wired 3 x 400 v, 50/60 hz or 3 x 230 v 50/60 hz. Please see wiring diagrams below. Max. Volt max. Volt.

Page 27

26 disa switch w/emergency stop 8.4.

Page 28

27 8.5 psd 5 connected to ex16 dust extraction.

Page 29

28 8.5 guarantee if within 2 year of purchase this machine supplied by kef a/s becomes defective due to faulty materials or workmanship we guarantee to repair or replace the machine or defective part or parts free of charge provided that: 1. The product is returned complete to one of our service bra...