- DL manuals

- Keithley

- Other

- 1801

- Instruction Manual

Keithley 1801 Instruction Manual

Summary of 1801

Page 1

Model 1801 nanovolt preamp instruction manual a g r e a t e r m e a s u r e o f c o n f i d e n c e.

Page 2: Warranty

Warranty keithley instruments, inc. Warrants this product to be free from defects in material and workmanship for a period of 1 year from date of shipment. Keithley instruments, inc. Warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes...

Page 3

Model 1801 nanovolt preamp instruction manual ©1993, keithley instruments, inc. All rights reserved. Third printing april 1999 cleveland, ohio, u.S.A. Document number: 1801-901-01 rev. C.

Page 4: Manual Print History

Manual print history the print history shown below lists the printing dates of all revisions and addenda created for this manual. The revision level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between revisions, contain important change inf...

Page 5: Safety Precautions

Safety precautions the following safety precautions should be observed before using this product and any associated instrumentation. Although some in- struments and accessories would normally be used with non-haz- ardous voltages, there are situations where hazardous conditions may be present. This ...

Page 6

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation. The symbol on an instrument indicates that the user should re- fer to the operating instructions located in the manual. The symbol on an instrument shows that it can source or mea- sure 100...

Page 7: Table of Contents

Table of contents i 1 general information 1.1 introduction ..................................................................................................................................................... 1-1 1.2 features .............................................................................

Page 8

Ii 3 operation 3.1 introduction ..................................................................................................................................................... 3-1 3.2 preamplifier operation ..........................................................................................

Page 9

Iii 5.3 principles of operation .................................................................................................................................. 5-10 5.3.1 block diagram ...................................................................................................................

Page 10: List of Illustrations

List of illustrations v 2 installation figure 2-1 preamplifier module configuration ..................................................................................................... 2-2 figure 2-2 power supply card configuration ......................................................................

Page 11: List of Tables

List of tables vii 3 operation table 3-1 power-up error messages .................................................................................................................... 3-2 table 3-2 configure preamp menu structure ...........................................................................

Page 12: General Information

1 general information 1-1 1.1 introduction this section contains general information about the model 1801 nanovolt preamp option for the model 2001 multimeter. The model 1801 adds 20µv, 200µv, and 2mv dc volts and 500µv rms ac voltage measurement ranges to the model 2001 and includes 2m Ω through 20...

Page 13

General information 1-2 1.4 manual addenda any improvements or changes concerning the preampli- fier or manual will be explained in an addendum included with unit. 1.5 safety symbols and terms the following symbols and terms may be found on an instrument or used in this manual. The symbol on an inst...

Page 14

General information 1-3 1.9 model 2001 compatibility the model 1801 can be used only with model 2001 mul- timeters with main microcontroller revision b01 or later firmware. The firmware revision level is displayed during the power-up cycle (the main microcontroller firmware revision level appears on...

Page 15: Installation

2 installation 2-1 2.1 introduction this section includes information on installing the model 1801 in the model 2001 multimeter and making power supply and output connections. This section is arranged as follows: 2.2 card configuration: discusses the overall configu- ration of both the preamplifier ...

Page 16

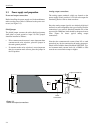

Installation 2-2 2.2 card configuration 2.2.1 preamplifier module figure 2-1 shows the configuration of the preamplifier module. Key items include: ❶ input terminals the hi and lo input terminals are pure copper studs and nuts intended for connecting input signals to the model 1801. To minimize ther...

Page 17

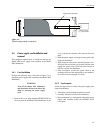

Installation 2-3 2.2.2 power supply card figure 2-2 shows the configuration of the power supply card. Components include: ❶ cover the plastic cover shields circuit board parts from damage and contamination. In order to open the cover, press in on the cover latch, then swing the cover open on its hin...

Page 18

Installation 2-4 analog output connections the analog output terminals, which are located on the power supply board, provide a 0-2v full scale output for monitoring devices such as chart recorders. Since the analog output signal is at a relatively high level and has low source impedance, the type of...

Page 19

Installation 2-5 2.4 power supply card installation and removal this paragraph explains how to install and remove the model 1801 power supply card assembly in the model 2001 multimeter. 2.4.1 card installation perform the following steps, and refer to figure 2-5 to install the power supply card asse...

Page 20

Installation 2-6 2.5 connections this paragraph provides the information necessary to connect the preamplifier module to the power supply card and multimeter. Lock card ejector arms (2) unlock card figure 2-5 power supply card installation 2.5.1 power supply connections after installing the power su...

Page 21

Installation 2-7 • use only shielded low-thermal cables such as the input cable supplied with the model 1801. • use only crimped-on copper lugs and copper wires for all input connections. Crimping results in an air- tight connection. • copper-to-copper oxide connections result in thermoelectric pote...

Page 22

Installation 2-8 figure 2-7 connections to multimeter input input hi hi (red) input lo lo (black) notes: 1. See paragraph 3.3.3 for 4-wire resistance output connections. 2. Select rear inputs using front panel switch. 1801 nanovolt preamp inputs hi lo 41v peak v zero i zero caution: no internal oper...

Page 23

Installation 2-9 2.6 operating considerations 2.6.1 using the thermal isolation container after making all connections, place the preamplifier mod- ule in the thermal isolation container, as shown in figure 2-9. Route the connecting wires through the slits in each end of the container, then cover th...

Page 24: Operation

3 operation 3-1 3.1 introduction this section contains basic information on operating the model 1801 using the host model 2001 multimeter. For more detailed information on operating the model 2001 multimeter, see the model 2001 operator’s manual. This section is organized as follows: 3.2 preamplifie...

Page 25

Operation 3-2 power-up error messages table 3-1 summarizes error messages that may occur dur- ing power-up when the model 1801 is installed. 3.2.2 preamplifier configuration menu table 3-2 summarizes the preamplifier configuration menu structure. In order to access this menu, press the front panel c...

Page 26

Operation 3-3 table 3-2 configure preamp menu structure menu item description control enable disable enable/disable preamplifier. Enable preamplifier. Disable preamplifier. Filter fast medium slow select preamplifier filter. Select fast response filter. Select medium response filter. Select slow res...

Page 27

Operation 3-4 3.2.5 preamplifier filtering the model 1801 has three analog filters with fast, medium, and slow responses respectively. These fil- ters are in addition to the model 2001 filter, which can also be used with the preamplifier. See paragraph 3.9 of the model 2001 operator’s manual for det...

Page 28

Operation 3-5 3.2.6 operational differences functions the following functions are available when using the model 1801: • dc volts • ac volts (low-frequency rms only) • 4-wire ohms • frequency (voltage only) • thermocouple temperature (differential only) note that dc current, ac current, and 2-wire o...

Page 29

Operation 3-6 saving setups model 1801 setups can be saved by using the savesetup selection in the front panel menu. (see paragraph 3.12.1 of the model 2001 operator’s manual for details.) in order to save a preamplifier setup, select the desired operating conditions, then save your setup as usual. ...

Page 30

Operation 3-7 an appropriate error message will be displayed if you select one of the above multiple displays with the preamp enabled. Also note that the freq bar graph range is lim- ited to 2khz with the preamp enabled. See paragraph 3.2.2 of the model 2001 operator’s manual for more information on...

Page 31

Operation 3-8 input hi hi (red) input lo lo (black) b. Output connections 1801 nanovolt preamp inputs hi lo 41v peak v zero i zero caution: no internal operator serviceable parts, service by qualified personnel only. ! Keithley 2mv peak hi lo low-thermal input cable noise shield note : use only clea...

Page 32

Operation 3-9 7. Observe the display. If the “overflow” message is displayed, select a higher range. Use the lowest range possible for the best resolution. 8. Take a reading from the display. If the reading is noisy, it may be necessary to change the filter response. (see paragraph 3.2.5 for details...

Page 33

Operation 3-10 input hi hi (red) input lo lo (black) b. Output connections 1801 nanovolt preamp inputs hi lo 41v peak v zero i zero caution: no internal operator serviceable parts, service by qualified personnel only. ! Keithley 2mv peak hi lo low-thermal input cable noise shield note : use only cle...

Page 34

Operation 3-11 3.3.3 four-wire resistance measurements the model 1801 can make 4-wire resistance measure- ments between 100p Ω and 200 Ω . Assuming “bench reset” conditions (see paragraph 3.12.1 of the model 2001 operator’s manual), the basic procedure for making 4-wire resistance measurements is as...

Page 35

Operation 3-12 figure 3-4 connections for 4-wire resistance measurements 1801 nanovolt preamp inputs hi lo 41v peak v zero i zero caution: no internal operator serviceable parts, service by qualified personnel only. ! Keithley 2mv peak hi lo low-thermal input cable noise shield notes : 1. Use only c...

Page 36

Operation 3-13 input hi hi (red) input lo lo (black) b. Output connections 1801 nanovolt preamp inputs hi lo 41v peak v zero i zero caution: no internal operator serviceable parts, service by qualified personnel only. ! Keithley 2mv peak hi lo low-thermal input cable noise shield note : use only cle...

Page 37

Operation 3-14 3.3.5 differential thermocouple temperature measurements the model 1801 can make differential temperature mea- surements using two thermocouples connected in a differ- ential configuration. The model 2001 will then display the difference in temperature between the two thermocou- ples....

Page 38

Operation 3-15 front panel measurement procedure the basic procedure for differential thermocouple tem- perature measurement is as follows: 1. Connect the two thermocouples to the model 1801 input in a differential configuration, as shown in fig- ure 3-6. Note both thermocouples must be of the same ...

Page 39

Operation 3-16 input hi hi (red) input lo lo (black) b. Output connections 1801 nanovolt preamp inputs hi lo 41v peak v zero i zero caution: no internal operator serviceable parts, service by qualified personnel only. ! Keithley 2mv peak a. Input connections t 1 t 2 + - thermocouples connected in di...

Page 40

Operation 3-17 temperature displays it is important to keep in mind that, with the model 1801 enabled, the model 2001 always displays the difference in temperature between the reference thermocouple and the measuring thermocouple in the currently selected temper- ature units (°c, °f, or k). This cha...

Page 41

Operation 3-18 3.4 measurement considerations low-level measurements made using the model 1801 can be adversely affected by various types of noise or other unwanted signals that can make it very difficult to obtain accurate readings. Some of the phenomena that can cause unwanted noise include thermo...

Page 42

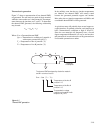

Operation 3-19 in the unlikely event that the two junction temperatures are identical, the thermal emfs will exactly cancel because the generated potentials oppose one another. More often, the two junction temperatures will differ, and considerable thermal emfs will be generated. A typical test setu...

Page 43

Operation 3-20 minimizing thermal emfs to minimize thermal emfs, use only copper wires, lugs, and test leads for the entire test setup. Also, it is impera- tive that all connecting surfaces are kept clean and free of oxides. As noted in table 3-2, copper-to-copper oxide junctions can result in therm...

Page 44

Operation 3-21 sometimes, cooling the source is the only practical method available to reduce noise. Again, however, the available reduction is not as large as it might seem because the reduction is related to the square root of the change in temperature. For example, to cut the noise in half, the t...

Page 45

Operation 3-22 3.4.4 electromagnetic interference (emi) the electromagnetic interference characteristics of the model 1801 nanovolt preamp comply with the electro- magnetic compatibility (emc) requirements of the european union (eu) directives as denoted by the ce mark. However, it is still possible...

Page 46

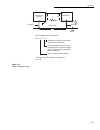

Operation 3-23 figure 3-10 power line ground loops experiment (source) e s r e in hi preamplifier lo i ground 2 ground bus v g input voltage to the preamplifier is: e in = e s + i r resistance of input lo connection (typically around 100m Ω ) current passing through input lo connection due to ground...

Page 47

Operation 3-24 figure 3-11 eliminating ground loops experiment (source) e s r e in hi preamplifier lo z cm i single system ground ground bus v g input voltage to the preamplifier is: e in = e s + i r resistance of input lo connection (typically around 100m Ω ) current passing through z cm (m Ω or g ...

Page 48: Performance Verification

4 performance verification 4-1 4.1 introduction the procedures in this section are intended to verify that model 1801 accuracy is within the limits stated in the preamplifier one-year specifications (see appendix a). These procedures can be performed when the unit is first received to ensure that no...

Page 49

Performance verification 4-2 4.3 warm-up period the model 1801 must be allowed to warm up for at least two hours before performing the verification procedures. If the preamplifier has been subjected to temperature extremes (outside the range stated in paragraph 4.2), allow additional time for intern...

Page 50

Performance verification 4-3 4.7 restoring default conditions before performing each performance verification proce- dure, restore model 1801 default conditions as follows: 1. From the normal display mode, press the menu key. The model 2001 will display the following: main menu savesetup gpib calibr...

Page 51

Performance verification 4-4 output hi output lo 5700a calibrator (output dc volts) sense lo sense hi sense hi lo input output note : put calibrator in external sense mode, and use 2.2v range. 262 low-thermal voltage divider input hi hi (red) input lo lo (black) b. Output connections 1801 nanovolt p...

Page 52

Performance verification 4-5 5. Select the slow response filter as follows: a. Press the chan key. The instrument will display the following: config preamp control filter calibration b. Select filter, then press enter. The unit will display filter response selections: select preamp filter fast mediu...

Page 53

Performance verification 4-6 4.8.2 ac volts verification ac voltage accuracy is checked by applying an accurate ac voltage at 100hz from an ac calibration source and then verifying that the model 1801 ac voltage reading falls within the specified range. Caution do not exceed 1v peak between in- put ...

Page 54

Performance verification 4-7 output hi output lo 5700a calibrator (output dc volts) input hi hi (red) input lo lo (black) b. Output connections 1801 nanovolt preamp inputs 41v peak v zero i zero caution: no internal operator serviceable parts, service by qualified personnel only. ! Keithley 2mv peak...

Page 55: Service Information

5 service information 5-1 5.1 introduction this section contains information necessary to service the model 1801 nanovolt preamplifier. Warning the information in this section is intended only for qualified service personnel. Do not attempt these pro- cedures unless you are qualified to do so. Infor...

Page 56

Service information 5-2 the calibration equipment should also be allowed to warm up for the minimum period specified by the manufacturer. 5.2.3 line power the model 1801 should be calibrated while the model 2001 is operating from a line voltage in the range of 90-134v or 180-250v at 50, 60, or 400hz...

Page 57

Service information 5-3 9. Make sure that the thermal isolation enclosure lid is in place, and allow two minutes for thermals to settle. 10. Adjust the current offset control (i zero) for a model 2001 front panel reading of 0µv ± 0.1µv 11. Disconnect the low-thermal resistor when the offset adjustme...

Page 58

Service information 5-4 5.2.6 normal calibration the normal calibration procedure calibrates the preampli- fier module and its power supply card as a unit. Since the constants derived during the calibration process are stored in nvram located on the power supply card, the pream- plifier module shoul...

Page 59

Service information 5-5 12. The unit will then prompt for a 10 4 divider ratio as follows: set 262 to 10^4 set the model 262 divider ratio to 10 4 , then press enter. 13. Next, the model 2001 will prompt you to set the dc calibrator output voltage to 200mv as follows: calibrator to 200 mv set the ca...

Page 60

Service information 5-6 14. The model 2001 will then display the precise calibra- tion voltage: cal: 200.00000 mvdc 15. Make sure that the divider ratio is still set to 10 4 . If you are using the recommended 200mv calibration voltage setting, simply press enter at this point. Otherwise, set the dis...

Page 61

Service information 5-7 table 5-2 model 1801 ieee-488 bus calibration commands command description :calibration :unprotected :preamp :g1k :g1k? :g10k :g10k? :g100k :g100k? :z1k :z10k :z100k :fs1k :fs10k :fs100k :date ÒÓ :date? :ndue ÒÓ :ndue? :calculate :save :abort calibration root command. Command...

Page 62

Service information 5-8 17. Set the model 262 divider ratio to 10 3 , then press enter. 18. Send the following command string over the bus: :cal:unpr:pre:fs10k 200e-6 be sure to use the exact calibration value if you are using a voltage other than 200µv. The allowable range is from 100µv to 200µv (1...

Page 63

Service information 5-9 calibration errors one of the errors listed in table 5-4 may occur during the course of calibration. (these errors will appear on the front panel and may be obtained over the bus by using the :syst:err? Query.) the most likely causes of these errors are: • incorrect connectio...

Page 64

Service information 5-10 storing constants calibration constants can be stored from the front panel or over the bus, as explained below. The nominal (ideal) value for each of these constants is 1.0. The allowable range is from 0.5 to 1.5; if you attempt to enter a value outside this range, a “parame...

Page 65

Service information 5-11 preamplifier power supply the preamplifier power supply uses a linear, high-fre- quency, dual-transformer topology operating at a fre- quency of 4.8khz. The two-transformer configuration (t101 and t102) reduces the 4.8khz common-mode cur- rent component, which is not fed thr...

Page 66

Service information 5-12 2001 reads these calibration constants from the device during power-up. Note that data transmission is performed serially. The gain and filter control circuits include u101, u106, at101 through at104, and associated components. Serial control data from the model 2001 is cloc...

Page 67

Service information 5-13 table 5-6 power supply card troubleshooting procedure step item/component required condition comments 1 u103, pin 3 4.8khz, 50% duty cycle square wave referenced to digital common (p1034, pin 1). 2 t102, pin 6 0.2v p-p rounded square wave referenced to 3 u104, pin 1 -8.5v dc...

Page 68: Replaceable Parts

6 replaceable parts 6-1 6.1 introduction this section contains replacement parts information, schematic diagrams, and component layout drawings for the model 1801. 6.2 parts lists parts lists for the preamplifier are included in tables inte- grated with schematic diagrams and component layout drawin...

Page 69

Replaceable parts 6-2 table 6-1 electrical, parts list circuit designation description keithley part number at101-104 ic, photo coupler, ps2501a-1 ic-670 c101 c102-105, 109, 119,121 c106, 117 c108 c110, 112, 113, 120, 122 c111 c114 c115 cap, 5600pf, +/-1%, 50vdc, dipped mica cap, 10uf, 20%, 20v, tan...

Page 70

Replaceable parts 6-3 table 6-2 mechanical, parts list description keithley part number cable assembly shielded cover, bottom cable clamp shielded cover, bottom strip, polyurethane shielded cover, top shielded cover, top shield, scanner bottom insulator, bottom shield, top card ejector, plastic ther...

Page 73: Specifications

A specifications a-1.

Page 77: Calibration Programs

B calibration programs b-1 introduction this appendix includes programs written in quickbasic and turbo c to aid you in calibrating the model 1801. See paragraph 5.2 in section 5 for details on offset adjust- ments, recommended calibration equipment, test connec- tions, and detailed calibration proc...

Page 78

Calibration programs b-2 program b-1. Calibration program for use with any suitable calibrator (quickbasic version) ' model 1801 calibration program for use with any suitable ' dc voltage calibrator. Open "\dev\ieeeout" for output as #1 ' open ieee-488 output path. Open "\dev\ieeein" for input as #2...

Page 79

Calibration programs b-3 program b-1. Calibration program for use with any suitable calibrator (quickbasic version) continued calend: ' check for cal step completion. Print "waiting for calibration step"; i; "completion..." stat: print #1, "status" ' request bus status. Input #2, st$ ' input status....

Page 80

Calibration programs b-4 program b-2. Calibration program for use with any suitable calibrator (turbo c version) /* model 1801 calibration program for use with any suitable dc voltage calibrator. */ #include "ieeeio.H" #include #include #include #include main() { static char *msg[] = { "set 262 divi...

Page 81

Calibration programs b-5 program b-2. Calibration program for use with any suitable calibrator (turbo c version) continued if (i ieeeprtf("output 16;%s;*opc",cmd[i]); calend(i); } errcheck(); printf("enter calibration date (mm/dd/yy): "); scanf("%s",date); ieeeprtf("output 16;:cal:unpr:pre:date '%...

Page 82

Calibration programs b-6 program b-2. Calibration program for use with any suitable calibrator (turbo c version) continued ieeerd(buf); if (strstr(buf,"1801") == null){ printf("model 1801 is not installed;" " program aborted."); exit(1); } }.

Page 83

Calibration programs b-7 program b-3. Calibration program for use with fluke 5700a calibrator (quickbasic version) ' model 1801 calibration program for use only with the ' fluke 5700a calibrator. Open "\dev\ieeeout" for output as #1 ' open ieee-488 output path. Open "\dev\ieeein" for input as #2 ' o...

Page 84

Calibration programs b-8 program b-3. Calibration program for use with fluke 5700a calibrator (quickbasic version) continued print #1, "output 16;:cal:unpr:pre:abor" close 1: close 2 print "program halted." end end if return ' calend: ' check for cal step completion. Print "waiting for calibration s...

Page 85

Calibration programs b-9 program b-4. Calibration program for use with fluke 5700a calibrator (turbo c version) /* model 1801 calibration program for use with the fluke 5700a calibrator. */ #include "ieeeio.H" #include #include #include #include main() { static char *msg[] = { "set 262 divider ratio...

Page 86

Calibration programs b-10 program b-4. Calibration program for use with fluke 5700a calibrator (turbo c version) continued if(i==3) ieeewt("output 04;out 0.2 v,0 hz"); printf("%s",msg[i]); if (i if (i ieeeprtf("output 16;%s;*opc",cmd[i]); calend(i); } ieeewt("output 04;stby"); errcheck(); pr...

Page 87

Calibration programs b-11 program b-4. Calibration program for use with fluke 5700a calibrator (turbo c version) continued char buf[40]; ieeewt("output 16;*opt?"); ieeewt("enter 16"); ieeerd(buf); if (strstr(buf,"1801") == null) { printf("model 1801 is not installed;" " program aborted."); exi...

Page 88: Ieee-488 Bus Command Summary

C ieee-488 bus command summary c-1 table c-1 summarizes ieee-488 bus commands associated exclusively with the model 1801. Refer to the model 2001 operator’s manual for additional commands that can be used with the model 1801. Table c-1 ieee-488 bus command summary command description :input :preamp ...

Page 89

Ieee-488 bus command summary c-2 :calibration :unprotected :preamp :g1k :g1k? :g10k :g10k? :g100k :g100k? :z1k :z10k :z100k :fs1k :fs10k :fs100k :date ÒÓ :date? :ndue ÒÓ :ndue? :calculate :save :abort calibration commands. Commands not protected by cal switch. Preamp commands. Directly enter 2mv gai...

Page 90: Index

Index i-1 a ac voltage measurements 3-9 ac volts verification 4-6 b block diagram 5-10 c calibration 5-1 calibration programs b-1 card configuration 2-2 card installation 2-5 card removal 2-5 component layouts and schematic diagrams 6-1 connections 2-6 d dc voltage measurements 3-7 dc volts verifica...

Page 91

I-2 s safety symbols and terms 1-2 service information 5-1 shielding 3-22 shipment contents 1-2 source resistance noise 3-20 special handling of static-sensitive devices 5-12 specifications 1-2, a-1 t thermoelectric potentials 3-18 troubleshooting 5-12 troubleshooting access 5-12 troubleshooting equ...

Page 92: Service Form

Service form model no. Serial no. Date name and telephone no. Company list all control settings, describe problem and check boxes that apply to problem. ❏ intermittent ❏ analog output follows display ❏ particular range or function bad; specify ❏ ieee failure ❏ obvious problem on power-up ❏ batteries...

Page 93

Specifications are subject to change without notice. All keithley trademarks and trade names are the property of keithley instruments, inc. All other trademarks and trade names are the property of their respective companies. Keithley instruments, inc. 28775 aurora road • cleveland, ohio 44139 • 440-...