- DL manuals

- Keithley

- Switch

- 2700

- Service Manual

Keithley 2700 Service Manual

Summary of 2700

Page 1

Contains servicing information model 2700 multimeter/ data acquisition system service manual.

Page 2: Warranty

Warranty keithley instruments, inc. Warrants this product to be free from defects in material and workmanship for a period of 1 year from date of shipment. Keithley instruments, inc. Warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes...

Page 3

Model 2700 multimeter/data aquisition system service manual ©1999, keithley instruments, inc. All rights reserved. Cleveland, ohio, u.S.A. Second printing, february 2000 document number: 2700-902-01 rev. B.

Page 4: Manual Print History

Manual print history the print history shown below lists the printing dates of all revisions and addenda created for this manual. The revision level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between revisions, contain important change inf...

Page 5: Safety Precautions

Safety precautions the following safety precautions should be observed before using this product and any associated in- strumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may be present. This pr...

Page 6

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface ca- pable of withstanding the voltage being measured. The instrument and accessories...

Page 7: Table of Contents

Table of contents 1 performance verification introduction ................................................................................ 1-2 verification test requirements ..................................................... 1-3 environmental conditions ..............................................

Page 8: Calibration

2 calibration introduction ................................................................................ 2-2 environmental conditions ........................................................... 2-2 warm-up period ................................................................... 2-2 line power ....

Page 9: Troubleshooting

4 troubleshooting introduction ................................................................................ 4-2 repair considerations ................................................................. 4-2 power-on self-test ....................................................................... 4...

Page 10: Specifications

A specifications accuracy calculations .............................................................. A-12 calculating dc characteristics accuracy .......................... A-12 calculating ac characteristics accuracy .......................... A-12 calculating dbm characteristics accuracy ...........

Page 11: Calibration Program

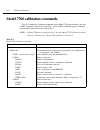

Manufacturing calibration commands ..................................... B-15 :ac:step ........................................................... B-15 :dc:step0 ...................................................................... B-15 model 7700 calibration commands .................................

Page 12: List of Illustrations

List of illustrations 1 performance verification figure 1-1 connections for model 2700 dc volts verification ................1-8 figure 1-2 connections for model 2700 ac volts verification .................1-9 figure 1-3 connections for model 2700 dc current verification ...........1-11 figure 1-4 c...

Page 13: Troubleshooting

4 troubleshooting figure 4-1 power supply block diagram ................................................... 4-4 figure 4-2 digital circuitry block diagram ............................................... 4-6 figure 4-3 analog circuitry block diagram .............................................. 4-9 ...

Page 14: List of Tables

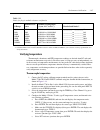

List of tables 1 performance verification table 1-1 recommended verification equipment ....................................1-4 table 1-2 dcv reading limits .................................................................1-9 table 1-3 acv reading limits .................................................

Page 15: Troubleshooting

4 troubleshooting table 4-1 power supply components ...................................................... 4-5 table 4-2 display board checks ............................................................ 4-11 table 4-3 power supply checks ............................................................. ...

Page 17

1 performance verification.

Page 18: Introduction

1-2 performance verification introduction use the procedures in this section to verify that model 2700 multimeter/data acquisition system accuracy is within the limits stated in the instrument’s one-year accuracy specifications. You can perform these verification procedures: • when you first receive...

Page 19: Environmental Conditions

Performance verification 1-3 verification test requirements be sure that you perform the verification tests: • under the proper environmental conditions. • after the specified warm-up period. • using the correct line voltage. • using the proper calibration equipment. • using the specified reading li...

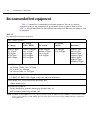

Page 20: Recommended Test Equipment

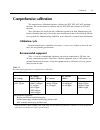

1-4 performance verification recommended test equipment table 1-1 summarizes recommended verification equipment. You can use alternate equipment as long as that equipment has specifications at least as good as those listed in table 1-1 . Keep in mind, however, that calibrator uncertainty will add to...

Page 21: Verification Limits

Performance verification 1-5 verification limits the verification limits stated in this section have been calculated using only the model 2700 one-year accuracy specifications, and they do not include test equipment uncertainty. If a par- ticular measurement falls slightly outside the allowable rang...

Page 22: Verification Test Summary

1-6 performance verification performing the verification test procedures verification test summary verification tests can be performed either through the model 2700 front panel terminals or through plug-in modules. This section contains the following procedures: • model 2700 verification : use this ...

Page 23: Test Considerations

Performance verification 1-7 test considerations when performing the verification procedures: • be sure to restore factory defaults as outlined above. • make sure that the equipment is properly warmed up and connected to the correct input terminals. Also make sure that the inputs switch is in the co...

Page 24: Model 2700 Verification

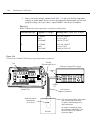

1-8 performance verification model 2700 verification perform these tests to verify accuracy using the model 2700 front panel terminals. Verifying dc voltage check dc voltage accuracy by applying accurate voltages from the dc voltage calibrator to the model 2700 input jacks and verifying that the dis...

Page 25: Verifying Ac Voltage

Performance verification 1-9 5. Source positive and negative and full-scale voltages for each of the ranges listed in table 1-2 . For each voltage setting, be sure that the reading is within stated limits. Verifying ac voltage check ac voltage accuracy by applying accurate ac voltages at specific fr...

Page 26

1-10 performance verification 2. Select the ac volts function by pressing the acv key. 3. Set the model 2700 for the 100mv range; make sure that rel is disabled. 4. Source 1khz and 50khz ac voltages for each of the ranges summarized in table 1-3 , and make sure that the respective model 2700 reading...

Page 27: Verifying Dc Current

Performance verification 1-11 verifying dc current check dc current accuracy by applying accurate dc currents from the dc current calibra- tor to the amps input of the model 2700 and verifying that the displayed readings fall within specified limits. Follow these steps to verify dc current accuracy:...

Page 28: Verifying Ac Current

1-12 performance verification verifying ac current check ac current accuracy by applying accurate ac voltage current at specific frequencies from the ac current calibrator to the model 2700 input, and verifying that the displayed read- ings fall within specified limits. Follow these steps to verify ...

Page 29: Verifying Resistance

Performance verification 1-13 verifying resistance check resistance by connecting accurate resistance values to the model 2700 and verifying that its resistance readings are within the specified limits. Caution do not apply more than 1000v peak between front terminals input hi and lo or more than 35...

Page 30

1-14 performance verification 6. Source the nominal full-scale resistance values for the 100 Ω-10mΩ ranges summarized in table 1-6 , and verify that the readings are within calculated limits. 7. Connect the model 2700 input and sense jacks to the calibrator as shown in figure 1-6 . 8. Disable extern...

Page 31: Verifying Temperature

Performance verification 1-15 verifying temperature thermocouple, thermistor, and rtd temperature readings are derived from dc volts and resistance measurements respectively. For that reason, it is not necessary to independently ver- ify the accuracy of temperature measurements. As long as the dc vo...

Page 32

1-16 performance verification 4. Source each of the voltages summarized in table 1-7 , and verify that the temperature readings are within limits. Be sure to select the appropriate thermocouple type for each group of readings. (see step 2 above.) rtd temperature 1. Connect the precision decade resis...

Page 33: Verifying Frequency

Performance verification 1-17 4. Set the decade resistance box to each of the values shown in table 1-8 , and verify that the temperature readings are within the required limits. Verifying frequency follow the steps below to verify the model 2700 frequency function: 1. Connect the function generator...

Page 34: Model 7700 Verification

1-18 performance verification model 7700 verification use these procedures to verify measurement accuracy through the model 7700 20-channel multiplexer card. Note although the following tests are based on the model 7700 20-channel multiplexer, the same general procedures can be used for other plug-i...

Page 35

Performance verification 1-19 2. Install the model 7700 in slot 1 of the model 2700, then turn on the power, and allow the unit to warm up for two hours before proceeding. Be sure the front panel inputs switch is set to the rear position. 3. Select the dc volts function by pressing the dcv key, and ...

Page 36: Verifying Ac Voltage

1-20 performance verification verifying ac voltage check ac voltage accuracy by applying accurate ac voltages at specific frequencies from the ac voltage calibrator to the model 7700 inputs and verifying that the displayed readings fall within specified ranges. Caution do not exceed 300v rms between...

Page 37

Performance verification 1-21 2. Install the model 7700 in slot 1 of the model 2700, then turn on the power, and allow the unit to warm up for two hours before proceeding. Be sure the front panel inputs switch is set to the rear position. 3. Select the ac volts function by pressing the acv key. Clos...

Page 38: Verifying Dc Current

1-22 performance verification verifying dc current check dc current accuracy by applying accurate dc currents from the dc current calibra- tor to the input terminals of the model 7700 and verifying that the displayed readings fall within specified limits. Follow these steps to verify dc current accu...

Page 39

Performance verification 1-23 2. Install the model 7700 in slot 1 of the model 2700, then turn on the power, and allow the unit to warm up for two hours before proceeding. Be sure the front panel inputs switch is set to the rear position. 3. Select the dc current measurement function by pressing the...

Page 40: Verifying Ac Current

1-24 performance verification verifying ac current check ac current accuracy by applying accurate ac voltage current at specific frequencies from the ac current calibrator to the model 7700 input terminals and verifying that the dis- played readings fall within specified limits. Follow these steps t...

Page 41: Verifying Resistance

Performance verification 1-25 verifying resistance check resistance by connecting accurate resistance values to the model 7700 and verifying that its resistance readings are within the specified limits. Caution do not apply more than 300v between plug-in module input or sense h and l terminal, or be...

Page 42

1-26 performance verification 7. Source the nominal full-scale resistance values for the 100 Ω-10mΩ ranges summarized in table 1-13 , and verify that the readings are within calculated limits. 8. Connect the model 7700 ch1 and ch11 terminals to the calibrator as shown in figure 1-13 . 9. Disable ext...

Page 43: Verifying Temperature

Performance verification 1-27 verifying temperature thermocouple, thermistor, and rtd temperature readings are derived from dc volts and resistance measurements respectively. For that reason, it is not necessary to independently ver- ify the accuracy of temperature measurements. As long as the dc vo...

Page 44

1-28 performance verification 5. Source each of the voltages summarized in table 1-14 and verify that the temperature readings are within limits. Be sure to select the appropriate thermocouple type for each group of readings. (see step 3 above.) open channel 1 after the test is complete. Figure 1-14...

Page 45

Performance verification 1-29 rtd temperature 1. Connect the precision decade resistance box (listed in table 1-1 ) to the model 7700 ch1 and ch11 h and l terminals using four-wire connections. (see figure 1-12 for similar connecting scheme.) 2. Install the model 7700 in slot 1 of the model 2700, th...

Page 46: Verifying Frequency

1-30 performance verification verifying frequency follow the steps below to verify the model 2700 frequency function: 1. Connect the function generator to the model 7700 ch1 h and l input terminals. (see figure 1-15 .) 2. Install the model 7700 in slot 1 of the model 2700, then turn on the power, an...

Page 47

Performance verification 1-31 4. Select the model 2700 ratio function (press shift then ratio). 5. Set the calibrator output to 1.00000v dc, and allow the reading to settle. 6. Verify that the ratio reading is between 0.9999926 and 1.000074. 7. Press open to open channel 1. Figure 1-16 connections f...

Page 48

1-32 performance verification.

Page 49

2 calibration.

Page 50: Introduction

2-2 calibration introduction use the procedures in this section to calibrate the model 2700. Calibration procedures include: • comprehensive calibration: usually the only calibration required in the field. • manufacturing calibration: usually only performed at the factory (unless the unit has been r...

Page 51: Calibration Considerations

Calibration 2-3 calibration considerations when performing the calibration procedures: • make sure that the equipment is properly warmed up and connected to the appropriate input jacks. Also make sure that the correct front or rear terminals are selected with the inputs switch. • make sure the calib...

Page 52: Calibration Code

2-4 calibration calibration code before performing comprehensive calibration, you must first unlock calibration by entering the appropriate calibration code. Front panel calibration code for front panel calibration, follow these steps: 1. Access the calibration menu by pressing shift then test, then...

Page 53: Comprehensive Calibration

Calibration 2-5 comprehensive calibration the comprehensive calibration procedure calibrates the dcv, dci, acv, aci, and ohms functions. You can also choose to calibrate only the dcv/dci and resistance or acv/aci functions. These procedures are usually the only calibration required in the field. Man...

Page 54: Aborting Calibration

2-6 calibration aborting calibration you can abort the front panel calibration process at any time by pressing exit. The instru- ment will then ask you to confirm your decision to abort with the following message: abort cal? Press exit to abort calibration at this point, or press any other key to re...

Page 55

Calibration 2-7 3. Choose which of the calibration tests summarized in table 2-2 you want to run at the cal: run prompt. Use the up and down range keys to scroll through the options; select your choice by pressing enter. Front panel short and open calibration at the model 2700 prompt for a front pan...

Page 56

2-8 calibration 2. Press enter to start short-circuit calibration. While the unit is calibrating, it will display: calibrating 3. When the unit is finished with short-circuit calibration, it will display the following prompt: open circuit 4. Remove the calibration short, and press enter. During this...

Page 57

Calibration 2-9 3. Perform the steps listed in table 2-3 to complete dc volts calibration. For each calibra- tion step: • set the calibrator to the indicated value, and make sure it is in operate. • press the enter key to calibrate that step. • wait until the model 2700 finishes each step. (the unit...

Page 58

2-10 calibration dc current calibration after the 1m Ω resistance point has been calibrated, the unit will prompt you to apply 10ma. Follow these steps for dc current calibration: 1. Connect the calibrator to the amps and input lo terminals of the model 2700 as shown in figure 2-3 . Figure 2-3 conne...

Page 59

Calibration 2-11 ac voltage calibration follow these steps for ac voltage calibration: 1. Connect the calibrator to the model 2700 input hi and lo terminals as shown in figure 2-4 . Figure 2-4 connections for ac volts calibration 2. Perform the calibration steps summarized in table 2-6 . For each st...

Page 60

2-12 calibration ac current calibration after the 700vac at 1khz point has been calibrated, the unit will prompt you for 100ma at 1khz. Follow these steps for ac current calibration: 1. Connect the calibrator to the amps and input lo terminals of the model 2700 as shown in figure 2-3 . 2. Perform th...

Page 61: Remote Calibration

Calibration 2-13 remote calibration follow the steps in this section to perform comprehensive procedures via remote. See appendix b for a detailed list and description of remote calibration commands. When sending calibration commands, be sure that the model 2700 completes each step before sending th...

Page 62

2-14 calibration short and open calibration 1. Connect the model 8610 low-thermal short to the instrument input and sense termi- nals as shown in figure 2-1 . Make sure the inputs button is not pressed in so that the front inputs are active. Wait at least three minutes before proceeding to allow for...

Page 63

Calibration 2-15 2. Perform the calibration steps summarized in table 2-8 . For each step: • set the calibrator to the indicated voltage, and make sure the unit is in operate. (use the recommended voltage if possible.) • send the indicated programming command. (change the voltage parameter if you ar...

Page 64

2-16 calibration dc current calibration after the 1m Ω resistance point has been calibrated, follow these steps for dc current calibration: 1. Connect the calibrator to the amps and input lo terminals of the model 2700 as shown in figure 2-3 . 2. Perform the calibration steps listed in table 2-10 . ...

Page 65

Calibration 2-17 ac current calibration follow these steps for ac current calibration: 1. Connect the calibrator to the amps and input lo terminals of the model 2700 as shown in figure 2-3 . 2. Perform the calibration steps summarized in table 2-12 . For each step: • set the calibrator to the indica...

Page 66: Manufacturing Calibration

2-18 calibration saving calibration constants after completing the calibration procedure, send the following command to save the new calibration constants: :cal:prot:save note calibration constants will not be saved unless the :cal:prot:save command is sent. Locking out calibration after saving cali...

Page 67: Extender Board Preparation

Calibration 2-19 extender board preparation before performing manufacturing calibration, short the output hi, lo, shi, and slo terminals of the 7798-250b calibration/extender/test board together using clean, solid copper wires. These connections will form a low-thermal short necessary for the manufa...

Page 68

2-20 calibration front panel manufacturing calibration 1. Install the shorted calibration extender board (see “extender board preparation” earlier in this section) in scanner card slot 1, and select the rear inputs with the inputs switch. Allow three minutes for thermal equilibrium. 2. Press in and ...

Page 69

Calibration 2-21 remote manufacturing calibration 1. Install the shorted calibration extender board (see “extender board preparation” earlier in this section) in scanner card slot 1, and select the rear inputs with the inputs switch. Allow three minutes for thermal equilibrium. 2. Press in and hold ...

Page 70: Model 7700 Calibration

2-22 calibration model 7700 calibration the following procedures calibrate the temperature sensors on the model 7700 plug-in modules. Note for additional information about the keithley modules, refer to the appropriate appendix in the model 2700 user’s manual. Recommended test equipment in order to ...

Page 71

Calibration 2-23 5. Press shift then test, then display test:calib with the up or down range key. Press enter, select run, then enter the appropriate calibration code (default: 002700). 6. Using the up or down range key, select card at the cal:run prompt, then press enter. 7. Set the display value t...

Page 72

2-24 calibration.

Page 73

3 routine maintenance.

Page 74: Introduction

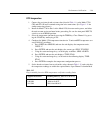

3-2 routine maintenance introduction the information in this section deals with routine type maintenance and includes procedures for setting the line voltage, replacing the model 2700 line and front terminal amps fuses, and replacing the amps fuses for the models 7700 and 7702 plug-in modules. Repla...

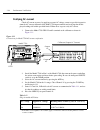

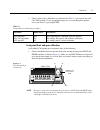

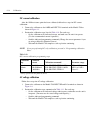

Page 75

Routine maintenance 3-3 table 3-1 power line fuse line voltage rating keithley part no. 100/120v 1/2a, 250v, 5 × 20 mm, slow-blow fu-71 200/240v 1/4a, 250v, 5 × 20 mm, slow-blow fu-96-4 model 2700 digital i/o trig. Link rs232 fuse spring window line voltage selector fuse holder assembly warning: no ...

Page 76

3-4 routine maintenance replacing the front terminal amps fuse the front terminal amps fuse protects the model 2700 current input from an over-current condition. Follow the steps below to replace the amps fuse. Warning make sure the instrument is disconnected from the power line and other equipment ...

Page 77

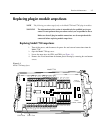

Routine maintenance 3-5 replacing plug-in module amps fuses note the following procedures apply only to the model 7700 and 7702 plug-in modules. Warning the information in this section is intended only for qualified service per- sonnel. Do not perform these procedures unless you are qualified to do ...

Page 78

3-6 routine maintenance 5. De-solder the blown ch21 or ch22 fuse as required, taking care not to damage the cir- cuit board or spread solder flux around the board. 6. Install a new 3a, 250v fast-blow fuse, keithley part number fu-107-1. Caution do not use a fuse with a higher current rating than spe...

Page 79

Routine maintenance 3-7 figure 3-4 model 7702 amps fuses ch42 fuse ch41 fuse model 7702 te122 te121.

Page 80

3-8 routine maintenance replacing non-volatile ram battery the model 2700 has a three year battery for non-volatile ram. Use the procedure below to replace the battery, if required. Refer to the disassembly procedures in section 5 and the parts list and component layout drawings at the end of sectio...

Page 81

4 troubleshooting.

Page 82: Introduction

4-2 troubleshooting introduction this section of the manual will assist you in troubleshooting and repairing the model 2700. Included are self-tests, test procedures, troubleshooting tables, and circuit descriptions. It is left to the discretion of the repair technician to select the appropriate tes...

Page 83: Front Panel Tests

Troubleshooting 4-3 front panel tests there are two front panel tests: one to test the functionality of the front panel keys and one to test the display. In the event of a test failure, refer to “display board checks” for details on troubleshooting the display board. Key test the key test allows you...

Page 84: Principles of Operation

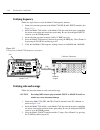

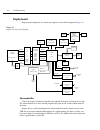

4-4 troubleshooting principles of operation the following information is provided to support the troubleshooting tests and procedures covered in this section of the manual. Refer to the following block diagrams: figure 4-1 — power supply block diagram figure 4-2 — digital circuitry block diagram fig...

Page 85

Troubleshooting 4-5 ac power is applied to the ac power module receptacle. Power is routed through the line fuse and line voltage selection switch of the power module to the power transformer. The power transformer has a total of four secondary windings for the various supplies. Ac voltage for the d...

Page 86: Display Board

4-6 troubleshooting display board display board components are shown in the digital circuitry block diagram in figure 4-2 . Figure 4-2 digital circuitry block diagram microcontroller u401 is the display board microcontroller that controls the display and interprets key data. The microcontroller uses...

Page 87: Digital Circuitry

Troubleshooting 4-7 display ds401 is the display module, which can display up to 12 alpha-numeric characters and includes the various annunciators. The display uses a common multiplexing scheme with each character refreshed in sequence. U402 and u403 are the drivers for the display characters and an...

Page 88: Analog Circuitry

4-8 troubleshooting rs-232 interface serial data transmission and reception is performed by the txdb and rxdb lines of the mpu. U159 provides the necessary voltage level conversion for the rs-232 interface port. Ieee-488 interface u158, u160, and u161 make up the ieee-488 interface. U158, a 9914a gp...

Page 89

Troubleshooting 4-9 figure 4-3 analog circuitry block diagram input hi input hi protection is provided by the ssp (solid state protection) circuit. The ssp is pri- marily made up of q101 and q102. An overload condition opens q101 and q102, which dis- connects the analog input signal from the rest of...

Page 90

4-10 troubleshooting amps input the aca or dca input signal is applied to the current shunt circuit, which is made up of k103, r158, r205, and r338. For the 20ma dc range, 5.1 Ω (r205/[r338 + r158]) is shunted across the input. Relay k103 is energized (set state) to select the shunts. For all other ...

Page 91: Troubleshooting

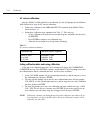

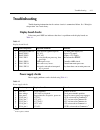

Troubleshooting 4-11 troubleshooting troubleshooting information for the various circuits is summarized below. See “principles of operation” for circuit theory. Display board checks if the front panel disp test indicates that there is a problem on the display board, use table 4-2 . Power supply chec...

Page 92: Digital Circuitry Checks

4-12 troubleshooting digital circuitry checks digital circuit problems can be checked using table 4-4 . Table 4-4 digital circuitry checks step item/component required condition remarks 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 power-on test u152, pin 16 u171, pin 16 u171, pin 15 u171, pin 4 u...

Page 93

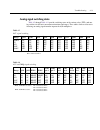

Troubleshooting 4-13 analog signal switching states table 4-5 through table 4-11 provide switching states of the various relays, fets, and ana- log switches for the basic measurement functions and ranges. These tables can be used to assist in tracing an analog signal from the input to the a/d multip...

Page 94

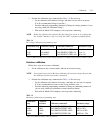

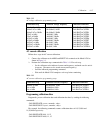

4-14 troubleshooting table 4-7 Ω2 signal switching range q101 q102 q114 q136 q109 k101* k102* q113 q105 q104 q108 100 Ω 1k Ω 10k Ω 100k Ω 1m Ω 10m Ω 100m Ω on on on on on on on on on on on on on on off off off off off off off off off off off off off off off off off off off on on set set set set set ...

Page 95

Troubleshooting 4-15 table 4-10 dca signal switching range k103 20ma 100ma 1a 3a set reset reset reset k103 set states: pin 8 to 7 pin 3 to 4 k103 reset states: pin 8 to 9 pin 3 to 2 table 4-11 aca signal switching range k103 u105 pin 16 u105 pin 1 u111 pin 16 u105 pin 8 u103 pin 16 u103 pin 1 1a 3a...

Page 96

4-16 troubleshooting table 4-12 through table 4-16 can be used to trace the analog signal through the a/d multi- plexer (u163) to the final amplifier stage. These tables show the mux lines (s3, s4, s6, s7) that are selected for measurement during the signal phase of the multiplexing cycle. Also incl...

Page 97

Troubleshooting 4-17 figure 4-3 provides a block diagram of the analog circuitry. Table 4-17 shows where the var- ious switching devices are located in the block diagram. Table 4-15 Ω2 signal multiplexing and gain range signal (u163) u129 pin 1 u129 pin 8 u129 pin 9 gain (u166) 100 Ω 1k Ω 10k Ω 100k...

Page 98: No Comm Link Error

4-18 troubleshooting no comm link error a “no comm link” error indicates that the front panel processor has ceased communication with the main processor, which is located on the motherboard. This error indicates that there may be a problem with the cable connection from the front panel display or on...

Page 99

5 disassembly.

Page 100: Introduction

5-2 disassembly introduction this section explains how to handle, clean, and disassemble the model 2700 multimeter/ data acquisition system. Disassembly drawings are located at the end of this section. Handling and cleaning to avoid contaminating pc board traces with body oil or other foreign matter...

Page 101: Static Sensitive Devices

Disassembly 5-3 static sensitive devices cmos devices operate at very high impedance levels. Therefore, any static that builds up on you or your clothing may be sufficient to destroy these devices if they are not handled properly. Use the following precautions to avoid damaging them: caution many cm...

Page 102: Disassembly Procedures

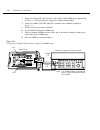

5-4 disassembly disassembly procedures case cover removal follow the steps below to remove the case cover to gain access to internal parts. Warning before removing the case cover, disconnect the line cord and any test leads from the instrument. 1. Remove handle — the handle serves as an adjustable t...

Page 103: Card Cage Removal

Disassembly 5-5 3. Disconnect the front input terminals. You must disconnect these input terminal connections: • input hi and lo • sense hi and lo • amps remove all the connections except the front amps connection by pulling the wires off the pin connectors. To remove the front panel amps input wire...

Page 104: Front Panel Disassembly

5-6 disassembly front panel disassembly use the following procedures to remove the display board and/or the pushbutton switch pad: note you must first remove the case cover, the front/rear input switch, and the front input terminal wires as described earlier in this section. 1. Unplug the display bo...

Page 105: Instrument Reassembly

Disassembly 5-7 instrument reassembly reassemble the instrument by reversing the previous disassembly procedures. Make sure that all parts are properly seated and secured, and that all connections are properly made. To ensure proper operation, replace and securely fasten the shield. Warning to ensur...

Page 106

5-8 disassembly.

Page 107

6 replaceable parts.

Page 108: Introduction

6-2 replaceable parts introduction this section contains replacement parts information and component layout drawings for the model 2700, model 7700, model 7702, model 7703, and model 7705. Note for additional information about the keithley modules, refer to the appropriate appendix in the model 2700...

Page 109

Replaceable parts 6-3 table 6-1 model 2700 motherboard parts list circuit designation description keithley part no. Bt100 l1 battery, 3.6v, 950mah ba-51 c102 cap, 0.01uf, 10%, 1000v, ceramic c-64-.01 c104 cap, 100uf, 20%, 63v, alum elec c-403-100 c105 cap, 0.22uf, 20%, 400v, film c-513-.22 c106,c291...

Page 110

6-4 replaceable parts cr106 diode, bridge, pe05 rf-48 cr110,cr118 diode, dual hsm-2822t31 rf-95 cr111,112,115-117,126 diode, dual switching, bav99l rf-82 cr114,cr119 diode, switching, mmbd914 rf-83 cr120,cr122,cr125 diode, dual common anode baw56lt2 rf-98 ds101,ds102 pilot lig, hsmh-t400, led pl-92-...

Page 111

Replaceable parts 6-5 r123 res, 73.2k, 1%, 100mw, thick film r-418-73.2k r126,r128,r185,r275 res, 475, 1%, 125mw, metal film r-391-475 r129 res, 215, 1%, 100mw, thick film r-418-215 r130,r177,r183,r186,r191,r193,r315, r154 res, 100k, 1%, 100mw, thick film r-418-100k r131,136,138,141,161,178,179,180,...

Page 112

6-6 replaceable parts r241 res, 34k, 1%, 100mw, thick film r-418-34k r243 res, 10, 10%, 100mw, thick film r-418-10 r246 res, 82.5, 1%, 100mw, thick film r-418-82.5 r249 res, 4.02k, 1%, 100mw, thick film r-418-4.02k r256,r284,r288,r298,r299,r334,340, 341,r340 res, 1k, 1%, 100mw, thick film r-418-1k r...

Page 113

Replaceable parts 6-7 u106,u109,u121,u130,u134 ic, 8 stage shift/store, mc14094bd ic-772 u107,u108 ic, photo, darlington trans, ps2506l-1 ic-911 u110 ic, trms to dc converter 637jr ic-796 u112 ic, j-fet op-amp lf357m ic-966 u113,u126 ic, op-amp, ltc1050cs8 ic-791 u114,u167 ic, dual j-fet op-amp, op-...

Page 114

6-8 replaceable parts u182 ic, retrig., multivib, 74hc123am ic-788 u187 ic, microprocessor reset max809leurt ic-1297 u188,u189 ic, protected quad power drivers ic-1212 u191 ic, tinylogic cmos inverter ic-1282 u192 ic, 2 - input and gate ic-1140 vr102 diode, zener, 6.0v, bzx84b6v2 dz-87 vr103,vr104 d...

Page 115

Replaceable parts 6-9 table 6-3 model 2700 connector board parts list circuit designation description keithley part no. J1009 conn, male, 3-pin cs-612-1 j1011 conn, female, 8-pin cs-612-8 j1013 conn, rt angle header cs-1066-1 j1015,j1016 conn 2 rows of 16 pins cs-736-4 l601,l602 ferrite chip, 600 oh...

Page 116

6-10 replaceable parts table 6-4 model 2700 miscellaneous parts list qty description keithley part no. 2 banana jack, push-in black bj-14-0 2 banana jack, push-in red bj-14-2 1 bezel, rear 428-303d 1 cable assembly ca-219-1a 1 cable clamp cc-37 2 captive panel screw fa-232-1c 1 card cage 2700-318a 1...

Page 117

Replaceable parts 6-11 table 6-5 model 7700 parts list circuit designation description keithley part no. C1,c9,c10,c11,c14,c15,c22,c4 cap, 0.1uf, 20%, 50v, ceramic c-418-.1 c16 cap, 220u, 20%, 10v, tantalum c-558-220 c17,c18,c19,c21,c25,c26,c23,c24,c15 cap, 47p, 5%, 100v, ceramic c-465-47p c2,c6,c7,...

Page 118

6-12 replaceable parts table 6-6 model 7702 parts list circuit designation description keithley part no. C1,c3,c9,c10,c11,c12,c13,c14 cap, 0.1uf, 20%, 50v, ceramic c-418-.1 c16 cap, 220u, 20%, 10v, tantalum c-558-220 c17,c18,c19,c20,c21,c22,c23,c24,c2,c6 cap, 47p, 5%, 100v, ceramic c-465-47p c25 cap...

Page 119

Replaceable parts 6-13 table 6-7 model 7703 parts list circuit designation description keithley part no. C1,c9,c20,c2,c23,c24,c25,c26,c27 cap, 47p, 5%, 100v, ceramic c-465-47p c22 cap, 4.7u, 10%, 35v, tantalum c-476-4.7 c3,c4-c8, c10-c14,c19,c21 cap, 0.1uf, 20%, 50v, ceramic c-418-.1 cr1,cr2 ultrafa...

Page 120

6-14 replaceable parts table 6-8 model 7705 parts list circuit designation description keithley part no. C100 cap, 4.7u, 10%, 35v, tantalum c-476-4.7 c102,106,107,108,109,110,111,121,101 cap, 0.1uf, 5%, 100v, ceramic c-465-.1 c103 cap, 220u, 20%, 10v, tantalum c-558-220 c104,c105,c112-c120 cap, 47p,...

Page 121

A specifications.

Page 122

A-2 specifications dc characteristics 1 conditions: med (1 plc) 2 or 10 plc or med (1 plc) with digital filter of 10 accuracy: ±(ppm of reading + ppm of range) input (ppm = parts per million) test current resistance (e.G., 10ppm = 0.001%) temperature or burden or open ckt. 24 hour 4 90 day 1 year co...

Page 123

Specifications a-3 dc speed vs. Noise rejection rms noise rate filter readings/s 12 digits 10v range nmrr cmrr 14 10 50 0.1 (0.08) 6.5 110 db 13 140 db 1 off 15 (12) 6.5 90 db 13 140 db 0.1 off 500 (400) 5.5 — 80 db 0.01 off 2000 (1800) 4.5 — 80 db dc operating characteristics 15 60hz (50hz) operati...

Page 124

A-4 specifications dc measurement characteristics dc volts a-d linearity: 2.0 ppm of reading + 1.0 ppm of range. Input impedance: 100mv–10v ranges: selectable >10g Ω // with Ω ±1%. 100v, 1000v ranges: 10m Ω ±1%. Input bias current: common mode current: autozero error: add ±(2ppm of range error + 5µv...

Page 125

Specifications a-5 ac specifications 1 accuracy: ±(% of reading + % of range), 23°c ± 5°c calibration 3 hz– 10 hz– 20 khz– 50 khz– 100 khz– function range resolution cycle 10 hz 20 khz 50 khz 100 khz 300 khz voltage 2 100.0000 mv 0.1 µv 90 days 0.35 + 0.03 0.05 + 0.03 0.11 + 0.05 0.6 + 0.08 4.0 + 0....

Page 126

A-6 specifications ac operating characteristics 7 60hz (50hz) operation function digits readings/s rate bandwidth acv, aci 6.5 8 2s/reading slow 3 hz–300 khz 6.5 8 1.4 (1.1) med 30 hz–300 khz 6.5 9 4.8 (4) med 30 hz–300 khz 6.5 9 35 (28) fast 300 hz–300 khz frequency, 6.5 1 (1) slow 3 hz–300 khz per...

Page 127

Specifications a-7 general specifications: power supply: 100v / 120v / 220v / 240v ±10%. Line frequency: 45hz to 66hz and 360hz to 440hz, automatically sensed at power-up. Power consumption: 28va. Operating environment: specified for 0°c to 50°c. Specified to 80% rh at 35°c. Storage environment: –40...

Page 128

A-8 specifications cold junction ref x3 channel 1 hi lo channel 10 hi lo (channels 2–9) channel 11 hi lo channel 20 hi lo (channels 12–19) channel 21 hi lo channel 22 hi lo amps hi lo sense hi lo input channel 23 2-pole (open) 4-pole (closed) (see note) 3a 3a to model 2700 backplane channel 25 (see ...

Page 129

Specifications a-9 general 40 channels: 40 channels of 2-pole relay input. All channels configurable to 4-pole. 2 channels: 2 channels of current only input. Relay type: latching electromechanical. Actuation time: capabilities channels 1-40: multiplex one of 40 2-pole or one of 20 4-pole signals int...

Page 130

A-10 specifications general 32 channels: 32 channels of 2-pole relay input. All channels configurable to 4-pole. Relay type: reed. Actuation time: capabilities channels 1-32: multiplex one of 32 2-pole or one of 16 4-pole signals into dmm. Inputs maximum signal level: channels (1-32): 300v dc or rms...

Page 131

Specifications a-11 general relay switch configuration: 40 independent channels of 1- pole switching. Isolated from internal dmm. Contact configuration: 1 pole form a. Relay type: latching electromechanical. Connector type: two 50-pin female d-sub connectors. Inputs maximum signal level: 300vdc or r...

Page 132: Accuracy Calculations

A-12 specifications accuracy calculations the information below discusses how to calculate accuracy for both dc and ac characteristics. Calculating dc characteristics accuracy dc characteristics accuracy is calculated as follows: accuracy = ±(ppm of reading + ppm of range) (ppm = parts per million, ...

Page 133

Specifications a-13 calculating dbm characteristics accuracy as an example of how to calculate the actual reading limits for a 13dbm measurement with a reference impedance of 50 Ω, assume an applied signal 0.998815v. The relationship between voltage and dbm is as follows: from the previous example o...

Page 134: Additional Derating Factors

A-14 specifications thus, the actual reading accuracy is 10mv ±36mv or 10.036mv to 9.964mv. Applying the voltage reading accuracy into the db equation yields: thus, the actual reading accuracy is -60db + 0.031213db to -60db - 0.031326db. Dbm and db for other voltage inputs can be calculated in exact...

Page 135: Optimizing Measurement Speed

Specifications a-15 optimizing measurement speed the configurations listed below assume that the multimeter has had factory setups restored. Dc voltage, dc current, and resistance: • select 3-1/2 digits, 0.01 plc, filter off, fixed range. Ac voltage and ac current: • select 3-1/2 digits, 0.01 plc, f...

Page 136

A-16 specifications.

Page 137

B calibration reference.

Page 138: Introduction

B-2 calibration reference introduction this appendix contains detailed information about the various model 2700 remote calibra- tion commands. Section 2 of this manual covers detailed calibration procedures. For informa- tion about additional commands to control other instrument functions, refer to ...

Page 139

Calibration reference b-3 command description :calibration :protected :dc :step10 10ma dc step. :step11 100ma dc step. :step12 1a dc step. :ac ac cal steps. :step1 10mv ac at 1khz step. :step2 100mv ac at 1khz step. :step3 100mv ac at 50khz step. :step4 1v ac at 1khz step. :step5 1v ac at 50khz step...

Page 140: :code

B-4 calibration reference miscellaneous calibration commands miscellaneous commands perform miscellaneous calibration functions such as program- ming the calibration code and date. These commands are discussed in detail in the following paragraphs. :code (:calibration:protected:code) purpose to prog...

Page 141: :init

Calibration reference b-5 :init (:calibration:protected:initiate) purpose to initiate comprehensive and factory calibration procedures. Format :cal:prot:init parameter none description the :init command enables model 2700 calibration when performing these procedures over the bus. This command must b...

Page 142: :lock?

B-6 calibration reference :lock? (:calibration:protected:lock?) purpose to read comprehensive calibration lock status. Format :cal:prot:lock? Response 0 comprehensive calibration locked. 1 comprehensive calibration unlocked. Description the :lock? Query requests status from the model 2700 on calibra...

Page 143: :date

Calibration reference b-7 :date (:calibration:protected:date) purpose to send the calibration date to the instrument. Format :cal:prot:date , , parameter = 1999 to 2098 = 1 to 12 = 1 to 31 query format :cal:prot:date? Response , , description the :date command allows you to store the calibration dat...

Page 144: Dc Calibration Commands

B-8 calibration reference dc calibration commands the :dc commands perform calibration of the dcv, dci, and ohms functions. Table b-2 summarizes these calibration commands along with parameter limits. :step1 (:calibration:protected:dc:step1) purpose to perform front terminal short-circuit calibratio...

Page 145: :step2

Calibration reference b-9 :step2 (:calibration:protected:dc:step2) purpose to perform front terminal open-circuit calibration. Format :cal:prot:dc:step2 parameter none description :step2 performs the open-circuit calibration step in the comprehensive calibration procedure. Disconnect all cables and ...

Page 146: :step5

B-10 calibration reference :step5 (:calibration:protected:dc:step5) purpose to program the 100v dc comprehensive calibration step. Format :cal:prot:dc:step5 parameter = 90 to 110 [v] description :step5 programs the 100v dc comprehensive calibration step. The allowable range of the calibration voltag...

Page 147: :step8

Calibration reference b-11 :step8 (:calibration:protected:dc:step8) purpose to program the 100k Ω 4-wire comprehensive calibration step. Format :cal:prot:dc:step8 parameter = 90e3 to 110e3 [ Ω] description :step8 programs the 100k Ω 4-wire resistance comprehensive calibration step. The allowable ran...

Page 148: :step11

B-12 calibration reference :step11 (calibration:protected:dc:step11) purpose to program the 100ma comprehensive calibration step. Format :cal:prot:dc:step11 parameter = 90e-3 to 110e-3 [a] description :step11 programs the 100ma comprehensive calibration step. The allow- able range of the calibration...

Page 149: Ac Calibration Commands

Calibration reference b-13 ac calibration commands the :ac commands perform comprehensive (user) calibration of the acv and aci func- tions. Table b-3 summarizes these calibration commands. Table b-3 ac calibration commands command description :calibration :protected :ac :step1 10mv ac at 1khz calib...

Page 150: :ac:step

B-14 calibration reference :ac:step (calibration:protected:ac:step) purpose to program individual ac calibration steps. Format :cal:prot:ac:step parameter 1 10mv ac at 1khz calibration step. 2 100mv ac at 1khz calibration step. 3 100mv ac at 50khz calibration step. 4 1v ac at 1khz calibration step. ...

Page 151: :ac:step

Calibration reference b-15 manufacturing calibration commands three calibration steps are only performed at the factory or when the unit has been repaired: :calibration:protected:ac:step14 1v ac at 3hz :calibration:protected:ac:step15 1v ac at 1khz :calibration:protected:dc:step0 rear scanner termin...

Page 152

B-16 calibration reference model 7700 calibration commands table b-4 summarizes calibration commands for the model 7700 plug-in module. Note that card1 commands calibrate the card in slot 1, while card2 commands request calibration count and date information from a card in slot 2. Note a model 7700 ...

Page 153: :code

Calibration reference b-17 :code (:calibration:protected:code) purpose to program the calibration code or password so that you can perform the model 7700 calibration procedures. Format :cal:prot:code '' parameter up to a 8-character string including letters and numbers. Description the :code command...

Page 154: :date?

B-18 calibration reference :date? (:calibration:protected:card1:date?) (:calibration:protected:card2:date?) purpose to request the model 7700 calibration date. Format :cal:prot:card1:date? :cal:prot:card2:date? Response , , description the :card1:date? And :card2:date? Queries allow you to read back...

Page 155: :lock

Calibration reference b-19 :lock (:calibration:protected:card1:lock) purpose to lock out model 7700 calibration. Format :cal:prot:card1:lock parameter none description the :lock command allows you to lock out model 7700 calibration after completing the procedure. Thus, :lock performs the opposite of...

Page 156: :save

B-20 calibration reference :save (:calibration:protected:card1:save) purpose to save calibration constants in card eerom after the calibration procedure. Format :cal:prot:card1:save parameter none description the :save command stores calculated calibration constants derived dur- ing model 7700 calib...

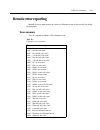

Page 157: Remote Error Reporting

Calibration reference b-21 remote error reporting methods to detect and determine the nature of calibration errors are discussed in the follow- ing paragraphs. Error summary table b-5 summarizes model 2700 calibration errors. Table b-5 calibration error summary error number and description +400, "10...

Page 158

B-22 calibration reference +451, "1 vac dac error" +452, "10 vac dac error" +453, "100 vac dac error" +454, "100m vac zero error" +455, "100m vac full scale error" +456, "1 vac zero error" +457, "1 vac full scale error" +458, "1 vac noise error" +459, "10 vac zero error" +460, "10 vac full scale err...

Page 159: Error Queue

Calibration reference b-23 error queue as with other model 2700 errors, any calibration error will be reported in the bus error queue. You can read this queue by using the :syst:err? Query. The model 2700 will respond with the appropriate error message, as summarized in table b-5 . Status byte eav (...

Page 160: Using The *opc Command

B-24 calibration reference using the *opc command the *opc (operation complete) command can also be used to detect the completion of each calibration step. To use *opc to detect the end of each calibration step, you must do the following: 1. Enable operation complete by sending *ese 1. This command ...

Page 161

C calibration program appendix c page 1 friday, february 18, 2000 7:45 am.

Page 162: Introduction

C-2 calibration program introduction this appendix includes a calibration program written in basic to help you calibrate the model 2700. Refer to section 2 for more details on calibration procedures, equipment, and connections. Computer hardware requirements the following computer hardware is requir...

Page 163: General Program Instructions

Calibration program c-3 general program instructions 1. With the power off, connect the model 2700 and the calibrator to the ieee-488 inter- face of the computer. Be sure to use shielded ieee-488 cables for bus connections. 2. Turn on the computer, the model 2700, and the calibrator. Allow the model...

Page 164

C-4 calibration program select case i ' select cal sequence. Case 1, 2 print msg$ gosub keycheck case 3 print "connect calibrator to input and sense jacks." print "wait 3 minutes." gosub keycheck print #1, "output 4;extsense off" print #1, "output 4;"; msg$ print #1, "output 4;oper" case 4, 5, 11, 1...

Page 165

Calibration program c-5 keycheck: ' check for key press routine. While inkey$ "": wend ' flush keyboard buffer. Print : print "press any key to continue (esc to abort program)." do: i$ = inkey$: loop while i$ = "" if i$ = chr$(27) then goto endprog ' abort if esc is pressed. Return ' calend: ' check...

Page 166

C-6 calibration program data "out 10 mv,1 khz","ac:step1" data "out 100 mv,1 khz","ac:step2" data "out 100 mv,50 khz","ac:step3" data "out 1 v,1 khz","ac:step4" data "out 1 v,50 khz","ac:step5" data "out 10 v,1 khz","ac:step6" data "out 10 v,50 khz","ac:step7" data "out 100 v,1 khz","ac:step8" data ...

Page 167: Index

Index :ac:step b-14 , b-15 :code b-4 , b-17 :count? B-4 , b-17 :date b-7 :date? B-18 :dc:step0 b-15 :init b-5 , b-18 :lock b-5 , b-19 :lock? B-6 , b-19 :ndue b-7 :rcount b-19 :save b-6 , b-20 :step0 b-20 :step1 b-8 :step10 b-11 :step11 b-12 :step12 b-12 :step2 b-9 :step3 b-9 :step4 b-9 :step5 b-10 :...

Page 168

Connections ac volts calibration 2-11 dc and ac amps calibration 2-10 dc volts and ohms calibration 2-8 input terminal wire 5-7 manufacturing calibration 2-20 model 2700 ac current verification 1-12 model 2700 ac volts verification 1-9 model 2700 dc current verification 1-11 model 2700 dc volts veri...

Page 169

Introduction calibration 2-2 calibration program c-2 calibration reference b-2 disassembly 5-2 performance verification 1-2 replaceable parts 6-2 routine maintenance 3-2 troubleshooting 4-2 k key matrix 4-7 key test 4-3 l limits aci, model 2700 1-12 dci, model 2700 1-11 plug-in module aci, model 770...

Page 170

Remote calibration 2-13 ac current 2-17 ac voltage 2-16 command summary b-2 dc current 2-16 dc volts 2-14 locking out calibration 2-18 preparing the model 2700 2-13 programming calibration dates 2-17 resistance 2-15 saving calibration constants 2-18 short and open 2-14 remote error reporting b-21 re...

Page 171: Service Form

Service form model no. _______________ serial no. __________________ date _________________ name and telephone no. ____________________________________________________ company _______________________________________________________________________ list all control settings, describe problem and chec...

Page 172

Service.Fm page 2 friday, february 18, 2000 7:44 am.

Page 174

Keithley instruments, inc. 28775 aurora road cleveland, ohio 44139 printed in the u.S.A..