- DL manuals

- Kelvinator

- Freezer

- 10DF-13

- Service & Installation Manual

Kelvinator 10DF-13 Service & Installation Manual

Summary of 10DF-13

Page 1

Service & installation manual chest freezers 51-1371-04 by national refrigeration products.

Page 2

Important information is contained in this manual which should be retained in a convenient location for future reference. All data and information in this manual is subject to change without notice. Model designation information 115v, 60hz part no. Models 52-1904-21 2sf-13 52-1904-22 4sf-13 52-1904-...

Page 3: Ice Cream Cabinets

Section i general maintenance & repair ice cream cabinets except for routine cleaning, these chest freezers require little maintenance. In the unusual event that repair should be necessary, this manual pre- sents information that is helpful in maintaining, diagnosing, and repairing these cabinets..

Page 4: Table of Contents

Table of contents general maintenance & repair installation/operation .......................................................... 3 grounding instructions ...................................................... 4 cleaning instructions .......................................................... 5 defros...

Page 5: Record For Service

Installation & operation instructions these instructions include information which is intended to assure the operator of correct installation, operation, and service. Before attempting installation, adjustment or maintenance, be certain of the following: 1. That you have read and fully understand th...

Page 6: Grounding Instructions

Grounding instructions this appliance is equipped with a three-prong (ground- ing) plug for your protection against shock hazards. The appliance should be plugged directly into a properly grounded three-prong receptacle. Where a two-prong wall receptacle is encountered, it must be replaced with a pr...

Page 7: Cleaning Instructions

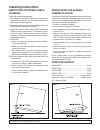

Fig. 2 cleaning instructions directions for proper care & cleaning 1. Wipe up spilled foods promptly. 2. Use lukewarm detergent solution for cleaning the cabinet interior, exterior, and lids. Follow with a clean, damp cloth and then wipe dry. 3. Protect the exterior enamel finish and plastic lid fra...

Page 8: Defrosting Instructions

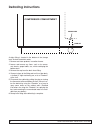

Defrosting instructions a drain fitting is located in the bottom of the storage tank. To drain the defrost water: 1. Remove and store products in another freezer. 2. Loosen and remove any items such as ice cream, nuts, berries, paper labels, etc., which could plug the bottom drain. 3. Remove the cap...

Page 9: Specifications -

Specifications - specifications subject to change without notice. Di4 2sf 4df 4sf compressor mount front front front front temperature range 0° to -20°f (-18° to -29°c) 0° to -25° 0° to -25° 0° to -20° number of lids 2 2 2 4 lid construction stainless steel, high density, high density, foamed-in-pla...

Page 10: Specifications -

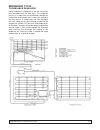

8 6df / 8df / 10df / 14df specifications specifications - specifications subject to change without notice. 6df 8df 10df 14df compressor mount front front front front temperature range 0° to -20°f 0° to -20° 0° to -20° 0° to -25° number of lids 4 4 6 8 lid construction high density, foamed-in-place h...

Page 11: Specifications -

8fr specifications 9 specifications - specifications subject to change without notice. 8fr compressor mount front temperature range 0° to -20°f number of lids 2 lid construction high density, foamed-in-place insulation w/ vinyl gaskets hinge type continuous composition insulation polyurethane foam w...

Page 12: Operation - General

Operation - general all the chest freezer models are of the same basic design consisting of a hot wall condenser cap tube fed tank wrap evaporator. Ice formation on the walls over a period of time is normal. This frost should be scraped off periodically in order to maintain peak performance. These c...

Page 13

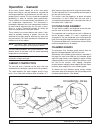

Replacing the chamber guard to install the new vinyl guards, proceed as follows: 1. Clear off the old mastic from around the top chamber guard retainer. 2. Mastic is to be used between the stainless steel top and the top chamber guard retainer. Hold the tapered edge of the spout at an angle, then pr...

Page 14

12 general operations cabinet in a warm room the wrapper will be warm to the touch. This is a normal condition with this type of condenser. The wrapper type condenser is free of many of the faults common to the conventional type system. Because of the design there are no fans to fail; no fins to clo...

Page 15

Refrigerant cycle - condenser & evaporator liquid refrigerant is evaporated in the low side coil by heat absorbed from the tank walls. The refrigerant passes as a vapor from the accumulator through the suction line to the compressor. It enters the interior of the shell which is at suction pressure. ...

Page 16

Electrical service thermostat the thermostat is mounted in the machine compartment at top or left side of front opening and the thermal ele- ment is extended into the thermostat well. See figure 10. The well is a cylindrical tube fastened to the exterior of the inside tank, it is located near left f...

Page 17: Condensate Heater

Condensate heater to replace heater wire 1. Unhook the bottom edge of the chamber guard and remove. 2. Pull out screw nails and lift out chamber guard retainer. 3. Unplug and pull out original heater, carefully checking for any damaged areas. Carefully check recess for heater where damaged heater wi...

Page 18

Motor & relay split phase motors are used in all compressors. Models 6-df, 8-df, and 10-df have 2-pole, 3450 rpm motors. The use of low starting torque motors is made possible by unloading the compressor prior to the start, thus reducing the required starting torque. The starting relays on the “a” l...

Page 19: Refrigeration Service

Checking for electrical trouble when checking for electrical trouble, always be sure there is a “live” electrical circuit to the cabinet and that the thermostat dial is not in the “off” position. When the sealed unit will not start and the cabinet temperature is warm, the trouble may be in the relay...

Page 20

Amount of refrigerant which will show up as a leak. Do not be quick to condemn the cabinet as a leaker. Let the cabinet air out for a few minutes, then make another leak test being careful not to pull on the tubing entering the insulated area as other cells may be opened. Proceed in a normal manner ...

Page 21

3. High head pressure high head pressure is a third cause of motor burn out. With high head pressure the motor load is increased and the increased current causes the windings to over- heat and eventually fail. Poor circulation of air over the high side condenser can cause motor failure for this reas...

Page 22

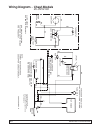

20 wiring diagram wiring diagram - chest models 26-0959-00 *for 220-50 and 220-60 export-connect the blue in place of white and brown in place of black. Start cap. Run cap. Terminal box compressor (ptcr) fan motor top heater thermostat (all models except (close on rise) service cord see electrical r...

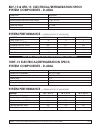

Page 23: System Components - R-404A

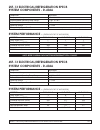

Electrical/refrigeration specifications 21 2sf-13 electrical/refrigeration specs system components - r-404a system performance - (thermostat set at #4 position) compressor americold compressor horsepower hp 110-1-3083 recommended operating temp. Range +10°f to -20°f cabinet volts 115 expansion devic...

Page 24: System Components - R-404A

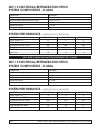

22 electrical/refrigeration specifications 4df-13 electrical/refrigeration specs system components - r-404a system performance - (thermostat set at #4 position) compressor americold compressor horsepower hp 110-1-3083 recommended operating temp. Range +10°f to -10°f cabinet volts 115 expansion devic...

Page 25: System Components - R-404A

Electrical/refrigeration specifications 23 8df-13 & 8fr-13 electrical/refrigeration specs system components - r-404a system performance - (thermostat set at #4 position) compressor americold compressor horsepower hp 121-1-3087 recommended operating temp. Range +10°f to -15°f cabinet volts 115 expans...

Page 26: System Components - R-404A

24 electrical/refrigeration specifications 14df-13 electrical/refrigeration specs system components - r-404a system performance - (thermostat set at #4 position) compressor americold compressor horsepower hp 127-1-3515 recommended operating temp. Range +10°f to -15°f cabinet volts 115 expansion devi...

Page 27

Parts list when ordering parts, order by part num- ber and description, including, if at all possible, the complete cabinet model and serial number..

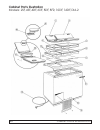

Page 28: Cabinet Parts Illustration

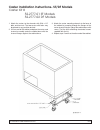

Cabinet parts illustration models: 2sf, 4sf, 4df, 6df, 8df, 8fr, 10df, 14df, di4-2 26 cabinet parts illustration.

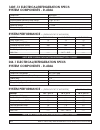

Page 29

Cabinet parts list – domestic 27 cabinet parts list – domestic models: 2sf, 4sf, 4df, 6df, 8df, 8fr, 10df, 14df, di4-2 item d escription 2sf 4sf 4df 6df 8df 8 fr 10df 1 4df di4-2 1l id ass'y, small 28903 28903 28903 28903 28903 2l id ass'y, large 29103 29103 29103 29103 29103 29103 29103 3c hambergu...

Page 30

Cabinet parts list – export models: e2sf, e4sf, e4df, e6df, e8df, 8fr 28 cabinet parts list – export item description e2sf e4sf e4df e6df e8df 8fr 1 lid ass'y, small 28903 28903 28903 2 lid ass'y, large 29103 29103 29103 29103 3 chamberguard, large 10-1077-02 10-1077-02 10-1077-02 10-1077-02 4 chamb...

Page 31

Cond. Unit compartment parts list – export 29 condensing unit compartment parts list – export models: e2sf, e4sf, e4df, e6df, e8df, e8fr item description e2sf e4sf e4df e6df e8df e8fr 1 thermostat 23-5117 23-5117 23-5117 23-5117 23-5117 23-5117 2 compressor 16-0311-00 16-0311-00 16-0311-00 16-0312-0...

Page 32

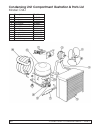

30 cond. Unit compartment parts illustration condensing unit compartment illustration models: 2sf, 4sf, 4df, 6df, 8df, 8fr, 10df, 14df.

Page 33

Cond. Unit compartment parts list – domestic 31 condensing unit compartment parts list – domestic models: 2sf, 4sf, 4df, 6df, 8df, 8fr, 10df, 14df item description 2sf 4sf 4df 6df 8df 8fr 10df 14df 1 thermostat 23-5117 23-5117 23-5117 23-5117 23-5117 23-5117 23-5117 23-5117 2 compressor 16-0308-00 1...

Page 34

32 cond. Unit compartment – di4-1 condensing unit compartment illustration & parts list model: di4-1 item description part number 1 thermostat 23-5117 2 fan motor 24-0396 3 fan blade 24-0260 5 fan bracket 24-0020 6 condenser assembly 50-4124-00 7 drier / filter 12-3024 8 start relay 17-0286-00 9 mot...

Page 35: 8Fr Accessories

8fr – parts & mounting 33 8fr accessories description part no. Dipperwell accessory 7300000 stainless steel syrup rail kit 76-3745 s.S. Housing cap ass’y 76-3733p short jar 33-0448 pump syrup 33-0449 chocolate pump 33-0450 lid with ladle 33-0544-01 hinged lid 33-0544 cover with ladle attached 33-054...

Page 36

To install a dipper well, remove two aluminum pop rivets in the area the dipper well is to be mounted. Remove the rivets using a no. 30 high speed drill. Use care to avoid enlarging the holes in either the cap or the cabinet. The drill should not penetrate more than 1/4 inch. Slip the dipper well fl...

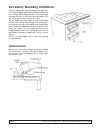

Page 37

Caster installation instructions– sf/df models caster kit # 52-2777-01 sf models 52-2777-02 df models caster installation 35 1. Attach the casters to the channels with 5/16 x 1/2" bolts and hex nuts. The two casters with locks may be placed at any position desired. 2. Lift one end of the cabinet and...

Page 40

By national refrigeration products 563 corbin road • honea path, south carolina • (800) 486-8369.