Summary of KM-200D

Page 1

Service manual microwave oven model: km-2 0 0d.

Page 2

Safety and precautions ........................................................................................................... 2 1. For safe operation .............................................................................................................. 2 2. For safe service procedures ....

Page 3

Safety and precautions 1. For safe operation d am age that allow s the m icrow ave energy (that cooks or heats the food) to escape w ill result in poor cooking and m ay cause serious bodily injury to the operator. If a n y o f t h e f o llo w in g co n d it io n s e x is t, o p e rato r m u s t n o ...

Page 4

Specifications specificatio ns are subject to chang e w itho ut no tice. Model km-200d p o w e r s u p ply 2 3 0v -5 0 h z, s in g l e p h a se w ith e a r th in g po w e r c o n su m ptio n m ic r o w ave 1 2 00 w g r il l c o m bin atio n m ic r o w ave e n e r g y o u tp u t 8 0 0w m ic r o w ave...

Page 5

External view 1. Outer dimension.

Page 6

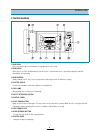

External view 2. Feature diagram 1. Door seal door seal surfaces prevent m icrowaves escaping from the oven cavity. 2. Door hook w hen door is closed, it will autom atically shut off. If door is opened while oven is operating, m agnetron tube will im m ediately stop operating. 3. Door screen allows ...

Page 7

External view 3. Control panel 1. Display - cooking tim e, power level, indicators and present tim e are displayed. 2. Defrost - used to defrost foods by weight or tim e. 3. Power - used to set power level. 4. Auto cook - used to cook using a program or to reheat. 5. Start/easy cook - used to start ...

Page 8

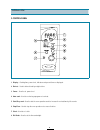

Installation 1. Steady, flat location t his m icrow ave oven should be set on a steady, flat surface. T his m icrow ave oven is designed for counter top use only. 2. Leave space behind and side a ll air vents should be kept a clearance. If all vents are covered during operation, the oven m ay overhe...

Page 9: Operations and Functions

8 1. Connect the main lead to an electrical outlet. 2. After placing the food in a suitable container, open the oven door and put it on the glass tray. The glass tray must always be in place during cooking. 3. Close the door securely. 4. When the oven door is opened, the light turns off. 5. The oven...

Page 10

Disassembly and assembly cautions to be observed when trouble shooting unlike many other appliances, the microwave oven is high-voltage, high-current equipment. It is completely safety during normal operation. However, carelessness in servicing the oven can result in an electric shock or possible da...

Page 11

Disassembly and assembly 1. To remove cabinet 1) rem ove three screws on cabinet back. 2) push the cabinet backward. 2. To remove door assem bly 1) rem ove a screw which secure the stopper hinge top. 2) rem ove the door assem bly from top plate of cavity. 3) reverse the above for reassem bly. Note a...

Page 12

Disassembly and assembly 3. To remove door parts. (1) km-200d ref. No pa rt code part n ame description q ty remark a 01 3512203800 fr a m e d o o r a bs x r -401 h -2938 1 a 02 351 7 0 0 3 05 0 ba r r ier -s c r e e n *o a c r y l 1 a 03 3515304610 su p p o rte r b ar r -s *o p p 1 a 04 3515204100 ...

Page 13

Disassembly and assembly 1) rem ove the gasket door from door plate. 2) rem ove the barrier screen inner from door plate. 3) rem ove the door fram e from door plate. 4) rem ove the stopper hinge top from door plate. 5) rem ove the spring and the hook. 6) rem ove the supporter barrier screen outer fr...

Page 14

13 disassembly and assembly 5. To remove control panel parts. (1) km-200d ref. No part code part name description q’ty remark b01 3515501500 window display pmma 1 b02 3516719420 control panel abs xr-401 h-2938 1 b03 3516907400 button function abs 1 b04 3516907600 button function abs 1 b05 3514321400...

Page 15

Disassembly and assembly 1) remove the screw which secure the control panel, push up two snap fits and draw forward the control panel assem bly. 2) rem ove the door open lever from the control panel. 3) rem ove four screws which secure the pcb assem bly to control panel. 4) disconnect m em brane tai...

Page 16

Disassembly and assembly 8. To remove wind guide assembly. 1) rem ove a screw for earthing. 2) rem ove the noise filter from the wind guide. 3) rem ove a screw which secure the wind guide assem bly. 4) draw forward the wind guide assem bly. 5) pull the fan from the m otor shaft. 6) rem ove two screw...

Page 17

Interlock mechanism and adjustment the door lock m echanism is a device which has been specially designed to com pletely elim inate m icrowave radiation when the door is opened during operation, and thus to perfectly prevent the danger resulting from the leakage of microwave. (1) prim ary interlock ...

Page 18

Trouble shooting guide following the procedure below to check if the oven is defective or not. 1) check earthing before trouble checking. 2) be careful of the high voltage circuit. 3) discharge the high voltage capacitor. 4) w hen checking the continuity of the switches, fuse or high voltage transfo...

Page 19

Trouble shooting guide ( trouble 2 ) display shows all figures selected, but oven does not start cooking, even though desired program and tim e are set and start pad is tapped. Con dition check result cause rem edy o utlet has proper voltage f use does not blow. C heck con tinuity of m agn etron n o...

Page 20

Trouble shooting guide ( trouble 3 ) no m icrowave oscillation even though fan m otor rotates. C o n ditio n c he c k r es u lt c ontinuity c ontinuity in backw ard direction 0 Ω or n o c ontinuity n o c ontinuity 0 v a pprox 15 v d c c au s e d efective high voltage transform er d efective high vol...

Page 21

Trouble shooting guide ( trouble 4 ) the following visual conditions indicate a probable defective touch control circuit or m em brane switch assem bly 1. Incom plete segm ents, 1) segm ents m issing. 2) partical segm ents m issing. 3) digit flickering other than norm al display slight flickering. 4...

Page 22

Measurement and test 1. Measurement of the microwave power output m icrowave output power can be checked by indirectly m easuring the tem perature rise of a certain am ount of water exposed to the m icrowave as directed below. Procedure 1. M icrowave power output m easurem ent is m ade with the m ic...

Page 23

Measurement and test 2. Microwave radiation test procedure 1. Prepare m icrowave energy survey m eter, 600cc glass beaker, and glass therm om eter 100° c (212° f ). 2. Pour 275cc ± 15cc of tap water initially at 20 ± 5 ° c (68 ± 9° f) in the 600 cc glass beaker with an inside diam eter of approx. 95...

Page 24

Measurement and test 3. Component test procedure high voltage is present at the high voltage term inal of the high voltage transform er during any cooking cycle. It is neither necessary nor advisable to attem pt m easurem ent of the high voltage. Before touching any oven components or wiring, always...

Page 25

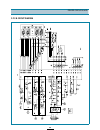

Wiring diagram.

Page 26

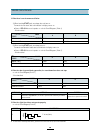

Printed circuit board 1. Circuit check procedure 1. Low voltage transformer check the low voltage transform er is located on the p.C.B. M easuring condition: input voltage: 230 v / frequency: 50hz 2. Voltage check - key check point - check m ethod term inal voltage lo ad n o lo a d 4 - 7 a c 12.6 v ...

Page 27

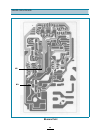

Printed circuit board mp1 mp2 measure point.

Page 28

Printed circuit board.

Page 29

Printed circuit board 3. W hen there is no microwave oscillation 1) w hen touching start pad, oven lam p does not turn on. Fan m otor do not rotate, but cook indicator in display com es on. Cause : relay 2 does not operate. Refer to circuit diagram ( point 3) - check m ethod 2) w hen touching start ...

Page 30

Printed circuit board 2. P.C.B. Circuit diagram.

Page 31

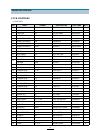

30 printed circuit board 3. P.C.B. Location no (1) km-200d no name symbol specification part code q'ty 1 buzzer bz1 bm-20k 3515600100 1 2 c array ca1 5p(4) 102 m 50v cn4xb-102m 1 3 c electro ec1 16v rss 100uf cexf1c101v 1 4 c electro ec2 25v rss 1000uf cexf1e102v 1 5 connector wafer cn1 yw396-02av 3...

Page 32

31 no name symbol specification part code q'ty printed circuit board.

Page 33

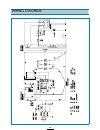

Exploded view and parts list 1. Door assembly refer to disassem bly and assem bly. 2. Control panel assembly refer to disassem bly and assem bly. 3. Total assembly.

Page 34

Exploded view and parts list (1) km-200d ref no part co de part nam e descr iptio n q'ty a 00 3511710300 d o o r a s k o r -63150s 1 b 00 3516720940 c o nt r o l pan e l as k o r -631r 0s 1 f 01 3510801310 c a bin e t p cm t 0.36 g e 1 f 02 7112401011 s c r e w ta p pin g t 1 t r s 4*10 m fz n 3 f 0...

Page 35

F 33 4415a 66910 s w m ic r o v p-531a -o f /s zm -v 16-fa -61 1 f 34 4415a 17352 s w m ic r o v p-533a -o f s pn o #187 200g 1 f 35 3513702600 le v er lo ck p o m 1 f 36 3513811700 lo c k p o m 1 f 37 4415a 17352 s w m ic r o v p-533a -o f s pn o #187 200g 1 f 38 3513601600 la m p b l 240v 25w t 25...