- DL manuals

- Kelvinator

- Refrigerator

- R-404A

- Installation Manual

Kelvinator R-404A Installation Manual

Summary of R-404A

Page 1

Service & installation manual dipping cabinets r-404a refrigerant 51-1298-02 dipping cabinet 1298.02 2/3/03 1:14 pm page 1 by national refrigeration products.

Page 2

Important information is contained in this manual which should be retained in a convenient location for future reference. Information in this manual is subject to change without notice. Manual effective for models produced january, 2003. Starting serial number 6527372. Model designation information ...

Page 3

Introduction dipping cabinet 1298.02 2/3/03 1:14 pm page 3.

Page 4: Dipping Cabinet Introduction

Dipping cabinet introduction 2 introduction these dipping cabinets are designed to merchandise ice cream or yogurt type products. Dipping cabinets are produced in four sizes: 4, 8, 12, and 16 facings of ice cream containers. The cabinet systems contain r-404a refrigerant, metered into the system by ...

Page 5: Table of Contents

Table of contents table of contents 3 specifications are subject to change without notice. Introduction introduction ........................................................................ 2 table of contents ................................................................3 cabinet specifications/d...

Page 6: Cabinet Specifications

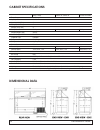

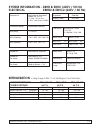

Cabinet specifications 4hc & 4hr/4hj e4hc & e4hr e4hc2 & e4hr2 temp. Range +10°f to -8°f capacity 4.6 cu. Ft. Capacity (3 gal. Tubs) 4 facings (3 gal. Tubs) 4 storage (3 gal. Tubs) 0 compressor size 1/4 hp. Shipping weight (app.) 235 lbs. Condenser type bare tube evaporator type cold wall refrigeran...

Page 7: Cabinet Specifications

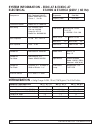

Cabinet specifications 8hc & 8hr/8hj & 8hf e8hc & e8hr e8hc2 & e8hr2 temp. Range +10°f to -8°f capacity 12.0 cu. Ft. Capacity (3 gal. Tubs) 12 facings (3 gal. Tubs) 8 storage (3 gal. Tubs) 4 compressor size 1/3 hp. Shipping weight (app.) 365 lbs. Condenser type bare tube evaporator type cold wall re...

Page 8: Cabinet Specifications

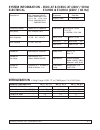

Cabinet specifications 12hc & 12hr eckdc-67 & ekdc-67 e12hc2 & e12hr2 temp. Range +10°f to -8°f capacity 19.1 cu. Ft. Capacity (3 gal. Tubs) 20 facings (3 gal. Tubs) 12 storage (3 gal. Tubs) 8 compressor size 1/3 hp. 3/4 hp. 3/4 hp. Shipping weight (app.) 525 lbs. Condenser type bare tube evaporator...

Page 9: Cabinet Specifications

Cabinet specifications 16hc & 16hr eckdc-87 & ekdc-87 e16hc2 & e16hr2 temp. Range +10°f to -8°f capacity 19.1 cu. Ft. Capacity (3 gal. Tubs) 20 facings (3 gal. Tubs) 12 storage (3 gal. Tubs) 8 compressor size 1/3 hp. 3/4 hp. 3/4 hp. Shipping weight (app.) 525 lbs. Condenser type bare tube evaporator...

Page 10

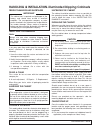

Handling & installation-illuminated dipping cabinets 8 introduction freight damages and shortages important the cabinet was inspected and packaged at the factory, and should have arrived in excellent condition. The transportation company or other parties involved in the shipment are responsible for ...

Page 11: Warning

B. Check for traces of oil on the compressor pan which could mean a broken or leaking refrigeration line. Under no circumstance should the compressor be started when oil is present until inspected by a service technician. C. Inspect the factory wiring for terminals that might have vibrated loose in ...

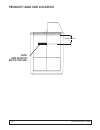

Page 12: Product Load Line Location

Product load line location 10 introduction note: keep product below this line. Keep product below red line 7" below breaker dipping cabinet 1298.02 2/3/03 1:14 pm page 12.

Page 13

Section ii principles of operation dipping cabinet 1298.02 2/3/03 1:14 pm page 13.

Page 14

Dipping cabinet 1298.02 2/3/03 1:14 pm page 14.

Page 15: General Operations

General operations principles of operation 13 all the dipping cabinet models are of the same basic design, consisting of a bare tube condenser and a cap tube fed tank wrap evaporator. Ice formation on the walls over a period of time is normal. This frost should be scraped off periodically in order t...

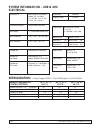

Page 16: Electrical

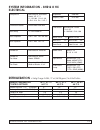

14 principles of operation system information - 4hr & 4hc electrical refrigeration - refrig. Charge: r-404a / 11.5 oz. / 326.02 grams / no. 4 stat position compressor manufacturer: americold model: hp-110-3083 v.: 115/100 r.L.A.: 2.0 l.R.A.: 10 phase 1 overload protector americold #1456-3453 start r...

Page 17: Electrical

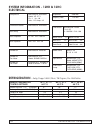

Principles of operation 15 system information - 8hr & 8 hc electrical refrigeration - refrig. Charge: r-404a / 17 oz. / 481.95 grams / no. 4 stat position compressor manufacturer: americold model: hp-117-1 v.: 115/100 r.L.A.: 3.0 l.R.A.: 21.4 ph.: 1 hp: 1 ⁄ 3 overload protector americold #1456-3454 ...

Page 18: Electrical

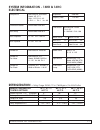

16 principles of operation system information - 12hr & 12hc electrical refrigeration - refrig. Charge: r-404a / 25 oz. / 708.75 grams / no. 4 stat position compressor manufacturer: americold model: hp-127-1 ph.: 1 hz.: 60 volts: 115 amps: 4.2 overload protector manufacturer: americold start relay ma...

Page 19: Electrical

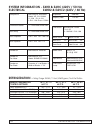

Principles of operation 17 system information - 16hr & 16hc electrical compressor manufacturer: americold model: hp-127-1 volts: 115 r.L.A.: 4.2 l.R.A.: — ph.: 1 hz.: 60 overload protector americold #1456-3321 start relay americold #1456-3374 start capacitor v.: 125 m.F.: 189-227 run capacitor v.: 3...

Page 20: Electrical

18 principles of operation system information - e4hr & e4hc (220v / 50 hz) electrical e4hr2 & e4hc2 (220v / 60 hz) refrigeration - refrig. Charge: r-404a / 11.5 oz. / 326.02 grams / no. 4 stat position compressor manufacturer: americold model: hp-110-12-3084 v.: 220 r.L.A.: 2.0 l.R.A.: 12.6 phase: 1...

Page 21: Electrical

Principles of operation 19 system information - e8hr & e8hc (220v / 50 hz) electrical e8hr2 & e8hc2 (220v / 60 hz) refrigeration - refrig. Charge: r-404a / 17 oz. / 481.95 grams / no. 4 stat position compressor manufacturer: americold model: hp-118-12 v.: 220 r.L.A.: 3.0 l.R.A.: 12.6 phase: 1/50hz. ...

Page 22: Electrical

20 principles of operation system information - ekdc-67 & eckdc-67 electrical e12hr2 & e12hc2 (220v / 60 hz) refrigeration - refrig. Charge: r-404a / 25 oz. / 708.75 grams / no. 4 stat position compressor mft: copeland (3/4 hp) model: kamb-007e-cav phase: 1 hz.:50 overload protector model no.: 071-0...

Page 23: Electrical

System information - ekdc-87 & eckdc-87 (220v / 50 hz) electrical e16hr2 & e16hc2 (220v / 60 hz) refrigeration - refrig. Charge: r-404a / 27 oz. / 765.45 grams / no. 4 stat position power cord a.W.G.: 16 amp: 15 light ballast vossloh schwabe model: l36.291 (50hz) robertson: 1-4025 (60 hz) fluorescen...

Page 24: E4Hr, E4Hc / E8Hr, E8Hc

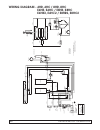

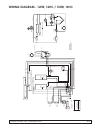

Wiring diagram - 4hr, 4hc / 8hr, 8hc e4hr, e4hc / e8hr, e8hc e4hr2, e4hc2 / e8hr2, e8hc2 22 principles of operation wire diagram 00-c-2030-00 f yellow blue blue white black black black black black black black white blue blue white red (extra) black black black blue white black white black black blk....

Page 25

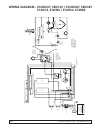

Principles of operation 23 wiring diagram - 12hr, 12hc / 16hr, 16hc wire diagram kdc67/87-brt68/90 00-2368-00 rev b yellow blue blue white black black black black black (brown) white (blue) black white blue blue white red (extra) black blue blue blue black white black (black-220) (black-220) white b...

Page 26

Wiring diagram - eckdc67, ekdc67 / eckdc87, ekdc87 e12hc2, e12hr2 / e16hc2, e16hr2 24 principles of operation wiring diagram ekdc/kkdc-67/87 & 00-c-2342-00 b ebrt/kbrt-68/90 potential blue blue white black black black black black black black black white white white blue blue blue white black white y...

Page 27

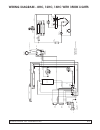

Principles of operation 25 wiring diagram - 8hc, 12hc, 16hc with 3500k lights wire diagram ckdc-47. 67 & 87 (3500k lights) 00-c-3020-00a blue blue blue blue black black black black black white black white black red blue blue black white yellow white (extra) white black red black blue black black 6 5...

Page 28

Dipping cabinet 1298.02 2/3/03 1:14 pm page 28.

Page 29

Section iii maintenance & repair dipping cabinet 1298.02 2/3/03 1:14 pm page 29.

Page 30: Warning:

Warning: to avoid the possibility of an electrical shock, turn off thermostat and unplug the power cord of the cabinet before cleaning or touching electrical connections or parts. Dipping cabinet 1298.02 2/3/03 1:14 pm page 30

Page 31

Maintenance & repair — pre-service check list maintenance & repair 29 you may avoid the cost and inconvenience of an unnecessary service call by first reviewing this check list of the most frequently encountered situations that are not the result of system component failure. Compressor runs too much...

Page 32: Section III

Section iii maintenance & repair 30 maintenance & repair tools: to provide full service diagnostics and repairs on these cabinets the following tools are needed: a volt meter an amp meter an ohm meter or tiplet meter to handle all three functions an electronic leak detector an electronic micron gaug...

Page 33

Maintenance & repair 31 entering the system entering the system should only be done as a last resort. Extreme care must be used no matter what the reason is for entering the system. Of course there are times it cannot be avoided, such as component or compressor replacement, or a leak within the syst...

Page 34

Compressor installation & maintenance / diagnostics 32 maintenance & repair hold down bolts all models with copeland compressors have hold down bolts. The compressor has a metal hold down band strapping it tightly to the cabinet body. This band should be removed and discarded upon installation. If c...

Page 35

Maintenance & repair 33 compressor installation & maintenance / diagnostics to check capacitors 1. Disconnect the cabinet from the power supply. 2. Make sure the capacitors are discharged before checking. (shunt across the terminal of capacitor with a heavy insulated wire.) 3. Remove the wires from ...

Page 36: Cleaning & Maintenance

Cleaning & maintenance 34 maintenance & repair cleaning the cabinet exterior wipe the exterior occasionally with a cloth dampened in mild detergent water; rinse, and wipe dry with a soft, dry cloth. Do not use abrasive or caustic cleaners or scouring pads. Cleaning the condenser - fig. 1a periodic c...

Page 37: Cleaning The Lid

Cleaning the lid maintenance & repair 35 if the lid has been removed from the cabinet, wash with plenty of non-abrasive soap or detergent and water. Use the bare hand to feel and dislodge any caked soil. Rinse thoroughly with clean water. Do not use hard, rough cloths that will scratch the surface o...

Page 38: Lid Seal Replacement

From epics 36 maintenance & repair lid seal replacement 1. Remove lids from the cabinet. 2. Remove screws on the underside of the stainless top on the server side of the cabinet. 3. Remove the stainless top from the cabinet. 4. Slide the lid seal off of the top channel. 5. Replace the lid seal with ...

Page 39: Lid Gasket Replacement

Maintenance & repair 37 1. Remove the lid from the cabinet. 2. Set the lid on a flat, protected surface. 3. Rotate lid upside down. 4. Slide old gasket from the aluminum lid frame. 5. Install new gasket in the groove provided. See end detail. 6. Reinstall lid in cabinet. Lid gasket replacement dippi...

Page 40

Lid pivot bushing assembly replacement old style new style the pivot pin bushing is located on the outside edge of each lid. 1. Remove the lid from the cabinet. Lay the lid on a smooth, non-scratch surface. 2. Remove the two acorn nuts from the outside edge of the lid assembly. 3. Remove the shake-p...

Page 41

Center/end pivot rod replacement maintenance & repair remove lids from the cabinet. Remove 2 mounting screws from the mounting bracket. Replace the pivot bracket with correct new part number. Reinstall lid assembly. The 4-hole and 8-hole dipping cabinets have end pivot pins only. The 12- and 16-hole...

Page 42: Socket Replacement

Fluorescent lamp holder/light starter socket replacement the lamp holder and the light starter socket are located on the lamp channel assembly. 40 maintenance & repair 1. Disconnect the power to the cabinet. 2. Remove the lids from the cabinet. 3. Remove the fluorescent bulbs. 4. Remove the screws h...

Page 43

Fluorescent bulb & starter replacement maintenance & repair 41 bulb replacement 1. Turn light switch off on the cabinet. 2. Pull down on the socket (a). 3. Remove the plastic outer lamp shield (b) and bulb (c). 4. Raise the bulb up. Pull out of the socket. 5. Remove lamp shields and end caps (d). 6....

Page 44: Thermostat Replacement

Thermostat replacement 42 maintenance & repair 1. Disconnect the power to the cabinet. 2. Remove the grill. 3. Remove screws from the thermostat mount. 4. Pull the thermal bulb out of the cabinet. 5. Replace the thermostat with the correct new part number. 6. Slide the capillary tube up the control ...

Page 45

Master power supply switch / light switch replacement maintenance & repair 43 the master supply switch (a) and the light switch (b) are located behind the grill panel, on the righthand server side of the unit. 1. Disconnect the power to the cabinet. 2. Remove the grill. 3. Remove screws holding the ...

Page 46

Condenser fan motor replacement 44 maintenance & repair the condenser fan motor is located in the machinery compartment, directly behind the condenser coil. Motor specifications: 220 volts 60 hz. 1 phase 9 watt 1. Disconnect the power to the cabinet. 2. Remove the grill panel. 3. Remove the condensi...

Page 47: Ballast Replacement

Ballast replacement ballast replacement 45 the ballast is located in the machinery compartment inside the electrical box. 1. Disconnect the power to the cabinet. 2. Remove the front grill. 3. Remove the electrical wiring box. 4. Disconnect the leads to the ballast. 5. Replace the ballast with correc...

Page 48

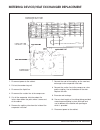

Metering device/heat exchanger replacement 46 maintenance & repair 1. Disconnect power to the cabinet. 2. Pull out the condensing unit. 3. Disconnect the liquid line. 4. Disconnect the suction line at the compressor. 5. Cut off the evaporator inlet tube about five inches down below the point where i...

Page 49

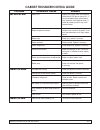

Cabinet troubleshooting guide maintenance & repair 47 trouble common cause remedy unit will not run. Cabinet too warm. Cabinet too cold. Blown fuse. Broken temperature control. Broken relay. Broken overload. Broken compressor. Defective service cord. Broken lead to compressors or cold control. Broke...

Page 50

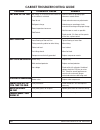

Cabinet troubleshooting guide 48 maintenance & repair trouble common cause remedy unit runs all the time. Noisy operation. Unit cycles on overload. Not enough air circulation around cabinet or air circulation is restricted. Poor lid seal. Refrigerant charge. Room temperature too warm. Cold control. ...

Page 51: Problems & Cause

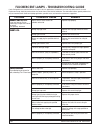

Compressor troubleshooting guide maintenance & repair 49 problems & cause remedy compressor won’t start—no hum. 1. Open line circuit. 1. Check wiring, fuses, receptacle. 2. Protector open. 2. Wait for reset - check current. 3. Control contacts open. 3. Check control; check pressures. Compressor won’...

Page 52

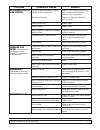

Fluorescent lamps - troubleshooting guide 50 maintenance & repair carrier refrigeration uses standard fluorescent lamps in all of its applications. Standard one- and two- lamp ballast circuits are used. Replacement lamps should be purchased over the counter from a local electrical wholesaler. The ta...

Page 53

Trouble common cause remedy no starting effort or slow starting. Decreased light output. Full illumination of bulbs requires correct assembly of all components of lighting system. Blinking on/off. Accompanied by shimmering effect during “lighted” period. Open lamp cathode circuit due to broken catho...

Page 54: Typical Two-Lamp Rs Ballast

Measurements - starting lamp voltage typical two-lamp rs ballast 52 maintenance & repair white black ballast y-1 y-2 r b starting voltage typical two-lamp rs ballast the largest percentage of light ballast used today are of the two-lamp rapid start type. In order to read starting or open circuit vol...

Page 55

Parts listing with illustration identification dipping cabinet 1298.02 2/3/03 1:15 pm page 55.

Page 56

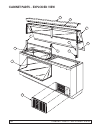

Cabinet parts - exploded view 54 cabinet parts - exploded view 2 1 3 4 7 9 8 6 10 11 5 dipping cabinet 1298.02 2/3/03 1:15 pm page 56.

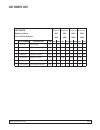

Page 57

Cabinet parts dipping cabinets curved & flat & export description u/m qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# 05-1199-* canopy top ea 1 -01 1 -02 1 -02 1 -03 1 -03 1 -04 1 -04 05-1187-* canopy top ea 1 -01 1 -02 1 -03 1 -04 2 44-0862 upper l...

Page 58

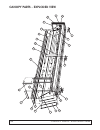

Canopy parts - exploded view 56 canopy parts - exploded view 1 2 3 4 6 7 6 6 8 15 6 9 22 10 11 12 17 14 13 18 20 21 23 24 5 19 25 16 dipping cabinet 1298.02 2/3/03 1:15 pm page 58.

Page 59

C anopy p a r ts list c anopy p a r ts 57 canopy parts dipping cabinets curved & flat & export description u/m qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# 01-0902-01 glass bracket, top ea 2 - 2 - 2 - 3 - 3 - 3 - 3 - 02-0942-00 glass bracket, top...

Page 60

Condensing unit exploded view 58 condensing unit exploded view dipping cabinet 1298.02 2/3/03 1:15 pm page 60

Page 61

Condensing unit parts dipping cabinets curved & flat & export description u/m qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# 1 310a0010 flavor strip holder ea 2 - 4 - 6 - 8 - 2 - 4 - 6 - 8 - 2 90-0125 insert bottom pad ea 1 - 2 - 3 - 4 - 1 - 2 - 3 - 4 - 3 315256 nameplate fr...

Page 62

Electrical parts - exploded view 60 electrical parts exploded view dipping cabinet 1298.02 2/3/03 1:15 pm page 62.

Page 63

Electrical parts dipping cabinets curved & flat & export description u/m qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# qty gr.# 19-1148-00 wire harness, compr ea 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 19-1149-00 wir...

Page 64: Lid - Exploded View

1 6 7 2 4 3 5 lid - exploded view 62 lid - exploded view dipping cabinet 1298.02 2/3/03 1:15 pm page 64.

Page 65: Lid Parts List

Lid parts dipping cabinets curved & flat & export description u/m qty gr.# qty gr.# qty gr.# qty gr.# 1 10-1141-* lid, plexiglas ea 1 -01 1 -02 1 -03 1 -04 2 08-0517-* lid frame, top ea 1 -01 1 -02 1 -03 1 -04 3 23-0164-00 u-clip ea 6 - 10 - 10 - 10 - 4 08-0520-* lid frame, handle ea 1 -01 1 -02 1 -...

Page 66

Dipping cabinet 1298.02 2/3/03 1:15 pm page 66.

Page 67

Accessories dipping cabinet 1298.02 2/3/03 1:15 pm page 67.

Page 68

Dipping cabinet 1298.02 2/3/03 1:15 pm page 68.

Page 69

Can skirt accessory parts list a can skirt assembly w/ gripper ................50-3326-02 gripper ......................................................09-0202-00 can skirt only ........................................ 10-0952-02 b thumbscrew ............................................ 22-1729-00 c...

Page 70

Can skirt installation information 68 accessories accessory part number cabinet model number 52-1804-01 4-hole ckdc27, ckdc27c, dl4c 4hc & 4hr 52-1804-02 8-hole ckdc47, ckdc47c, dl8c 8hc & 8hr (1) 52-1804-01 plus (1) 52-1804-2 12-hole ckdc67, ckdc67c, dl12c 12hc & 12 hr (2) 52-1804-01 plus (1) 52-18...

Page 71

Can skirt installation information accessories 69 11. Place product spacer e into the cabinet at center of tank. Eight-hole and 12-hole assemblies have one spacer bar; 16-hole has 2 spacer bars. 12. Can skirt is now installed. Dipping cabinet 1298.02 2/3/03 1:15 pm page 71.

Page 72

Dipperwell installation information - 7300000 70 accessories to install dipperwell: 1. Remove plastic hole tabs. 2. Mount dipperwell to cabinet using (2) 1/4-20 x 1/2 m.S. 3. Mounting plate must be under flange of stainless steel cap. 4. Slide flange of dipperwell under stainless steel cap and line ...

Page 73: Adjustable Leg Kit -

Adjustable leg kit - 52-1831-01 accessories 71 dipping cabinet 1298.02 2/3/03 1:15 pm page 73.

Page 74: Caster Kit-

Caster kit- 52-1830-01 72 accessories dipping cabinet 1298.02 2/3/03 1:15 pm page 74.

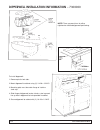

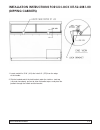

Page 75: (Dipping Cabinets)

Installation instructions for lid lock kit-52-2081-00 (dipping cabinets) accessories 73 1. Locate and drill a 5/16" (.313) dia. Hole 3/8" (.375) from the edge of the handle. 2. Slip the hooked end of the lock bracket under the stainless steel top (see end view above), pull out to allow lid handle to...

Page 76: Can Clamp Installation

Can clamp installation 74 accessories dipping cabinet 1298.02 2/3/03 1:15 pm page 76.

Page 77: Parts List

Each accessory contains parts to clamp one 4-can cluster of ice cream containers. 1. Install 4 mounting angles, using 2 thumbscrews each. Select a hole location which will meet your height requirements. Other cans or other means to obtain proper height of the four cans in relation to the can clamps ...

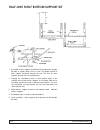

Page 78

Half-way shelf bottom support kit 76 accessories 1. Assemble vertical supports to cabinet with thumbscrews through top hole of support onto rivnuts in liner. The dimple formed in each support should be towards the wall. The four (4) short supports go over the unit compartment. 2. Engage the shoulder...

Page 79

Dipping cabinet 1298.02 2/3/03 1:15 pm page 79.

Page 80

Dipping cabinet 1298.02 2/3/03 1:15 pm page 80 by national refrigeration products 563 corbin road • honea path, south carolina • (800) 486-8369.