- DL manuals

- KEM

- Measuring Instruments

- RA-600

- Operation Manual

KEM RA-600 Operation Manual

Summary of RA-600

Page 1

Refractometer ra-620/ra-600 operation manual * p 5 9 0 0 0 3 3 0 1 * read this operation manual thoroughly before use. An 59-00033-01ver.10

Page 3: 1. Introduction

1. Introduction ra-620/ra-600 1 1. Introduction thank you for choosing a kem refractometer. This refractometer (ra-620/ra-600) is a precision instrument which measures the refractive index of liquid samples. The reflection signal of led light from prism received by ccd (charge-coupled device) is com...

Page 4: 1-1. Safety Controls

1. Introduction 2 1-1. Safety controls important: you must observe the following rules in order to prevent physical or property damage of yourself as well as of the others. Meaning of symbols warning danger of severe injury or possible death caution risk of physical or property damage this symbol me...

Page 5

1. Introduction ra-620/ra-600 3 test sample warning some sample or chemical requires protective gloves, glasses and mask. Ventilate the room. Splashing chemical may injure the eyes or skin. Windpipe may be hurt if fume is inhaled. Do not use chemical which may generate inflammable gas or work in suc...

Page 6: 1-2. About The Manual

1. Introduction 4 1-2. About the manual read this operation manual thoroughly before use. It describes all that are required for routine measurements. Keep this manual beside your equipment so that you can refer to whenever necessary. For detailed test methods, see the separate function description....

Page 7

1. Introduction ra-620/ra-600 5 1-3. Supplied parts and installation supplied parts the carton box contains main unit of ra-620 or ra-600 together with supplied parts and operating manual. Check the contents according to the below list. If you should find any missing or broken part or parts, contact...

Page 8: Table Of Contents

Table of contents 6 table of contents page 1. Introduction 1 1-1. Safety controls .............................................................. 2 1-2. About the manual ........................................................... 4 1-3. Supplied parts and installation ...................................

Page 9: Contents By Subject

Contents by subject ra-620/ra-600 7 contents by subject measurement measure p. 19 stop measurement p. 20 measurement data read the data p. 21 download data to usb flash drive p. 21 set up condition・check・calibrate set up measuring condition p. 18 configure contents (nd, brix) p. 18 check on unit and...

Page 10: 2. Parts Configuration

2. Parts configuration 8 2. Parts configuration 2-1. Main unit front and top touchscreen » [2-2. Touchscreen] sample cover anti volatilization device sample stage prism as measurement temperature is set to high, the sample stage and prism will warm-up accordingly. Note the stopper on sample cover pr...

Page 11

2. Parts configuration ra-620/ra-600 9 rear stylus holder stylus » [6-4. Consumables and parts] usb connector exhaust vent lan connector power switch power connector » [1-3. Supplied parts and installation] intake vent » [2-2. Change filter] rs-232c connector (com2) rs-232c connector (com1) bottom r...

Page 12: 2-2. Touchscreen

2. Parts configuration 10 2-2. Touchscreen main window simple mode contents when pressed, the window for selection of contents appears. » see [3-4. Set up conditions] set temp. Measurement temp. Shows set temp. And measurement temp. Press here to enter set temp. » see [3-4. Set up conditions] date, ...

Page 13

2. Parts configuration ra-620/ra-600 11 main window normal mode operator shows operator’s name. When pressed, the window for selection of user name. » see separate function description. Method shows method name. When pressed, it turns to the window for selection of method. » see separate function de...

Page 14

2. Parts configuration 12 main window normal mode (when selecting changer) sample no. Shows sample no. Press here to enter sample no. » see function description. Rinse & purge press here to start rinse & purge. » see function description. Purge press here to start purge. Switches to skip when change...

Page 15

2. Parts configuration ra-620/ra-600 13 entry window the entry window always appears whenever you access to the touch-screen. Enter with alphabet, numeric .To confirm entry that you have entered, press enter key. The cap ▪ small key switches capital ▪ small letter. Up to 16 characters can be entered...

Page 16

2. Parts configuration 14 operational window each window has buttons in common. Print out contents on display. Returns to main window. Returns to previous window. Tab buttons switch the tabs. Turns the page. For details of operation, see the separate function description. Note to operate the touch s...

Page 17: 3-1. Warming-Up

3. Preparation for measurement ra-620/ra-600 15 3. Preparation for measurement the following preparations are necessary prior to sample measurement. 3-1. Warming-up you can start measurement once the set temp. Is reached after turning on the power. (if calibration is not done at the set temp., condu...

Page 18

3. Preparation for measurement 16 3-2. Supply reference water reference water used for check and calibration plays an important role as check point or reference point in maintaining performance and reliability of ra-620/ra-600 refractometer. Therefore, the quality of water has to meet the following ...

Page 19: 3-3. Prepare Tools

3. Preparation for measurement ra-620/ra-600 17 3-3. Prepare tools the following tools are recommended to prepare for correct measurement. For sampling on prism 1) plastic spoon convenient for low viscosity sample like fruit juice, soft drink, etc. 2) plastic rod with round tip suitable for high vis...

Page 20: 3-4. Set Up Conditions

3. Preparation for measurement 18 3-4. Set up conditions (temperature, contents) most of measure conditions can be selected direct on main window. Contents button temp. Button set the temperature 1 press “temp.” button on main window 2 enter numerals on numeric pad to confirm, press enter key. Note ...

Page 21: 4. Measurement

4. Measurement ra-620/ra-600 19 4. Measurement 4-1. Sample measurement perform sample measurement 1 clean sample stage and prism well clean and dry them all. Refer to [3-3. Prepare tools]. Note if sample stage or prism is not clean, correct measurement cannot be expected. 2 drop sample more than 0.2...

Page 22

4. Measurement 20 4 press “start” button 5 now measuring measurement can be interrupted by pressing “reset”. If an error appears, refer to [7-1. Error message]. 6 measurement results appear on display immediately wipe off the sample after measurement and clean the prism and the sample stage. Leaving...

Page 23

4. Measurement ra-620/ra-600 21 4-2. Read data, store in usb flash drive review data stored in memory. Save data in usb flash drive. 1 press “results” (measured value). 2 press left box of data you wish to save. Mark appears. When pressed again, it disappears. Changes the page. Press if you wish to ...

Page 24

4. Measurement 22 3 insert usb flash drive into usb connector 4 press “save to usb” button 5 enter a file name enter a file name and press “enter” to confirm and save. Automatically folder [ra6xx] is created and stored in csv format. When data reading is underway, all buttons stop functioning. Note ...

Page 25: 4-3. Check

4. Measurement ra-620/ra-600 23 4-3. Check to verify performance of refractometer, check measurement results with water. Check is recommended prior to sample measurement. Just follow the navigation. The steps are simple. 1 press “check” 2 press “next” “stop” returns to main window. “calibration navi...

Page 26

4. Measurement 24 4 close sample cover and press “check start”. Note close sample cover securely to shut out incoming rays for correct measurement. 5 when check is ok the value in ( ) shows the difference between check reference and measured value. “finished” returns to main window. When check fails...

Page 27: 4-4. Calibration

4. Measurement ra-620/ra-600 25 4-4. Calibration save reference ri of water in refractometer. Calibration is necessary when the unit is used for the first time or when check is failed. Just follow guiding navigation. Be sure to clean the prism. No sample residue should remain on prism. 1 press “chec...

Page 28

4. Measurement 26 3 close sample cover and press “air calib.” “calibration setup” goes to check/calibration. Warm-up is suggested right after turning on the power or changing the set temp. The measurement time may get longer without a warm-up operation. See [3-1. Warming-up] for details. Note well c...

Page 29

4. Measurement ra-620/ra-600 27 5 when calibration is ok “failed” means calibration has not succeeded. “ok” means it has been accepted. Previous difference=ri at calibration - ri of water at preset temperature ri (refractive index) of water at each temperature is shown in [8-1 terminology and refere...

Page 30: 5. Function Tools

5. Function tools 28 5. Function tools 5-1. Function function window is a convenient tool to practice exciting features of the unit. To start with, let us learn about function window itself. 1 press “menu” 2 press “function” 3 select select the item to be worked on from “critical angle image”, “adju...

Page 31

5. Function tools ra-620/ra-600 29 critical angle image the critical angle image helps you anticipate detection point of refractive index visually. The display shows graduated scale of ri meter. Some sample type may show scattered results. If the border line is unclear, the sample may result with di...

Page 32

5. Function tools 30 menu includes the following items: method is a group of configured parameters that can be used in measurements under the same conditions. New methods can be selected and saved. “sample id” stores sample name with lot number. The number of sample is counted up each time, and “sam...

Page 33: 6. Maintenance

6. Maintenance ra-620/ra-600 31 6. Maintenance 6-1. Daily maintenance daily maintenance is important for correct measurement. Before measurement 1) check the unit with water or calibrate as necessary. (refer to [4-3. Check] [4-4. Calibration]) after measurement 1) clean sample stage and prism thorou...

Page 34: 6-2. Periodic Check

6. Maintenance 32 6-2. Periodic check periodic check is necessary to verify performance of refractometer. When unexpected physical force is given to the unit, precision of measurement must also be checked to see if different results should appear. Check by user 1) check or calibrate the unit accordi...

Page 35: 6-3. Change Filter

6. Maintenance ra-620/ra-600 33 6-3. Change filter the dustproof filter of intake vent will collect dust particles that have accumulated during the course of time. We suggest that you wash the filter with water or vacuum it every one to two months. If the dust is not eliminated, replace the filter. ...

Page 36

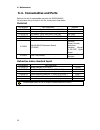

6. Maintenance 34 6-4. Consumables and parts below is the list of consumables and parts for ra-620/ra-600. For purchase of any of those in the list, contact your local dealer. Parts list part number part description remarks 12-02529 ac adapter type2 with power cord (eu,kr) 200~240v 12-02529-01 ac ad...

Page 37: 7. Troubleshooting

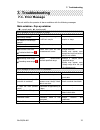

7. Troubleshooting ra-620/ra-600 35 7. Troubleshooting 7-1. Error message the unit notifies the operator of alarm conditions with the following messages: main window・pop-up window ( :normal mode :simple mode) error message at time of measure or check error message possible cause remedies not enough ...

Page 38

7. Troubleshooting 36 error message at time of entry or registration error message possible cause remedies enter name. Name is blank. Enter the name. Same name exists. Enter different name. The name is already registered. Register a different name. Unable to enter. Data exceeds limit. Delete excessi...

Page 39

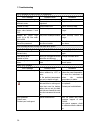

7. Troubleshooting ra-620/ra-600 37 other error message error message possible cause remedies temp error inside instrument see operation manual. (e-1400) temperature inside instrument exceeds upper limit. * upper limit set temp ≤75: 60°c set temp >75: 50°c reduce set temperature or room temperature....

Page 40: 7-2. Technical Tips

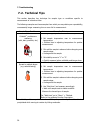

7. Troubleshooting 38 7-2. Technical tips this section describes key technique for sample type or conditions specific to measurement of refractive index. The following examples are those samples from which you may obtain poor repeatability, unnecessarily longer measuring time or even fail in measure...

Page 41

7. Troubleshooting ra-620/ra-600 39 sample type, condition cause, key technique sparkling (soda, beer, etc.) the air bubbles on prism disperse light. 1) degas the sample by shaking vigorously or use ultrasonic cleaner or filter it. » reduce air bubbles on prism. 2) remove air bubbles on prism first....

Page 42: 8. Technical Information

8. Technical information 40 8. Technical information 8-1. Terminology and references about refractive index refractive index (n) is the ratio of wave velocity of light ray in vacuum to that of the medium. For convenience sake, air is used as reference medium. When light comes from the air into water...

Page 43

8. Technical information ra-620/ra-600 41 about refractive index of water (nd) the following list shows relative refractive index (nd) of water at various temperatures (celsius) with light source of sodium na-d line. Temp. ( c) ri (nd) temp. ( c) ri (nd) temp. ( c) ri (nd) temp. ( c) ri (nd) 5 1.333...

Page 44

8. Technical information 42 refractive index (nd) of sucrose solution sucrose g/100g ri (nd) sucrose g/100g ri (nd) sucrose g/100g ri (nd) sucrose g/100g ri (nd) 0 1.33299 25 1.37233 50 1.42009 75 1.47787 1 1.33442 26 1.37407 51 1.42220 76 1.48040 2 1.33586 27 1.37582 52 1.42432 77 1.48295 3 1.33732...

Page 45

8. Technical information ra-620/ra-600 43 about isomerized liquid sugar concentration the isomerized liquid sugar means mixture of glucose, fructose, maltose and sucrose, and is made from corn syrup. It is classified by weight % of fructose contained in the isomerized liquid sugar. Major category is...

Page 46: 8-2. Options

8. Technical information 44 8-2. Options various convenient peripherals are available as shown below. These options can be purchased from kem. Contact your local dealer or sales representative. Ra-620/ra-600 dot matrix printer idp-100 print out of measurement results thermal printer dp-600 epson a4 ...

Page 47

8. Technical information ra-620/ra-600 45 part number part description remarks 12-02028-01 dot matrix printer (ac 120v) for ac 120v w/ connection cable idp-100 12-02028-02 dot matrix printer (ac 230v) for ac 230v w/ connection cable idp-100 12-02618-01 thermal printer (eu/kr) for ac 200~240v w/ conn...

Page 48: 8-3. Specifications

8. Technical information 46 8-3. Specifications model ra-620 ra-600 measurement method detection of critical angle of optical refraction light source led na-d line (589.3nm) measurement items refractive index, brix, other concentrations measurement range refractive index (nd) 1.32000 ~ 1.58000 1.320...

Page 49

9. Warranty and after-sales service ra-620/ra-600 47 9. Warranty and after-sales service 1. Warranty period one (1) year from the date of receipt of this product or the date of installation by kem service personnel or by authorized personnel. 2. Warranty details, after-sales service this product pas...