- DL manuals

- KEMPACT

- Welding System

- 181A

- Operating Manual

KEMPACT 181A Operating Manual

Kempact

251R, 253R, 323R, 181A, 251A, 253A, 323A,

253RMV, 253AMV, 323RMV, 323AMV

Operating manual

Bruksanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Brugsanvisning

Instrukcja obsługi

Manual de utilização

Инструкции по эксплуатации

Bruksanvisning

操作手册

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

RU

SV

ZH

Summary of 181A

Page 1

Kempact 251r, 253r, 323r, 181a, 251a, 253a, 323a, 253rmv, 253amv, 323rmv, 323amv operating manual bruksanvisning gebrauchsanweisung manual de instrucciones käyttöohje manuel d’utilisation manuale d’uso gebruiksaanwijzing brugsanvisning instrukcja obsługi manual de utilização Инструкции по эксплуатац...

Page 3: Operating Manual

Operating manual english.

Page 4: Contents

Contents 1. Introduction ............................................................................................. 3 1.1 general .................................................................................................................................. 3 1.2 about kempact ra ................

Page 5: Introduction

En 1. Introduction 1.1 general congratulations on choosing kempact ra welding equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance ...

Page 6: Preparations

En 1.2.2 about welding in addition to the welding machine, welding outcome is influenced by the work piece to be welded, welding technique and the welding environment. Therefore, recommendations in this manual must be followed. During welding, an electric welding circuit is created between the fille...

Page 7: 2.3 Distribution Network

En 2.2 positioning and location of the machine place the machine on a firm, dry and level surface. Where possible, do not allow dust or other impurities to enter the machines cooling air flow. Notes for positioning the machine • the surface inclination should not exceed 15 degrees. • ensure the free...

Page 8: 2.4 Serial Number

En kempact 323r, 323a: this equipment complies with iec 61000-3-12 provided that the short-circuit power ssc is greater than or equal to 2.1 mva at the interface point between the user’s supply and the public supply network. It is the responsibility of the installer or user of the equipment to ensur...

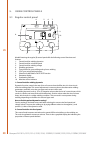

Page 9: Machine Introduction

En 3. Machine introduction 3.1 general view of the machine fe 32 1. 3. 5. 4. 2. 1. Supply voltage cable 2. Main switch 3. Shielding gas hose connector 4. Welding gun and cable 5. Earth return clamp and cable 7 © kemppi oy / 1442.

Page 10: 3.2 Cable Connections

En 3.2 cable connections connection to the mains kempact ra models are available in either 1-phase 230 v, 3-phase 400 v, or multi-voltage units. Machines supplied with a mains power cable are not equipped with a plug, so you must select and fit a suitable mains plug before you use the machine for th...

Page 11

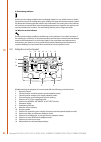

En shielding gas 1. 2. 4. L/min 5 10 15 20 3. Shielding gas is used for replacing air around the welding arc. For steel wires, use co₂ (carbon dioxide) or a mixture of ar (argon) and co₂ for shielding gas. Welding performance will be improved when using mixed gas products. For stainless steel filler...

Page 12

En moving the machine and gas cylinder the kempact ra is designed to provide safe gas cylinder storage and movement in satisfactory workshop conditions. The floor surface should be sound, level and free from obstructions. These notes must be followed and an adequate risk assessment completed prior t...

Page 13

En note! The chassis is designed to provide stability in the upright position, when loaded with or without a gas cylinder. Reasonable effort is required to raise and lower the machine and cylinder to a position of movement. If you are light in weight or in any way unsure about moving the machine and...

Page 14

En 4.2 mounting and locking of filler wire spool 2. 1. 3. To mount the wire spool: 1. Turn the locking knob of the spool holder so that the locking clips are opened (1). 2. Check the rotating direction of the wire spool and push the spool into its place so that it rotates in the right direction (2)....

Page 15

En 4.4 loading the welding wire to feed mechanism gt02 duratorque note! Always ensure that all wire guide tubes are correctly selected and installed before connecting the welding gun. 1. Release the pressure lever(s) and open the pressure arm(s) carrying the top wire feed roll, lifting clear on its ...

Page 16: 4.5 Welding Gun

En 4.5 welding gun connect the welding gun connector to the euro adapter socket located below the wire feed mechanism and hand tighten only. Do not over tighten the gun collar. Note! Remember to remove the sharp cut tip of the filler wire before loading the wire to the welding gun, so preventing dam...

Page 17

En 4.6 setting the pressure of the feed rolls to ensure the filler wire runs smoothly into the welding gun wire liner you should adjust the pressure of the feed rolls of the wire drive mechanism. Turn the orange coloured pressure adjustment knob(s) in a clockwise direction to increase the pressure a...

Page 18

En 4.7 wire guide tubes and feed rolls wire guide tubes a = outlet tube, b = middle tube, c = inlet tube, d = wire spiral guide gt 02c: models 181a, 251r, 251a ø mm outlet tube inlet tube wire spiral guide ss, al, (fe, mc, fc) plastic 0.6 w007532 w006019 w006410 0.8 – 0.9 w007533 1.0 w007534 1.2 w00...

Page 19

En removing outlet tube release pressure tension arm. Push the outlet tube out of its housing with a piece of filler wire. Wire feed rolls gt 02c and duratorque plastic ø mm lower upper fe, ss, (al, mc, fc) v-groove 0.6 w001045 w001046 0.8 – 0.9 w001047 w001048 1.0 w000675 w000676 1.2 w000960 w00096...

Page 20

En 4.8 changing the feed rolls kemppi feed rolls and gun liners are colour-coded in order to make identification easy. Make sure that you select appropriate feed rolls/groove size, welding gun contact tip and gun liner for the filler wire used. 1. 2. 5. 3. 4. To change the feed rolls: 1. Pull and re...

Page 21: 4.9 Reversing Polarity

En 4.9 reversing polarity some filler wires are recommended to be welded with the gun in the minus pole (–), so the polarity should be reversed. Check the recommended polarity from the filler wire package. 1. Disconnect the machine from the mains. 2. Expose the terminal connections by bending the pr...

Page 22: Using Control Panels

En 5. Using control panels 5.1 regular control panel dynamics u w006169 2t / 4t gas mig hot spot spot / cycle post gas m min manual 4t v 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Models featuring the regular (r) control panel offer the following control functions and features. 1. Control knob for welding dynam...

Page 23

En 3. Control knob for welding voltage this control knob increases and reduces the available output voltage of the machine to the welding arc. The scale is regulated in volts and is also supported by a graphical display bar that indicates the proportion of the available output voltage selected. 4. S...

Page 24

En 9. Overheating indicator under normal working conditions the overheating indicator is not visible. However, should the machine exceed its working duty cycle, welding will cease and the thermometer symbol will illuminate indicating that the machine has overheated. The cooling fans of the machine w...

Page 25

En 1. Dynamics control dynamics function controls the rate of rise of current when the filler wire is in short circuit with the welding plate. This control adjustment is necessary due to the alternative welding parameters, materials, wire sizes, gas types and current values used. The welding dynamic...

Page 26

En 6. Selection for manual, automatic or hot spot function mode hot spot this button switches the machine from standard mig/mag welding mode to a specialised process function for localised spot heating and stress relieving for metal panels. This function is normally used in the automotive industry a...

Page 27

En 12. Selection for filler wire diameter (adaptive mode) wire Ø when operating in adaptive mode and automatic is selected from the mode selection button 6, you can select from the filler wire diameter options. Following your materials selection through button 11, press button 12 briefly to select t...

Page 28: 5.3 Parameter Guides

En 16. Material thickness and weld shape display mm when operating in adaptive mode and automatic is selected from the mode selection button 6, the material thickness and weld shape is displayed, based on your input selections for plate thickness in mm and weld shape. Adjust these values though cont...

Page 29: Mig/mag Welding

En 6. Mig/mag welding note! Welding fumes may be dangerous to your health. Ensure that there is ample ventilation during welding! Never look at the arc without a face shield specifically designed for arc welding! Protect yourself and your surrounding area from the arc and hot welding spatter! Note! ...

Page 30: 6.1 Hot Spot Function

En pull the welding gun trigger. The filler wire will move forward, and a short circuit will occur and the arc will be established. Keeping the gun trigger depressed, the molten weld pool will start to form. Begin to travel the gun forwards, in a controlled manner and travel speed. Providing you hav...

Page 31: Maintenance

En 7. Maintenance note! Be careful when handling electrical cables! In maintaining the unit, take into consideration the rate of use and the environment it is used in. When the unit is used properly and serviced regularly, you will avoid unnecessary disturbances in use and production. 7.1 daily main...

Page 32: 7.2 Troubleshooting

En 7.2 troubleshooting welding performance can be effected by a number of issues, including the welding gun and/ or other parts of the welding system. The following information will help you to check, identify and rectify possible causes of welding malfunction. Note! The problems listed and the poss...

Page 33: 7.3 Storage

En 7.3 storage store the unit in a clean and dry place. Shield it from rain, and in temperatures exceeding +25 °c from direct exposure to sun. 7.4 disposal of the machine do not dispose of electrical equipment with normal waste! In observance of european directive 2002/96/ec on waste electrical and ...

Page 34: Ordering Codes

En 9. Ordering codes kempact 251r, 253r, 323r, 181a, 251a, 253a, 323a 253rmv, 323rmv, 253amv, 323amv kempact 251r, fe25 3.5m p2203 kempact 323rmv, fe 27, 3.5m p2216 kempact 251r, fe25 5m p2204 kempact 323rmv, fe 27, 5m p2215 kempact 253r, fe27 3.5m p2207 kempact 323rmv, fe 32, 3.5m p2219 kempact 253...

Page 35: 10. Technical Data

En 10. Technical data 1phase models kempact 181a 251r, 251a connection voltage 1~, 50/60 hz 230 v ±15% 1~, 50/60hz 240v ±15% rated power at max. Current 50% ed i 1max (180a) 5 kva 30% ed i 1max (250a) 8.5 kva supply current 50 % ed i 1max (180a) 22 a 30 % ed i 1max (250a) 36 a 100 % ed i 1eff (140a)...

Page 36

En 3 phase models kempact 253r, 253a 323r, 323a connection voltage 3~, 50/60hz 400 v ±15% 3~, 50/60hz 400 v ±15% rated power at max. Current 40% ed i 1max (250a) 8.5 kva 35% ed i 1max (320a) 12 kva supply current 40% ed i 1max (250 a) 11.9 a 35% ed i 1max (320a) 17.2 a 100% ed i 1eff (150 a) 6.1 a 1...

Page 37

3 phase models, mvu kempact 253 mvu 323 mvu connection voltage 3~, 50/60 hz 230v –15%…400v +15% 3~, 50/60 hz 230v –15%…400v +15% rated power at max. Current 40% ed i 1max (250 a, 230 v) 9 kva 35% ed i 1max (320 a, 230 v) 13.5 kva 40% ed i 1max (250 a, 400 v) 8.5 kva 35% ed i 1max (320 a, 400 v) 12.5...

Page 38

Operating temperature range –20…+40 °c –20…+40 °c storage temperature range –40…+60 °c –40…+60 °c standards iec 60974-1 iec 60974-1 iec 60974-5 iec 60974-5 iec 60974-10 iec 60974-10

Page 40

Www.Kemppi.Com 1922090 1442 kemppi oy kempinkatu 1 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46...