- DL manuals

- Kempi

- Respiratory Product

- FreshAir Flow Control

- Operating Manual

Kempi FreshAir Flow Control Operating Manual

Operating manual

Brugsanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Bruksanvisning

Instrukcja obsługi

Manual de utilização

Инструкции по эксплуатации

Bruksanvisning

操作手册

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

RU

SV

ZH

FreshAir

Flow Control

Summary of FreshAir Flow Control

Page 1

Operating manual brugsanvisning gebrauchsanweisung manual de instrucciones käyttöohje manuel d’utilisation manuale d’uso gebruiksaanwijzing bruksanvisning instrukcja obsługi manual de utilização Инструкции по эксплуатации bruksanvisning 操作手册 en da de es fi fr it nl no pl pt ru sv zh freshair flow co...

Page 3: Operating Manual

En 3 © kemppi oy / 1309 operating manual english 3 © kemppi oy / 1309.

Page 4: Contents

En 4 freshair flow control contents 1. Introduction ......................................................................... 5 1.1 general ...................................................................................... 5 1.2 about freshair flow control system ...................................

Page 5: Introduction

En 5 © kemppi oy / 1309 1. Introduction 1.1 general congratulations on choosing the freshair flow control respiratory system. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important...

Page 6: 1.3

En 6 freshair flow control 1.3 manufactured by manufactured for and on behalf of kemppi oy by: cleanair ltd. 2. Preconditions for use freshair flow control respiratory system can be used for protection against solid and liquid particles in breathing air in welding and similar processes. Do not use i...

Page 7: Unpacking And Assembly

En 7 © kemppi oy / 1309 • if the breathing air in the workplace contains both particle and gas contamination, an adequate combined filter must be used. • when using filters protecting against gases, which are difficult to identify by smell or other senses, special rules depending on the current cond...

Page 8: 3.2

En 8 freshair flow control 3.2 assembly 1. Attach the respiratory unit onto the belt. Make sure that the filter or filters are fitted properly. 2. Connect the air hose to the blower unit via a bayonet connector. 3. Connect the air hose to the headpiece and hand tighten. 4. Usage 4.1 inspection befor...

Page 9: 4.4

En 9 © kemppi oy / 1309 the unit ensures a constant supply of air. The microprocessor inside the unit automatically regulates the motor speed to compensate the filter clogging and the battery state. If the microprocessor cannot maintain the adjusted airflow, an acoustic alarm signal can be heard and...

Page 10: 4.5

En 10 freshair flow control 4.5 checking the filter press and hold the right button (+) for more than 1 second. The more yellow led diodes come on, the more clogged the filter is. > 1 s after releasing the buttons, the led diodes return to the green light state indicating the current airflow. 5. Mai...

Page 11: 6.2

En 11 © kemppi oy / 1309 the particle filter can be used with a pre-filter to prolong the main filter life, or with an odor filter which removes unwanted odors. 6.2 changing the filter remove the filter cover: have the orange filter cover facing you and do the following: 1. Put your index fingers an...

Page 12: 6.3

En 12 freshair flow control insert a new filter: 1. 2. 3. 1. If you are using a prefilter or an odor filter, place and fix it around the new filter as tightly as possible, sticking the ends together using the sticky tape located on the ends of the prefilter or odor filter. 2. Put the filter back int...

Page 13: 6.5

En 13 © kemppi oy / 1309 6.5 changing the battery remove the battery: 1. Take the blower unit in both hands with the rear side of battery facing you. 2. Open the battery latch with your thumb. The latch is positioned in the middle of the battery. 3. Push the battery off the unit using your thumbs. M...

Page 14: Troubleshooting

En 14 freshair flow control 7. Troubleshooting if there is a sudden change in air supply while using the freshair system, do the following checks: • ensure that all parts of the air-supply system are assembled properly. • check the battery and its connector. • check if the charger is faulty or malfu...

Page 15: Storage

8. Storage all parts of a freshair system must be stored in an environment with temperature between 0 – 40 °c and humidity between 20 – 80 % rh. The storage life is 2 years for the product if stored in its original unopened package. Note! Batteries get discharged even if not in use. Therefore for lo...

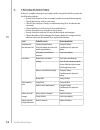

Page 16: 10. Technical Data

10. Technical data freshair flow control airflow 140 – 210 l/min at 8 adjustable flow rates weight of the blower unit incl. The filter and battery 900 g noise level 55 – 61 db nimh battery lifetime 500 – 700 charging cycles charging time 10 – 14 hours belt size 80 – 100 cm recommended temperature ra...

Page 17: 11. Ordering Codes

11. Ordering codes beta 90 freshair with flow control (9873065 + w007513) p1700 delta 90 freshair with flow control (9873066 + w007513) p1701 freshair flow control with alarm complete package w007512 spare parts and consumables fa battery charger euro plug w007485 fa flow control flexi hose w007487 ...

Page 18

1918820 1309 www.Kemppi.Com kemppi oy kempinkatu 1 pl 13 fi-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46 ...