- DL manuals

- Kempi

- Welding System

- SuperSnake GT02S

- Operating Manual

Kempi SuperSnake GT02S Operating Manual

Operating manual • English

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Gebrauchsanweisung • Deutsch

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

操作手册

•

中文

Manuale d’uso • Italiano

EN

FI

SV

NO

DA

DE

NL

FR

ES

PL

RU

ZH

IT

SuperSnake

GT02S, GT02SW

Summary of SuperSnake GT02S

Page 1

Operating manual • english käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk brugsanvisning • dansk gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español instrukcja obsługi • polski Инструкции по эксплуатации •...

Page 3: Operating Manual

Operating manual english supersnake gt02s, gt02sw / © kemppi o y / 1110

Page 4

En contents 1. Preface ................................................................................................................................ 3 1.1 general .........................................................................................................................................

Page 5

En 1. Preface 1.1 general congratulations on choosing the supersnake equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance and safet...

Page 6

En 2. Installation 2.1 before use the product is packed in specially designed transport cartons. However, before use always make sure the products have not been damaged during transportation. Check also that you have received the components you ordered and the instruction manuals needed, as describe...

Page 7

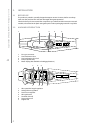

En 2.3 connecting cables note! Always check before use that the interconnecting cable, shielding gas hose, earth return lead/clamp, and mains cable is in a serviceable condition. Ensure that connectors are correctly fastened. Lose connectors can impair welding performance and damage connectors. Sub ...

Page 8

En 2.3.2 gas cooled system fastmig pulse + mxf 1. 4. 5. 7. 6. 9. 2. 3. 8. 1. Mxf or promig wire feed unit 2. Fastmig pulse or pro evolution power source 3. Gas supply 4. Mma electrode holder 5. Remote control device 6. Supersnake gt02s 7. Air cooled welding gun 8. Power cable 9. Earth return lead an...

Page 9

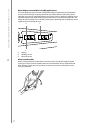

En filler wire support liners ø, mm m order number fe, mc, fc 0.8 – 1.6 10.5 w004214 15.5 w004216 20.5 w004217 25.5 w004218 ss, al, fe, mc, fc 0.8 – 1.6 10 w004145 15 w004219 20 w004220 25 w004221 supersnake wire feed mechanism before loading the filler wire to supersnake please set the wire feed me...

Page 10

En 3.2 mounting and locking of wire spool ensure quality filler wire is loaded to the wire feed cabinet. Check that the correct wire guide tube and wire drive rolls are selected and fitted for the filler wire type used. Note! Check that the filler wire spool is correctly mounted and locked into posi...

Page 11

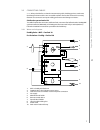

En now take a fine file or abrasive cloth and remove any sharp edges from the filler wire end, before loading to supersnake. This prevents damage to plastic liners in particular, and also prevents pick-up and stubbing inside metal liners when loading. Note! Smaller diameter filler wires may need to ...

Page 12

En communication cables support the supersnake coupling and guide the filler wire into the supersnake liner. Then carefully mate and connect supersnake to the wire feed unit connector. Secure the supersnake by hand tightening the orange collar. The supersnake coupling transfers welding power, shield...

Page 13

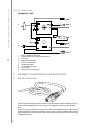

En connecting the welding gun prepare your welding gun for connection. Supersnake is designed to accept a wide variety of welding guns fitted with the standard euro fitting. To ensure reliable welding performance, please ensure the gun is suitable for the intended welding application and is in good ...

Page 14

En meter display (not available in promig applications) the meter display provides essential welding data indicators. Depending on the mig/mag process selected, voltage, amperage, wire feed speed, plate thickness and polarity will be indicated. Power and arc length adjustment can be made, prior to, ...

Page 15

En setting the shielding gas the shielding gas flow rate from the welding gun is set according to the application, weld joint, gas type and gas nozzle shape and size. The flow rate should be measured at the welding gun nozzle before welding via a rotameter, and normally measure’s between 10 – 20 lit...

Page 16

En 4.2 service shop maintenance kemppi service workshops complete maintenance according to their kemppi service agreement. Regular preventative maintenance by trained technicians will increase equipment life and ensure reliable operation. 5. Disposal of the machine do not dispose of electrical equip...

Page 17

En 7. Technical data connection voltage 50 v dc output 40 °c 380 a cabel ø 50 mm2 welding current i₂ 100% 300 a i₂ 60% 380 a supply voltage u₁ 50 v dc supply current i₁ 20 ma motor voltage u motor 0 – 24 v dc motor current i motor 5 a wire feed mechanism 2 roll filler wires, 25 m fe/ss ø 1.0 – 1.6 a...

Page 18

Www.Kemppi.Com 1923520 1110 kemppi oy hennalankatu 39 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel ...