Pmt 25, 27, 32, 35, 42 30w, 42w, 52w operating manual • english käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk brugsanvisning • dansk gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français Инструкции по эксплуатации • По-русски en fi sv no da...

En operating manual english pm t © kemppi o y / 1130

En contents 1. Preface ................................................................................................................. 3 1.1 general .......................................................................................................................... 3 1.2 product introduction...

En 1. Preface 1.1 general congratulations on having purchased this product. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance and safety of...

En 1.2 product introduction kemppi pmt mig/mag guns for manual welding are designed for demanding professional use. They are suitable to be used in all mig units equipped with a euro adapter. 1.3 operation safety please study these operation safety instructions and respect them when installing, oper...

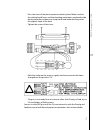

En 2. Connecting the gun in its delivery state, internal connections of pmt guns are made so that they are suitable to be used only with promig and feed wire feeders. Do not use the pmt gun in any other wire feeder than promig and feed before you have changed internal connections of gun according to...

En 3. Using the pmt gun with units other than promig and feed in the pmt guns, in addition to start operations, gun control and thermal protection operations are also transmitted along the control lines of the snap connector (pmt 30w, pmt 42w, pmt 52w). Hence the delivery state of the guns is such t...

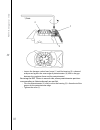

En • press the cover of the plastic protection back in place. Make sure that the cooling liquid hoses and their bending protections are placed inside plastic protection without any sharp bends and make that they retain the original shape of the hose. • tighten the screws of the cover. • mark the sti...

En 4. Mounting the gun regulator rmt 10 in the handle of the pmt gun there is a place for the gun regulator rmt 10 (6185475), which is available as an accessory. This regulator enables you to ragulate the welding power of synergic mig or pulsed mig welding with the promig and feed, or select preprog...

En 5. Using the gun regulator rmt 10 depending on the panel used in the promig (or feed) wire feeder, the gun regulator rmt 10 will enable you to regulate wire feed speed in mig welding as well as the welding power of synergic mig or pulsed mig welding. You can also select preprogrammed welding para...

En 1,5 mm 3 2 1 • loosen the hexagon socket head screw (1) until the bearing (2) is released and pressed against the outer edge of potentiometer (3) (look in the gap between the regulator frame and the potentiometer). Restoring the rmt 10 into its normal state, where potentiometer positions correspo...

En 6. Operation of the thermal shield inside the plastic protection of the snap connector head, pmt / w guns have, as an extension for a liquid-current cable, a ptc thermal shield, which in promig or feed equipment switches off the welding when gun overheats. The thermal shield prevents overheating ...

En pmt 25, pmt 27, pmt 32: when adjusting the neck, always make sure that the fastening thread of the gun neck has been tighthened almost completely. If you twist the neck too much outwards, the connection between the neck and the cable becomes loose, which increases the voltage drop. As a result, p...

En 9. Operation disturbances welding is stopped and the pilot lamp of thermal shield of the promig unit is lit: • thermal shield of the gun has stopped welding. Find the fault before you continue welding. Especially check connections of the cooling liquid hoses (also in the interconnecting cable). S...

En • pressure cumulated in long gas hoses will cause a burst of shielding gas at the beginning of welding, which may cause turbulence or mixing of air into the shielding gas. The reason for this might also be a faulty or a poorly adjusted relief valve, which puts too much pressure into the gas hoses...

En 11. Technical data gun loading capacity ar + co2 (a) duty cycle (%) wire diameters (mm) type of cooling cooling data max. Temp. In inlet (°c) min. Flow rate (l/min) min. Pressure (bar) max. Pressure (bar) pmt 25 250 35 0,6 – 1,2 air pmt 27 270 35 0,6 – 1,2 air pmt 32 320 35 0,8 – 1,6 air pmt 35 3...

Www.Kemppi.Com 1925050 1130 kemppi oy hennalankatu 39 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel ...