- DL manuals

- Kemppi

- Welding System

- 350

- Operating Manual

Kemppi 350 Operating Manual - Operating Manual

Summary of 350

Page 1

Operating manual • english käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk brugsanvisning • dansk gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español instrukcja obsługi • polski Инструкции по эксплуатации •...

Page 3: Operating Manual

Operating manual english fastm ig p ulse 350, 450 / © kemppi o y / 1110

Page 4

En contents 1. Introduction .............................................................................................................. 3 1.1 general ....................................................................................................................................... 3 1.2 about...

Page 5

En 1. Introduction 1.1 general congratulations on choosing the fastmig pulse welding equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maint...

Page 6

En 2. Installation 2.1 before use the product is packed in specially designed transport cartons. However, before use always make sure the products have not been damaged during transportation. Check also that you have received the components you ordered and the instruction manuals needed, as describe...

Page 7

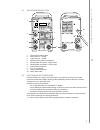

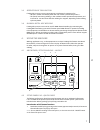

En 2.3 machine introduction channel 6,3a 1. 2. 3. 4. 8. 10. 5. 7. 9. 6. 1. Setup panel 'arc wizard p65' 2. Main switch i/o – on/off 3. Signal lamp i/o – on/off 4. Warning lamp for thermal protection 5. Welding cable connection - negative pole 6. Welding cable connection + positive pole 7. Control ca...

Page 8

En 2.5 connecting cables note! Always check before use that the interconnecting cable, shielding gas hose, earth return lead/clamp, and mains cable is in a serviceable condition. Ensure that connectors are correctly fastened. Lose connectors can impair welding performance and damage connectors. 2.5....

Page 9

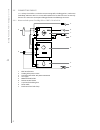

En 2.5.2 gas cooled system: fastmig pulse + mxf 1. 4. 5. 6. 8. 2. 3. 7. 1. Mxf wire feed unit 2. Fastmig pulse power source 3. Gas supply 4. Mma electrode holder 5. Remote control device 6. Air cooled welding gun 7. Power cable 8. Earth return lead and clamp 2.5.3 connecting to mains power fastmig p...

Page 10

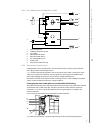

En 2.5.4 welding and earth return cables kemppi always recommend the use of high quality copper cables with a suitable cross- sectional area. Cable size should be selected depending on the intended welding application. 50mm2 copper welding cables may be used for low duty work in basic or synergic 1-...

Page 11

En 3.3 operation of cooling fan fastmig pulse power sources incorporate two simultaneously operating fans. • the fan is started momentarily when the main switch is placed into position - i. • the fan will start during welding as the machine reaches operational temperature, and it will run for 1 to 1...

Page 12

En 2. Welding channel (job) selection. There are 10 memory channels available per user channel. There are 10 user channels . If the channel is empty you can create a new (job) channel by pressing the key below the lcd screen text stating new. 3. Menu button for entering the main menu list. Proceed f...

Page 13

En 1-mig wfspeed 0.7 – 25 m/min * 0.05 m/min steps when wfspeed 0.1 m/min steps when wfspeed > 5 m/min wfs-max set the limit for maximum wfspeed wfs-min set the limit for minimum wfspeed finetuning -9 ... +9 factory setting is 0 ( = curve point) adjusts the arc voltage of the curve within certain li...

Page 14

En wiseroot / wisethin wfspeed 0.7 – 14 m/min * 0.05 m/min steps when wfspeed 0.1 m/min steps when wfspeed > 5 m/min wfs-max set the limit for maximum wfspeed wfs-min set the limit for minimum wfspeed basecurrent -50 ... +50 adjusts the base current of the curve – the arc length – within certain lim...

Page 15

En cratertime 0.0 – 10.0 s 0.1 s steps. Factory setting 1.0 s cratefill slope time crater 4t timer on or off factory setting is off on: if 4t is selected crater filling will last at least time that has been ad-justed by cratertime or as long as trigger is pressed. Off: if 4t is selected crater filli...

Page 16

En advanced functions wisepenet on or off penetration control selection penet%(123a) -30 ... +30 % factory setting: 0 % wise penetration percent setting. Set penetration current. Wisefusion on or off wisefusion selection wisefusion% 10 – 60 % or curve factory setting is curve when wise fusion is on ...

Page 17

En welddata delay adjustment range: 1s – 60s, 1s steps. Factory setting: 20s. Defines how long the weld data is displayed after welding ends. Weld data display is also turned off when pulse encoder is turned or any button is pressed. Display delay adjustment range: 1 – 20, 1 steps. Factory setting: ...

Page 18

En administrator menu (in main menu 2/7, user identification) change pin code administrator pin code change. Factory pin code: 0000 ask pin pin code inquiry selection: off / startup / menu factory setting: off off: no pin code inquiry. Startup: setup panel (p65) always asks for the pin code when the...

Page 19

En 4.3.3 welding software delivery profile fastmig pulse is designed to allow customer specified welding software choice. Following delivery and installation your machine will include welding software specified at the point of order. Detailed in the table below are typical welding curves available. ...

Page 20

En fe f22 x x 0.9 fe co2 fe f23 x x 1 fe co2 fe f24 x x 1.2 fe co2 ss s01 x 0.8 ss-316/308 ar+2%co2 ss s02 x x 0.9 ss-316/308 ar+2%co2 ss s12 x 0.9 ss-316/308 ar+he+co2 ss s13 x 1 ss-316/308 ar+he+co2 ss s14 x 1.2 ss-316/308 ar+he+co2 4.4 getting started step by step for the first time user first se...

Page 21

En 8. Choose and select shielding gas – press select button 9. Choose and select curve – press select button. (note: the curve(s) presented in this view are based on your previous selections from items 4 through to 8.) 10. Choose and save memory channel number. Memory channel selections are made usi...

Page 22

En 5. Basic troubleshooting note! The problems listed and the possible causes are not definitive, but serve to suggest some standard and typical situations that may present during normal environmental use when using the mig/mag process with fastmig pulse. Problem check the following machine won’t wo...

Page 23

En 6. Operation disturbances should you experience a malfunction from your machine, please consult the basic troubleshooting text above first, and complete some basic checks. If the machine malfunction cannot be corrected with these measures, contact your kemppi maintenance service workshop. 6.1 ope...

Page 24

En 7.2 period maintenance note! Period maintenance should only be carried out by a suitably qualified person. Disconnect the plug of the machine from the mains socket and wait approx.2 minutes (capacitor charge) before removing the cover plate. Check at least every half year: • electric connectors o...

Page 25

En 9. Ordering numbers fastmig pulse 350 power source 6150400 fastmig pulse 450 power source 6150500 fastmig pulse setup panel p65 included with power source 6155300 fastmig mxf 63 wire feeder 200 mm work pack profile 6152300el fastmig mxf 65 wire feeder 300 mm work pack profile 6152100el fastmig mx...

Page 26

En supersnake gt02s sub feeder 10 m 6153100 supersnake gt02s sub feeder 15 m 6153150 supersnake gt02s sub feeder 20 m 6153200 supersnake gt02s sub feeder 25 m 6153250 supersnake gt02s w sub feeder 10 m 6154100 supersnake gt02s w sub feeder 15 m 6154150 supersnake gt02s w sub feeder 20 m 6154200 supe...

Page 27

En 10. Technical data fastmig™ pulse 350 450 connection voltage 3~50/60 hz 400 v -15 %...+20 % 400 v -15 %...+20 % rated power 60 % ed 22.1 kva 80 % ed 16.0 kva 100 % ed 15.3 kva 16.0 kva connection cable ho7rn-f 4g6 (5 m) 4g6 (5 m) fuse (delayed) 25 a 35 a output 40 °c 60 % ed 450 a 80 % ed 350 a 1...

Page 28

Www.Kemppi.Com 1923670 1110 kemppi oy hennalankatu 39 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel ...