- DL manuals

- Kemppi

- Welding System

- 450

- Operating Manual

Kemppi 450 Operating Manual

Operating manual • English

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Gebrauchsanweisung • Deutsch

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

操作手册 • 中文

Manual de utilização • Português

EN

FI

SV

NO

DA

DE

NL

FR

ES

PL

RU

ZH

KempArc™

Pulse 350, 450

DT 400

PT

Summary of 450

Page 1

Operating manual • english käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk brugsanvisning • dansk gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español instrukcja obsługi • polski Инструкции по эксплуатации •...

Page 3: English

En operating manual english kemp a rc pulse 350, 450 / © kemppi o y / 1044.

Page 4

En contents 1. Introduction .................................................................................................................................. 3 1.1 general ..................................................................................................................................

Page 5

En 1. Introduction 1.1 general congratulations on choosing the kemparc™ pulse welding equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, main...

Page 6

En 2. Installation 2.1 before use the product is packed in specially designed transport cartons. However, before use always make sure the products have not been damaged during transportation. Product packaging material is recyclable. Note! When moving the welding machine, always lift it from the han...

Page 7

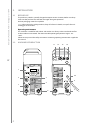

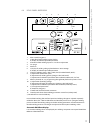

En 1. Setup panel k 60 2. Main switch i/o - on/off 3. Signal lamp i/o - on/off 4. Warning lamp for thermal protection 5. Welding cable connection - negative pole 6. Welding cable connection + positive pole 7. Control cable connection 8. Fuse – 6.3 a delayed 9. Control cable connection 10. Mains powe...

Page 8

En 2.5 connecting cables note! Always check before use that the interconnecting cable, shielding gas hose, earth return lead/clamp, and mains cable is in a serviceable condition. Ensure that connectors are correctly fastened. Lose connectors can impair welding performance and damage connectors. 2.5....

Page 9

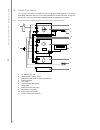

En 2.5.2 gas cooled system: kemparc pulse + dt 400 1. 4. 6. 7. 2. 8. 3. 5. 1. Dt 400 wire feed unit 2. Kemparc pulse power source 3. Gas supply 4. Gas cooled welding gun 5. Power cable 6. Earth return lead and clamp 7. Kf 62 remote panel (optional) 8. Robot controller 2.5.3 connecting to mains power...

Page 10

En if changing the mains cable take into consideration the following: the cable is entered into the machine through the inlet ring on the rear panel of the machine and fastened with a cable clamp. The phase conductors of the cable are coupled to connectors l1, l2 and l3. The earth protection coloure...

Page 11

En cable duty cycle ed voltage loss / 10 m 100 % 60 % 30 % 70 mm² 355 a 460 a 650 a 0.25 v / 100 a 95 mm² 430 a 560 a 790 a 0.18 v / 100 a do not overload welding cables due to voltage losses and heating. Note! Always check the serviceability of the earth return cable and clamp. Ensure the metal sur...

Page 12

En 4. Using the machine welding applications vary, so the equipment must adapt. Kemparc pulse features k 60 interface, a clear and logical lcd menu display. Arc wizard menu allows the operator to refine, adapt and manage the arc process and system function before, during and after welding. 4.1 setup...

Page 13

En k 60 main menu list value range factory setting description edit channel for making changes to existing welding channel weld data for checking out the values of the last weld special settings for adjusting special welding parametres system config menu for device configuration and information lang...

Page 14

En 4.3 welding parametres and functions 4.3.1 welding parametres (in edit channel menu 2/6) mig wfspeed 0.7 – 25 m/min 0.05 m/min steps when wfspeed 0.1 m/min steps when wfspeed > 5 m/min wfs-max set the limit for maximum wfspeed wfs-min set the limit for minimum wfspeed voltage 8 – 50v 0.1v steps c...

Page 15

En double pulse mig wfspeed 0.7 – 25 m/min 0.05 m/min steps when wfspeed 0.1 m/min steps when wfspeed > 5 m/min wfs-max set the limit for maximum wfspeed wfs-min set the limit for minimum wfspeed finetuning factory setting is 0 ( = curve point) adjusts the base current of the curve in certain limits...

Page 16

En 4.3.2 welding functions other processes (in edit channel menu 3/6) hotstart on, off or user factory setting is user => user can freely choose is the hotstart on or off hotstartlevel -50 – 100 % 1 % steps. Factory setting 40 % hot 2t time 0 – 9.9 s 0.1 s steps. Factory setting 1.2 s craterfill on,...

Page 17

En system config menu (in main menu 4/7) water cooling water cooler control: off / auto / on. Factory setting: auto off: water cooler always off. Auto: water cooler automatic control on. Water cooler starts when welding starts and is turned off after a delay when welding stops. On: water cooler is a...

Page 18

En administrator menu (in main menu 2/7, user identification) change pin code administrator pin code change. Factory pin code: 0000. Ask pin pin code inquiry selection: off / startup / menu factory setting: off off: no pin code inquiry. Startup: setup panel (k 60) always asks for the pin code when t...

Page 19

En welding software delivery profile kemparc pulse is designed to allow customer specified welding software choice. Following delivery and installation your machine will include welding software specified at the point of order. Detailed in the table below are typical welding curves available. If the...

Page 20

En kemppi wise products are welding process solutions. Wiseroot and wisethin process group curves are listed below. Group n:o wiseroot wisethin wire ø mm material gas fe f01 x 0.8 fe ar+18–25%co2 fe f02 x x 0.9 fe ar+18–25%co2 fe f03 x x 1 fe ar+18–25%co2 fe f04 x x 1.2 fe ar+18–25%co2 ss s03 x x 1 ...

Page 21

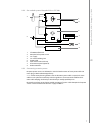

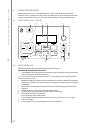

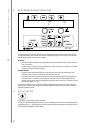

En 4.4 kf 62 panel overview power wise pulse channel 1-mig save robot panel control mig double pulse u a s v m/min mm kf 62 w004330 + / – 12. 13. 11. 9. 7. 1. 4. 3. 5. 2. 6. 8. 10. 1. Main switch (long press) 2. A) wire feed speed/welding current display b) display of selected adjustable parametre 3...

Page 22

En 5. Kf 62 panel button functions power wise pulse channel 1-mig save robot panel control mig double pulse u a s v m/min mm kf 62 w004330 + / – the control panel is used for controlling and monitoring the operation of the power source and the wire feeder. The buttons are used for adjusting function...

Page 23

En 5.2 dynamics button 2. Short press: dynamics setting if welding process is mig/synergic mig. Forming pulse setting if welding process is wiseroot/wisethin. 5.3 gas test button 3. Gas test function. Pressing the button will show the gas test time. Gas test time can be adjusted by using the pulse e...

Page 24: Power

En 5.7 save button save 7. For saving the memory channel. Short press: save. Long press: panel is locked. No panel parametre changes allowed (panel lock). 5.8 extra functions button 8. Short press: crater filling selection / hot start selection. 5.9 control display robot panel control 9. Robot: weld...

Page 25

En 5.12 getting started step by step for the first time user first select your language note! The default menu language is english. In the following steps you will be able to select alternative languages 1. Connect mains power and switch on power source. If this is the initial system activation you ...

Page 26

En ready to weld: your basic welding selection and set-up is now complete. You are ready to weld, providing you select the corresponding channel ‘job’ number on the kf 62 remote control panel. Set your welding power and arc length and weld. Note! If you select ‘mig’ (i.E. Basic mig/mag selection in ...

Page 27

En 6. Basic troubleshooting note! The problems listed and the possible causes are not definitive, but serve to suggest some standard and typical situations that may present during normal environmental use when using the mig/mag process with kemparc pulse. Problem check the following machine won’t wo...

Page 28

En 7. Operation disturbances should you experience a malfunction from your machine, please consult the basic troubleshooting text above first, and complete some basic checks. If the machine malfunction cannot be corrected with these measures, contact your kemppi maintenance service workshop. 7.1 ope...

Page 29

En 8.2 period maintenance note! Period maintenance should only be carried out by a suitably qualified person. Disconnect the plug of the machine from the mains socket and wait approx. 2 minutes (capacitor charge) before removing the cover plate. Check at least every half year: • electric connectors ...

Page 30

En 10. Ordering numbers kemparc pulse 350 power source 6200350 kemparc pulse 450 power source 6200450 kemparc pulse 350 power source analogue 6200350an kemparc pulse 450 power source analogue 6200450an kemparc pulse 350 power source work pack profile 6200350el kemparc pulse 450 power source work pac...

Page 31

En 11. Technical data kemparc pulse 350 kemparc pulse 450 connection voltage 3~50/60 hz 400 v -15 %...+20 % 400 v -15 %...+20 % rated power 60 % ed 22.1 kva 80 % ed 16.0 kva 100 % ed 15.3 kva 17.8 kva connection cable ho7rn-f 4g6 (5 m) 4g6 (5 m) fuse (delayed) 25 a 35 a load capacity 40 °c 60 % ed 4...

Page 32

En dt 400 operating voltage 50 v dc rated power 100 w load capacity 40 °c 80% ed 600 a 100% ed 500 a operating principle 4 wheel feed wire feed speed 0 ... 25 m/min filler wires ø fe, ss 0.6 ... 1.6 mm flux-cored wire 0.8 ... 1.6 mm al 1.0 ... 1.6 mm welding gun connector euro operating temperature ...

Page 34

Www.Kemppi.Com 1920150 1044 kemppi oy hennalankatu 39 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel ...