- DL manuals

- Kemppi

- Welding System

- FastMig KM 500

- Service Manual

Kemppi FastMig KM 500 Service Manual

Summary of FastMig KM 500

Page 1

Service manual v. 1.0 fastmig km 300 km 400 km 500 1 kms 300 kms 400 kms 500 mf 29 mf 33 msf 53 msf 55 msf 57.

Page 2: Table of Contents

Table of contents technical data fastmig km / mf............................................................................. 3 fastmig kms / mfs........................................................................ 4 fastmig kms / mvu..................................................................

Page 3: Technical Data

Technical data fastmig km / mf 3.

Page 4: Technical Data

Technical data fastmig kms / msf 4.

Page 5: Technical Data

Technical data fastmig kms / mvu 5.

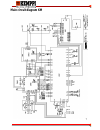

Page 6: Main Circuit Diagram

Main circuit diagram m001 cooling fan g003 diode bridge f001 fuse 6,3 a a001 control card r001 varistors l001 choke z002 capasitor card t001 main transformer z003 secondary card l001 secondary choke t002 aux. Transformer s001 main switch rc001 rc-protection h001 / 002 leds a002 control card p001 pan...

Page 7: Main Circuit Diagram Km

Main circuit diagram km 7.

Page 8: Main Circuit Diagram Mf

Main circuit diagram mf 8.

Page 9: Main Circuit Diagram Kms

Main circuit diagram kms 9.

Page 10: Main Circuit Diagram Msf

Main circuit diagram msf 10

Page 11

Main circuit diagram km / mvu 11.

Page 12

Main circuit diagram kms / mvu 12.

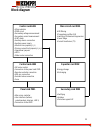

Page 13: Block Diagram

Block diagram control card a001 •microcontroller •pwm circuit •secondary voltage measurement •secondary current measurement •igbt driver •auxiliary device connection •auxiliary power supply •machine size jumpers (j1, j2) •primary current limit jumpers (j3, j4, j5) •operational jumpers •led’s •water ...

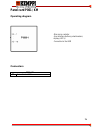

Page 14: Operating Diagram

Main circuit card z001 km / kms main transformer primary coil dc-link (+) igbt gates from main switch dc-link (-) operating diagram - emi filtering - three phase rectifier (v6) - switching-on transient suppression - power stage - current transformer (t1) 14.

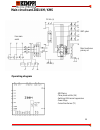

Page 15: Main Circuit Card Z001

Main circuit card z001 operation principle g1 g3 g2 g4 g5 l1 u g1 u g3 u g4 u g2 u t1 u g5 u l1 approx.. + 570 v u g1 u g2 u g3 u g4 u t1 u g5 u l1 t t t t t t t when igbt-transistors g1 and g4 conduct, there is a positive voltage u t1 in main transformer t1 primary and when igbt-transistors g2 and ...

Page 16: Main Circuit Card Z001

Main circuit card z001 connectors 16 x19 x21 x10 x11 x14 x15 x12 x13 x18 x1 x20 x8 x9 x40 x29 x41 x6 x37 x17 x7 x36 x16 x3 x2 x5 x4 x16 primary choke x17 primary choke x18 dc-link voltage (+) x19 dc-link voltage (+) x20 dc-link voltage (-) x21 dc-link voltage (-) x29 chassis ground x36 current trans...

Page 17: Main Circuit Card Z001

Main circuit card z001 operational measurings a b 17 b. Igbt-gate pulses, set values 50 a/16,5 v a. Main transformer t001 primary voltage, set values 50 a/16,5 v.

Page 18: Capacitor Card Z002

Capacitor card z002 18 connectors x3 x1 x4 x2 operating diagram - energy storage - discharging x1 dc + x2 dc + x3 dc - x4 dc - z002 connectors / signals.

Page 19: Connectors

Secondary rectifier card z003 connectors x1 main transformer x2 main transformer x3 main transformer x4 main transformer z003 connectors / signals x5 secondary choke x6 secondary choke x7 secondary choke x8 secondary choke z003 x1 x2 x3 x4 x5 x6 x7 x8 operating diagram - rectifying - snubber - prote...

Page 20: Control Card A001

Control card a001 h4 x2 x17 20 operating diagram - microcontroller - pwm circuit - secondary voltage measurement - secondary current measurement - igbt driver - auxiliary device connection - auxiliary power supply - machine size jumpers (j1, j2) - primary current limit jumpers (j3, j4, j5) - operati...

Page 21: Control Card A001

Control card a001 connectors x9/1 system bus data x9/2 system bus data b x9/3 gnd x9/4 + 50 v x9/6 - x9/7 - x9/8 - x9/9 - x9/10 connection a002 x1/4 x9/11 - a001 / x9 / km x1 dc-link voltage (+) a001 / x1 x2/1 20v auxiliary voltage~ x2/2 20v auxiliary voltage ground x2/3 20v auxiliary voltage~ a001 ...

Page 22: Control Card A001

Control card a001 connectors x16/7 h002 + (yellow led) x16/8 h002 - x16/9 h001 + (green led) x16/10 h001 - a001 / x16 x13/1 ptc, rg 101 (z001) x13/2 ptc, rg 101 (z001) a001 / x13 x14/1 ptc, rt 101 (t001) x14/2 ptc, rt 101 (t001) a001 / x14 x17/1 +24v a001 / x17 x17/2 clu_fault x17/3 gnd x17/4 clu_ad...

Page 23: Motor Control Card A002

Motor control card a002 x3 x1 x2 x4 23 operating diagram - wf-motor control - connection to the panel card p001 - remote controller connection - mig gun connection - solenoid valve connection - fuse - id-chip connection (msf).

Page 24: Connectors

Motor control card a002 (a001 = msf) connectors x1/1 connection to a001, x9/4 x1/4 connection to a001, x9/10 a002 / x1 / km x1/1 bus +50v x1/3 tacho +5v x1/4 bus gnd x1/5 tacho gnd a001 / x1 / msf x1/6 tacho signal x2 connection to panel card a002/a001 / x2 x4/2 start x4/3 motor+ x4/4 u-measurement ...

Page 25: Id Chip Card A002 (Msf)

Id chip card a002 (msf) a002 id-chip card connectors tp1 id bus 1 (connection to a001) tp2 id bus 2 (connection to a001) a002 25.

Page 26: Panel Card P001 / Km

Panel card p001 / km operating diagram - main micro controller - user interface (buttons, potentiometers, displays, led’s) - connection to the a002 26 connectors x2 connection to a002 p001 / x2.

Page 27: Error Codes

Error codes power source 1 ..... 50 mig logic 51 ….. 100 curve access 101 ….. 130 robot interface 131 ….. 150 mig / tig unit 151 ….. 200 user interface 201 ….. 250 others 0 ….. 999 err 2: power source undervoltage ( new start up ) err 3: power source overvoltage ( new start up ) err 4: power source ...

Page 28: Setup Menu

Setup menu mf 29 / 33 fastmig basic (mf) setup menu sf 51, 52, 53, 54 normal mig 1-mig fr-mig all mig processes mma fastmig synergic (msf) setup menu 28.

Page 29

Wire feed speed calibration / km • in factory set wfs is adjusted in the range of 4...100 without any unit • led light and feed roll symbol tells that the parameter to be set is wfs • after wfs calibration m/min unit is displayed • drive filler wire through the mig gun and contact tip • enter to use...

Page 30

Wire feed speed calibration if wire feeding speed is not correct (too slow or too fast), motor control card a002 must be calibrated by following instruction: • set ‘min’ and ‘max’ -trimmers to middle position. • set ‘ir-comp’ -trimmer to clock vice maximum. • set wire feeding speed to maximum from t...

Page 31: Structure

Structure km / kms mains connector and varistors z001 main circuit board z002 dc-link capasitor board s001 main switch r001 shunt resistor 31 p001 panel card a001 control card a002 (km) wire feed control card water cooler power connector.

Page 32: Structure

Structure km / kms t002 auxiliary transformer l001 choke 32 z003 secondary rectifier diodes l002 secondary choke capacitors and varistors.

Page 33: Structure

Structure mf 29 / 33 dura torque wire feeding mechanism axle for wire reel coop 33 dura torque wire feeding mechanism welding current connector & copper bar control cable connector & wiring solenoid valve welding gun connection.

Page 34: Structure

Structure msf 53 / 55 / 57 a001 motor control card a002 id-chip card 34.

Page 35: Igbt Testing

Igbt testing c1/3 c2e1/1 b1/4 b2/6 e2/2 x14 g3 x12 g1 x10 g4 x8 g2 x15 e3 x13 e1 x6 x7 x11 e4 x9 e2 c1 e2 x10/g4 x11/ x14/g3 x15 x12/g1 x13 x8/g2 x9 x6 x7 c1/3 c2e1/1 b1/4 b2/6 e2/2 x14 g3 x12 g1 x10 g4 x8 g2 x15 e3 x13 e1 x6 x7 x11 e4 x9 e2 g c e ig b t -t e s te r t r 1 t r 2 c o n t r o l o ff o ...

Page 36: Igbt Replacing

Igbt replacing mounting the igbt to the heat sink the tools and premises used in this work must be clean and free of dirt and dust. Even very small particles (0,050mm) between the surfaces may increase the gap between heatsink and module, causing overheating ans possible damage. Heat transfer compou...