Summary of HiArc M 400R

Page 1

Operating manual manual de instrucciones manuel d’utilisation manual de utilização Инструкции по эксплуатации en fr es ru pt hiarc m 400r, m 500r.

Page 3: Operating Manual

Operating manual english.

Page 4

En contents 1. Introduction ......................................................................................................................... 3 1.1 general ....................................................................................................................................... ...

Page 5

En 1. Introduction 1.1 general congratulations on choosing the hiarc series power source. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance...

Page 6

En 2. Installation 2.1 before use the product is packed in cartons designed specifically for them. However, always make sure before use that the products have not been damaged during transportation. Check also that you have received the components you ordered and the instruction manuals needed. Prod...

Page 7

En 2.3 positioning of the machine place the machine on a sturdy, level surface that is dry and does not allow dust or other impurities to enter the machines cooling air flow. Preferably site the machine to a suitable carriage unit so it is above floor level. Notes for positioning the machine • the s...

Page 8

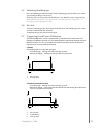

En 2.5.1 mains connection hiarc must be connected to an earthed 3-phase power supply using the terminal strip connector in the backside of the machine. Attach the mains cable leads as shown in the picture below. L1 l2 l3 to connect the mains cable do the following: 1. Remove the mains lead cover pla...

Page 9

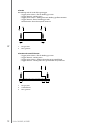

En 2.5.2 wire feeder connection the hiarc power source is designed to be used with the hiarc f wire feed unit. To connect the hiarc f wire feeder unit to the power source, complete the following steps: 1. 2. 3. 1. Attach the hiarc f wire feed unit power cable to the + connector of the hiarc power so...

Page 10

En 2.5.3 earth return cable connection attach the earth return cable to the minus (–) connector. Hand tighten the connector with a clockwise push and twist action to lock. Attach the other end of the earth return cable to the workpiece before welding. Note! When attaching the earth return clamp to t...

Page 11

En 3. Using the machine 3.1 control panel functions on/off switch this switch turns the machine on and off. Gas test button press to test the shielding gas flow. Gas selection button press to select either co₂ or mixed shielding gas (mag). Press to select between 2t and 4t gun trigger modes. Crater ...

Page 12

En 3.2 starting the machine to start the machine, turn the main switch to position 'i'. Initially, the firmware version number is displayed in the lcd display. After that, the firmware number is replaced with the parameter display, and the machine is ready for setup. 3.3 lcd display the hiarc power ...

Page 13

En 3.5 selecting shielding gas press the shielding gas selection button to set the shielding gas type to either co₂ or mixed gas according to the gas you are using. Select co₂ if you are using carbon dioxide. Select ar + co₂ (mag) if you are using mixed gas. Note! Hiarc m has a factory set pre-gas t...

Page 14

En 4t mode mig welding with 4t mode of the gun trigger. • trigger pushed down – flow of shielding gas starts. • trigger released – welding starts. • trigger pushed down – welding ends and shielding gas flow continues. • trigger released – flow of shielding gas ends. Notice: postgas time at least pre...

Page 15

En 3.8 calibrating wire feed speed to ensure that the pre-sets and meter displays work as planned, you must calibrate the wire feed speed of your hiarc power source and f 10 wire feeder welding equipment. Calibration 1. Start the calibration by pressing crater fill button for 3 seconds. 2. Press gas...

Page 16

En 6. At the power source control panel, enter the length of the wire using the buttons below. To toggle between ones, tens and hundreds to add the number by one to subtract the number by one note! If you enter a value that does not fit in, the machine forces the value within the acceptable limits. ...

Page 17

En 4. Troubleshooting problem cause the machine stops working. Overheating indicator is lit, and err 4 is displayed. The machine has overheated. • ensure that cooling air has unrestricted flow. • the machine’s duty cycle has been exceeded. If no other damage is caused, the fan starts working and the...

Page 18

En 5. Maintenance 5.1 regular maintenance check regularly the electrical connections of the machine. Clean any oxidised connections, and tighten the loosened cable connections. Let authorised kemppi service workshop make periodic service to your machine. Appropriate use and regular service guarantee...

Page 19

En 7. Ordering codes hiarc m 400r power source 63104002 hiarc m 500r power source 63105002 hiarc f 10 wire feeder 6310010 hiarc f 30 wire feeder 6310030 welding guns fe 42 3.5 m 6604203 fe 42 5.0 m 6604204 interconnection cables hiarc f30 50-5-gh 50 mm², 5 m 6260500 hiarc f30 70-5-gh 70 mm², 5 m 626...

Page 20

Kemppi oy kempinkatu 1 pl 13 fi-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46 8 590 783 00 telefax +46 8 5...