- DL manuals

- Kemppi

- Welding System

- HiArc S 140

- Operating Manual

Kemppi HiArc S 140 Operating Manual

Summary of HiArc S 140

Page 1

Operating manual manual de instrucciones manuel d’utilisation manual de utilização Инструкции по эксплуатации en es fr pt ru hiarc s 140

Page 3: Operating Manual

© kemppi oy / 1418 operating manual english.

Page 4: Contents

4 hiarc s 140 en 4 contents 1. Preface .................................................................................... 5 1.1 general ...................................................................................... 5 1.2 product introduction ...................................................

Page 5: Preface

5 © kemppi oy / 1418 en 5 1. Preface 1.1 general congratulations on choosing the hiarc equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, mai...

Page 6: Before Starting

6 hiarc s 140 en 6 2. Before starting the equipment is packed in durable packages, designed specially for them. Nevertheless, always before using the equipment, make sure it was not damaged during transportation. Also check that you have received what you ordered and that there are instructions for ...

Page 7: 2.2

7 © kemppi oy / 1418 en 7 2.2 distribution network all regular electrical devices without special circuits generate harmonic currents into distribution network. High rates of harmonic current may cause losses and disturbance to some equipment. Hiarc s 140 warning: this equipment does not comply with...

Page 8: 2.4

8 hiarc s 140 en 8 shielding gas in tig welding, shielding gas is used to prevent atmospheric contamination of the molten weld pool and cooling weld. Normally, the shielding gas is argon (ar). Normally the gas flow rate is approximately 8–15 litres per minute, but this can vary according to the weld...

Page 9: Use

9 © kemppi oy / 1418 en 9 3. Use note! It is forbidden to weld in places where there is a danger of fire or explosion! 3.1 welding processes 3.1.1 manual metal arc welding (mma) in manual metal arc welding (mma) the welding filler material is melted from the electrode to the weld pool. The rate of t...

Page 10: 3.2

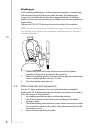

10 hiarc s 140 en 10 3.2 operating functions see also 2.1. Main components and 3.3. Welding selections. 1. Signal light, machine 'on' 2. Welding process selecting switch 3. Welding current adjuster 4. Signal light for overheating 5. Suitable electrodes; reference values for welding current 1 3 2 4 5...

Page 11: 3.3

11 © kemppi oy / 1418 en 11 3.3 welding selections 3.3.1 manual metal arc welding (mma) select welding parameters according to filler manufacturer’s recommendations. 1. Select polarity (+ or -) of welding current cable and return current cable according to filler. 2. Select mma welding with the swit...

Page 12: 3.5

12 hiarc s 140 en 12 shielding gas is used in dc tig welding. Your dealer will give you advice on choosing gas and equipment. Open the gas valve on the ttm 15v tig torch. When gas starts to flow, arc is lit by lightly scratching work piece with the tip of the tungsten electrode. When arc is lit, its...

Page 13: 4.2

13 © kemppi oy / 1418 en 13 4.2 troubleshooting problem cause the main switch indicator will not light up no electricity connected to the machine • check the mains supply fuses. • check the mains cable and plug. Poor welding result several factors affect the welding quality. • check that the earthin...

Page 14: Ordering Numbers

14 hiarc s 140 en 14 5. Ordering numbers item ordering number hiarc s 140 6302140 earth return cable and clamp 6184015 welding cable and electrode holder 6184005 carrying strap 9592162 optional: tig torch ttm15v, 4 m 6271432.

Page 15: Technical Data

15 © kemppi oy / 1418 en 15 6. Technical data hiarc s 140 connection voltage 1 ~, 50/60 hz 230 v ± 15 % rated power at max. Current 35 % ed mma 140 a/7.5 kva 100 % ed mma 100 a/5.1 kva 35 % ed tig 150 a/5.0 kva 100 % ed tig 110 a/3.3 kva supply current 35 % ed i1max 27 a 100 % ed i1eff 16 a connecti...

Page 16

1921810 1418 www.Kemppi.Com kemppi oy kempinkatu 1 pl 13 fi-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46 ...