Summary of HiArc S 400A

Page 1

Hiarc s 400r, 400a en es fr pt ru operating manual manual de instrucciones manuel d’utilisation manual de utilização Инструкции по эксплуатации.

Page 3: Operating Manual

Operating manual english.

Page 4

Hiarc s 400r, 400a 2 en contents 1. Introduction ......................................................................................................................... 3 1.1 general ......................................................................................................................

Page 5

3 © kemppi oy / 1418 en 1. Introduction 1.1 general congratulations on choosing the hiarc series power source. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on...

Page 6

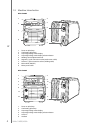

Hiarc s 400r, 400a 4 en 1.3 machine introduction hiarc s 400r 1. 3. 6. 4. 2. 5. 7. 8. 9. 1. Power on pilot lamp 2. Overheating pilot lamp 3. Amperage/voltage meter display 4. Amperage/voltage meter display selection button 5. Welding current adjustment knob 6. Negative (-) pole connection socket (ea...

Page 7

5 © kemppi oy / 1418 en 7. Remote control 8. Welding mode 9. Welding current adjustment knob 10. Negative (-) pole connection socket (earth return cable) 11. Positive (+) pole connection socket (welding cable) 12. Main switch (on/off) 13. Mains power cable 14. Remote control connector there is an op...

Page 8

Hiarc s 400r, 400a 6 en 2.3 distribution network all regular electrical devices without special circuits generate harmonic currents into distribution network. High rates of harmonic current may cause losses and disturbance to some equipment. 2.4 welding and earth return cable connections 2.4.1 choos...

Page 9

7 © kemppi oy / 1418 en 3.2.2 control panel and setup functions, hiarc s 400r welddata after welding has finished, the display shows the measured average current of the last weld. This weld data is only displayed if the welding cycle lasts for 5 seconds or more. Regular control panel 1. 5. 2. 3. 4. ...

Page 10

Hiarc s 400r, 400a 8 en 3.2.4 control panel and setup functions, hiarc s 400a welddata after welding has finished, the display shows the measured average current of the last weld. This weld data is only displayed if the welding cycle lasts for 5 seconds or more. Advanced control panel 1. 7. 6. 2. 3....

Page 11

9 © kemppi oy / 1418 en 3.2.5 activation and setup parameter adjustment, hiarc s 400a 1. Press a/v selection button (3) for at least 3 seconds, until the text ”set” appears on the screen. 2. Choose the needed parameter with the welding current adjustment knob (4). 3. To select the required parameter...

Page 12

Hiarc s 400r, 400a 10 en 3.3 mma welding in manual metal arc welding (mma), the filler material is melted from the electrode to the weld pool. The rate of welding current is selected on the basis of the electrode size and welding position. The arc forms between the electrode tip and work piece. The ...

Page 13

11 © kemppi oy / 1418 en 3. Select a suitable welding current by adjusting the current adjustment knob. 4. Make a small test weld to check the selections made. Site your equipment in a suitable location, ensuring there is adequate cable length to complete the weld pass. Before you start welding, ens...

Page 14

Hiarc s 400r, 400a 12 en 3.4 tig welding tig welding is possible only with hiarc s 400a model, not with the r model. Note! In tig welding the welding cable must be connected to the negative (-) pole connection socket and the earth return cable to the positive (+) pole connection socket. Select your ...

Page 15

13 © kemppi oy / 1418 en 3.5 carbon arc gouging refer to the table below for amperage settings for carbon arc gouging. Electrode amperage (a) 6.35 mm (1/4”) 170–330 a 8 mm (5/16”) 230–450 a 4. Maintenance note! Watch out for mains voltage when handling electric cables! Degree and circumstances of ma...

Page 16

Hiarc s 400r, 400a 14 en 4.4 disposal of the machine do not dispose of electrical equipment with normal waste! Electrical equipment that has reached the end of its life must be collected separately and taken to an appropriate environmentally responsible recycling facility. The owner of the equipment...

Page 17

15 © kemppi oy / 1418 en 5.2 control panel error codes error 1 (e1) power source is not calibrated. Calibrate power source. Error 2 (e2) undervoltage check the mains network connection and fuses. Error 3 (e3) overvoltage check the mains network connection and fuses. Error 4 (e4) overheating. Also th...

Page 18

Hiarc s 400r, 400a 16 en 7. Technical data hiarc s 400r hiarc s 400a connection voltage 3~50/60 hz 380 – 440 v (-10…+10 %) 380 – 440 v (-10 %…+10 %) rated power at max. Current 60 % ed 20 kva 20kva fuse (delayed) 25 a 25 a output at 40 °c mma 60 % ed 400 a / 36 v 400 a / 36 v mma 100 % ed 310 a / 32...

Page 20

Www.Kemppi.Com 1921800 1418 kemppi oy kempinkatu 1 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46...