Summary of HiFeed

Page 1

Operating manual • english en hifeed.

Page 3: Operating Manual

Operating manual english h if eed / © kemppi o y / 1102.

Page 4

En contents 1.1 general ....................................................................................................................................... 3 1.2 about hifeed wire feeder ................................................................................................... 3 1.3 gen...

Page 5

En 1.1 general congratulations on choosing the hifeed wire feeder. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance and safety of your kem...

Page 6

En small spaces, where the user may be directly exposed to the surrounding conductive materials. • do not use arc welding equipment for pipe thawing. Spatter and fire safety • welding is always classified as hot work, so pay particular attention to the fire safety regulations during welding and afte...

Page 7

En • do not exceed the maximum allowable load of suspension beams or the transportation trolley of welding equipment. It is recommended that the wire coil be removed during lifting or transportation. Environment • welding equipment is not recommended for use in rain or snow – see manual. Protect the...

Page 8

En 1. Machine introduction 1.1 before use the product is packed in cartons designed specifically for them. However, always make sure before use that the products have not been damaged during transportation. Check also that you have received the components you ordered and the instruction manuals need...

Page 9

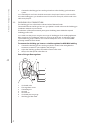

En 1.3 wire feed mechanism 2. 3. 4. 6. 5. 1. 1. Pressure adjustment arm 2. Wire guide tube 3. Wire drive roll 4. Straightening rolls adjustment knob 5. Straightening rolls 6. Top feed roll holder 2. Installation 2.1 power source connection the hifeed wire feeder is recommended to be used with the hi...

Page 10

En 3. Connect the shielding gas hose to the gas bottle or to the shielding gas distribution system. Note! Normally the wire feeder should be connected to the plus pole. However, with some filler wires and shielding gases, you should connect the feeder to the minus pole, and the earth return cable to...

Page 11

En connector for shielding gas heater • when using co₂ shielding gas, a 110v gas heater can be connected to the power supply located at the back of the hiarc power source. Please see the plug-in delivery package for usage and fitting instructions. 2.3 installing filler wire with hifeed you can use 0...

Page 12

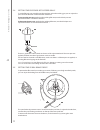

En 2.3.2 feeding the welding wire to feed the wire from the spool to the welding gun: 1. A 1. B 2 . 4 . 3 . 1. Open the pressure arm of the wire feed mechanism (a) and lift the top roll holder (b) to its up position. 2. Draw some loose wire from the spool and push it through the straightening rolls ...

Page 13

En note! Remember to remove the sharp cut tip of the filler wire before loading the wire to the welding gun, so preventing damage to the liner inside the welding gun cable. It will also improve feed quality and increase the service life of your gun liner. Note! When feeding the welding wire into the...

Page 14

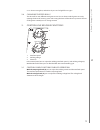

En 2.4 setting the pressure of the feed rolls to make filler wire run smoothly into the wire liner and to the welding gun you can adjust the pressure of the feed rolls of the wire feed mechanism. To increase the pressure applied to the welding filler wire, turn the black pressure adjustment knob in ...

Page 15

En note! Do not over tighten, and reduce the pressure for light filler wire types. 2.6 changing the feed rolls the drive roll has two different sized grooves in it. You can choose which groove to use by opening the drive roll securing screw and turning the drive roll the other way around. The size o...

Page 16

En 4. Maintenance 4.1 regular maintenance check regularly the electrical connections of the machine. Clean any oxidised connections, and tighten the loosened cable connections. Remove regularly any dust and filings from the wire conduit tip and feed rolls. Do not try to open the motor and the reduct...

Page 17

En 6. Ordering codes wire feeder hifeed 6310100 wire feeder consumables intermediate cable set, 5 m w005805 pressure arm assembly w004642 pressure roller assembly w004643 euro adapter w004648 wire feeder roll 0.8 / 1.2 mm, factory setting w004653 wire feeder roll 1.2 / 1.6 mm w004646 wire guide tube...

Page 18

En 7. Warranty policy kemppi oy provides a warranty for products manufactured and sold by the company if defects in materials or workmanship occur. Warranty repairs are to be carried out only by an authorised kemppi service agent. Packing, shipping, and insurance are at the orderer’s expense. The wa...

Page 20

Www.Kemppi.Com 1921690 1102 kemppi oy hennalankatu 39 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel ...